Patents

Literature

55results about How to "The spinning process is smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane fiber dry spinning oil agent and preparation method thereof

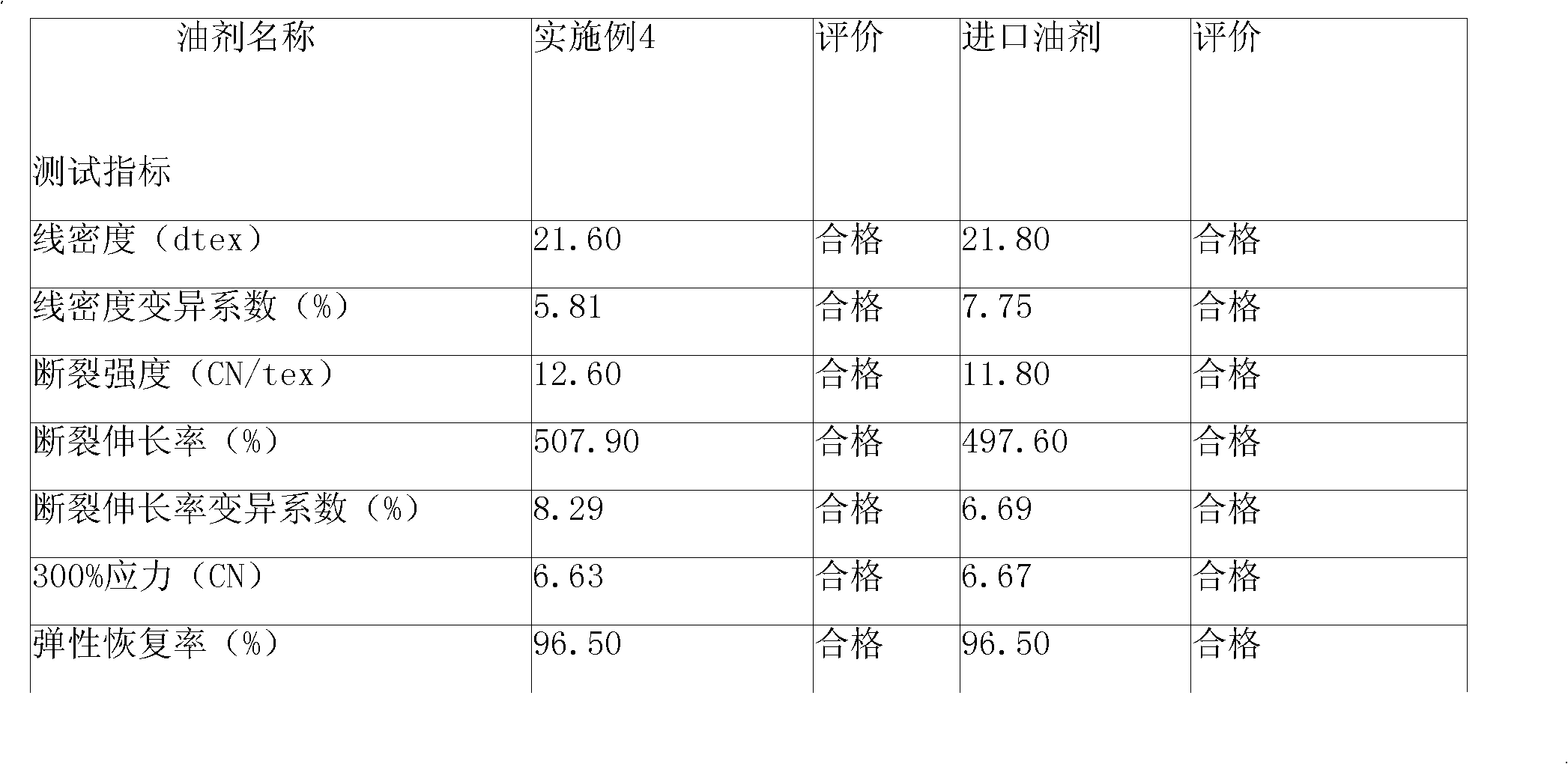

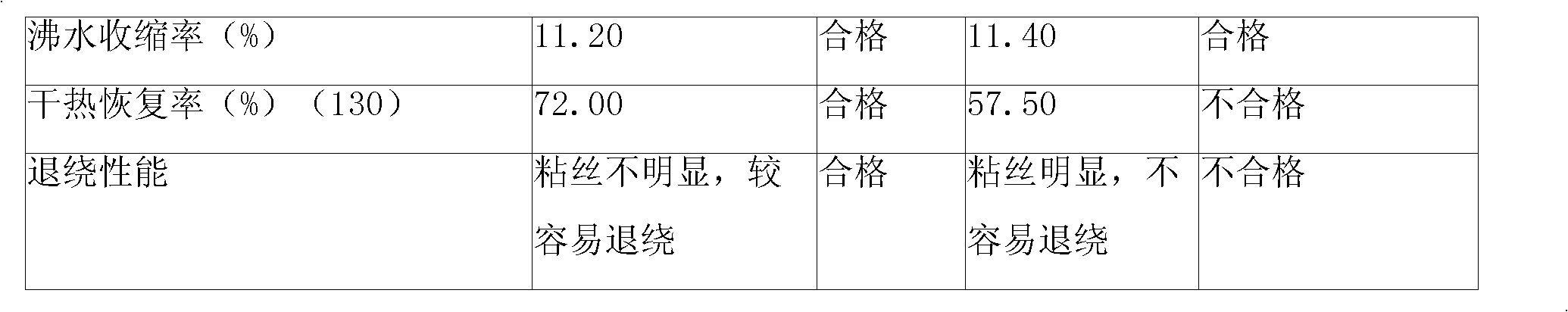

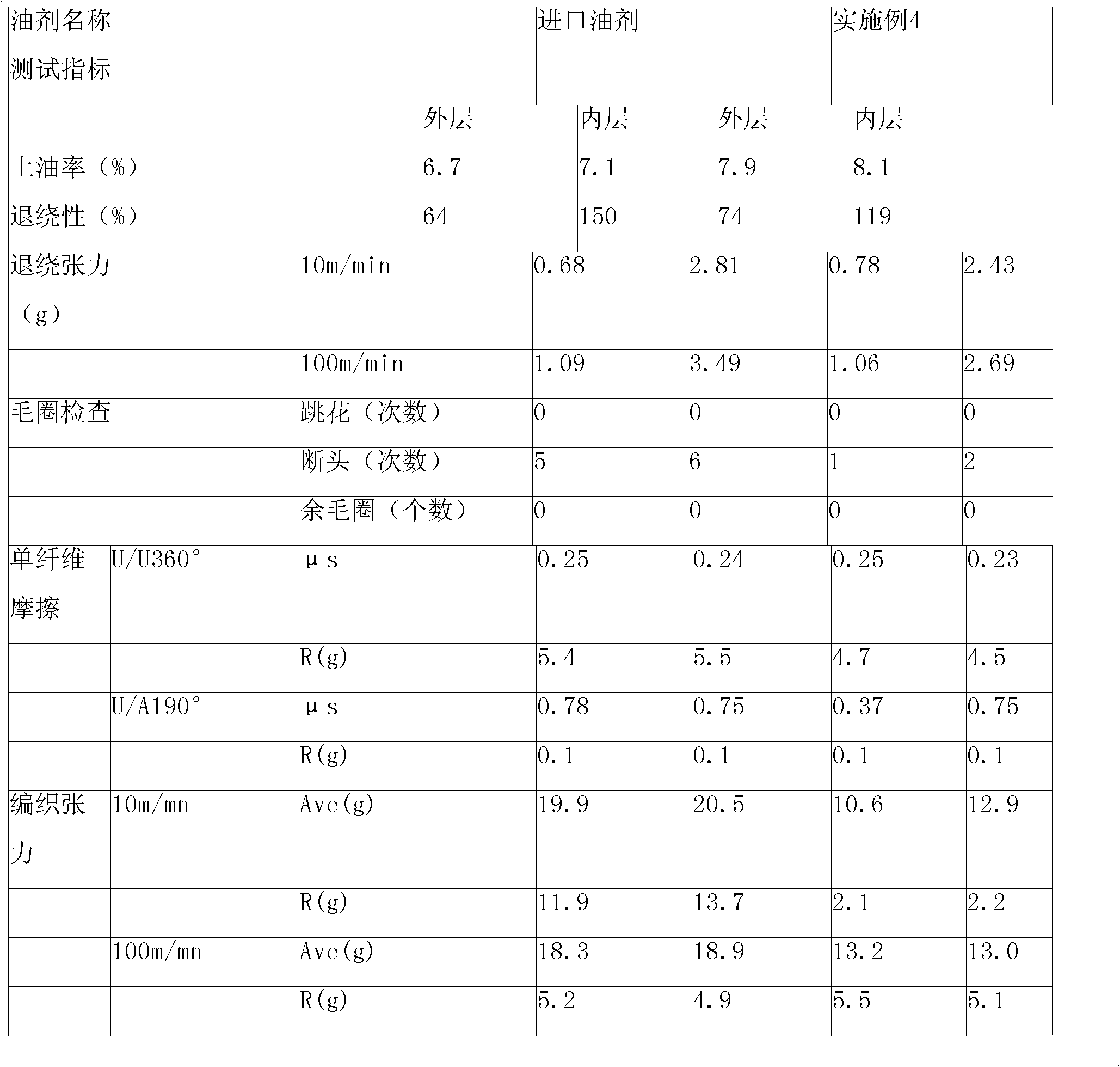

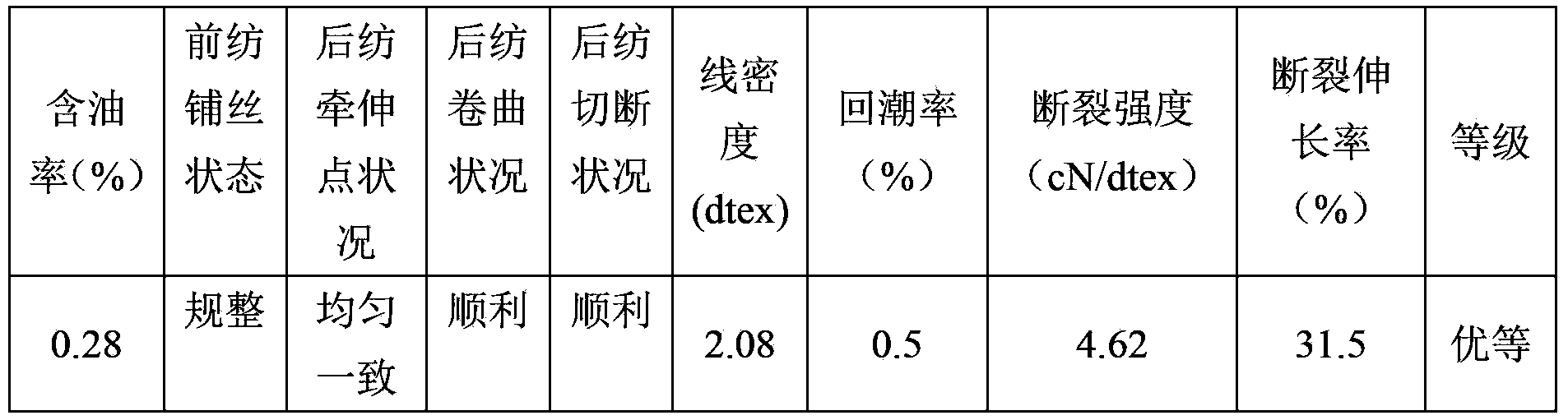

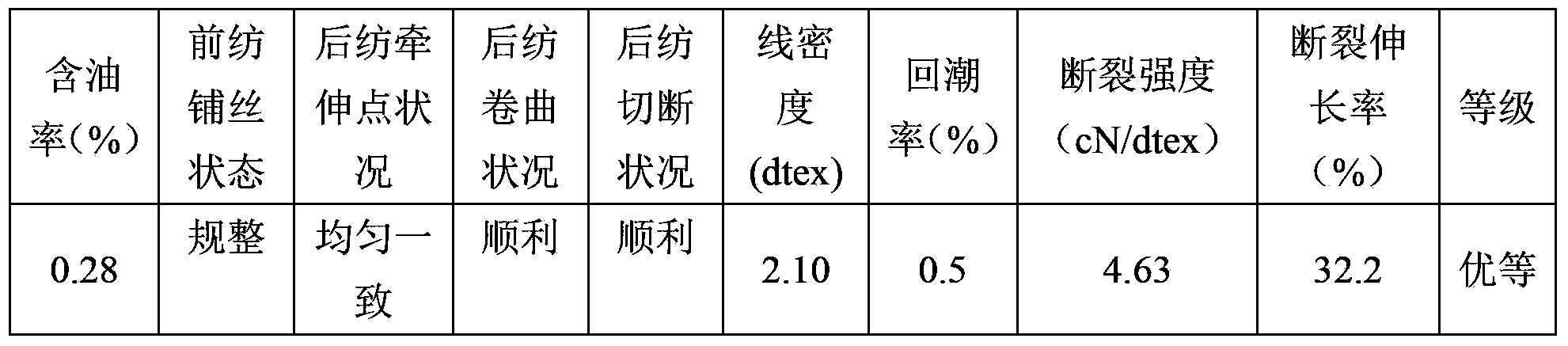

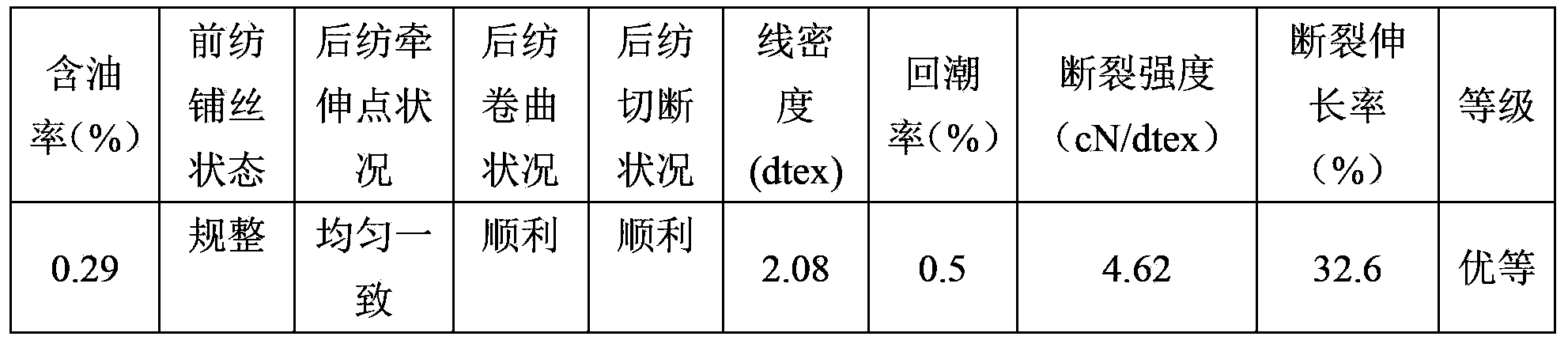

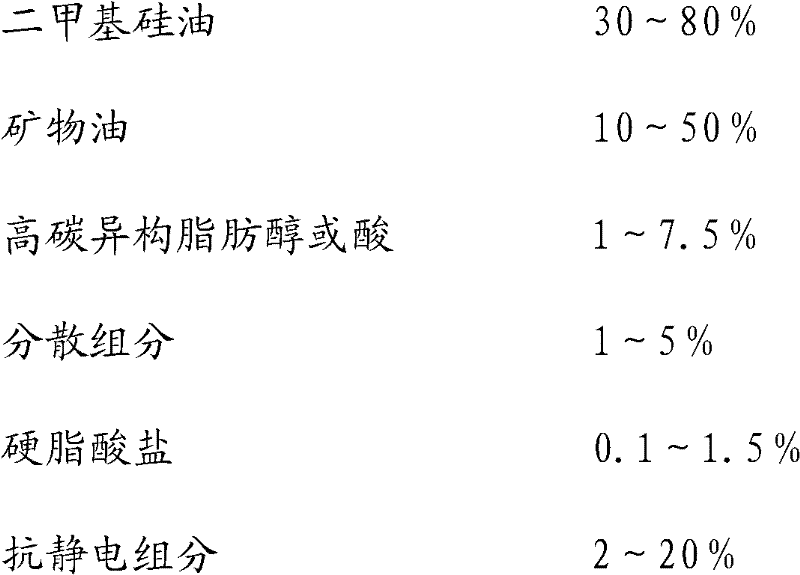

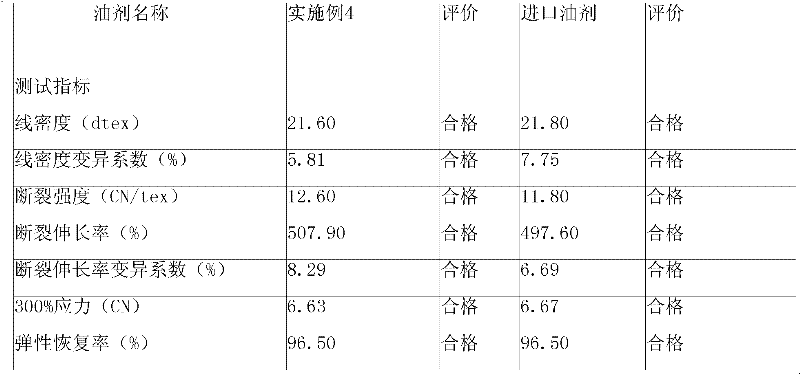

The invention discloses a polyurethane fiber dry spinning oil agent, which comprises 30 to 80 weight percent of dimethyl silicon oil, 10 to 50 weight percent of mineral oil, 1 to 7.5 weight percent of high-carbon isomeric fatty alcohol or acid, 1 to 5 weight percent of dispersed component, 0.1 to 1.5 weight percent of stearate and 2 to 20 weight percent of antistatic component. The dispersed component is a mixture of an organic silicon surfactant and acrylic acid-maleic acid copolymer, and the weight ratio of the organic silicon surfactant to the crylic acid-maleic acid copolymer is 1:0.5-2; and the antistatic component is a mixture of polyether silicon oil and nonionic isomeric alcohol polyethenoxy ether, and the weight ratio of the polyether silicon oil to the nonionic isomeric alcohol polyethenoxy ether is 1:0.5-2. The polyurethane fiber dry spinning oil agent has excellent smoothness, softness, antistatic property, stable performance and excellent anti-adherent performance; polyurethane fiber treated by the oil agent has good unreeling property and forming property; and in the subsequent processing flow, polyurethane filaments are easy to unreel, not drop edge and has few broken filaments.

Owner:BEIJING GUANGHUA TEXTILE GRP +2

Synthetic fibre with functions of heat storage, warm keeping and health protection and preparation method thereof

InactiveCN102115920AGuaranteed durabilityImprove heat storage and heat preservation effectMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCoupling

The invention relates to a synthetic fibre with the functions of heat storage, warm keeping and health protection. The fibre consists of a master batch with the functions of heat storage, warm keeping and health protection and a fibre grade resin slice, wherein the master batch comprises the following components in percent by weight: 30-70 percent of carrier resin, 10-40 percent of zirconium carbide powder, 3-8 percent of silane coupling agents, 5-10 percent of solid coupling agents and 15-18 percent of dispersing agents. The method for preparing the fibre comprises the step of preparing the master batch with the functions of heat storage and warm keeping as well as the step of spinning. The invention has the beneficial effects that the zirconium carbide can be used for absorbing visible light and near and far infrared light, the concept of applying the absorption and thermal conversion characteristics of the zirconium carbide to the heat storage and warm keeping fibre is different from the traditional fibre, and the heat storage and warm keeping effects are obviously improved. The method for preparing the fibre has peculiar process for treating the zirconium carbide, thus causing the spinning process to be smoothly carried out and ensuring the fibre quality and the durability of the heat storage function.

Owner:TIANJIN SAIYUAN HEALTH PROD

Far infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275AImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceFar infrared

The invention discloses provides a far infrared bamboo charcoal viscose fiber and a preparation method thereof, in order to make up for the blank of the conventional far infrared bamboo charcoal viscose fiber and solve the problem of poor spinnability of the bamboo charcoal viscose fiber. The far infrared bamboo charcoal viscose fiber is characterized in that the fiber comprises 1-10 percent by weight of far infrared ceramic powder and 0.1-10 percent by weight of bamboo charcoal, wherein the far infrared emissivity is greater than 80 percent, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500 mm / s, and the color fastness to washing is class 4-5. The far infrared bamboo charcoal viscose fiber has a heat insulation effect; the radiated far infrared also has the health-care functions of activating cell tissues and promoting the blood circulation.

Owner:YIBIN HIEST FIBER +1

Lyocell fiber containing nano particles and preparation method thereof

ActiveCN104975366AHigh recovery rateSimple spinning processArtificial filaments from cellulose solutionsWet spinning methodsCelluloseNanoparticle

The invention discloses lyocell fiber containing nano particles and a preparation method thereof. The preparation method includes following steps: mixing hydrosol containing nano particles with a 50% NNMO aqueous solution, adding cellulose wood pulp meal chips being 0.1-0.5 mm in length according to proportion, and performing a traditional lyocell fiber spinning process to obtain the lyocell fiber being 0.2-20% in the content of the nano particles. By means of different addition of nano materials, the lyocell fiber achieves a flame-retarding function, an anti-bacterial function, an ultraviolet-proofing function and the like. The method achieves uniform dispersion of the nano particles in the lyocell fiber, integrates the dewatering processes of the nano particle hydrosol and a lyocell cellulose spinning solution, thereby omitting a pre-treatment process of the nano material, simplifying the spinning process and reducing production cost.

Owner:TIANJIN POLYTECHNIC UNIV

Extinction bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556261ASignificant shielding rateGood deodorizing functionArtificial filaments from viscoseWet spinning methodsChemistryComposite material

