Poly-p-phenylene benzobisoxazole fiber spinning oil agent and preparation method thereof

A technology of benzobisoxazole and poly-p-phenylene, which is applied in the direction of fiber type, fiber treatment, wear-resistant fiber, etc., can solve the problems of high price, achieve convenient operation, good washability, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

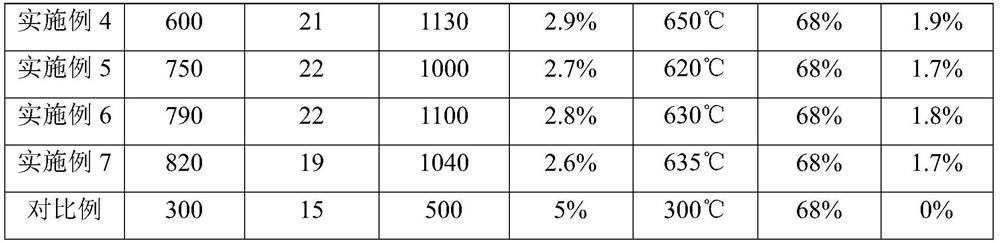

Examples

Embodiment 1

[0022] The two-component smoothing agent of 45% mass fraction (the mineral oil of 25% mass fraction, the isomeric octaol fatty acid ester of 20% mass fraction) and the adjuster triol propionate of 10% mass fraction are mixed and stirred to 120 ℃, stirred for 1h, cooled to 75°C, and then added a three-component emulsifier (10% mass fraction of polyoxyethylene sorbitan ester, 15% mass fraction of C 16 Alcohol polyoxyethylene ether, 10% mass fraction of polyethylene glycol synthetic ester) and 10% mass fraction of antistatic agent (5% mass fraction of C 6 Alkyl phosphate potassium salt, 5% mass fraction of metulin derivative type), add into the reaction kettle, stir for 2 hours, cool to 60°C, filter, discharge, and pack to obtain the product.

Embodiment 2

[0024] The two-component smoothing agent of 50% mass fraction (the vegetable oil of 25% mass fraction, the isomeric octaol fatty acid ester of 20% mass fraction, the animal oil of 5% mass fraction) and the regulator dipropionic acid of 8% mass fraction The pentaerythyl alcohol ester was mixed and stirred to 125°C, stirred for 1h, cooled to 85°C, and then added a three-component emulsifier (10% mass fraction of sorbitol monooleate, 15% mass fraction of C 14 Alcohol polyoxyethylene ether, 7% mass fraction of polyethylene glycol synthetic ester) and 10% mass fraction of antistatic agent (7% mass fraction of C 8 Alkyl phosphate potassium salt, 3% mass fraction of C 8 Alkylbenzene sulfonate), add to the reaction kettle, stir for 1.5h, cool to 55°C, filter, discharge, and pack.

Embodiment 3

[0026] The two-component smoothing agent of 50% mass fraction (the vegetable oil of 20% mass fraction, the isomeric tridecyl alcohol fatty acid ester of 30% mass fraction) and the modifier pentaerythyl dipropionate of 5% mass fraction are mixed and stirred to 120°C, stirred for 1h, cooled to 80°C, and then added a three-component emulsifier (10% mass fraction of sorbitol monooleate, 15% mass fraction of C 16 Alcohol polyoxyethylene ether, 10% mass fraction of C 18 Fatty alcohol polyoxyethylene polyoxypropylene ether) and 10% mass fraction of antistatic agent (6% mass fraction of C 12 Alkyl phosphate potassium salt, 4% mass fraction of C 28 Alkylbenzene sulfonate), added to the reaction kettle, stirred for 1 hour, cooled to 57°C, filtered, discharged, and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com