Preparation method of moisture-absorbing heating fiber containing plant extract and having antibacterial function

A technology of moisture-absorbing and heating fibers and plant extracts, which is applied in wet spinning, fiber chemical characteristics, conductive/anti-static filament manufacturing, etc., can solve the problems of low moisture absorption and heating performance of cellulose fibers, affecting fiber use efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

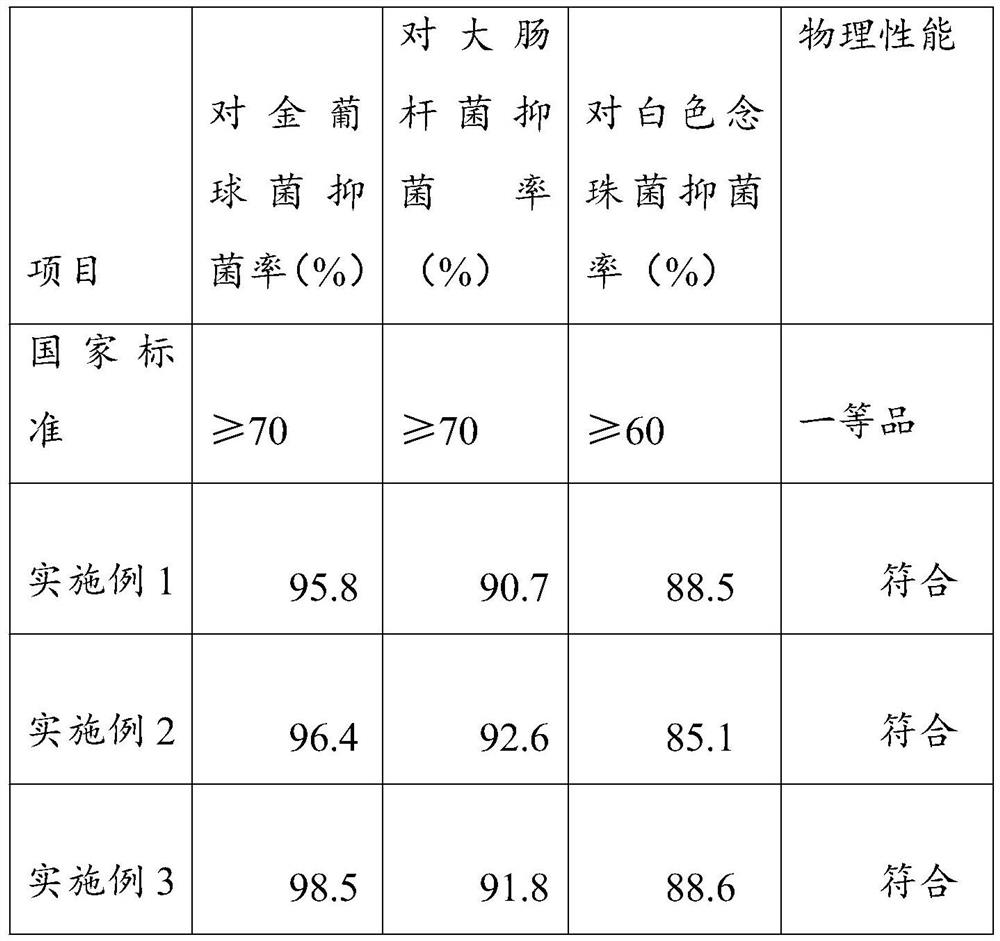

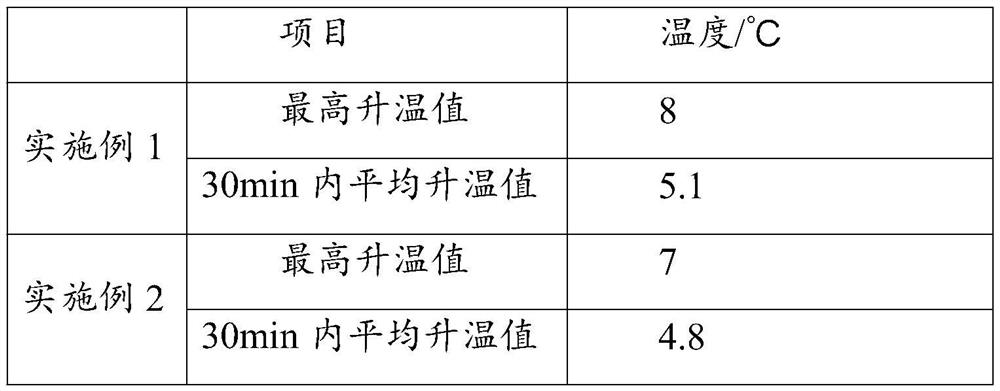

Embodiment 1

[0038] The preparation method of the hygroscopic and heating fiber containing plant extracts with antibacterial function, taking the preparation of 1.33dtex×38mm as an example, includes the following steps:

[0039] Step 1, the preparation of spinning solution:

[0040] Cellulose pulp and A-type cellulose (A-type cellulose can be cotton fiber or hemp fiber) are mixed according to a weight ratio of 1:2, and then 10% of a composite modification additive is added, and a stirrer is used for high-speed stirring to realize blending. The blended spinning solution is made, and then it is set aside, passed through, defoamed, and matured for later use;

[0041] Step 2, spinning and forming:

[0042] The spinning solution in step 1 is processed by a metering pump and a filter, the spinning speed is set in advance, the spinning solution is sprayed out through the spinneret, and enters the coagulation bath, where it reacts with the reagents and solidifies, and the formed fiber bundle It ...

Embodiment 2

[0063] The preparation method of the hygroscopic and heating fiber containing plant extracts with antibacterial function, taking the preparation of 1.33dtex×38mm as an example, includes the following steps:

[0064] Step 1, the preparation of spinning solution:

