Digital printing machine for wide Dacron wall cloth

A technology for digital printing machines and wall coverings, applied in printing, typewriters, printing devices, etc., can solve the problems of inability to make bright color patterns, high weight of polyester wide wall coverings, complicated heating process, etc., to improve printing quality, Good preheating effect and good rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

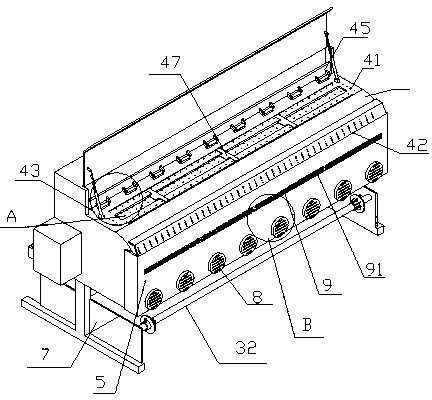

[0031] Example 1, such as figure 1Shown: a digital printing machine for wide-width polyester wall coverings, including a printing device with a frame on the frame, a transmission device and a heating device on the frame. The stretching reel and rewinding reel 32 that are located on the frame, the stretching reel is also provided with depression bar by the rear of conveying direction, and depression bar is lower than the stretching reel in vertical direction, and the position below the depression bar is provided with sensing device. The unwinding drum and the rewinding drum 32 are each provided with a rotating fixing device, and the rotating fixing device includes a fixing part fixed with the unwinding drum or the rewinding drum 32, a blocking part for blocking the two sides of the cloth and inserting the cloth material drum The insertion part in the center is surrounded by a plurality of insertion pieces that gradually converge toward the center in the direction away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com