The invention provides an extinction bamboo charcoal viscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The extinction bamboo charcoal viscose fiber is characterized by comprising the components by weight percent: 0.01-10 percent of titanium dioxide and 0.1-10 percent of bamboo charcoal, wherein the ammonia absorption rate is more than or equal to 50 percent, the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The extinction bamboo charcoal viscose fiber disclosed by the invention is a novel product, has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption, has soft handfeel and has an extinction function.

Owner:YIBIN HIEST FIBER +1

Polyphenylene sulfide short fiber spinning oil and preparation method thereof

ActiveCN103409855ASuitable for antistaticSuitable smoothnessSynthetic polymer filament chemical after-treatmentSpin effectAntistatic agent

The invention discloses a polyphenylene sulfide short fiber spinning oil and a preparation method thereof. The polyphenylene sulfide short fiber spinning oil comprises the following compound raw materials by weight percentage: 25-50 percent of antistat, 15-25 percent of smoothing agent, 18-35 percent of saturant, 5-20 percent of emulsifier and 2-8 percent of modifier. According to the weight percentage of each raw material component, the accurately metered antistat, smoothing agent, saturant, and emulsifier are pumped into a reaction pot, heated to 50-80 DEG C, and uniformly mixed; the modifier is pumped into the reaction pot, agitated for 1-3 h, cooled, filtered, unloaded and packaged. The polyphenylene sulfide short fiber spinning oil has good anti-static electricity performance, smoothness, saturation and the like, is uniform and stable in oil loading, can ensure smooth operation of spinning production and postprocessing working procedure, and satisfies production requirements on spinning effect and the mechanical performance of the fiber.

Owner:天津工大纺织助剂有限公司

Bamboo charcoal viscose fiber rich in nano-copper and preparation method of bamboo charcoal viscose fiber

ActiveCN103556272AImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

The invention provides a bamboo charcoal viscose fiber rich in nano-copper and a preparation method of the bamboo charcoal viscose fiber in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The bamboo charcoal viscose fiber rich in nano-copper is characterized by being prepared by mixing a nano-copper bamboo charcoal solution with viscose throug injection before spinning, and carrying out wet spinning and post-treatment; the nano-copper bamboo charcoal solution is formed by mixing masterbatches containing the nano-copper and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-5 percent of nano-copper and 0.1-10 percent of bamboo charcoal; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The bamboo charcoal viscose fiber rich in the nano-copper has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Anti-ultraviolet bamboo charcoalviscose fiber and preparation method thereof

ActiveCN103556252AGood antibacterial effectGood deodorizing functionArtificial thread manufacturing machinesArtificial filaments from viscoseBamboo charcoalViscose fiber

The invention provides an anti-ultraviolet bamboo charcoalviscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoalviscose fiber is poor in spinning property. The anti-ultraviolet bamboo charcoalviscose fiber is characterized by being obtained by mixing an anti-ultraviolet bamboo charcoal solution with mucilage glue through spinning before injection, and carrying out wet spinning and post-treatment, wherein the anti-ultraviolet bamboo charcoal solution is formed by mixing an anti-ultraviolet masterbatches and a bamboo charcoal solution; the anti-ultraviolet masterbatches contain an anti-ultraviolet agent. The fiber comprises the components by weight percent: 0.01-10 percent of the anti-ultraviolet agents and 0.1-10 percent of bamboo charcoal; the ultraviolet shielding rate is more than or equal to 95 percent, the ammonia absorption rate is more than or equal to 50 percent, and the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The anti-ultraviolet bamboo charcoalviscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the anti-ultraviolet effect of the anti-ultraviolet bamboo charcoalviscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Preparation method of low-melting-point hot-melting tynex

InactiveCN102560706AAvoid breakingNot easy to produceNew-spun product collectionFilament-forming treatmentAgricultural engineeringMagnification

The invention discloses a preparation method of low-melting-point hot-melting tynex, which is characterized by including process steps of slicing,drying,spinning,drawing nylon, and the like. In the drying step, drying temperature ranges from 50 DEG C to 70 DEG C, and drying time ranges from 12 hours to 20 hours. In the spinning step, spinning is realized through a spinning screw, and the temperature of the spinning step is in different control in different areas, the temperature areas include a screw area, a metering pump area, a bend area and a spinning box area, wherein the temperature of the screw area ranges from 180 DEG C to 225 DEG C, the temperature in the spinning box ranges from 200 DEG C to 235 DEG C, and spinning speed is 500-800 meters per minute; spinning oil with weight ratio concentration of 20% is added during spinning, the temperature of a heating plate ranges from 45 DEG C to 55 DEG C and the forming temperature of a heating plate ranges from 55 DEG C to 65 DEG C during drawing, and the drawing magnification ranges from 3.2 to 3.6. The low-melting-pint hot-melting tynex prepared by the preparation method is not easy to break or to be fuzzy, is not easy to be loose, free of edge turned down after winding and smooth in spinning, and breakage strength and linear density thereof meet the requirements after weaving.

