Anti-package loop pile cutting circular machine for double-face knitting

A double-sided, circular knitting technology, applied in the direction of weft knitting, knitting, textiles and papermaking, etc., can solve the problems of loose wool surface density, low thermal performance of double-sided base fabric, and cannot satisfy customers, etc., to achieve wool surface density Increase, strong warmth retention, increase the effect of needle output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

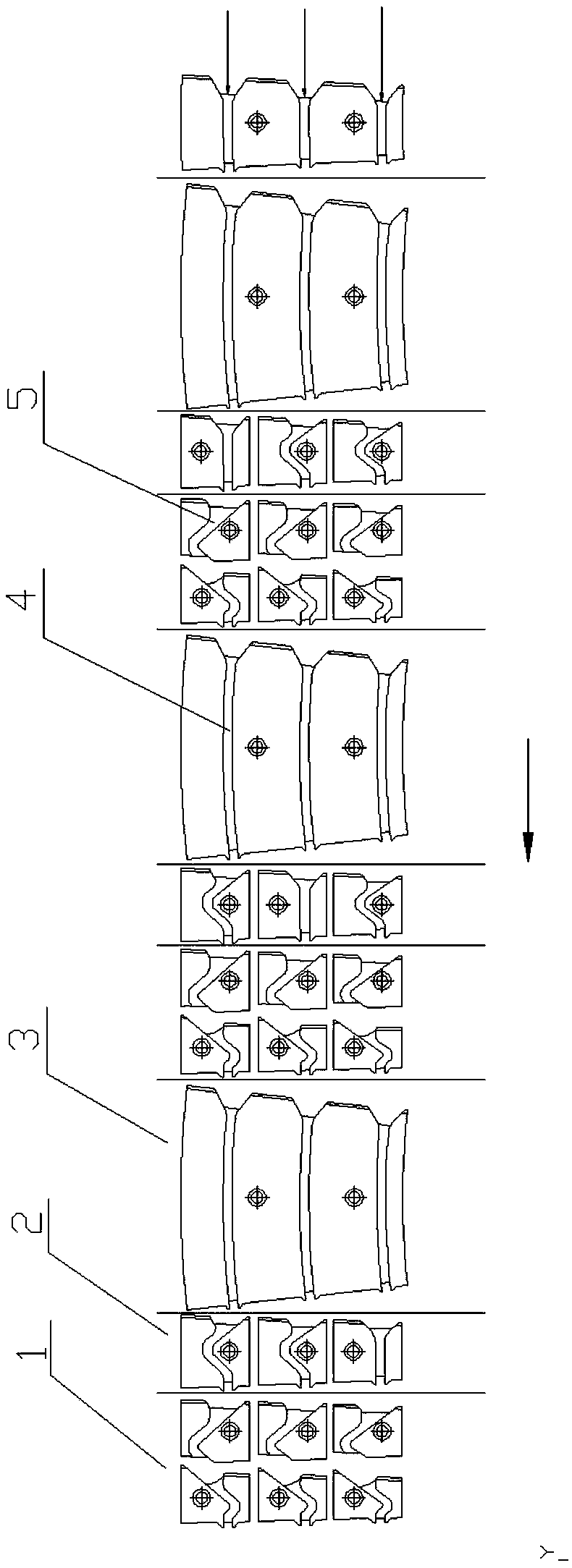

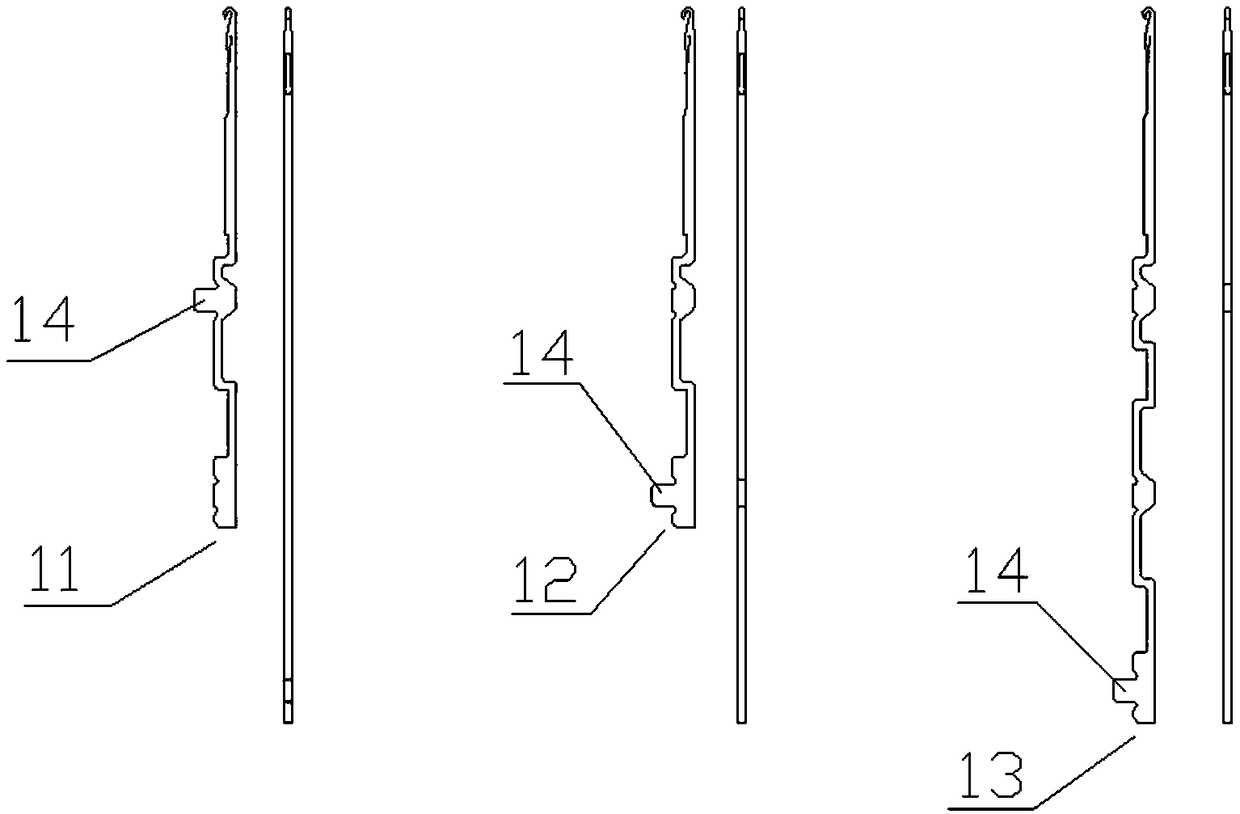

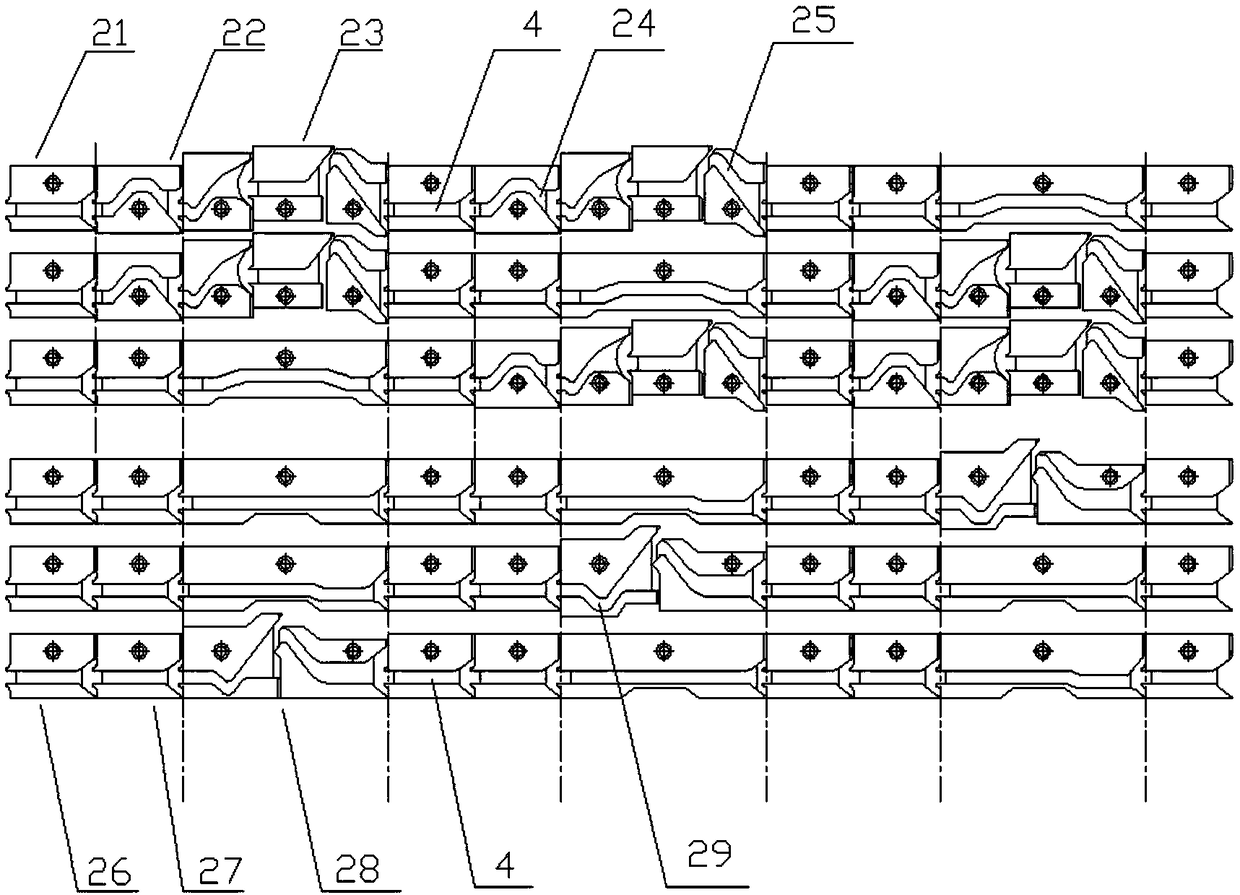

[0027] The reverse-wrapping loop pile machine for double-sided knitting includes an upper needle plate and a lower needle cylinder. There are needle slots on the upper needle plate, knitting needles are installed in the needle grooves, and hook knife grooves are opened on the lower needle cylinder. The knife groove is equipped with a hook and knife assembly; the upper part of the upper dial is provided with a needle mountain angle to control the movement track of the knitting needle, and the needle mountain angle forms a ring-like mountain angle combination along the circumference of the upper dial, and a control hook is arranged outside the lower needle cylinder The knife mountain angle and the hook mountain angle of the movement track of the knife assembly, the knife mounta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com