Hard coating film and flexible display having the same

A technology of hard coating film and hard coating, which is applied to devices, coatings, instruments and other directions for coating liquid on the surface, which can solve the problem of lack of flexibility of flexible displays, and achieve excellent bending resistance, excellent impact resistance and curling resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0068] Preparation Example 1: Preparation of the first hard coating composition

[0069] Using a stirrer, 60 wt% of urethane acrylate oligomer (elongation: 70%, UF-8001G from Kyoeisha Chemical Co., Ltd.), 37 wt% of methyl ethyl ketone, 2.5 wt% of Photoinitiator (1-hydroxycyclohexyl phenyl ketone) and 0.5wt% leveling agent (BYK-3570 from BYK Chemical Company) were mixed, and then filtered with a polypropylene (PP) filter to prepare First hardcoat composition.

preparation example 2

[0070] Preparation Example 2: Preparation of the second hard coating composition

[0071] Using a stirrer, 37 wt% of methyl ethyl ketone, 30 wt% of methyl ethyl ketone silica sol (MEK-AC-2140Z from Nissan Chemical Industry, particle size: 10 to 15 nm), 30 wt% of urethane acrylic acid Ester oligomer (elongation: 17%, CN989NS from Sartomer Company), 2.5wt% photoinitiator (1-hydroxycyclohexyl phenyl ketone) and 0.5wt% leveling agent (from Bi BYK-3570 from Ke Chemical Company) and then filtered through a polypropylene (PP) filter to prepare a hard coating composition.

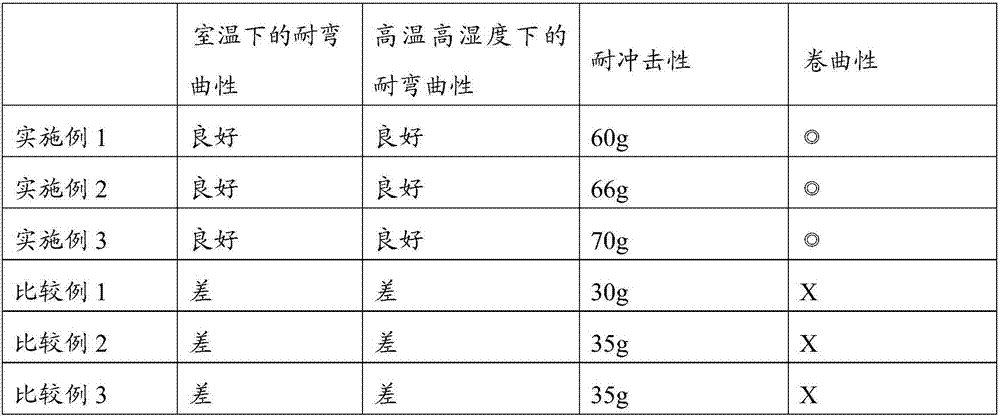

Embodiment 1 to 3 and comparative example 1 to 4

[0072] Embodiment 1 to 3 and comparative example 1 to 4: the preparation of hard coating film

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com