Owner:瑞安市瑞邦针纺科技有限公司

Aromatic bamboo charcoal fiber and production process thereof

ActiveCN103541035AGood deodorizing functionGood air permeabilityArtificial filaments from viscoseWet spinning methodsAnti bacterialBamboo charcoal

The invention aims at meeting market customer demands of a product, solving the problem of poor spinnability of bamboo charcoal viscose fiber and providing aromatic bamboo charcoal fiber and a production process thereof. The aromatic bamboo charcoal fiber is characterized in that the fiber contains 0.01-10% by weight of aromatic fragrance and 0.1-10% of bamboo charcoal, the ammonia absorption rate is not less than 50%, the air permeability is not less than 500mm / s, and the color fastness to washing is level 4-5. The aromatic bamboo charcoal fiber provided by the invention has not only anti-bacterial, anti-ultraviolet and deodorizing functions, but also good air permeability and absorption, and can effectively and continuously emit aroma and realize the effects of relieving stress and refreshing people.

Owner:YIBIN HIEST FIBER +1

Antibacterial bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556278AImprove breathabilityImprove antibacterial propertiesArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceAnti bacterial

The invention provides an antibacterial bamboo charcoal viscose fiber and a preparation method thereof, which meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antibacterial bamboo charcoal viscose fiber is characterized by being obtained by mixing an antibacterial bamboo charcoal solution with viscose through injection before spinning, and carrying out wet spinning and post-treatment, wherein the antibacterial bamboo charcoal solution is formed by mixing an antibacterial solution and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-10 percent of an antibacterial agent and 0.1-10 percent of bamboo charcoal; the bacteriostasis rate is more than or equal to 90 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The antibacterial bamboo charcoal viscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the antibacterial bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Spinning stock solution for dry method acrylic fiber spinning and preparation method thereof

InactiveCN105220256AReduce moisture contentModerate molecular weightMonocomponent synthetic polymer artificial filamentDry spinning methodsPorosityAcrylonitrile

The invention relates to a spinning stock solution for polyacrylonitrile spinning and especially relates to a spinning stock solution for dry method acrylic fiber spinning. The spinning stock solution is prepared from polyacrylonitrile dry powder and a solvent by mixing. The polyacrylonitrile dry powder is prepared from acrylonitrile, methyl acrylate, sodium p-styrenesulfonate and 2-acrylamide-2-methylpropanesulfonic acid as copolymerization monomers by a polymerization reaction. Through selection of appropriate copolymerization monomers and weight parts, the polyacrylonitrile dry powder with appropriate porosity, molecular weight and molecular weight distribution is obtained, and through selection of the appropriate solvent and content and control of a mixing temperature and a dissolving temperature, the spinning stock solution with rotary viscosity of 45000-65000 mpa. s is prepared from the polyacrylonitrile dry powder. The spinning stock solution has moderate viscoelasticity and less water content, is conducive to stable spinning, reduces a spinneret plate use amount and increases the number of spinning positions. The invention also provides a preparation method. The preparation method has reasonable processes.

Owner:CHINA PETROLEUM & CHEM CORP

Aromaticity bamboo charcoal fiber and preparation method thereof

ActiveCN103556264AImprove breathabilitySignificant shielding rateArtificial filaments from viscoseWet spinning methodsSpinningPulp and paper industry

The invention provides an aromaticity bamboo charcoal fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The aromaticity bamboo charcoal fiber is characterized in that a finished product is obtained by taking cellulose fiber pulp as a raw material, mixing an aromaticity bamboo charcoal solution and viscose through injection before spinning and performing wet spinning and post-treatment, wherein the aromaticity bamboo charcoal solution is prepared by mixing fragrant masterbatches and a bamboo charcoal solution; the fragrant masterbatches contain perfumes; the fragrant perfume content of the fiber is 0.01-10 percent; the bamboo charcoal content is 0.1-10 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The aromaticity bamboo charcoal fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and hygroscopicity, can effectively and continuously scatter fragrance and has the effects of relieving pressure and enabling people to be invigorating.

Owner:YIBIN HIEST FIBER +1

Polyurethane fiber dry spinning oil agent and preparation method thereof

Owner:BEIJING GUANGHUA TEXTILE GRP +2

Antistatic bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556280ASignificant far infrared health functionSignificant UV shielding rateArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceMoisture absorption

The invention provides an antistatic bamboo charcoal viscose fiber and a preparation method thereof, which fill up the blank of the conventional antistatic bamboo charcoal viscose fiber and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antistatic bamboo charcoal viscose fiber is characterized by comprising 1-10 percent of graphite and 0.1-10 percent of bamboo charcoal, wherein the volume resistivity is lower than 1,010 ohm.cm, the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The antistatic bamboo charcoal viscose fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption and has soft handfeel; the antistatic effect is obvious and lasting.

Owner:YIBIN HIEST FIBER +1

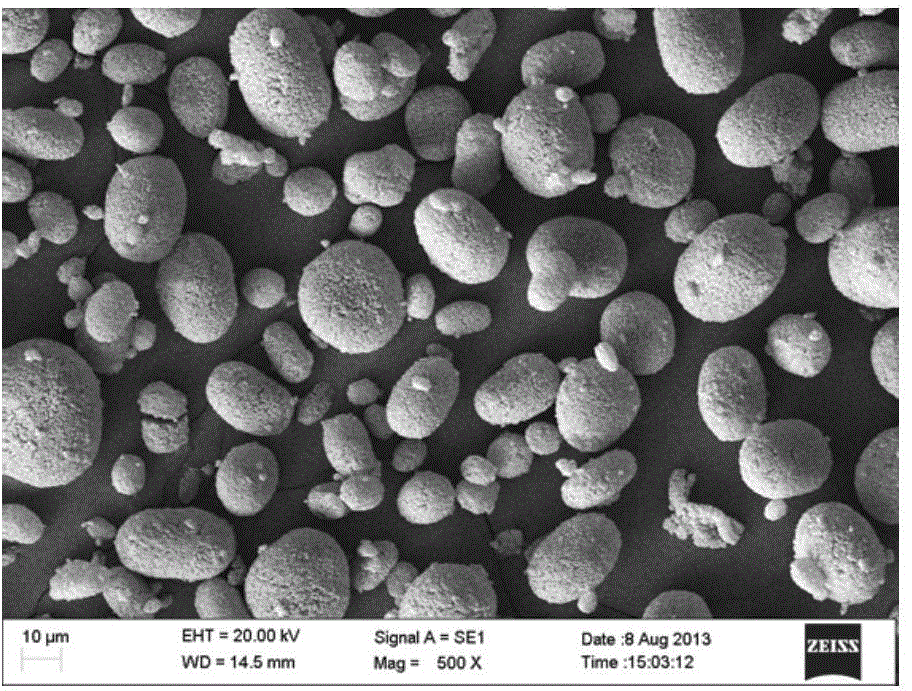

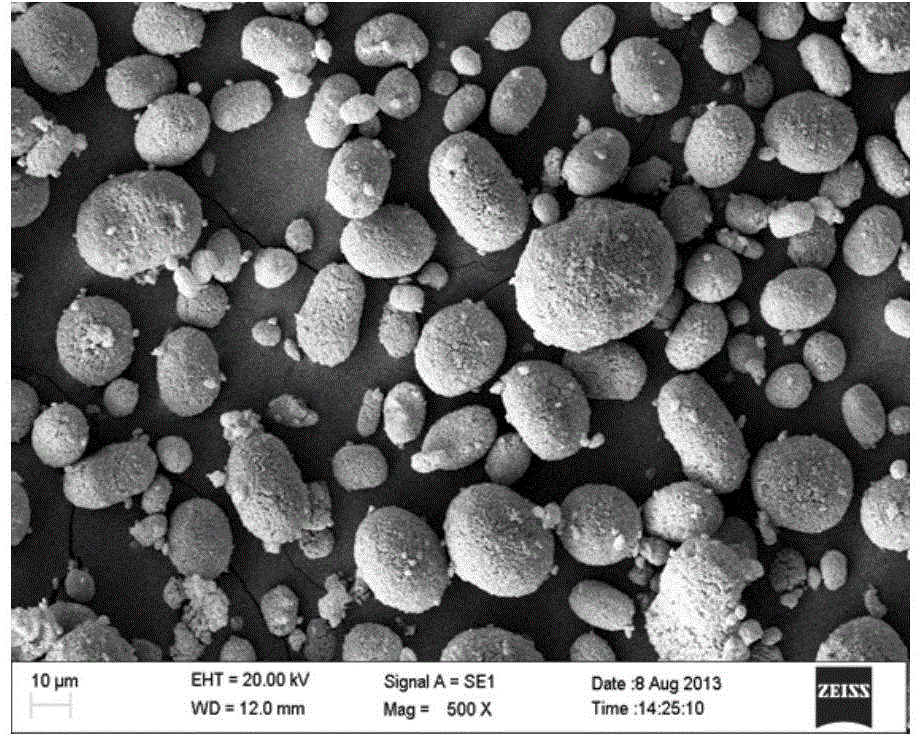

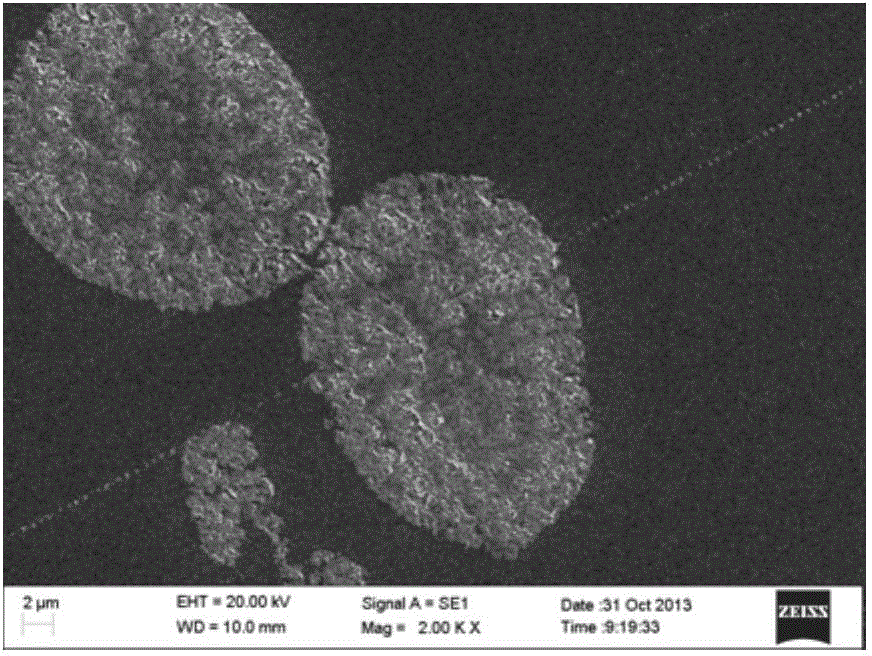

Polyacrylonitrile dry powder suitable for dry acrylic fiber spinning, and preparation method thereof

InactiveCN105273125ALoose structureQuality assuranceMonocomponent synthetic polymer artificial filamentPorosityPolymer science

The invention relates to a polyacrylonitrile dry powder and a preparation method thereof, and especially relates to a polyacrylonitrile dry powder suitable for dry acrylic fiber spinning. The polyacrylonitrile dry powder is prepared through a polymerization reaction of acrylonitrile, methyl acrylate, sodium styrenesulfonate and 2-acrylamido-2-methylpropanesulfonic acid used as copolymerization monomers. The polyacrylonitrile dry powder prepared in the invention has the advantages of low water content, moderate molecular weight and molecular weight distribution, good granularity and good internal porosity amount of particles, so a spinning stock solution prepared in the dry spinning process has the advantages of good elasticity, few bubbles, bright color, smooth spinning process, and obtaining of a spinning product with good chromaticity and strong hygroscopicity. The invention also provides a preparation method of the polyacrylonitrile dry powder suitable for dry acrylic fiber spinning. The method comprises the following steps: adding the copolymerization monomers into a polymerization kettle, adding an assistant, and carrying out a polymerization reaction; and adding EDTA to end the reaction, filtering a material obtained after the polymerization reaction, washing, drying to obtain polyacrylonitrile resin, and crushing to form fine powder in order to obtain the polyacrylonitrile dry powder suitable for dry acrylic fiber spinning.

