Method of stabilizing activity of monomer isocyanate

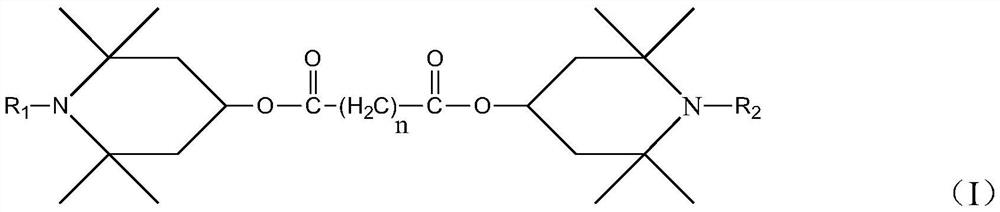

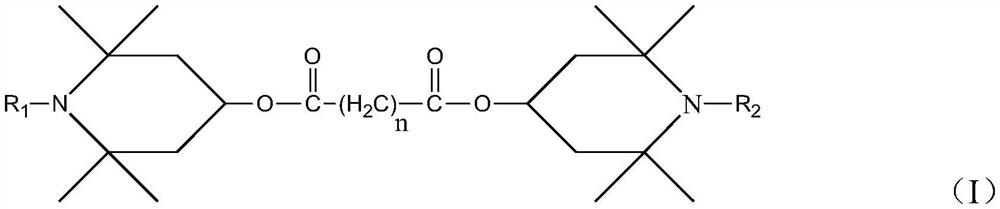

An isocyanate and diisocyanate technology is applied in the field of stabilizing the reactivity of monomeric isocyanates, which can solve the problems of uncontrollable molecular structure of polyurethane products, increased process adjustment complexity, and inability to reduce content, and achieves effective stabilization of activity, convenient and reliable preparation, and reaction. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a) Component hindered amine selection (Switzerland Ciba, Tinuvin 770), compounded with epoxidized soybean oil (Longda oil, Z-10L) to obtain additive I, wherein the mass fractions of hindered amine and epoxidized soybean oil are 10% and 90% respectively. Select the monomeric isocyanate B with an acid value of 20ppm, add the above-mentioned additive I at a mass fraction of the monomeric isocyanate of 0.01%, and obtain a monomeric isocyanate sample B' with stable activity, and test the activity of B and B' according to the above-mentioned standard sample activity test method . The results are shown in the table below.

[0036] Numbering monomeric isocyanate thermometer reading 1 Sample A 53.5℃ 2 Sample B 47.6℃ 3 Sample B' 53.1℃

[0037] It can be seen that Additive I can stabilize the activity of monomeric isocyanate with an acid value of 20 ppm to the level of monomeric isocyanate with an acid value of 1 ppm.

Embodiment 2

[0039] a) Component hindered amine selection (Shanxi Research Institute of Chemical Industry, GW 508), compounded with epoxidized soybean oil (Yancheng Shuanghong Chemical, ESO) to obtain Additive II, wherein the mass fractions of hindered amine and epoxidized soybean oil are 50% and 50%, respectively. Select the monomeric isocyanate C with an acid value of 12ppm, add the above-mentioned additive II according to the mass fraction of the monomeric isocyanate at 1%, and obtain the monomeric isocyanate sample C' with stable activity, and test the activity of C and C' according to the above-mentioned standard sample activity test method . The results are shown in the table below.

[0040] Numbering monomeric isocyanate thermometer reading 1 Sample A 53.5℃ 2 Sample C 48.3℃ 3 Sample C' 53.3℃

[0041] It can be seen that Additive II can stabilize the activity of the monomeric isocyanate with an acid value of 12 ppm to the level of a monomeric ...

Embodiment 3

[0043] a) Component hindered amine selection (Switzerland Ciba, Tinuvin 123), compounded with epoxidized soybean oil (Aladdin's reagent) to obtain additive III, wherein the mass fractions of hindered amine and epoxidized soybean oil are 20% and 80% respectively. Select the monomeric isocyanate D with an acid value of 16ppm, add the above-mentioned additive III according to the mass fraction of the monomeric isocyanate at 0.5%, to obtain a monomeric isocyanate sample D' with stable activity, and test the activity of D and D' according to the above-mentioned standard sample activity test method . The results are shown in the table below.

[0044] Numbering monomeric isocyanate thermometer reading 1 Sample A 53.5℃ 2 Sample D 47.9℃ 3 Sample D' 53.6℃

[0045] It can be seen that Additive III can stabilize the activity of the monomeric isocyanate with an acid value of 16 ppm to the level of a monomeric isocyanate with an acid value of 1 ppm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com