Protein/cellulose fiber preparation method based on cellulase activation treatment

A technology of cellulose fiber and cellulase, which is applied in fiber treatment, biochemical fiber treatment, enzyme/microbial biochemical treatment, etc., can solve the problem of poor washing resistance of silkworm chrysalis protein modified cellulose fiber and grafting of collagen viscose fiber Low efficiency, not conducive to production safety and environmental protection, etc., to achieve the effect of good product performance, excellent wearing performance, and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

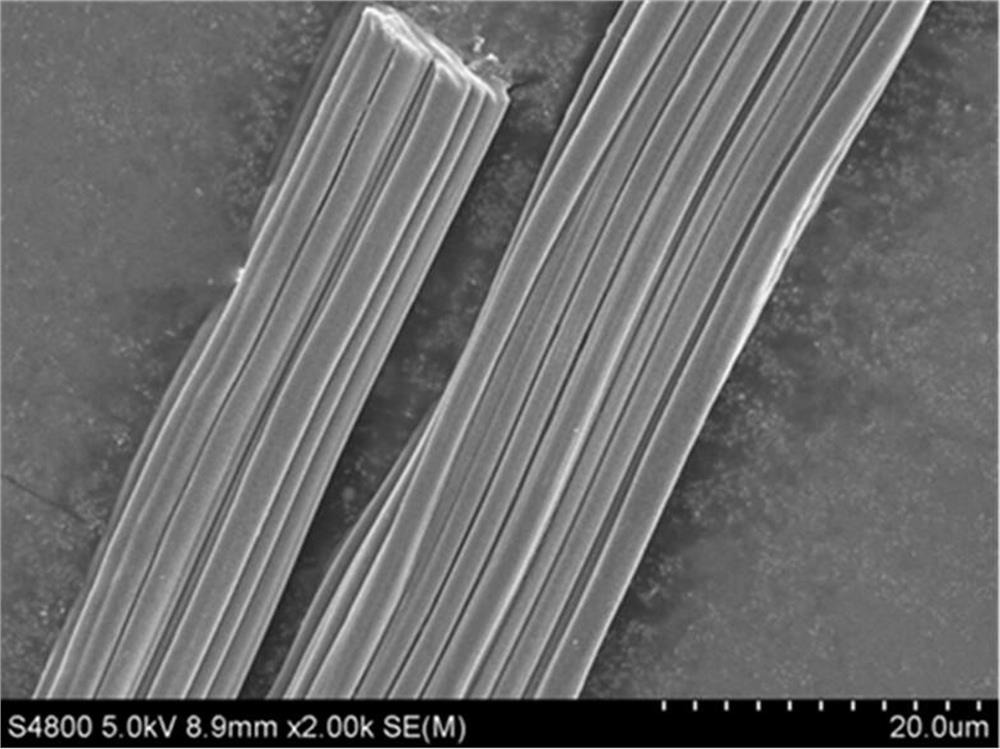

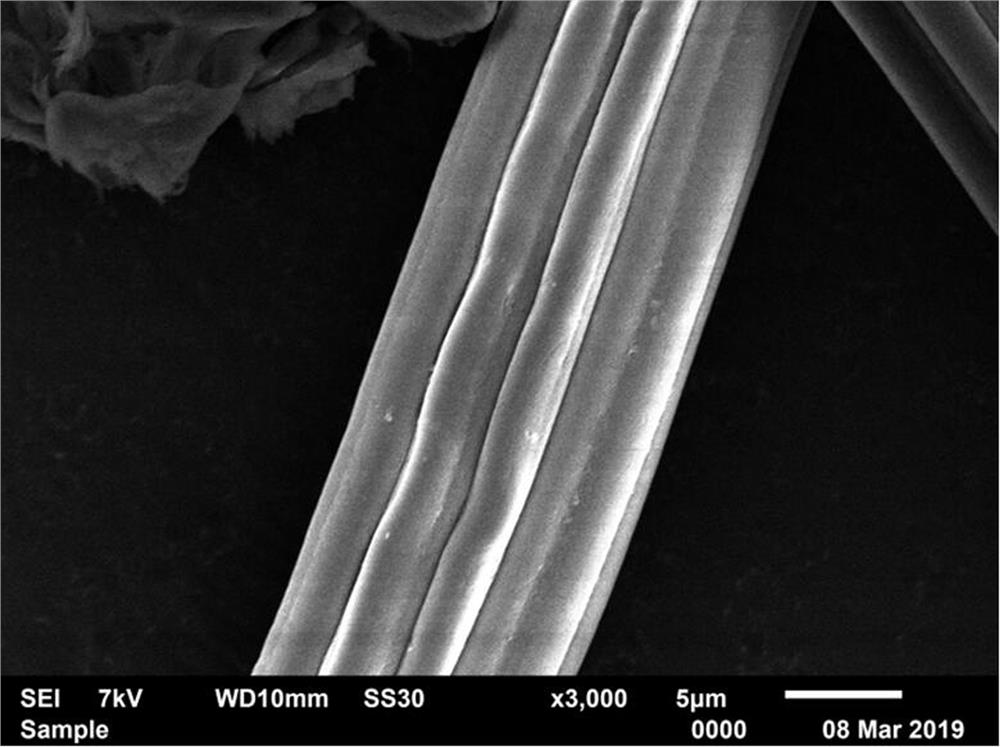

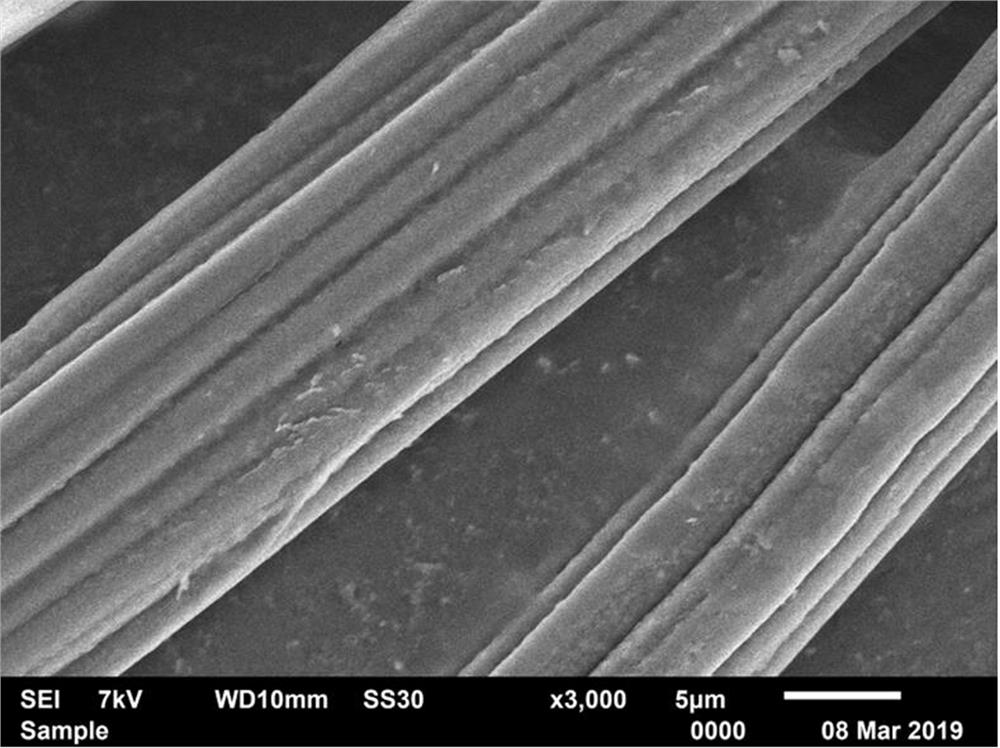

Image

Examples

Embodiment 1

[0045] Weigh 300g of surfactant alkyl glucoside, add it into 19.7L of industrial soft water, stir evenly, and prepare a pretreatment solution with a mass fraction of alkyl glucoside of 1.5%.

[0046] Add the above pretreatment solution into the reaction kettle, weigh 1Kg viscose fiber, disperse evenly in the pretreatment solution, raise the temperature to 40°C, stir for 0.5h, remove the pretreated viscose fiber and collect the waste liquid.

[0047] Add 20L of industrial soft water into the reaction kettle, add the pretreated viscose fiber, wash at room temperature, and dry the water. Repeat washing twice to obtain pretreated viscose fiber.

[0048] Add all the pretreated viscose fibers prepared above into a reaction kettle with 20L of industrial soft water, raise the temperature to 50°C under constant stirring, then add 10g of liquid cellulase, and activate the reaction for 0.5h. The pH value of the reaction solution was adjusted to 4.0 with glacial acetic acid solution, the...

Embodiment 2

[0061] Weigh 200g of surfactant alkyl glucoside, add it into 19.8L of industrial soft water, stir evenly, and prepare a pretreatment solution with a mass fraction of alkyl glucoside of 1%.

