Multilayer composite felt for filtration

A multi-layer composite and filter layer technology, applied in the direction of filtration separation, membrane filter, dispersed particle filtration, etc., can solve the problems of limited acid and alkali resistance, and achieve excellent heat insulation performance, excellent chemical stability, and low thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

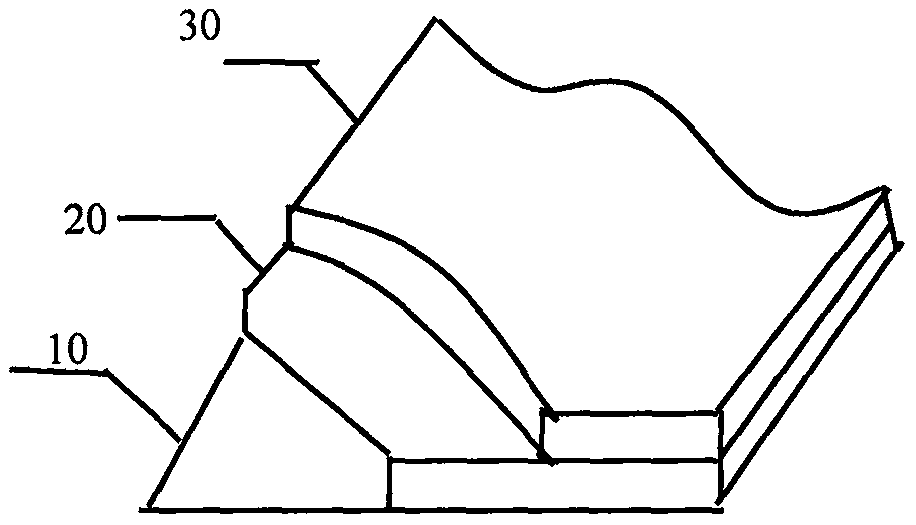

[0018] Such as figure 1 As shown, a multi-layer composite felt for filtering includes a base cloth, a first filter layer and a second filter layer arranged in sequence. The base cloth material is made of polyphenylene sulfide fiber and glass fiber. The material is glass fiber composite felt with different fiber diameters, and the second filter layer is made of superfine glass fiber and polytetrafluoroethylene fiber composite felt.

[0019] Polyphenylene sulfide fibers and glass fibers are mixed at a mass ratio of 1:5 and then woven into warp or weft yarns, located in the outermost layer, with a thickness of 1.00 mm and a glass fiber diameter of 20 μm.

[0020] The glass fiber composite mat is made by mixing glass fibers with a diameter of 2 μm and 30 μm at a mass ratio of 1:15, and placed on the upper surface layer of the base cloth with a thickness of 6 mm.

[0021] Ultrafine glass fiber and polytetrafluoroethylene fiber composite mat are mixed according to the mass ratio of...

Embodiment 2

[0024] Such as figure 1 As shown, a multi-layer composite felt for filtering includes a base cloth, a first filter layer and a second filter layer arranged in sequence. The base cloth material is made of polyphenylene sulfide fiber and glass fiber. The material is glass fiber composite felt with different fiber diameters, and the second filter layer is made of superfine glass fiber and polytetrafluoroethylene fiber composite felt.

[0025] Polyphenylene sulfide fibers and glass fibers are mixed at a mass ratio of 1:4 and then woven into warp or weft yarns, located in the outermost layer, with a thickness of 1.50 mm and a glass fiber diameter of 10 μm.

[0026] Glass fiber composite mats with different fiber diameters are made by mixing glass fibers with a diameter of 4 μm and 25 μm at a mass ratio of 1:10, and placed on the upper surface layer of the base cloth with a thickness of 8 mm.

[0027] Superfine glass fiber and polytetrafluoroethylene fiber composite mat are mixed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com