Fractal spinning mold with crossed key and method for determining crossed key

A certain method, cross-shaped technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of workpiece sliding, eccentricity, jamming, and affecting the normal spinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

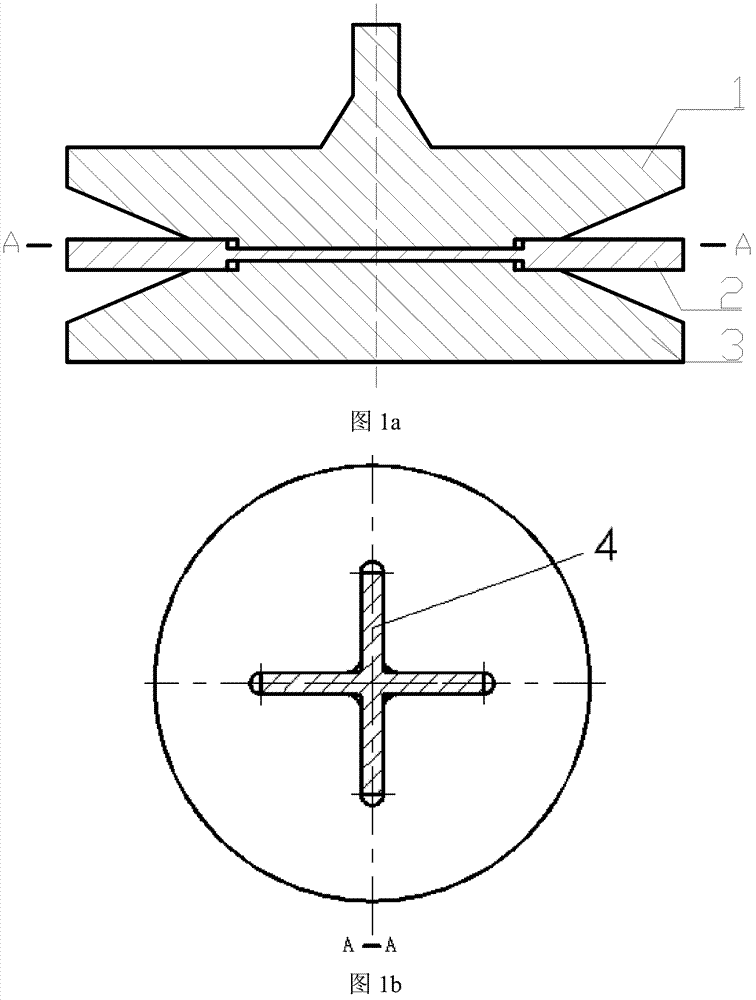

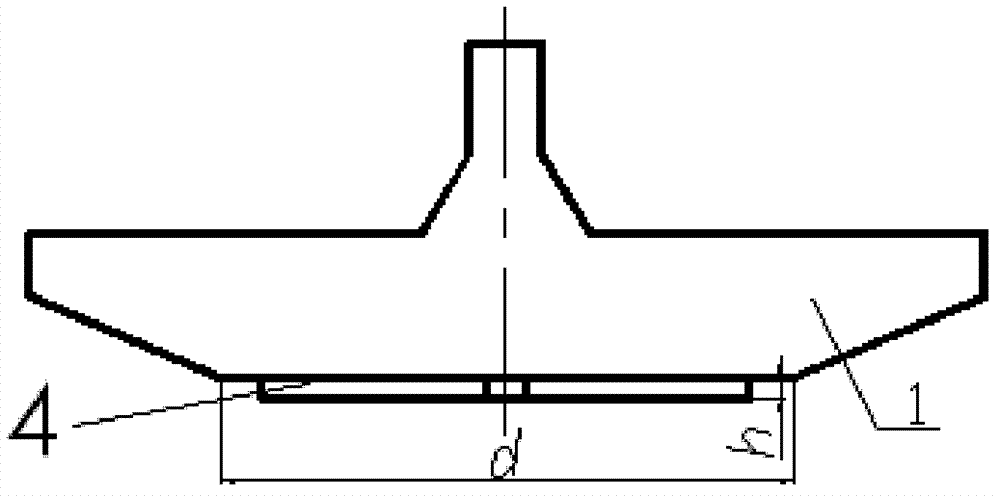

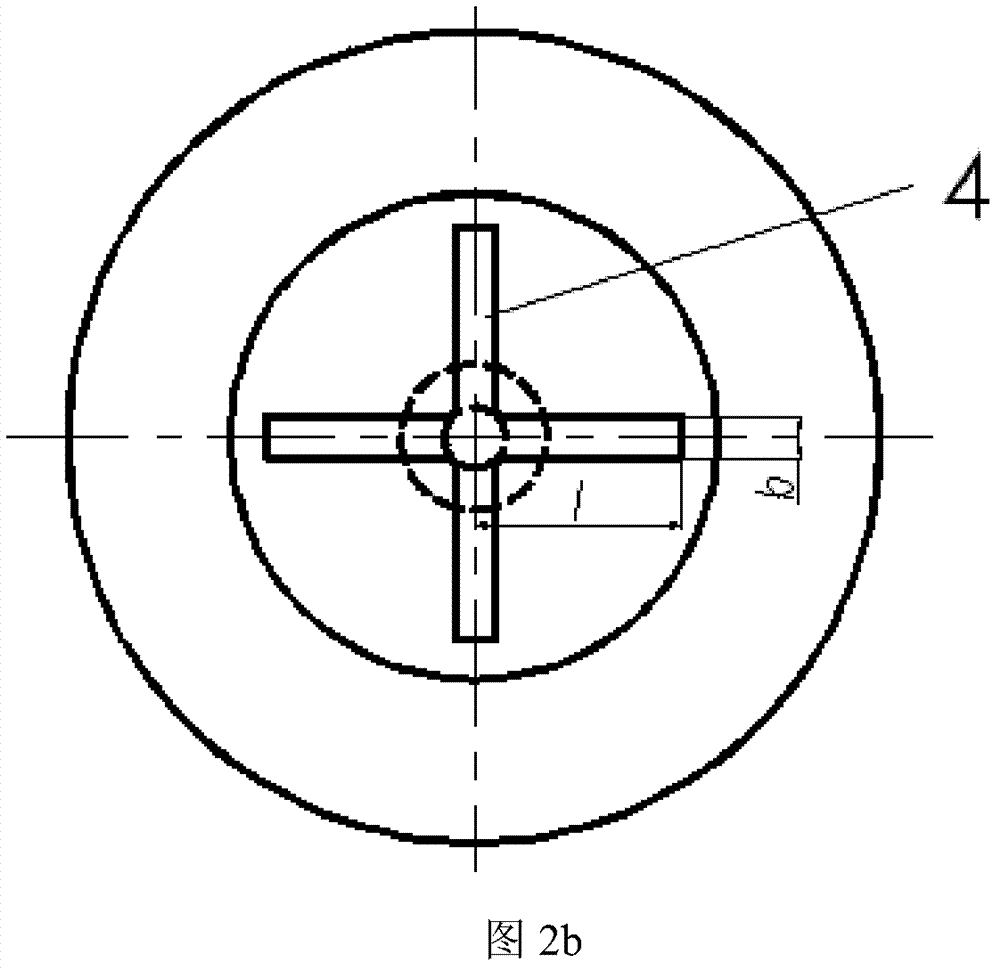

[0042] This embodiment is a fractal spinning die with cross-shaped keys used for fractal spinning of integral hubs. The hub fractal spinning die is used to form a hub with a mounting surface diameter of 120mm. In this embodiment, a circular LF21M aluminum alloy is used as the blank material, and the diameter of the blank is 200 mm, and the thickness of the blank is t 0 =10mm; Since the diameter of the mounting surface of the formed hub is 120mm, the diameter d of the small end of the active mandrel and the driven mandrel is both 120mm.

[0043]This embodiment includes a driving mandrel 1 and a driven mandrel 3 . The active mandrel 1 is a revolving body with an inverted trapezoidal longitudinal section, and the peripheral surface of the active mandrel 1 is the forming surface of the hub. In the center of the large end face of the active mandrel 1 there is a connecting rod fixedly connected to the machine tool spindle, and in the center of the small end face of the active mand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com