High-heat preservation air-layer wool fabric and process thereof

An air layer and fabric technology, which is applied in the field of textile and clothing, can solve the problems of insufficient warmth retention of wool knitted fabrics, and achieve the effects of improved bulkiness, reduced air convection, and easy care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

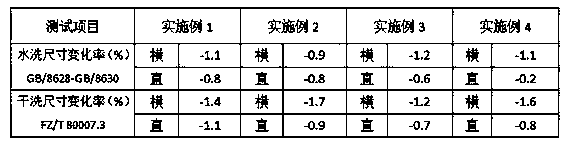

Examples

Embodiment 1

[0047] A preparation process of woolen fabric with high heat-retaining air layer, comprising the following steps:

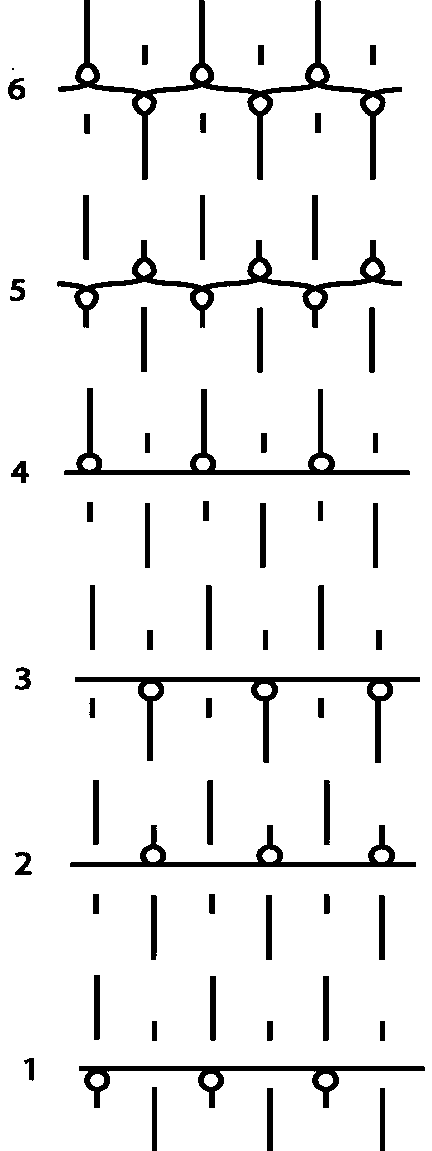

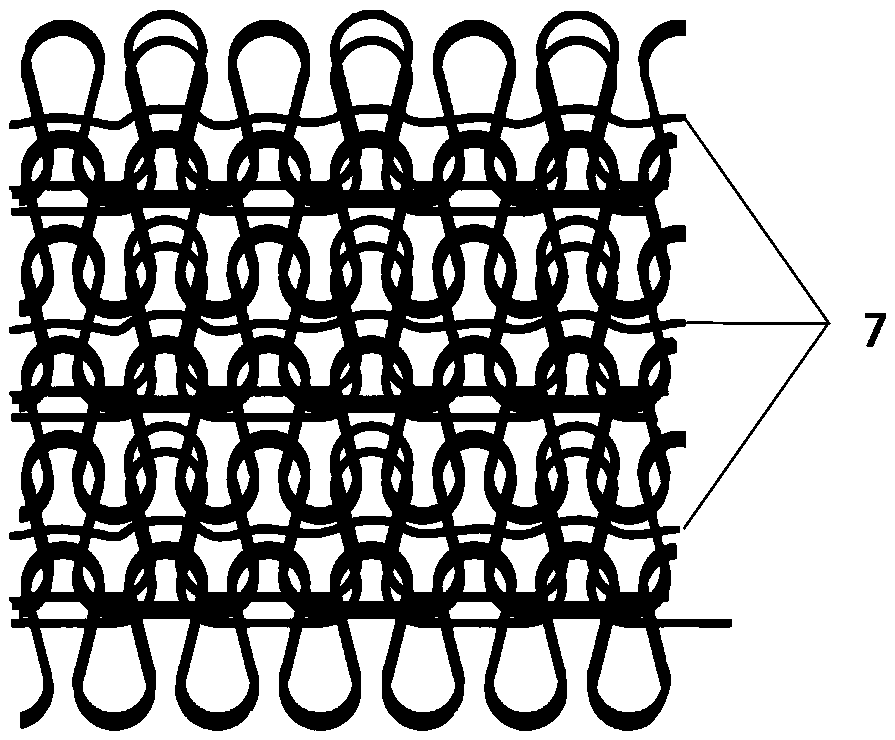

[0048] Step S1: weaving, such as figure 1 As shown, the knitting method of upper and lower double dials is adopted, six-way knitting, in which the low-heel needles of the first way are fed with wool / cashmere blended yarn, and the low-heel needles of the second way are fed with wool / nylon blended yarn , The high-heel needles of the lower dial in the third way are fed with wool / cashmere blended yarn, the high-heel needles of the fourth way are fed with wool / nylon blended yarn, and the low-heel needles of the fifth way are all fed with wool / cashmere For cashmere blended yarn, wool / cashmere blended yarn is fed to the high-heel needles of the upper and lower dials on the 6th road, and hollow polyester DTY filaments 7 are introduced between the front and back stitch courses of the 1st to 4th roads by weft insertion. get gray cloth;

[0049] Step S2: shake the pellets...

Embodiment 2

[0057] A preparation process of woolen fabric with high heat-retaining air layer, comprising the following steps:

[0058] Step S1: weaving, such as figure 1 As shown, the knitting method of upper and lower double dials is adopted, and six knitting methods are used, in which the low-heel needles of the lower dial are fed with cashmere yarn in the first pass, wool / nylon blended yarn is fed with the low-heel needles of the second pass, and the third pass is knitting. The high-heel needles of the lower dial are fed with cashmere yarn, the high-heel needles of the fourth road are fed with wool / nylon blended yarn, the low-heel needles of the upper and lower dials of the fifth road are all fed with cashmere blended yarn, and the upper and lower needles of the sixth road Feed all the cashmere yarns into the pan-heel needles, and insert hollow polyester filaments 7 between the front and back courses of the 1st to 4th loops by weft insertion to obtain gray fabrics;

[0059] Step S2: s...

Embodiment 3

[0067] A preparation process of woolen fabric with high heat-retaining air layer, comprising the following steps:

[0068] Step S1: weaving, such as figure 1 As shown, the method of knitting with upper and lower double dials is adopted, and six knitting methods are used, in which the low-heel needles of the first way are fed with cashmere yarn, the low-heel needles of the second way are fed with cashmere yarn, and the lower needles of the third way are high Feed cashmere yarn to the heel needles, cashmere yarn to the high heel needles on the 4th road, cashmere yarn to all the low heel needles on the 5th road, and cashmere yarn to all the high heel needles on the 6th road. Introducing hollow polyester filaments 7 between the front and back coil courses of the 1st to 4th roads in a weft insertion manner to obtain gray fabrics;

[0069] Step S2: shake the pellets, use the shaker to process the rough cloth, the processing temperature is 45°C, and the processing time is 15 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com