Cotton carding transfer suction

A suction port and carding technology, which is applied in the deburring device, textile and papermaking, fiber treatment, etc., can solve the problems of low transfer rate between cylinder and doffer, backlog of cylinder cotton layer, uneven doffer cotton layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

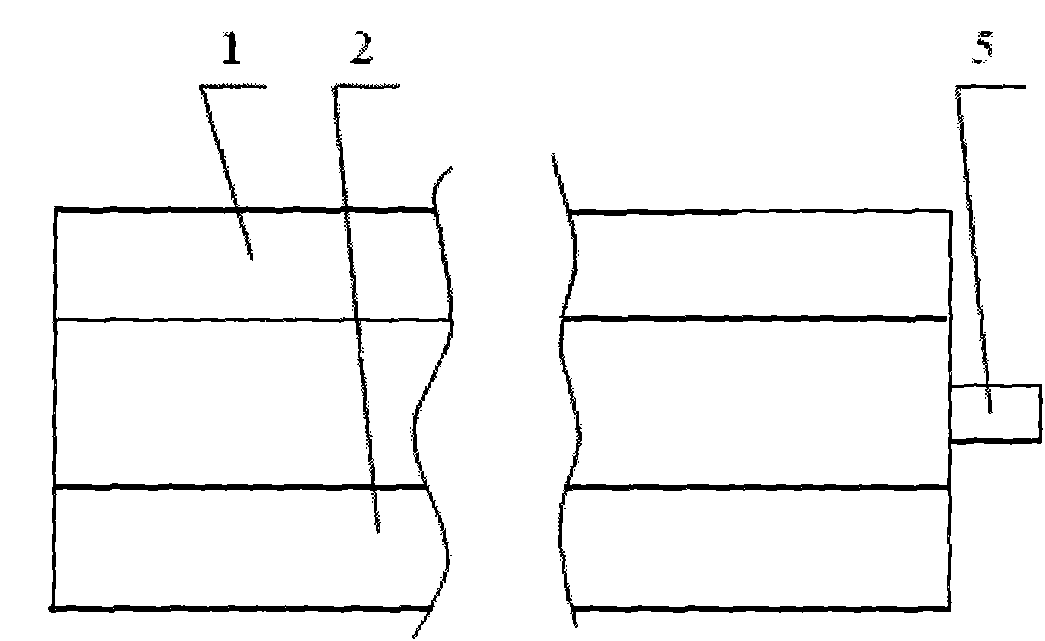

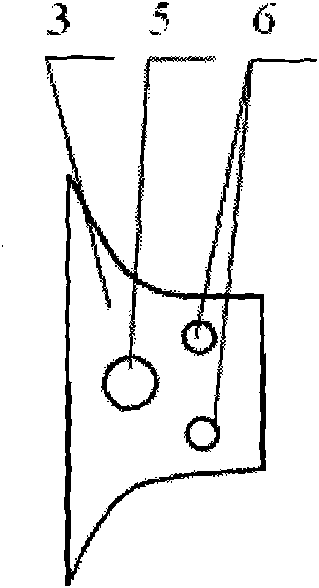

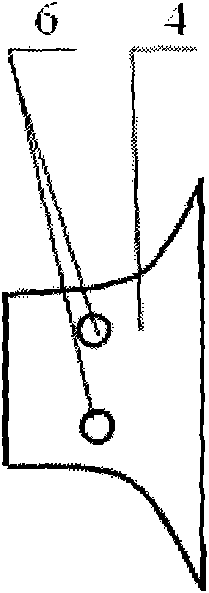

[0017] Such as figure 1 , figure 2 and image 3 As shown, a carding transfer suction port 9, the strip-shaped suction port upper wall 1 is located at the top, the suction port lower wall 2 with the same structure is located at the bottom, and there is a gap in the middle, the upper surface of the suction port upper wall 1 and the bottom of the suction port lower wall 2 The surface is composed of curved board walls with the same width of the carding machine. The suction port R side plate 3 is installed on the right side of the suction port upper wall 1 and the suction port lower wall 2, and the position of the suction port R side plate 3 corresponding to the middle gap is arranged with an air intake duct 5 , Offer fixed hole 6 simultaneously; Suction port upper wall 1 and the left side device suction port L side plate 2 of suction port lower wall 2, offer fixed hole 6 on the suction port L side plate 4.

[0018] Such as Figure 4 As shown, the above-mentioned carding transf...

Embodiment 2

[0020] According to the carding transfer suction port 9 of embodiment 1, the air intake duct 5 is arranged at the suction port L side plate 4, to strengthen the negative pressure of the transfer suction port 9 small mouths, increase the transfer rate between the cylinder and the doffer. Other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com