[0065] Cellulose pulp and A-type cellulose (A-type cellulose can be cotton fiber or hemp fiber) are mixed according to a weight ratio of 1:2, and then 18% of composite modification additives are added, and agitator is used for high-speed stirring to realize blending. The blended spinning solution is made, and then it is set aside, passed through, defoamed, and matured for later use;

[0066] Step 2, spinning and forming:

[0067] The spinning solution in step 1 is processed by a metering pump and a filter, the spinning speed is set in advance, the spinning solution is sprayed out through the spinneret, and enters the coagulation bath, where it reacts with the reagents and solidifies, and the formed fiber bundle It n...

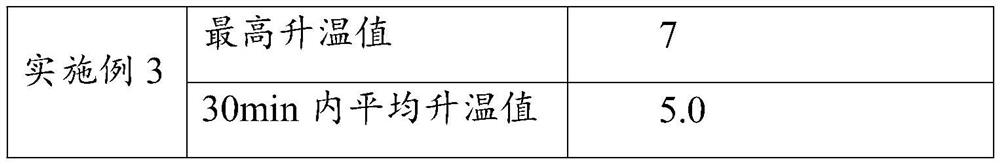

Embodiment 3

[0088] The preparation method of the hygroscopic and heating fiber containing plant extract and having antibacterial function comprises the following steps:

[0089] Step 1, the preparation of spinning solution:

[0090] Cellulose pulp and A-type cellulose (A-type cellulose can be cotton fiber or hemp fiber) are mixed according to a weight ratio of 1:2, and then 15% of a composite modification additive is added, and a stirrer is used for high-speed stirring to realize blending. The blended spinning solution is made, and then it is set aside, passed through, defoamed, and matured for later use;

[0091] Step 2, spinning and forming:

[0092] The spinning solution in step 1 is processed by a metering pump and a filter, the spinning speed is set in advance, the spinning solution is sprayed out through the spinneret, and enters the coagulation bath, where it reacts with the reagents and solidifies, and the formed fiber bundle It needs to be stretched by drafting rollers first, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com