Coarse denier and raw yarn reeling machine

A silk reeling machine and raw silk technology, which is applied in the field of silk reeling machine design, can solve the problems of low efficiency and unachievable operation of coarse denier silk, and achieve the effect of beautiful appearance, clear principle and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

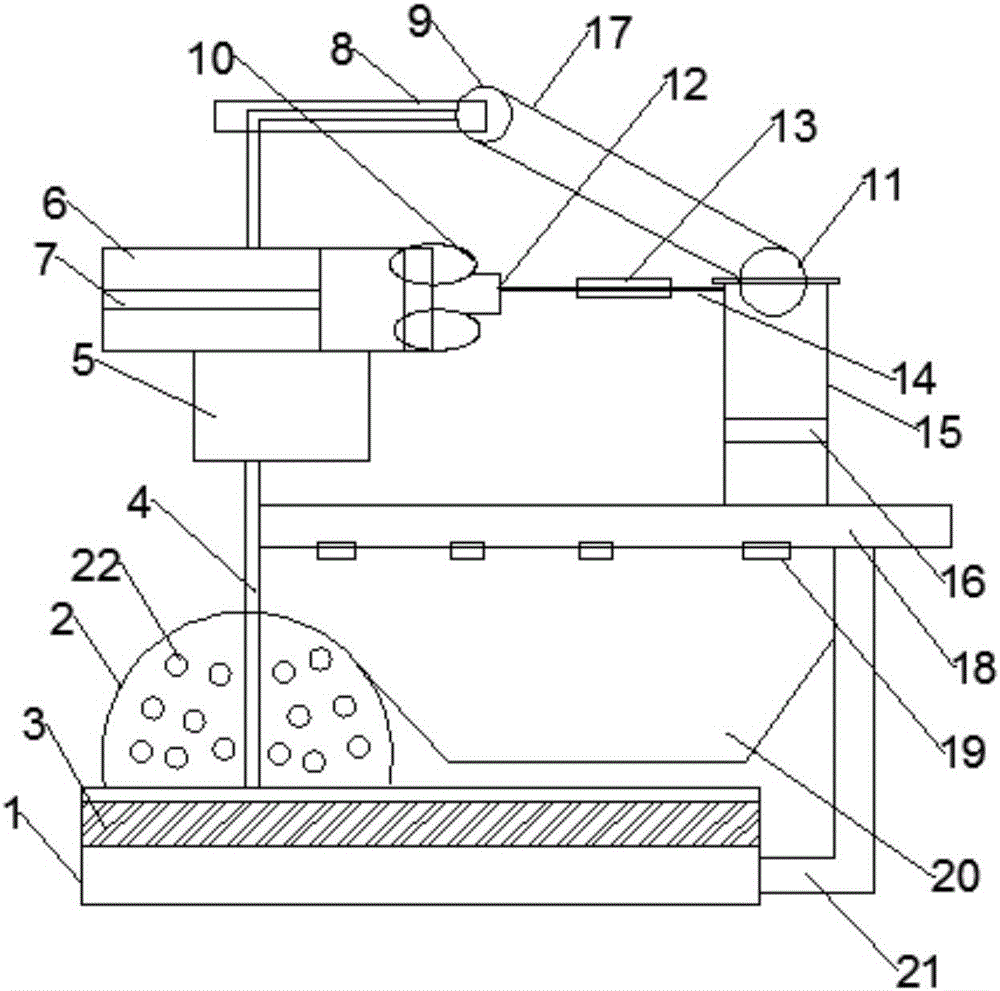

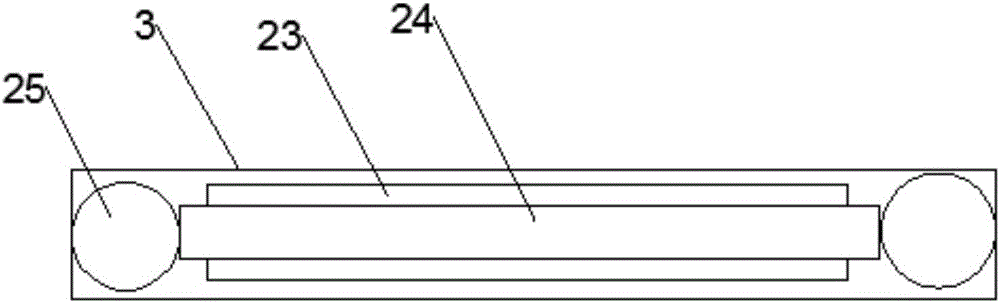

[0016] see figure 1 and figure 2 , the present invention provides a technical solution: a coarse denier raw silk reeling machine, comprising a connecting rod 21 and a rotating rod 4, the two ends of the connecting rod 21 are respectively connected with a processing tank 1 and a transmission belt 18, and a roller is arranged in the processing tank 1 3. The spinning shaft 24 is installed inside the drum 3, which can be used for spinning processing. Heaters 23 are fixed on both sides of the spinning shaft 24, and the spinning process is smoother. An anti-winding device 2 is connected above the processing tank 1 to prevent knotting , the bottom end of the rotating rod 4 is connected with the processing tank 1, and the rotating rod 4 is vertically connected with the conveyor belt 18, and the fixing effect is good. The middle position of the rotating rod 4 is provided with a temperature control box 5 and a buffer box 6. To control the temperature, the buffer box 6 is arranged abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com