Polyacrylonitrile dry powder suitable for dry acrylic fiber spinning, and preparation method thereof

A technology of polyacrylonitrile dry powder and dry-process acrylic fiber, which is applied in textiles and papermaking, single-component synthetic polymer rayon, fiber chemical characteristics, etc. Solve problems such as poor color of silk stock solution, and achieve the effect of smooth spinning process, moderate molecular weight and distribution, and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

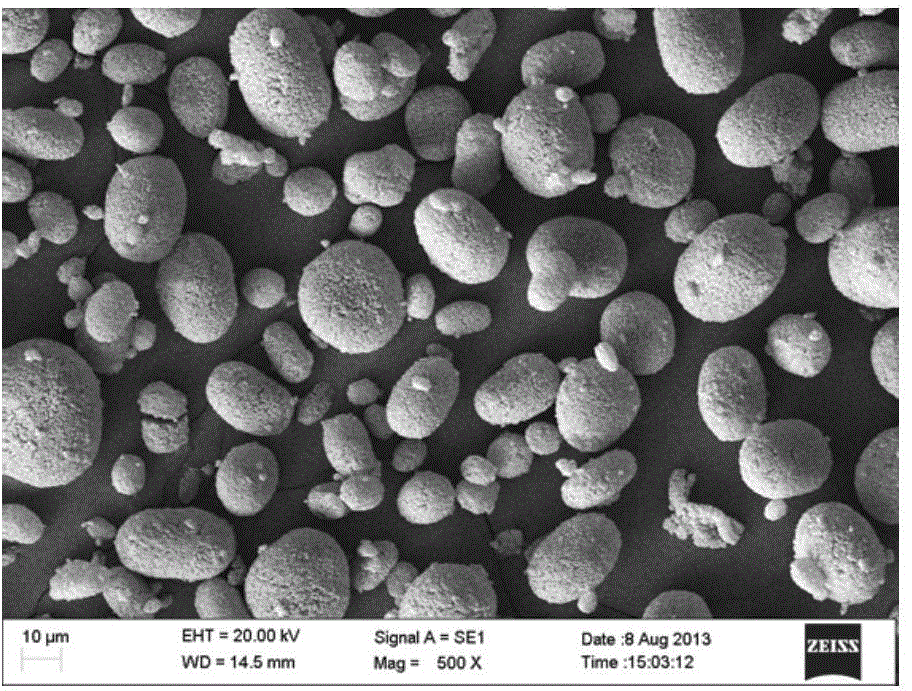

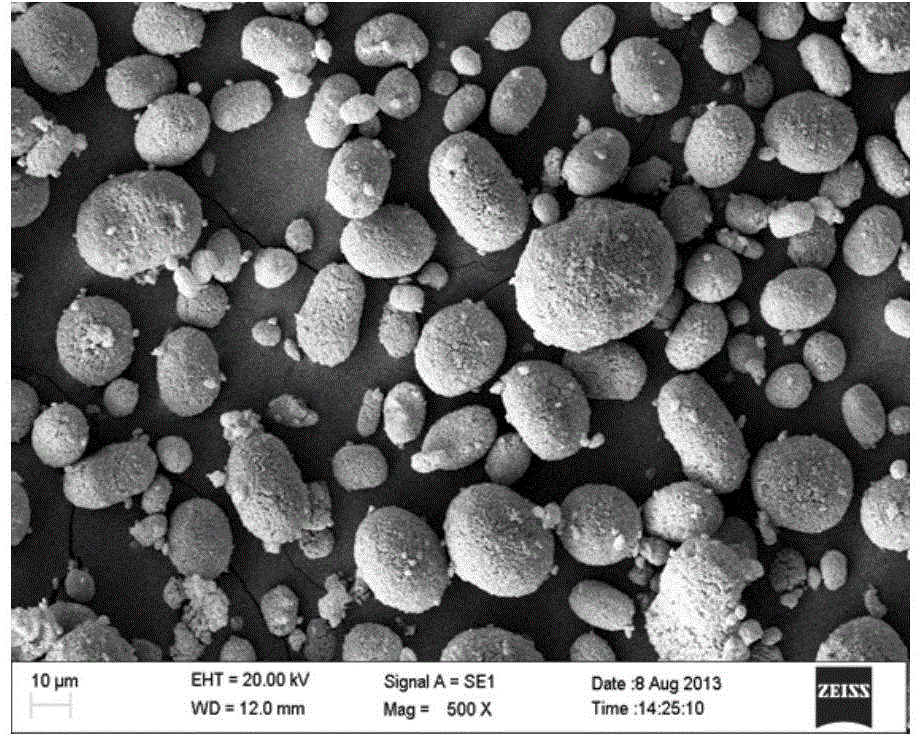

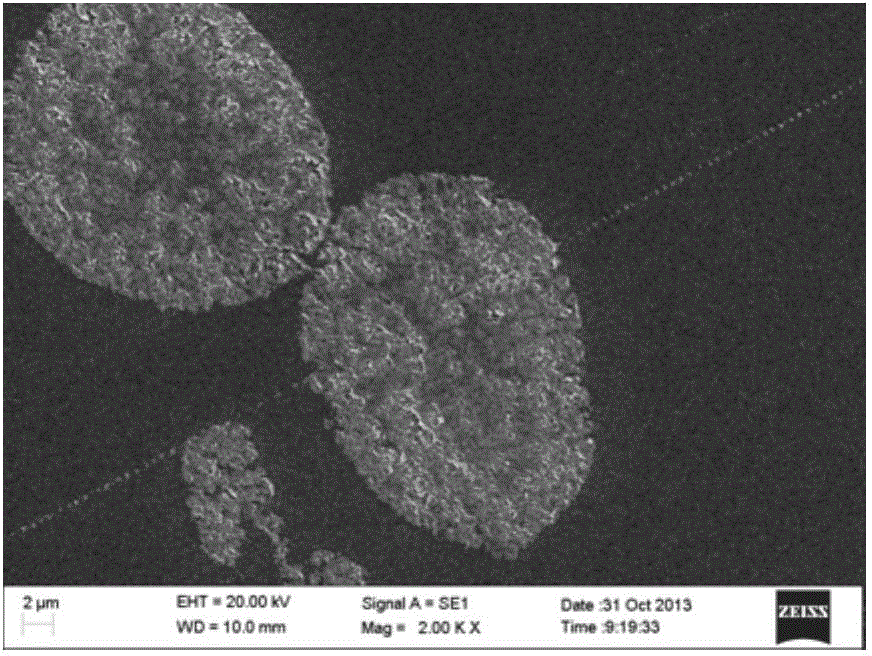

Image

Examples

Embodiment 1

[0031] (1) Acrylonitrile=92 in parts by weight, methyl acrylate=6.7, sodium styrene sulfonate=1.2,2-acrylamido-2-methylpropanesulfonic acid=0.1 ratio, comonomer acrylonitrile , methyl acrylate, sodium styrene sulfonate and 2-acrylamido-2-methylpropanesulfonic acid are added to the polymerization kettle, and at the same time, the amount of initiator potassium persulfate, sodium bisulfite, and ferrous sulfate required for the reaction are added Add ammonium, quantitative desalted water, and sulfur dioxide together into the polymerization kettle, control the polymerization temperature to 60°C, and the pH value of the polymerization reaction system to be 3.0 to carry out the polymerization reaction;

[0032] (2) After the polymerization reaction, EDTA is added to terminate the reaction. After the materials obtained from the polymerization are filtered, washed and dried, the polymer with a water content of about 54% is reduced to 0.3% to obtain polyacrylonitrile resin, which is then...

Embodiment 2

[0038] According to the dry polyacrylonitrile powder prepared by the method of Example 1, the difference is that the parts by weight of its comonomers are: acrylonitrile=92, methyl acrylate=4.0, sodium styrene sulfonate=4.0, 2-acrylamide -2-Methylpropanesulfonic acid=2.0, see Table 1 for specific relevant technical indicators. The sliced SEM pictures of the particles are shown in Figure 5 .

Embodiment 3

[0040] The polyacrylonitrile dry powder prepared according to the method of Example 1 differs in that the pH value of the polymerization system is 2.5, and specific relevant technical indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com