Owner:CHINA PETROLEUM & CHEM CORP

Low-temperature dyeing process for fox fleece

InactiveCN104420349AEasy to control cylinder differenceLess damageDry-cleaning apparatus for textilesDyeing processSocial benefitsYarn

The invention discloses a low-temperature dyeing process for a fox fleece. The process flow comprises soaping, washing with running water, dyeing, washing with running water, washing with ammonia water, washing with hot water, soaping, washing with hot water, fixing color, softening and drying. By adopting the low-temperature dyeing process, fox fleece fibers can be damaged little, the strength of single fibers can be kept to ensure smooth operation of a spinning procedure, and yarn faults can be reduced. The low-temperature dyed fox fleece fibers are soft, smooth and elastic, are good in moisture absorption, and can reserve original excellent performance, and especially can reserve original luster, style and handfeel after being made into knitted sweaters and underwear and improve the price and grade of products. The low-temperature dyeing process for the fox fleece is convenient in control of color difference from batch to batch, has energy-saving and emission-reducing effects and has good economic benefit and social benefit.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

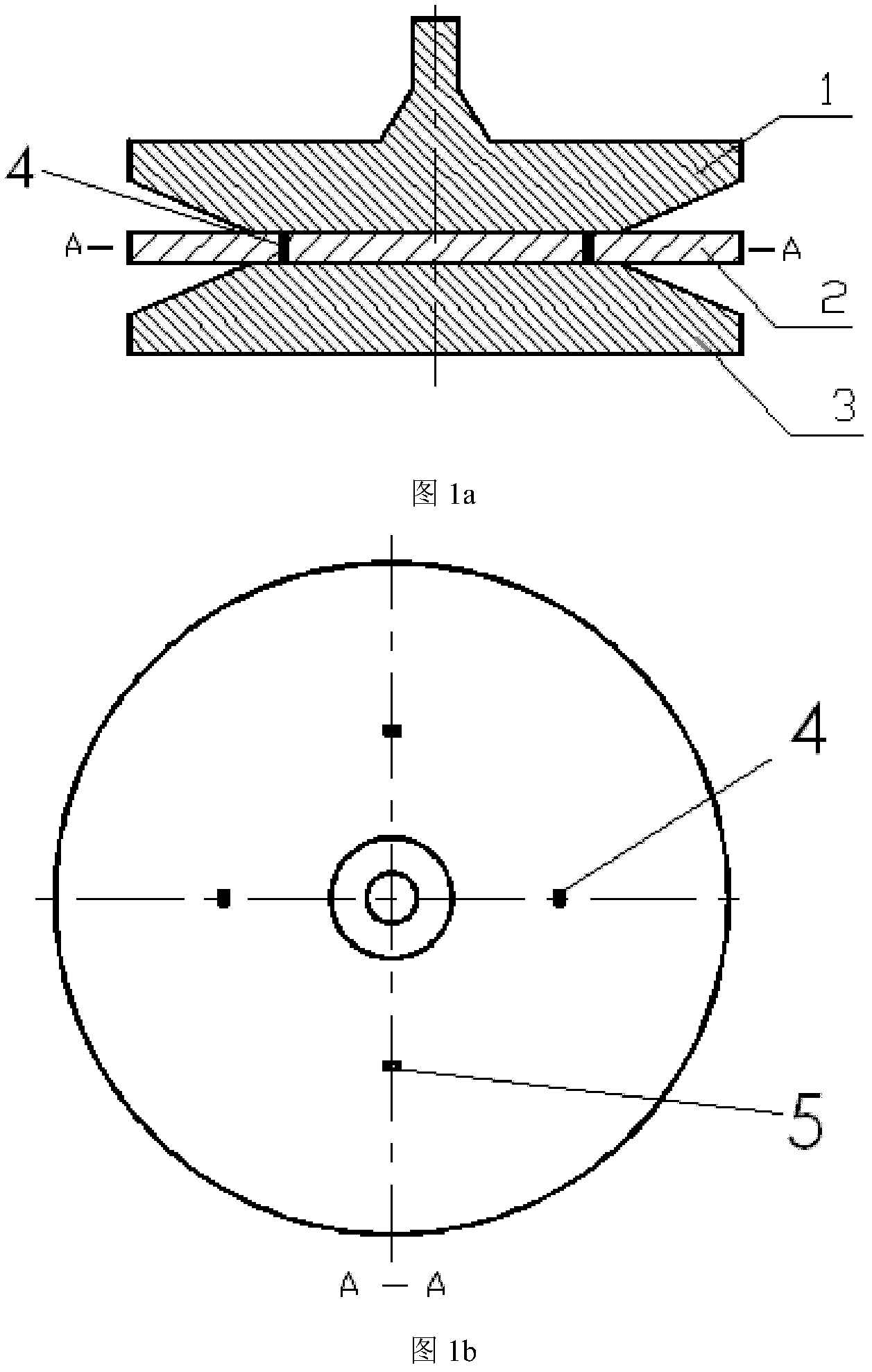

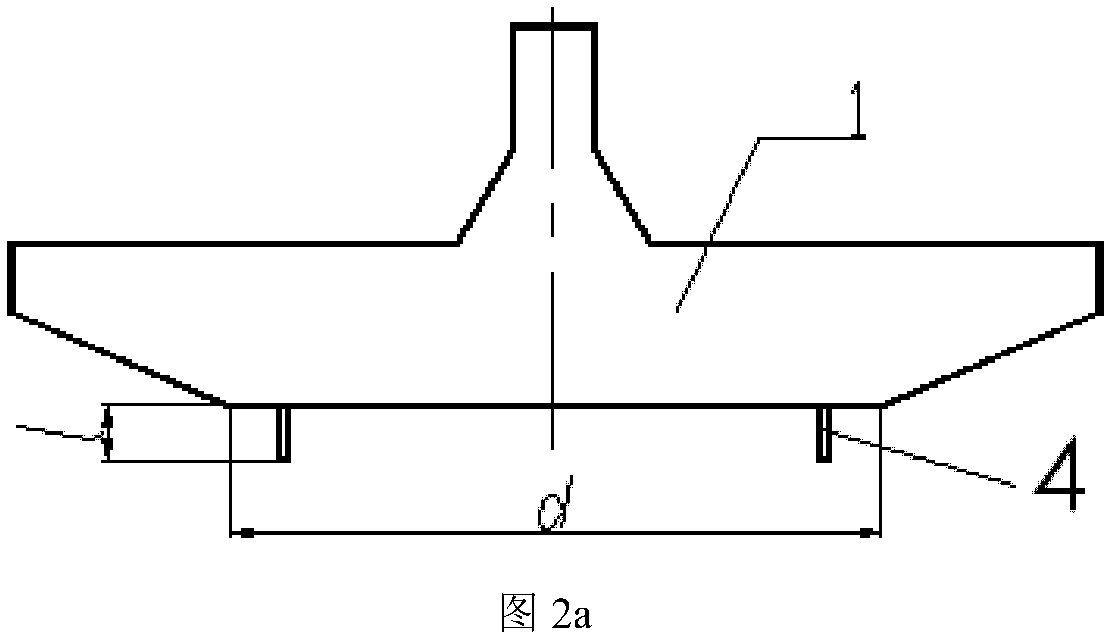

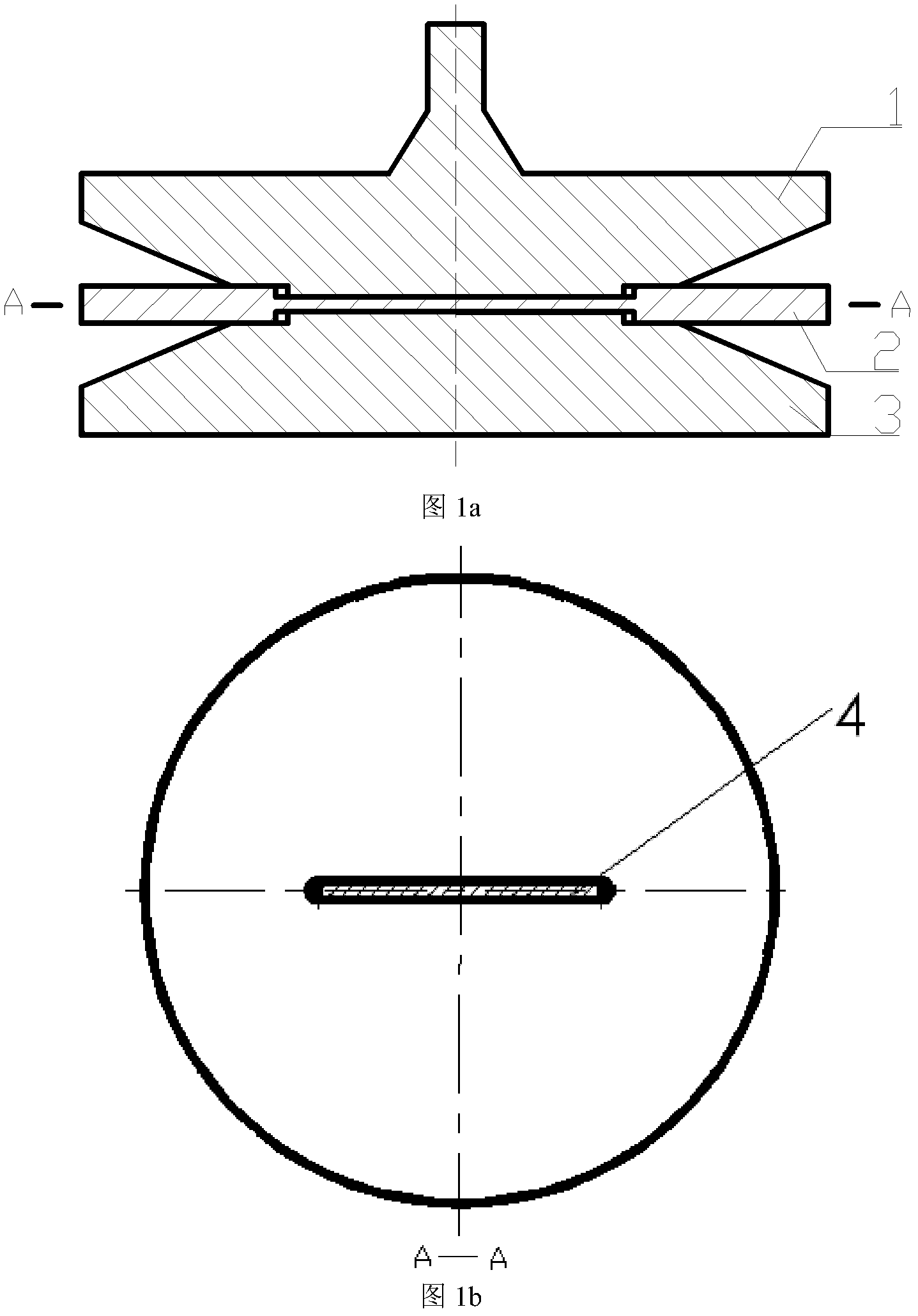

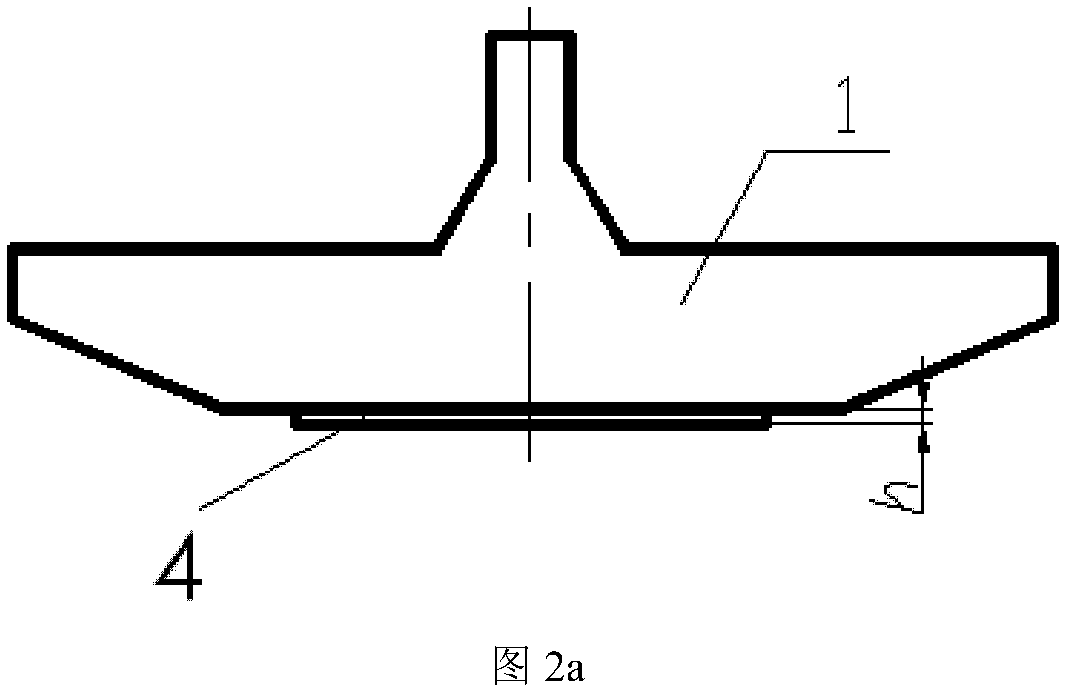

