Production method of double-component spinneret outside composite parallel self-crimping elastic short fiber

A production method and composite fiber technology, applied in fiber processing, filament/thread forming, stretch spinning, etc., can solve the problems of easy generation of static electricity, single use, poor hand feeling, etc., and achieve permanent three-dimensional crimping and excellent crimping performance. , good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

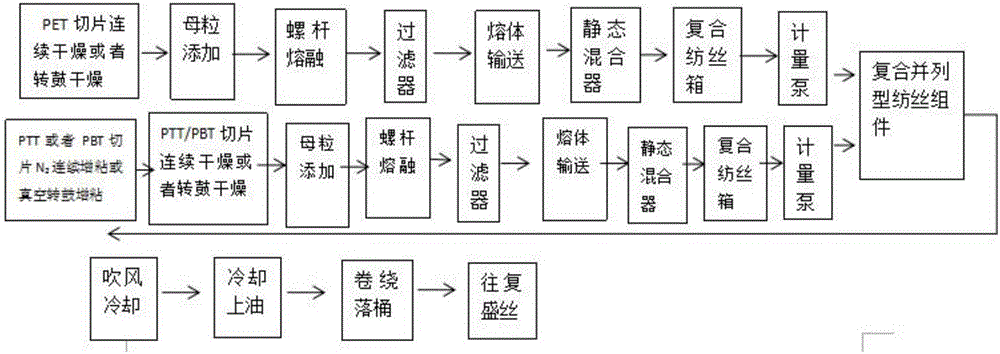

[0041] A method for producing two-component spinneret composite side-by-side self-crimping elastic short fibers, using PET with an intrinsic viscosity of 0.448dl / g as fiber component A, and PTT with an intrinsic viscosity of 0.93dl / g as fiber component B , the mass ratio of the fiber component A to the fiber component B is 50:50, specifically comprising the steps of:

[0042] (1) Dry the slices of fiber component A at 150°C for 8 hours, and then melt and extrude at 270°C to obtain a melt. After filtering through a filter, the filtered melt is passed through a static mixer and then transported to the composite After the spinning box is metered by the metering pump, it is sent into the parallel compound component for parallel compound distribution;

[0043] At the same time, the 0.93dl / L chips of fiber component B were first viscosified at 180°C for 45 hours to obtain viscosified chips with a viscosity of 1.35dl / L, dried at 140°C for 4 hours during fiber production, and then mel...

Embodiment 2

[0052] A method for producing two-component spinneret composite side-by-side self-crimping elastic short fibers, using PET with an intrinsic viscosity of 0.52dl / g as fiber component A, and PBT with an intrinsic viscosity of 0.78dl / g as fiber component B , the mass ratio of the fiber component A to the fiber component B is 50:50, specifically comprising the steps of:

[0053] (1) Dry the slices of fiber component A at 130°C for 12 hours, and then melt and extrude at 280°C to obtain a melt. After filtering through a filter, the filtered melt is conveyed to the composite After the spinning box is metered by the metering pump, it is sent into the parallel compound component for parallel compound distribution;

[0054] At the same time, the slices of fiber component B were first viscosified at 210°C for 25 hours to obtain 1.51dl / g viscosified slices, then dried at 140°C for 3 hours, and then melted and extruded at 280°C to obtain a melt, which was filtered through a filter Finally...

Embodiment 3

[0064] A method for producing two-component spinneret composite side-by-side self-crimping elastic short fibers, using PET with an intrinsic viscosity of 0.55dl / g as fiber component A, and HSPBT with an intrinsic viscosity of 0.78dl / g as fiber component B , the mass ratio of the fiber component A to the fiber component B is 50:50, specifically comprising the steps of:

[0065] (1) Dry the slices of fiber component A at 150°C for 8 hours, and then melt and extrude at 280°C to obtain a melt. After filtering through a filter, transfer the filtered melt to a composite After the spinning box is metered by the metering pump, it is sent into the parallel compound component for parallel compound distribution;

[0066] At the same time, the chips of fiber component B were dried at 135°C for 12 hours, and then melted and extruded at 290°C to obtain a melt. After filtering through a filter, the filtered melt was sent to a composite spinning box through a static mixer After being metered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com