Preparation and application of tea extract oil composite modified additive

A technology of tea extract and compound modification, applied in the direction of rayon made of viscose, etc., can solve the problems of hindering the expansion of the application field, limiting the color of fibers, loss of microcapsules, etc. Less and more stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

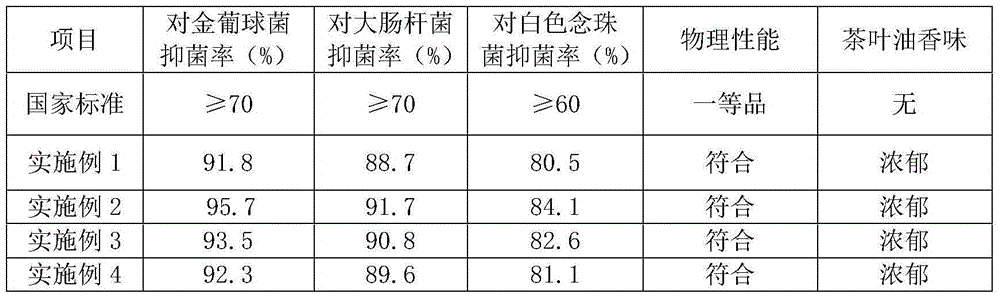

Examples

Embodiment 1

[0036] The preparation of the tea extract tea oil composite modified additive of the present embodiment comprises the following steps:

[0037] Step 1: Preparation of solid sorbent containing tea extract

[0038] The tea extract is dissolved in a solvent, the mass ratio of the tea extract to the solvent is 1:2, an adsorbent and a dispersant are added to the solution, the mass ratio of the tea extract to the adsorbent is 1:1, the tea extract and the The mass ratio of the dispersant is 1:0.02, and the dispersion liquid is prepared; after the dispersion liquid is dried, the obtained solid is ground into a powder with a particle size below 3um to obtain a solid adsorbent containing tea extract;

[0039] The tea extract is powdery solid, the solvent is distilled water; the adsorbent is rectorite, and the dispersant is sodium tripolyphosphate;

[0040] Tea extract is extracted from green tea.

[0041] Step 2: Preparation of tea oil microcapsule slurry

[0042] Dissolve the modified...

Embodiment 2

[0054] The preparation of the tea extract tea oil composite modified additive of the present embodiment comprises the following steps:

[0055] Step 1: Preparation of solid sorbent containing tea extract

[0056] Dissolve the tea extract in the solvent, the mass ratio of the tea extract to the solvent is: 1:5, add adsorbent and dispersant to the solution, the mass ratio of the tea extract to the adsorbent is 1:1.2, the tea extract The mass ratio to the dispersant is 1:0.08, and the dispersion liquid is prepared; after the dispersion liquid is dried, the obtained solid is ground into a powder with a particle size below 3um to obtain a solid adsorbent containing tea extract;

[0057] The tea extract is solid powder, and the solvent is distilled water; the adsorbent is a combination of molecular sieve and white bamboo charcoal, and the dispersant is a combination of sodium hexametaphosphate and sodium pyrophosphate; the tea extract is extracted from white tea.

[0058] Step 2: P...

Embodiment 3

[0071] The preparation of the tea extract tea oil composite modified additive of the present embodiment comprises the following steps:

[0072] Step 1: Preparation of solid sorbent containing tea extract

[0073] Dissolve the tea extract in a solvent, the mass ratio of the tea extract to the solvent is 1:3, add an adsorbent and a dispersant to the solution, the mass ratio of the tea extract to the adsorbent is 1:1.05, the tea extract The mass ratio to the dispersant is 1:0.04, and the dispersion liquid is prepared; after the dispersion liquid is dried, the obtained solid is ground into a powder with a particle size below 3um to obtain a solid adsorbent containing tea extract;

[0074] The tea extract is solid powder, the solvent is distilled water; the adsorbent is a combination of molecular sieve and white bamboo charcoal, and the dispersant is a combination of sodium hexametaphosphate and sodium pyrophosphate; the tea extract is extracted from green tea and green tea.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com