Fractal spinning mould with flat keys and determining method of flat keys

A technology of flat keys and molds, applied in the field of fractal spinning molds, which can solve the problems of workpiece sliding and eccentricity, affecting the normal progress of spinning processing, being stuck and unable to rotate, etc., to achieve the effect of preventing eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

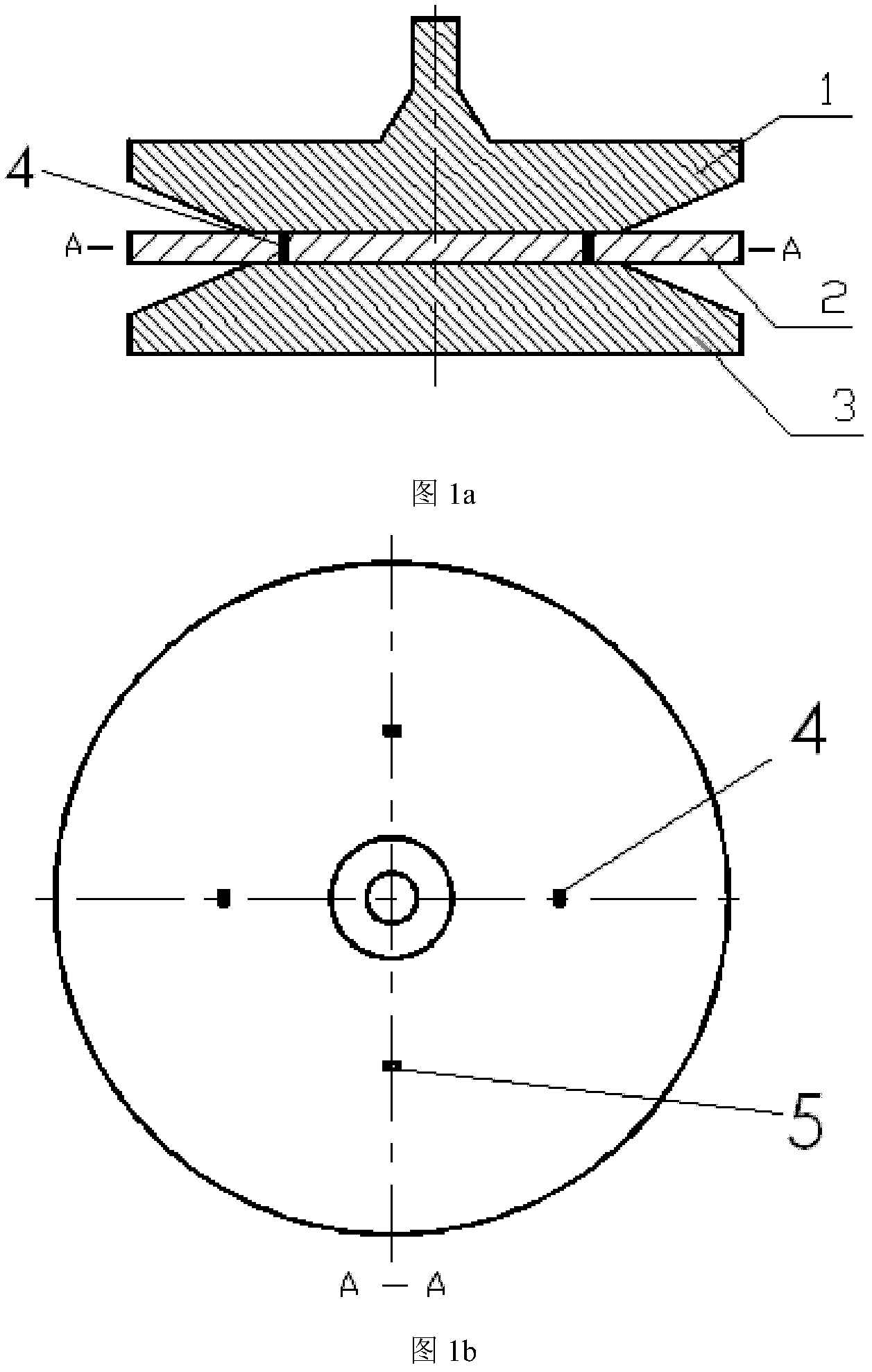

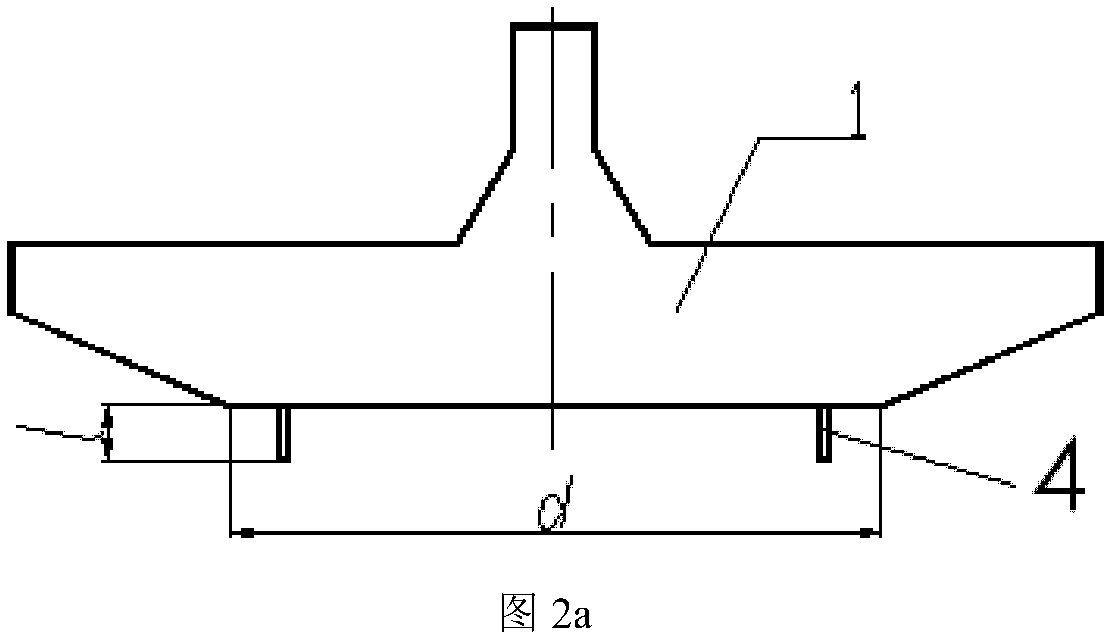

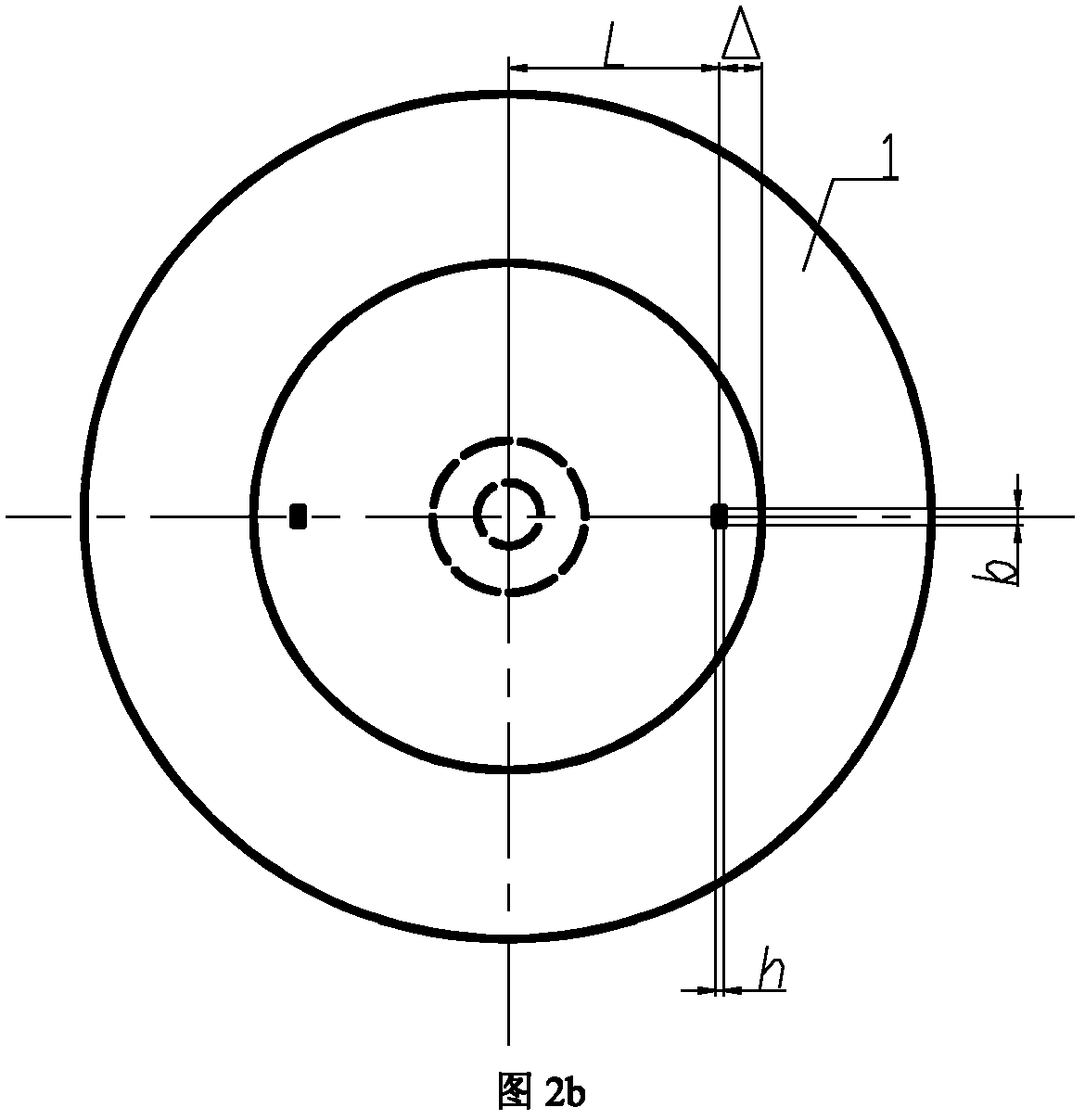

[0042] This embodiment is a fractal spinning die with flat keys for the fractal spinning of integral wheel hubs. The hub fractal spinning die is used to form a wheel hub with a mounting surface diameter of 120 mm. In this embodiment, a circular LF21M aluminum alloy is used as the blank material, and the diameter of the blank is 200 mm, and the thickness of the blank is t 0 = 10mm; Since the diameter of the mounting surface of the formed hub is 120mm, the diameter d of the small end of the driving mandrel and the driven mandrel is both 120mm.

[0043] This embodiment includes a driving mandrel 1 and a driven mandrel 3 . The active mandrel 1 is a revolving body with an inverted trapezoidal longitudinal section, and the peripheral surface of the active mandrel 1 is the forming surface of the hub. In the center of the large end face of the active mandrel 1 there is a connecting rod fixedly connected to the spindle of the machine tool, and a pair of active mandrel flat keys 4 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com