Method for preparing PBT/PET 3-D crimped fiber and use thereof

A three-dimensional crimping and fiber technology, applied in fiber processing, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve the limitation of PBT fiber use, strong temperature dependence of PBT fiber strength, PBT fiber Problems such as low heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] PBT / PET three-dimensional crimped fiber

[0027] Raw material specifications Intrinsic viscosity [η] of PBT chips: 1.00dl / g, PET intrinsic viscosity [η]: 0.64dl / g.

[0028] The composite ratio of PBT / PET three-dimensional crimped fiber is 50:50, and the fiber fineness is 11.11dtex.

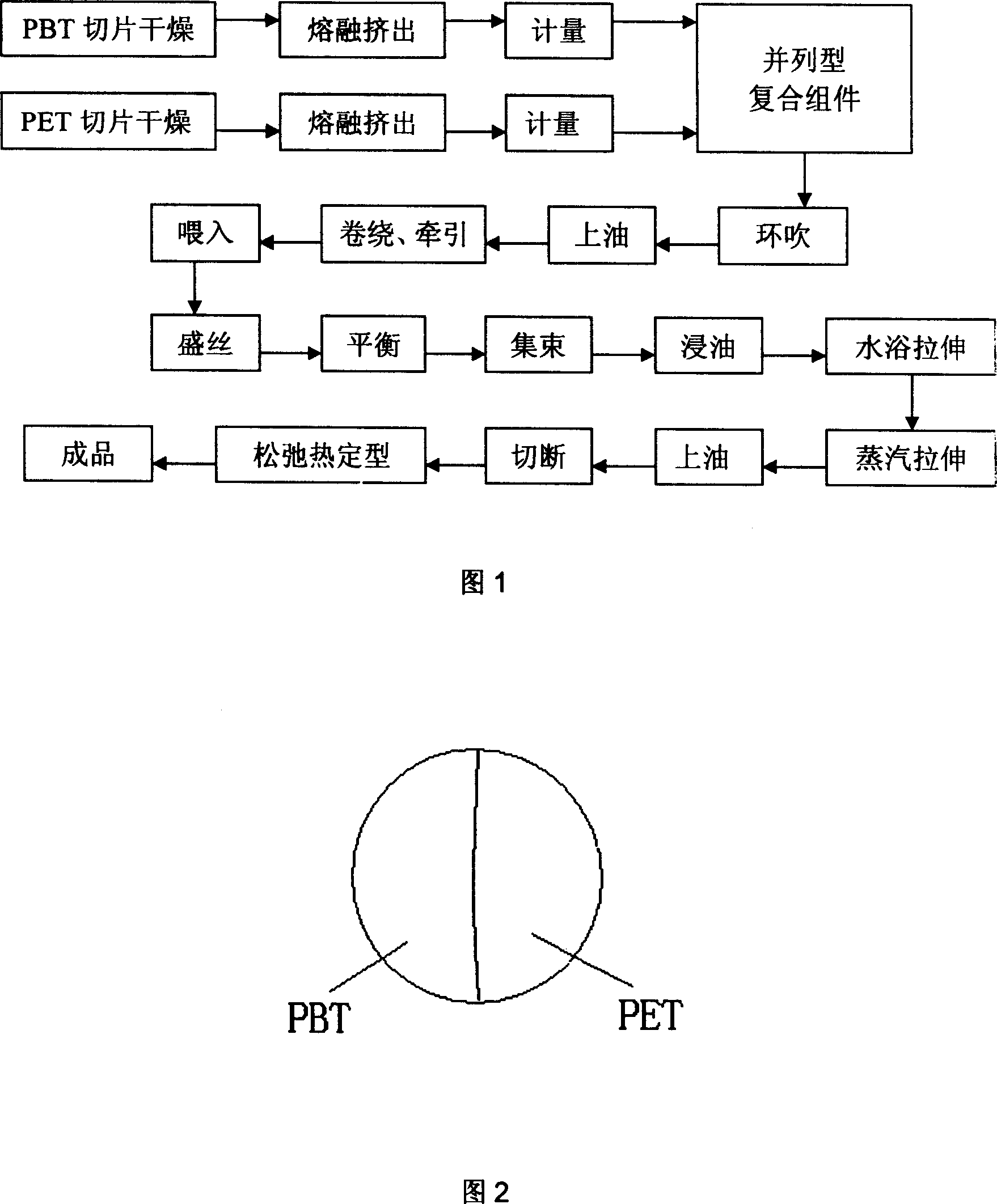

[0029] Adopt the production process route of accompanying drawing 1:

[0030] PBT slices are dried, melted at low temperature and extruded at high temperature by the screw, metered and then enter the side-by-side composite component for parallel compounding and distribution, and compound side by side with PET at the composite spinneret; PET chips are dried and extruded through the screw at high temperature and low temperature , After metering, it enters the side-by-side composite component, performs parallel compound distribution, and is compounded side by side with PBT at the composite spinneret; the side-by-side composite fiber coming out of the spinneret is subjected to ring blowing, oi...

Embodiment 2

[0043] PBT / PET three-dimensional crimped fiber

[0044] Raw material specifications Intrinsic viscosity [η] of PBT chips: 1.00dl / g, PET intrinsic viscosity [η]: 0.64dl / g. The composite ratio of PBT / PET three-dimensional crimped fiber is 40:60, and the fiber fineness is 8.88dtex.

[0045] Adopt the production process road of accompanying drawing 1:

[0046] PBT slices are dried, melted at low temperature and extruded at high temperature by the screw, metered and then enter the side-by-side composite component for parallel compounding and distribution, and compound side by side with PET at the composite spinneret; PET chips are dried and extruded through the screw at high temperature and low temperature , After metering, it enters the side-by-side composite component, performs parallel compound distribution, and is compounded side by side with PBT at the composite spinneret; the side-by-side composite fiber coming out of the spinneret is subjected to ring blowing, oiling, windi...

Embodiment 3

[0058] PBT / PET three-dimensional crimped fiber

[0059] Raw material specifications Intrinsic viscosity [η] of PBT chips: 1.00dl / g, PET intrinsic viscosity [η]: 0.64dl / g.

[0060] The composite ratio of PBT / PET three-dimensional crimped fiber is 30:70, and the fiber fineness is 12.10dtex.

[0061] Adopt the production process route of accompanying drawing 1:

[0062] PBT slices are dried, melted at low temperature and extruded at high temperature by the screw, metered and then enter the side-by-side composite component for parallel compounding and distribution, and compound side by side with PET at the composite spinneret; PET chips are dried and extruded through the screw at high temperature and low temperature , After metering, it enters the side-by-side composite component, performs parallel compound distribution, and is compounded side by side with PBT at the composite spinneret; the side-by-side composite fiber coming out of the spinneret is subjected to ring blowing, oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com