[0062] Add the above pretreatment solution into the reaction kettle, weigh 1Kg of cotton fibers, disperse evenly in the pretreatment solution, raise the temperature to 45°C, stir for 0.8h, remove the pretreated cotton fibers and collect the waste liquid.

[0063] Add 25L of industrial soft water into the reaction kettle, add the pretreated cotton fibers, wash at room temperature, and dry the water. Washing was repeated once to obtain pretreated cotton fibers.

[0064] Add all the pretreated cotton fibers prepared above into a reaction kettle with 23L of industrial soft water, raise the temperature to 40°C under constant stirring, then add 15g of liquid cellulase, and activate the reaction for 0.6h. The pH value of the reaction solution was adjusted to 4.2 with glacial acetic acid solution...

Embodiment 3

[0073] Weigh 400g of surfactant alkyl glucoside, add it into 19.6L of industrial soft water, stir evenly, and prepare a pretreatment solution with a mass fraction of alkyl glucoside of 2%.

[0074] Add the above pretreatment liquid into the reaction kettle, weigh 1Kg of Tencel fibers, disperse them evenly in the pretreatment liquid, raise the temperature to 50°C, stir for 1 hour, remove the pretreated Tencel fibers and collect the waste liquid.

[0075] Add 23L of industrial soft water into the reaction kettle, add the pretreated Tencel fiber, wash at room temperature, and dry the water. Washing was repeated twice to obtain pretreated tencel fibers.

[0076] Add all the pretreated Tencel fibers prepared above into a reaction kettle with 25L of industrial soft water, raise the temperature to 55°C under constant stirring, then add 30g of liquid cellulase, and activate the reaction for 0.8h. The pH value of the reaction solution was adjusted to 4.5 with glacial acetic acid solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com