Method for effectively converting commercial power into heat energy and system thereof and heat transferring medium

A technology of heat exchange medium and heating system, applied in electric heating system, heating system, heating method, etc., to achieve the effect of stable physical and chemical properties, good stability and fast temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The composition of the heat exchange medium is 50% of coke (carbon material), 10% of cobalt oxide, 15% of manganese carbonate, 15% of nickel zinc ferrite, and 10% of titanium diboride.

[0052] The heat exchange medium of embodiment 1 is used in the first kind of system,

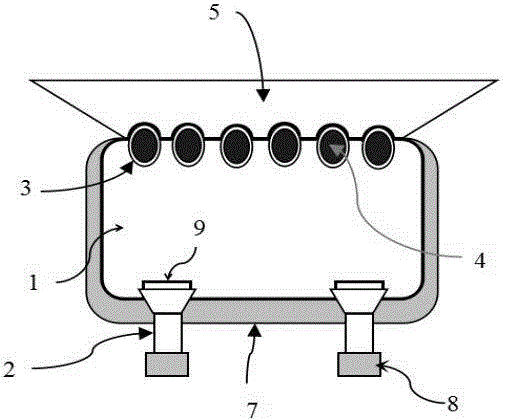

[0053] like figure 1 , connect the microwave source guide heat insulation protection device on the wall of the heat insulation chamber, and the outer end of the microwave source guide heat insulation protection device is connected to the microwave source; add the heat exchange medium into the ceramic tube of the sealed hollow part, and then pump the ceramic tube Vacuum and fill the protective gas nitrogen, seal the ceramic tube and install it in a metal heat-insulating chamber with good high-temperature resistance and thermal conductivity, and make the ceramic tube close to the inner wall of the metal heat-insulating chamber, and connect it to the outer layer of the heat-insulating chamber The mater...

Embodiment 2

[0055] The composition of the heat exchange medium is 70% charcoal, 5% nickel oxide, 5% cobalt sulfate, 5% nickel zinc ferrite, 5% boron nitride, and 10% silicon carbide.

[0056] The heat exchange medium of embodiment 2 is used in the first system,

[0057] like figure 1 , connect the microwave source guide heat insulation protection device on the wall of the heat insulation chamber, and the outer end of the microwave source guide heat insulation protection device is connected to the microwave source; add the heat exchange medium into the cordierite tube of the sealed hollow part, and then put the cordierite Vacuumize the tube and fill it with protective gas nitrogen, seal the cordierite tube and install it in a metal heat-insulating chamber with good high-temperature resistance and thermal conductivity, and make the cordierite tube close to the inner wall of the metal heat-insulating chamber. The outer layer of the chamber is connected to the material container to be heate...

Embodiment 3

[0059] The mass percentage of the heat exchange medium is: graphite powder 45%, nickel oxide 10%, lithium manganate 10%, zinc manganese ferrite 15%, silicon carbide 15%, molybdenum disilicide 5%.

[0060] The heat exchange medium of embodiment 3 is used in the second system,

[0061] like figure 2, the microwave source guide heat insulation protection device is connected to the wall of the heat insulation chamber, and the outer end of the microwave source guide heat insulation protection device is connected to the microwave source; the metal heat insulation chamber is composed of an air inlet suppressor and an air outlet suppressor, and the Add the heat exchange medium into the sealed hollow quartz tube, then vacuumize and seal the quartz tube, put it into the heat-insulating chamber, and arrange the quartz tubes evenly in the space of the heat-insulating chamber. Cotton wrapped to prevent heat loss. Turn on the microwave source with a microwave frequency of 5700MHz±50MHz, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com