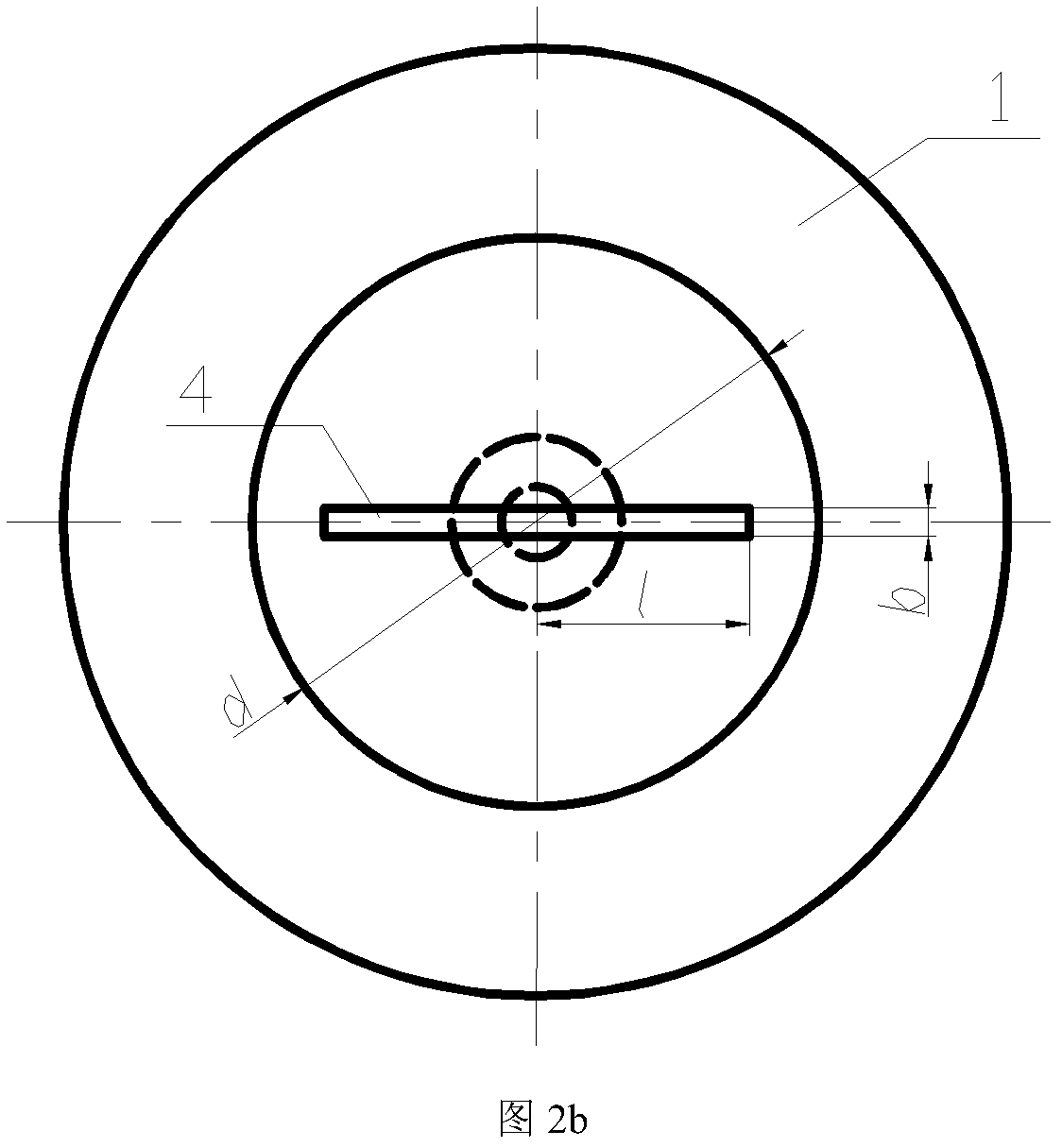

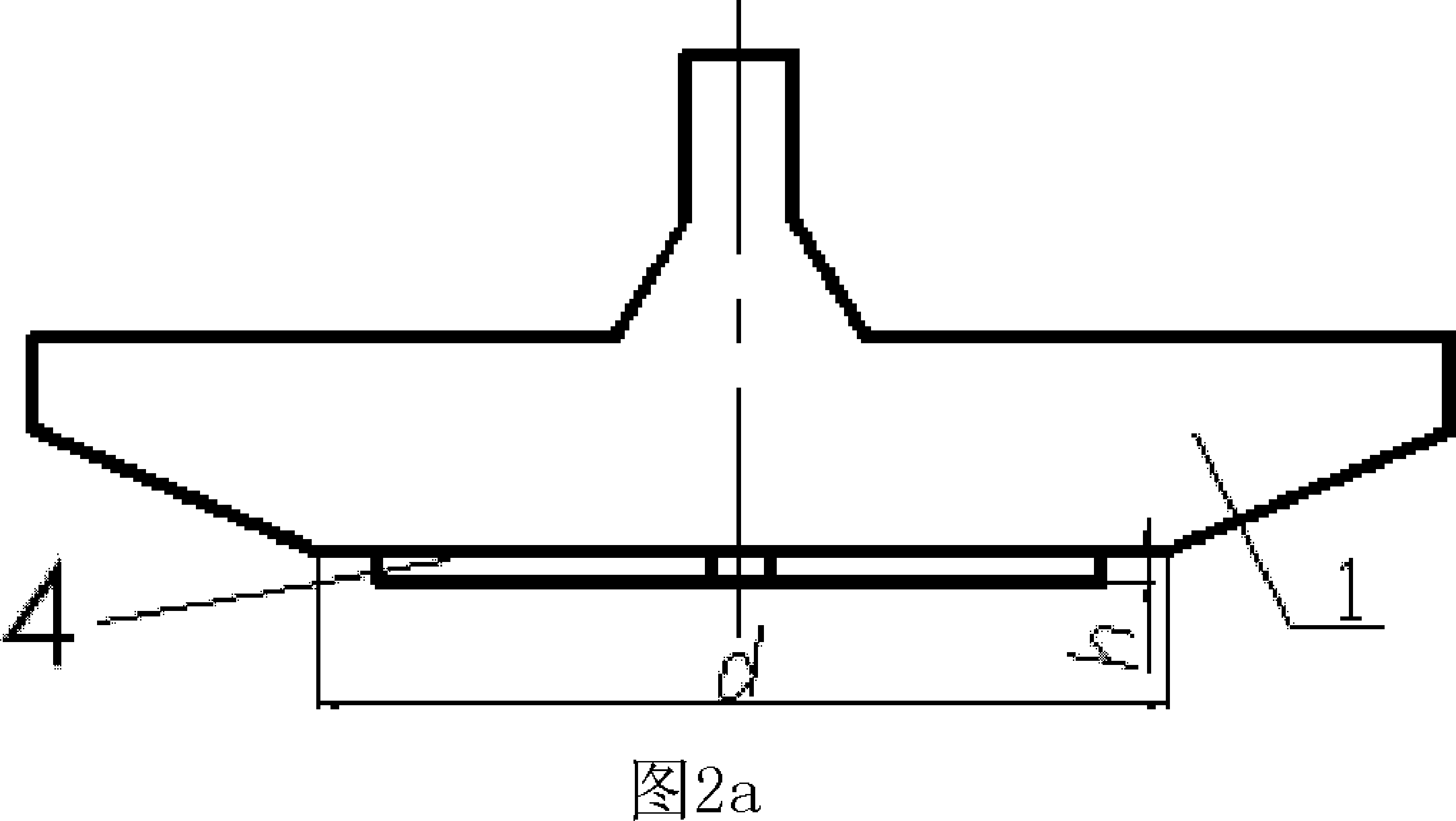

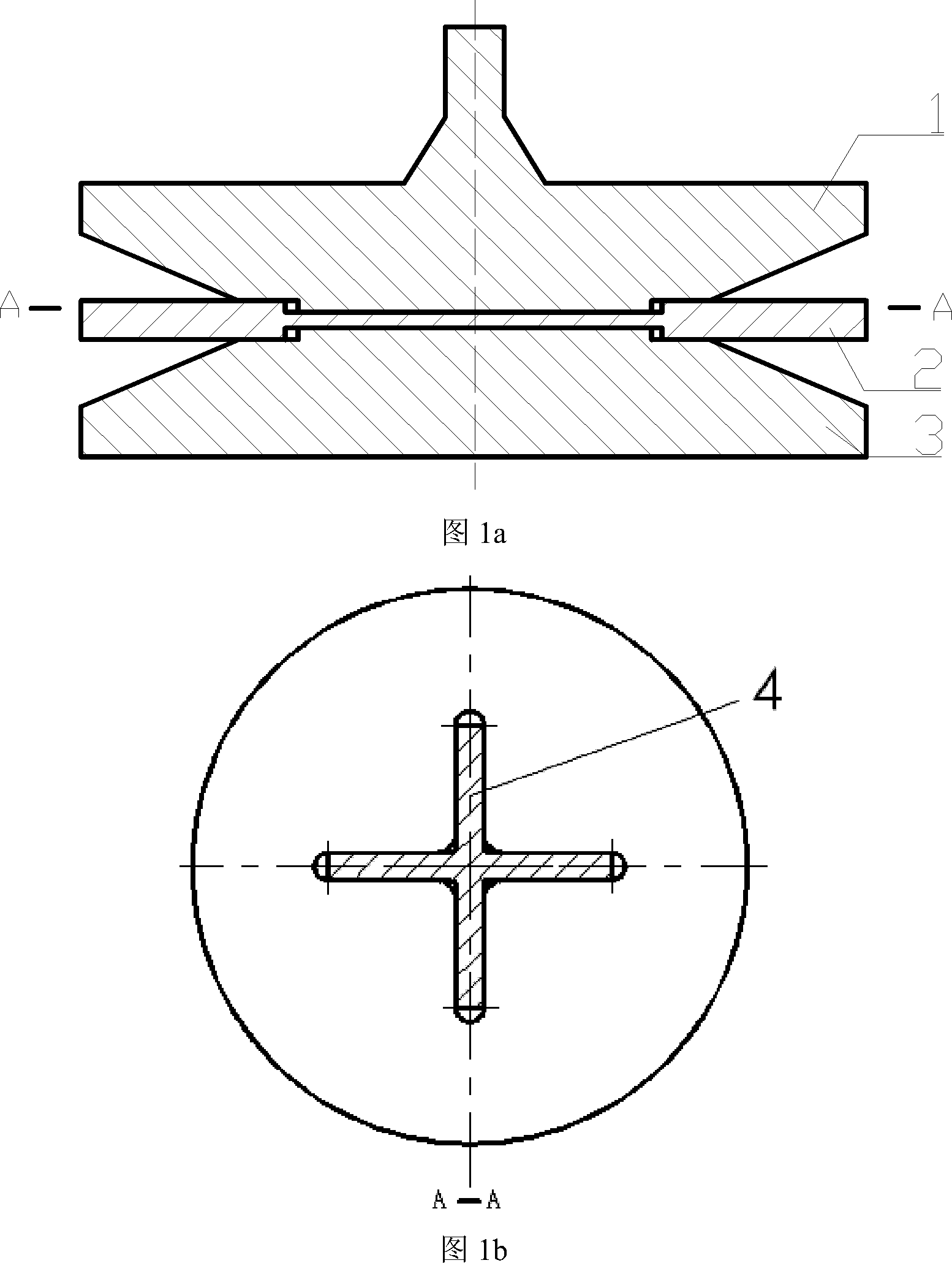

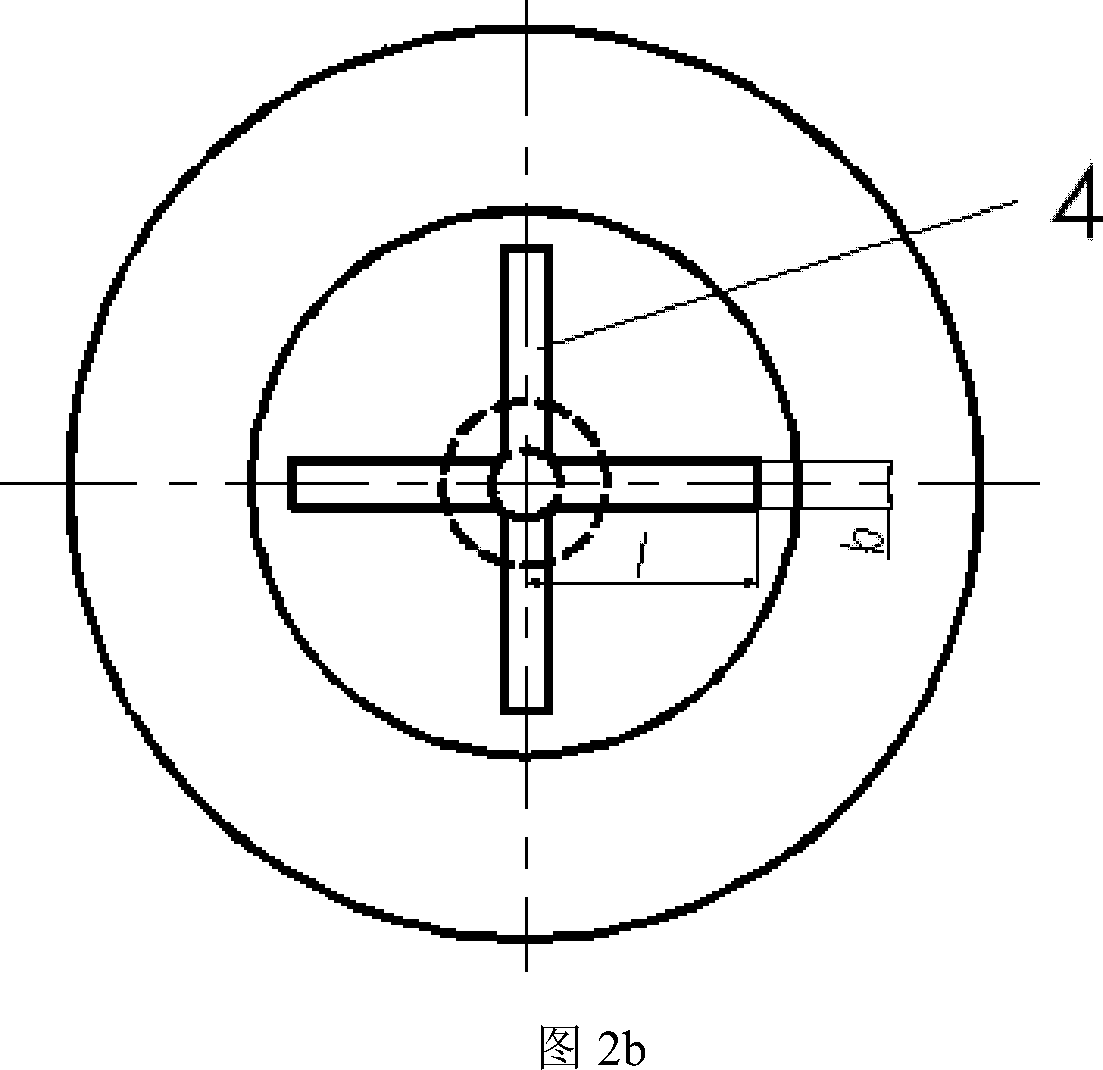

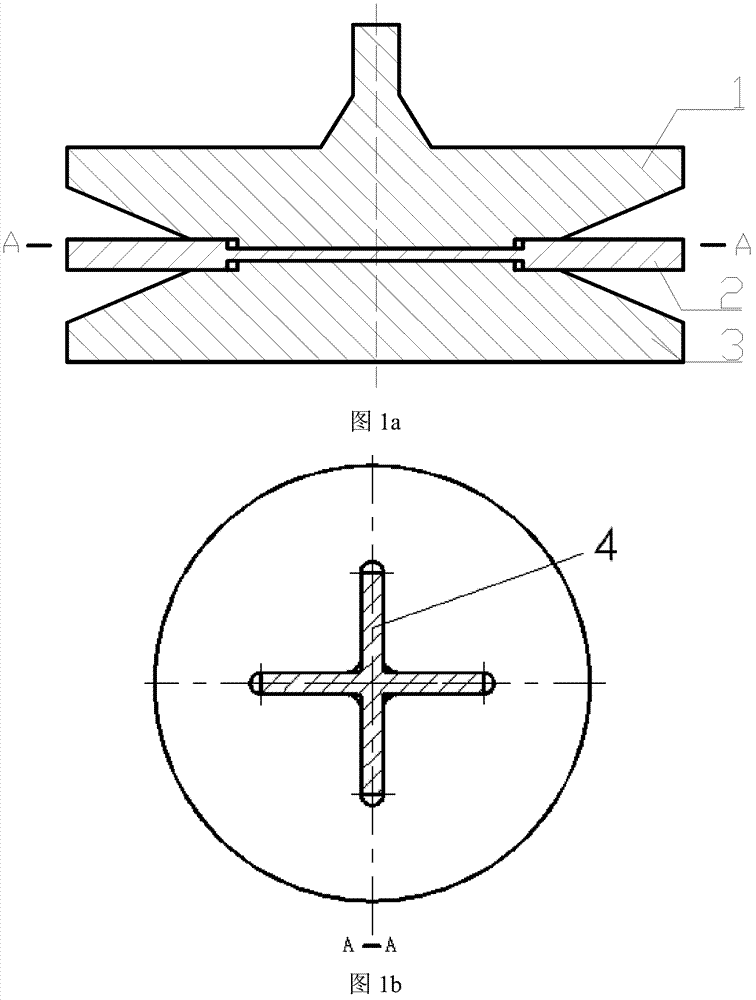

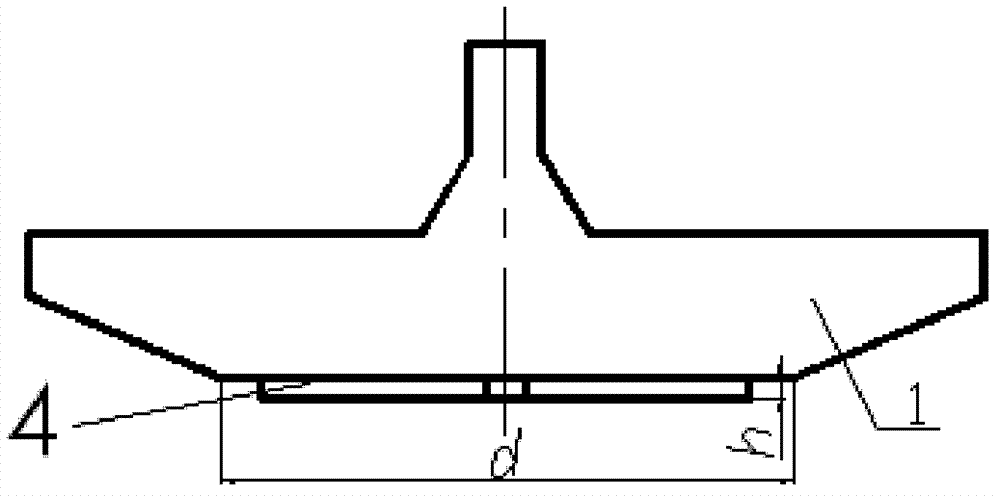

Fractal spinning mould with flat keys and determining method of flat keys

Provided are a fractal spinning mould with flat keys and a determining method of the flat keys. The fractal spinning mould comprises a driving core mould and a driven core mould. A pair of flat keys is arranged on the surface where the driving core mould and the driven core mould are matched with a blank, and a pair of flat keys on the lower end face of the driving core mould and a pair of flat keys on the upper end face of the driven core mould form a 90-degree angle in intersection mode. The fractal spinning mould is used, and the flat keys on the driving core mould and the flat keys on the driven core mould are respectively inserted into key grooves distributed on the blank. Rotation torque applied by a machine tool spindle to the driving core mould is transmitted to a work piece through the pair of flat keys on the driving core mould, and rotating of the work piece and the driven core mould with the spindle can be achieved by the work piece and a pair of flat keys matched with the driven core mould, so that synchronous rotation of the driving core mould, the work piece and the driven core mould can be achieved, and the work piece is prevented from sliding relative to the core module. Due to the fact that the flat keys on the driving core mould and the driven core mould are symmetrically distributed and inserted into the key grooves distributed on the blank in 90-degree insertion mode, the fractal spinning mould achieves location effects and prevents eccentricity.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of bamboo charcoal viscose fiber rich in nano copper and preparation method thereof

ActiveCN103556272BImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

In order to meet the needs of customers in the product market and solve the problem of poor spinnability of the bamboo charcoal viscose fiber, the invention provides a nano-copper bamboo charcoal viscose fiber and a preparation method thereof. It is characterized in that: the nano-copper bamboo charcoal solution is mixed with viscose by pre-spinning injection, and the finished product is obtained through wet spinning and post-processing. By weight, the nano-copper content in the fiber is 0.01~5%, the bamboo charcoal content is 0.1~10%, the ammonia absorption rate is ≥50%, the air permeability is ≥500mm / s, and the color fastness to washing is 4~5. The nano-copper bamboo charcoal viscose fiber of the present invention not only has anti-ultraviolet and deodorizing functions, but also has good air permeability and absorbency, and the antibacterial effect is stronger than that of ordinary bamboo charcoal fiber, the fiber has high breaking strength and low cost.

