Superfine denier yew yarn

A technology of ultra-fine denier and fir yarn, applied in the textile field, can solve the problems of difficult application of outer-wear clothing fabrics, and achieve the effect of widening application and good textile processability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

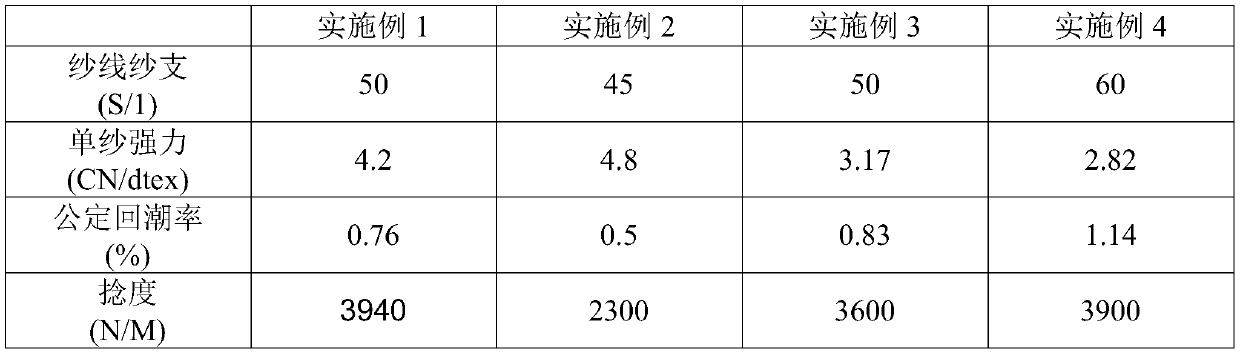

Embodiment 1

[0022] The yarn of the present invention is formed by blending yew fiber and superfine polyester staple fiber. The yew fiber is wood pulp fiber with a specification of 1.56D and a length of 38mm. The specification of superfine denier polyester staple fiber is 0.89D and the length 33mm, the weight ratio of yew fiber and superfine polyester staple fiber is 20%:80%

[0023] The technological process is as follows: proportioning cotton, yew, and mulberry silk according to the content - mixing and removing impurities - carding - cotton sliver - roving - fine - winding, to obtain a yarn with a thickness of 50S / 1 and a twist of 3940N / M.

[0024] The preparation method of superfine denier yew yarn, comprises the following steps:

[0025] (1) mix yew and superfine denier polyester staple fiber according to the content ratio, and make evenly mixed cotton laps by feeding cotton, mixing cotton, and opening cotton;

[0026] (2) Carding the mixed cotton roll on the carding machine to obtai...

Embodiment 2

[0033] The weight ratio of yew fiber and superfine denier polyester staple fiber is 5%:95%, and other processes are the same as in Example 1.

Embodiment 3

[0035] The weight ratio of yew fiber and superfine denier polyester staple fiber is 10%:90%, and other processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com