Binchotan composite modified nano platinum bamboo pulp fiber for mask base cloth and preparation method of Binchotan composite modified nano platinum bamboo pulp fiber

A nano-platinum, composite modification technology, applied in the field of fibers, can solve the problems that are difficult to meet the requirements of mask liquid absorption, durability, softness, safety, uneven mask base fabric, skin barrier damage, etc., to achieve Excellent textile processability, good liquid absorption, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

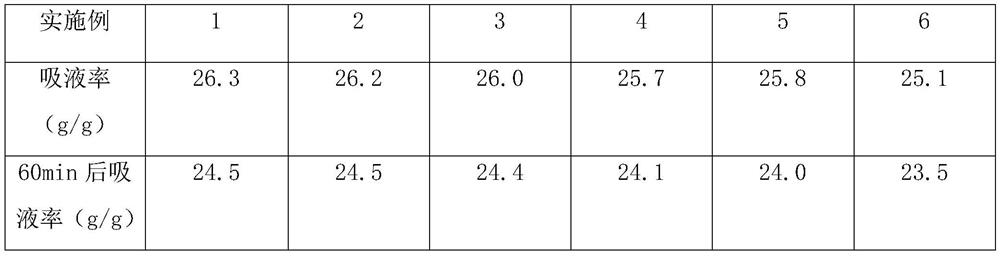

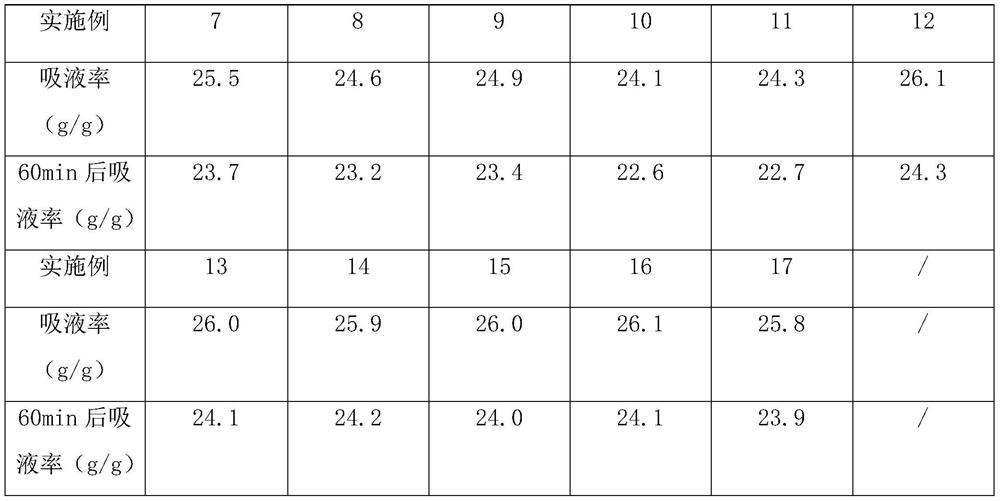

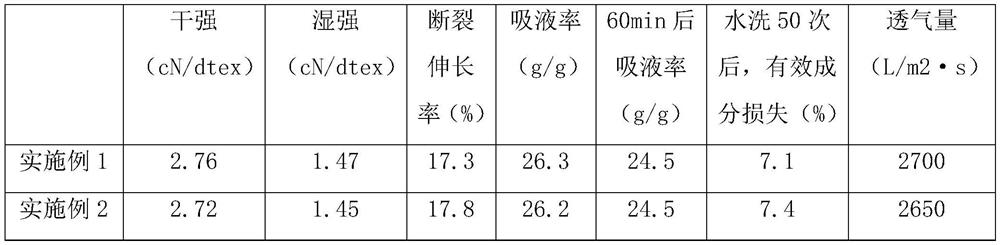

Examples

Embodiment 1

[0054] Embodiment 1 A kind of facial mask base cloth uses long charcoal composite modified nano-platinum gold bamboo pulp fiber and preparation method thereof, comprising the following steps:

[0055] 1. Preparation of Binchochar composite modified nano-platinum slurry

[0056] S1. Preprocessing

[0057] Add nano-platinum particles into softened water at 65°C, stir at a speed of 1300r / min, add 0.8% dilute sulfuric acid for pickling for 1 hour, then add 1% sodium hydroxide solution for alkaline washing for 1 hour, until the pH is neutral, and remove surface impurities , filtered and dried at 85°C for 3h;

[0058] The particle size of the nano-platinum particles is 1nm, and the addition amount is 2% of the cellulose;

[0059] The added amount of the dilute sulfuric acid is 4 times that of the nano-platinum particles.

[0060] S2. Collagen peptide coordination nano platinum

[0061] Add collagen to 5 times distilled water, stir for 8 minutes, add collagenase, adjust the pH to...

Embodiment 2

[0089] Embodiment 2 A kind of facial mask base cloth uses long charcoal composite modified nano-platinum gold bamboo pulp fiber and preparation method thereof

[0090] The difference between this embodiment and embodiment 1 is that the S1 pretreatment steps are different, and the rest are consistent with embodiment 1, specifically as follows:

[0091] Add nano-platinum particles into softened water at 65°C, stir at a speed of 1000r / min, add 0.5% dilute sulfuric acid to pickle for 0.5h, then add 0.5% sodium hydroxide solution to wash with alkali for 1h, until the pH is neutral, remove the surface Impurities, filtered and dried at 80°C for 2.5h;

[0092] The particle size of the nano-platinum particles is 10nm, and the addition amount is 1% of the cellulose;

[0093] The added amount of the dilute sulfuric acid is 5 times that of the nano-platinum particles.

Embodiment 3

[0094] Embodiment 3 A kind of facial mask base cloth is compounded modified nano-platinum gold bamboo pulp fiber and preparation method thereof with long charcoal, comprising the following steps:

[0095] The difference between this embodiment and embodiments 1 and 2 is that the S1 pretreatment step is different, and all the other are consistent with embodiments 1 and 2, specifically as follows:

[0096] Add nano-platinum particles into softened water at 65°C, stir at a speed of 1500r / min, add 1% dilute sulfuric acid for pickling for 1 hour, then add 2% sodium hydroxide solution for alkaline washing for 0.5 hours, until the pH is neutral, and remove the surface Impurities, filtered and dried at 90°C for 2h;

[0097] The particle size of the nano-platinum particles is 15nm, and the addition amount is 3% of the cellulose;

[0098] The added amount of the dilute sulfuric acid is 3 times that of the nano-platinum particles.

[0099] The added amount of the dilute sulfuric acid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com