Owner:YIBIN HIEST FIBER +1

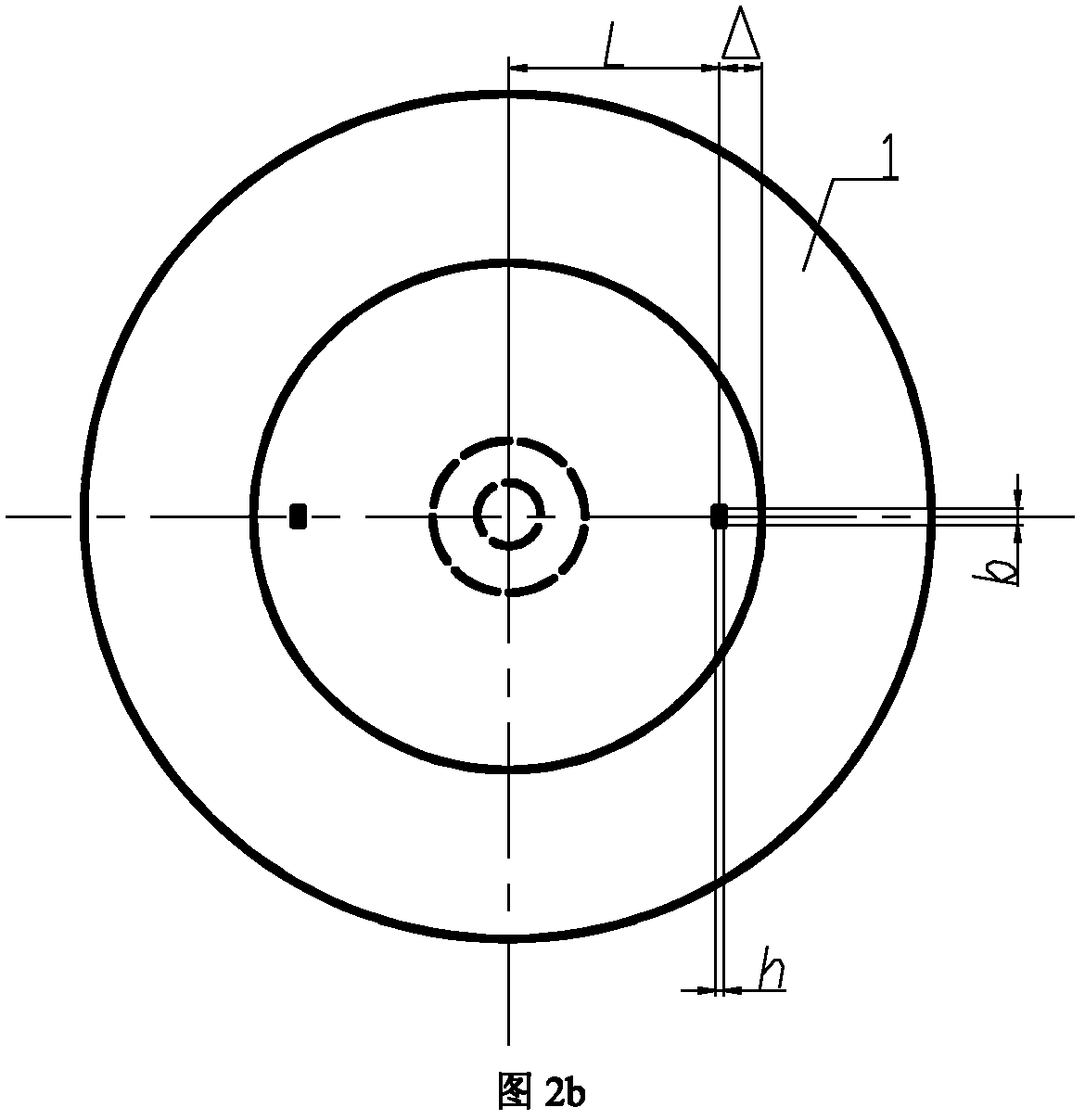

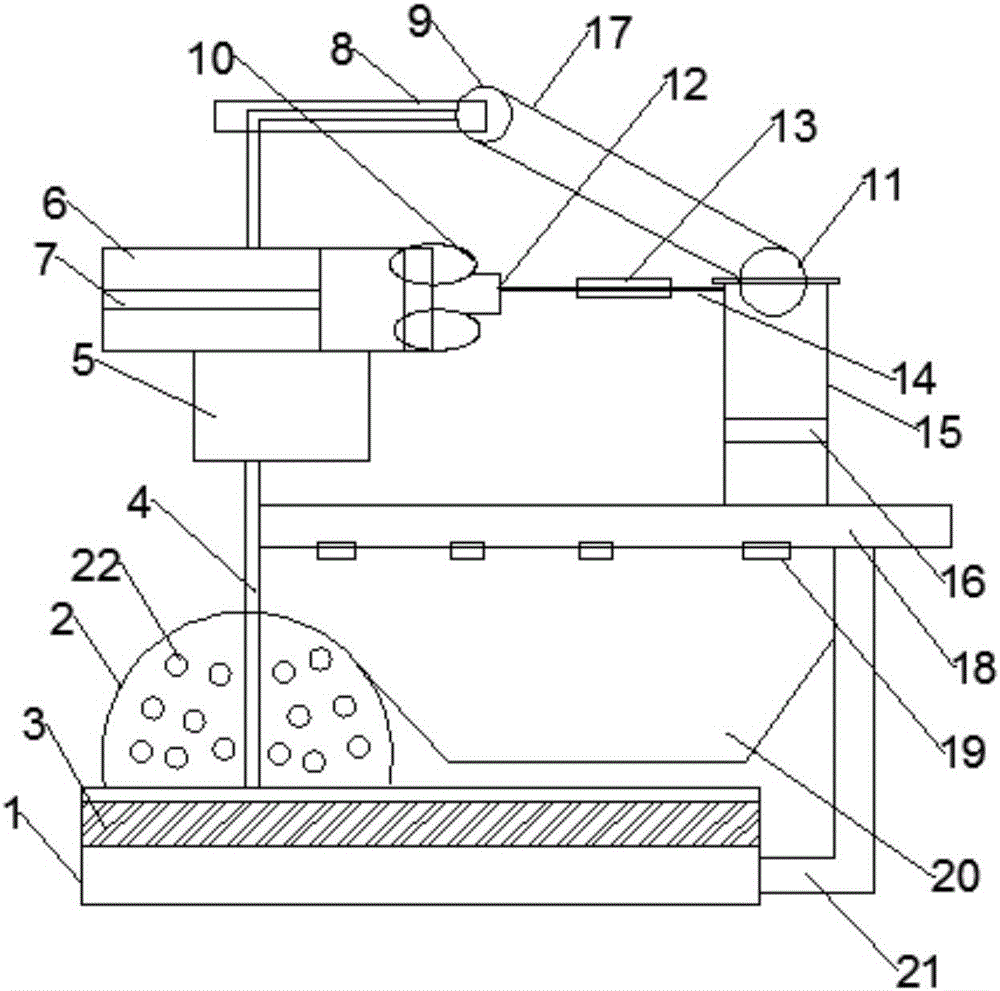

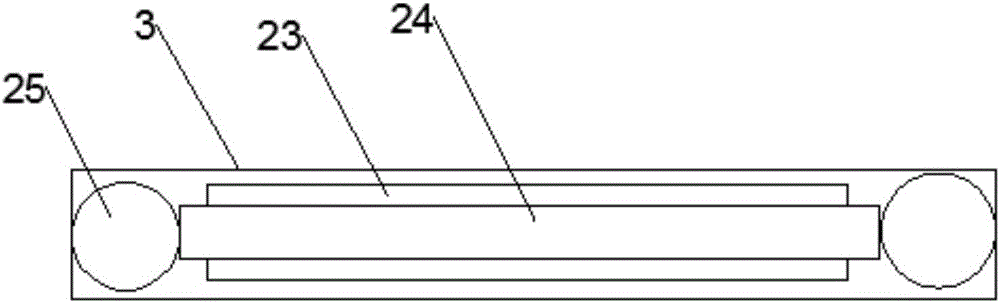

Conveying device of chips dried by vacuum dry air

InactiveCN105937834AReduce dustThe spinning process is smoothGas treatmentDispersed particle filtrationPolyesterEngineering

The invention discloses a conveying device of chips dried by vacuum dry air. The device comprises a pipeline purging valve unit and a vacuum valve unit which are successively arranged between a chip sucking opening and a drying tower, wherein the chip sucking opening, the pipeline purging valve unit and the vacuum valve unit communicate with a feeding opening of the drying tower via a chip conveying pipeline; the side wall of the drying tower communicates with an external vacuumizing fan; a discharging opening of the drying tower communicates with a mixing bin; a discharging opening of the mixing bin communicates with one inlet of a mixer; a cooler and an air blower are successively arranged between the other inlet of the mixer and a nitrogen gas inlet; the outlet of the mixer communicates with a bag-type dust remover; and a discharging valve is arranged at the outlet of the bag-type dust remover. The conveying device is used for conveying chips under the vacuum condition, so that the dust generated in the process of conveying low-melting-point polyester chips is reduced; the adhesion and agglomeration are also avoided, so that the subsequent spinning process is smooth; and the product quality is uniform.

Owner:张家港新丝纬化纤有限公司

Splitting spinning mold with retainer stages and determination method for retainer stages

The invention discloses a splitting spinning mold with retainer stages and a determination method for the retainer stages. The splitting spinning mold comprises a driving core mold and a driven core mold, the surfaces matched with a blank, of the driving core mold and the driven core mold, are respectively provided with one retainer stage in respective center. When the splitting spinning mold is in use, the retainer stages on the driving core mold and the driven core mold are respectively inserted in bar-shaped grooves on two surfaces of the blank, wherein the bar-shaped grooves are matched with the retainer stages at the small end surfaces of the driving core mold and the driven core mold, the torque exerted onto the driving core mold by a machine tool spindle is transmitted to work through the retainer stage on the driving core mold and then a workpiece and the driven core mold rotate along with the spindle through the retainer stage with the workpiece matched with the driven core mold, so that the driving core mold, the workpiece and the driven core mold rotate synchronously along with the spindle, the sliding of the workpiece relative to the core molds is avoided and the blank is positioned.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Bamboo charcoal viscose flat yarn and production process thereof

ActiveCN103556266AMeet diverse needsSignificant far infrared health functionArtificial filaments from viscoseWet spinning methodsYarnPolymer science

The invention provides a bamboo charcoal viscose flat yarn and a production process thereof, in order to meet the requirements of clients on product markets. The bamboo charcoal viscose flat yarn is characterized by being prepared through the following steps: mixing the bamboo charcoal pulp with viscose through injection before spinning and performing wet spinning and post-treatment, wherein the flatness of the yarn is (10-500):1, the content of the bamboo charcoal is 0.1-10 percent of the total weight of the fiber, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500mm / s, and the color fastness to washing is class 4-5. The bamboo charcoal viscose flat yarn is a new product, which has antibacterial, anti-ultraviolet and deodorization functions, also has good permeability and wet absorption and is a degradable environment-friendly fiber.

Owner:YIBIN HIEST FIBER +1

A kind of far-infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275BImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscoseFar infraredMechanical engineering

In order to make up for the blank of the current far -infrared bamboo charcoal sticky glue fiber and solve the problem of poor texture of bamboo charcoal sticky fiber, it provides a method of far -infrared bamboo charcoal sticky fiber and its preparation method.It is characterized by: according to the weight meter, the content of far -infrared ceramic powder in the fiber is 1 ~ 10%, the content of bamboo charcoal is 0.1 ~ 10%, the far -infrared emission rate is> 80%, the ammonia absorption rate is ≥50%, the breathability is ≥500mm / s, the water -resistant washing resistance is resistant to water washingSection 4 ~ 5.The far -infrared vibraous glue fiber of the invention not only has the effect of insulation, but also the radiation far -infrared rays also have a health care function of activating cell tissue and promoting blood circulation.

Owner:YIBIN HIEST FIBER +1

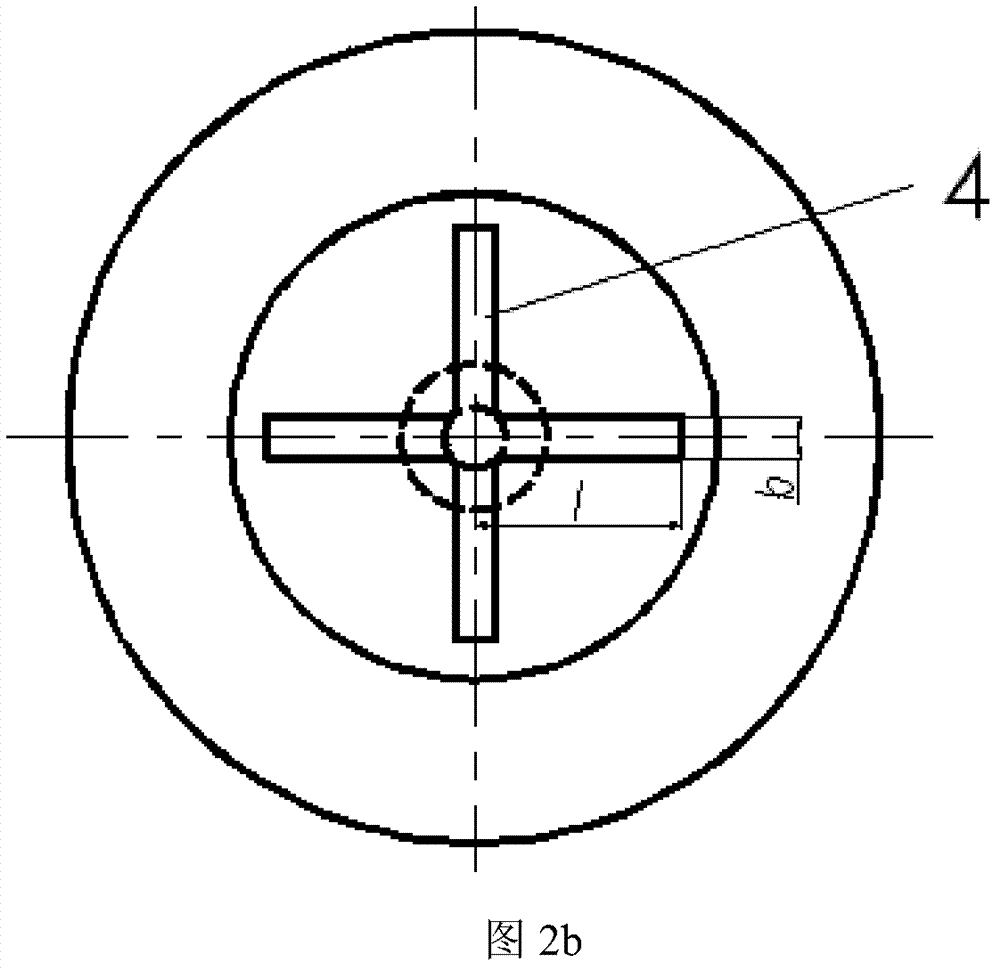

Fractal spinning mold with crossed key and method for determining crossed key

The invention discloses a fractal spinning mold with crossed keys and a method for determining the crossed keys. The fractal spinning mold comprises a driving core mandrel and a driven mandrel, wherein the crossed keys are arranged on the end faces of the driving mandrel and the driven mandrel, which are matched with a blank. When the fractal spinning mold is used, the crossed key on the driving mandrel and the crossed key on the driven mandrel are respectively inserted into two key grooves on two surfaces of the blank, which are matched with the crossed keys on the end faces of the driving mandrel and the driven mandrel, so that the torque applied by a main shaft of a machine tool to the driving mandrel is transmitted to a workpiece through the crossed key on the driving mandrel; the workpiece and the driven mandrel rotate along with the main shaft through the crossed key by which the workpiece is matched with the driven mandrel; therefore, the driving mandrel, the workpiece and the driven mandrel can synchronously rotate along with the main shaft, and the workpiece can be prevented from sliding relative to the mandrels; and the crossed keys on the driving mandrel and the driven mandrel are inserted into the key grooves on the blank, so that the blank can be positioned and prevented from being eccentric.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Polyoxymethylene monofilament for fishing as well as preparation method and application of polyformaldehyde monofilament

ActiveCN110129921AGood spinnability and comprehensive performanceNo broken wireMonocomponent synthetic polymer artificial filamentConjugated synthetic polymer artificial filamentsChemistryMelt spinning

The invention discloses a polyformaldehyde monofilament for fishing. The polyformaldehyde monofilament is prepared from the following components in parts by weight: 75-90 parts of polyformaldehyde, 0.5-3 parts of graphene, 7.5-17 parts of thermoplastic polyurethane, 0.5-3 parts of an antioxidant, 0.5-1 part of a formaldehyde absorbent and 0. 5-1 part of a lubricant. According to the fishing polyformaldehyde monofilament, graphene and thermoplastic polyurethane are blended, then polyformaldehyde is reinforced, toughened and modified, and the polyformaldehyde monofilament for fishing is preparedby melt spinning, three-stage thermal stretching and heat setting processes. A preparation method has the advantages of simple operation process and low production cost. The prepared reinforced and toughened polyformaldehyde monofilament for fishing can be used for polyformaldehyde rope nets, ocean trawls, breeding nets, polyformaldehyde ropes and the like.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

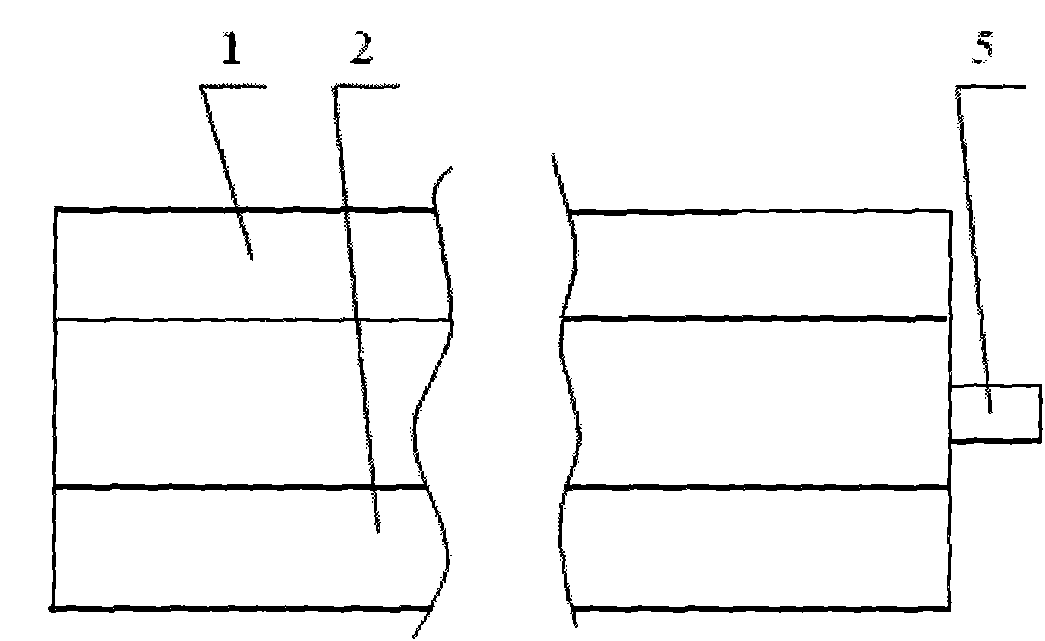

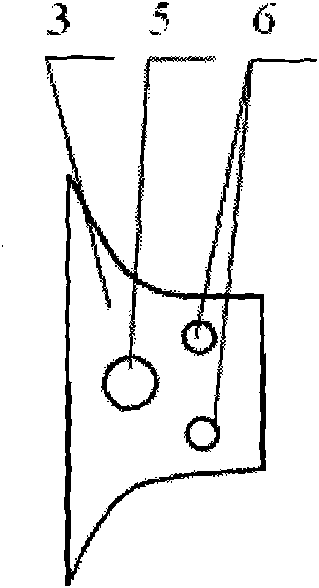

Cotton carding transfer suction

InactiveCN101768800AImprove transfer rateNot easy to create backlogCarding machinesEngineeringGuide tube

The invention relates to a cotton carding transfer suction which comprises a suction upper wall (1), a suction lower wall (2), a suction R side plate (3), a suction L side plate (4), a gas inlet conduit (5) and a fixed hole (6); the suction upper wall (1) is strip-shaped, the upper surface is circular arc-shaped, the suction lower wall (2) has the same structure and is strip-shaped, the lower surface thereof is circular arc-shaped, the suction upper wall (1) is positioned at the upper side, and the suction lower wall (2) is positioned at lower side with space between the upper and lower walls, both sides are respectively connected with the suction R side plate (3) and the suction L side plate (4), the gas inlet conduit (5) is placed in the middle space corresponding to the suction R side plate (3), and the fixed hole (6) is machined on the suction L side plate (4). A gas inlet conduit (5) is placed on the suction L side plate (4). The invention solves the problems that the cotton carding machine in prior art has low transfer rate of cylinder and doffer, and can easily cause cylinder cotton layer overstock and uneven doffer cotton layer.

Owner:SHANGHAI RISOO TECH TEXTILE

Coarse denier and raw yarn reeling machine

ActiveCN106637428ATo achieve different temperature requirementsRealize generationSilk reelingYarnTemperature control

The invention discloses a coarse denier and raw yarn reeling machine which comprises a connecting rod and a rotating rod, wherein a treating groove and a conveying belt are respectively connected with the two ends of the connecting rod; a roller is arranged in the treating groove; a drawing spindle is arranged in the roller; heaters are fixedly arranged on the two sides of the drawing spindle; an anti-winding device is jointed above the treating groove; the bottom end of the rotating rod is connected with the treating groove; the rotating rod is vertically connected with the conveying belt; a temperature control box and a buffering box are arranged in the middle of the rotating rod; the buffering box is arranged above the temperature control box; a cutter is arranged in the buffering box; two extruding gears are arranged on the right side of the buffering box; a sprayer is arranged between the two extruding gears; an idler wheel is connected with the top end of the rotating rod through a fixing shaft; the coarse denier and raw yarn reeling machine is especially designed for the coarse denier and raw yarn, is highly targeted and is capable of timely cutting; the appearance of the produced products is beautiful; the defective goods can be collected; the production efficiency is high; the coarse denier and raw yarn reeling machine is worthy of popularization.

Owner:广西柳城县鹏翔茧丝绸有限责任公司

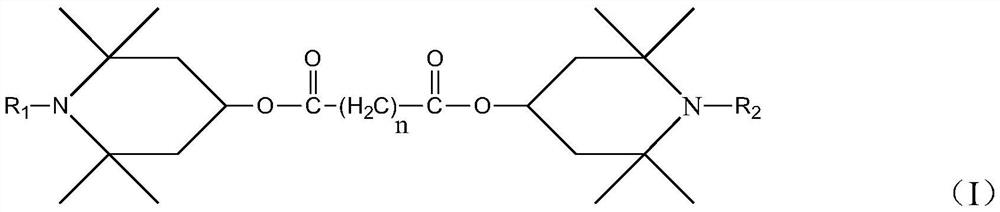

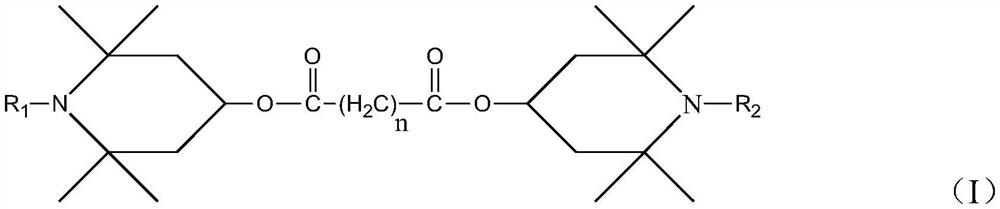

Method of stabilizing activity of monomer isocyanate

ActiveCN112300030ADoes not change reactivityImprove responseIsocyanic acid derivatives purification/separationMonocomponent synthetic polymer artificial filamentPolymer scienceHydrolysis

The present invention provides a method of stabilizing the activity of monomer isocyanate, which comprises the step of adding to the monomer isocyanate an effective amount of (a) a hindered amine and(b) epoxidized soybean oil. The hindered amine includes at least one of the compounds as shown in a formula (I) (see the specification), wherein n is an integer of 1-10, and R1 and R2 are hydrogen, aC1-C4 alkyl group or a C2-C8 alkanoyl group. The additives disclosed by the invention can be well dissolved in monomer isocyanate and stabilize hydrolyzed chlorine and acidic substances, thereby beingbeneficial to reducing the activity fluctuation of the monomer isocyanate.

Owner:WANHUA CHEM GRP CO LTD +1

A kind of antibacterial bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556278BImprove breathabilityImprove antibacterial propertiesArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceAnti bacterial

In order to meet the needs of customers in the product market and solve the problem of poor spinnability of the bamboo charcoal viscose fiber, the invention provides an antibacterial bamboo charcoal viscose fiber and a preparation method thereof. It is characterized in that: the antibacterial bamboo charcoal solution is mixed with viscose by pre-spinning injection, and the finished product is obtained through wet spinning and post-treatment. The antibacterial bamboo charcoal solution is formed by mixing the antibacterial solution and bamboo charcoal solution. Antibacterial agent 0.01~10%, bamboo charcoal 0.1~10%, antibacterial rate ≥ 90%, ammonia absorption rate ≥ 50%, air permeability ≥ 500mm / s, color fastness to washing 4-5. The antibacterial bamboo charcoal viscose fiber of the present invention not only has anti-ultraviolet and deodorizing functions, but also has good air permeability and absorbency, and the antibacterial effect is stronger than ordinary bamboo charcoal fiber, the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Fractal spinning mold with crossed key and method for determining crossed key

The invention discloses a fractal spinning mold with crossed keys and a method for determining the crossed keys. The fractal spinning mold comprises a driving core mandrel and a driven mandrel, wherein the crossed keys are arranged on the end faces of the driving mandrel and the driven mandrel, which are matched with a blank. When the fractal spinning mold is used, the crossed key on the driving mandrel and the crossed key on the driven mandrel are respectively inserted into two key grooves on two surfaces of the blank, which are matched with the crossed keys on the end faces of the driving mandrel and the driven mandrel, so that the torque applied by a main shaft of a machine tool to the driving mandrel is transmitted to a workpiece through the crossed key on the driving mandrel; the workpiece and the driven mandrel rotate along with the main shaft through the crossed key by which the workpiece is matched with the driven mandrel; therefore, the driving mandrel, the workpiece and the driven mandrel can synchronously rotate along with the main shaft, and the workpiece can be prevented from sliding relative to the mandrels; and the crossed keys on the driving mandrel and the driven mandrel are inserted into the key grooves on the blank, so that the blank can be positioned and prevented from being eccentric.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com