Rotary printed circuit board (PCB) surface automatic processing apparatus

A PCB board and automatic processing technology, which is applied in the direction of circuit liquid processing, electrical components, printed circuit manufacturing, etc., can solve the problem of large footprint of the linear PCB board surface processing line, to improve the surface processing effect and high degree of automation , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

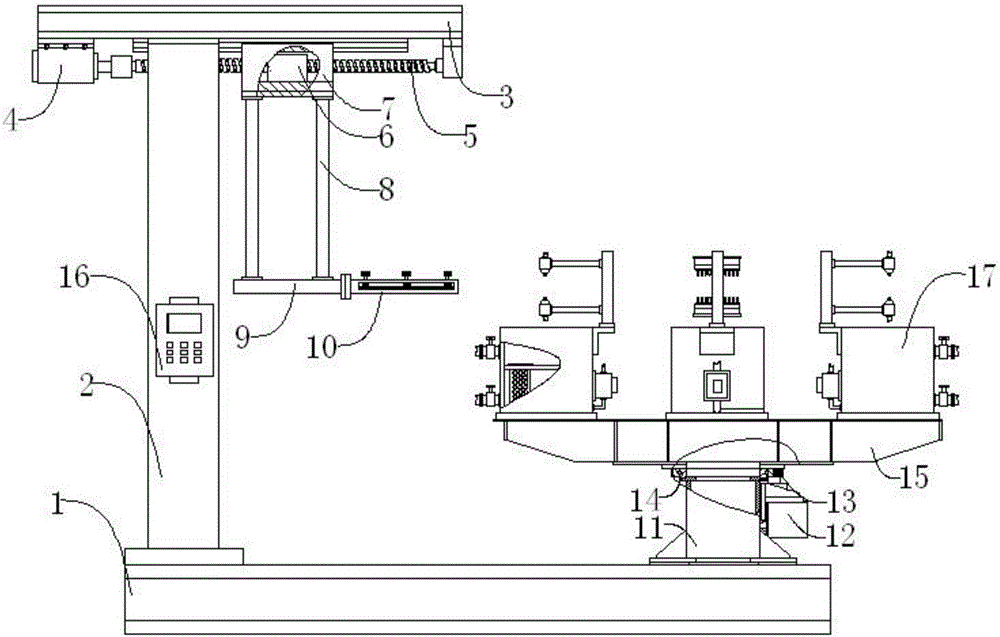

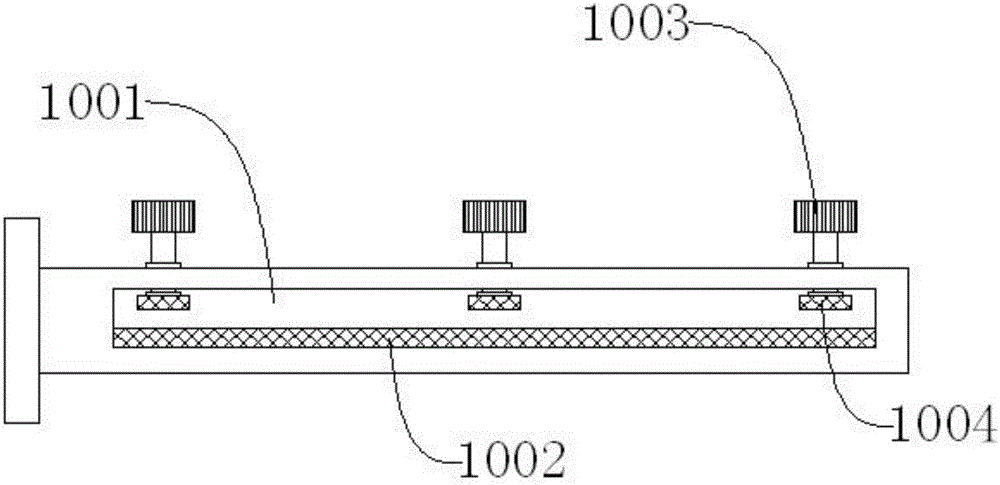

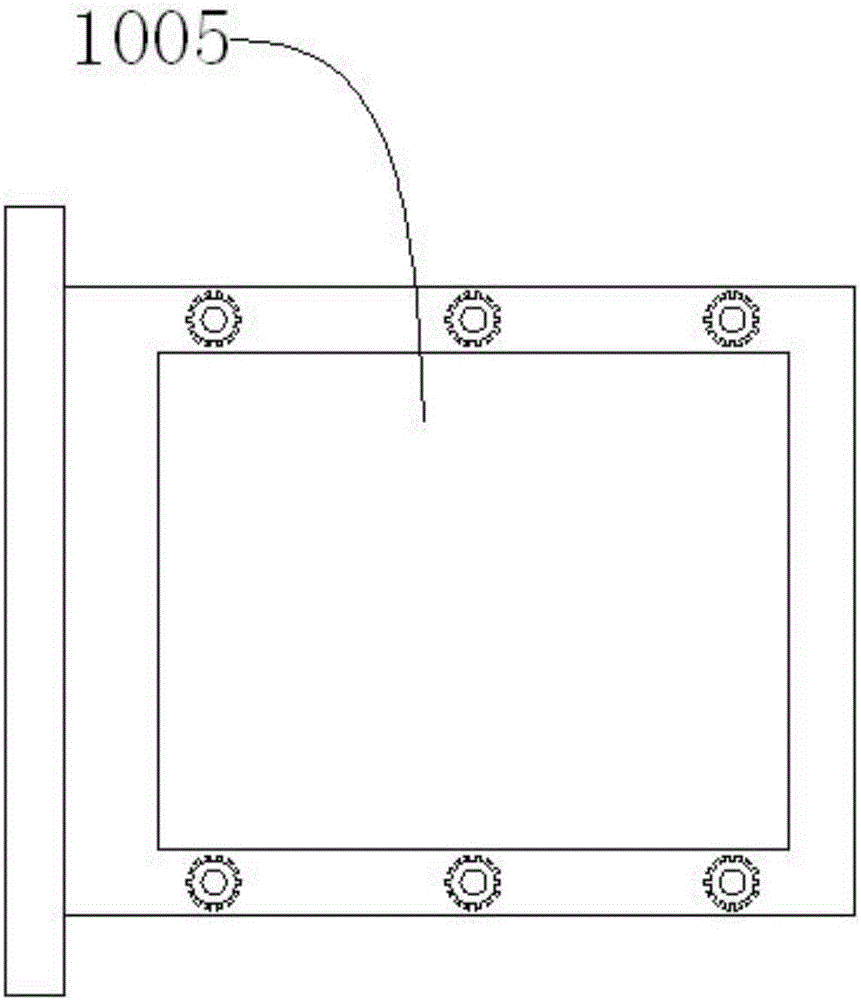

[0035] like figure 1 , figure 2 , image 3 , Figure 4As shown, a rotary PCB surface automatic processing device includes a base 1, two columns 2 arranged parallel to the base, a top frame 3, a first servo motor 4, a lead screw 5, a feed nut 6, and a sliding seat 7 , Two support rods 8, supporting plate 9, clamping frame 10, support seat 11, second servo motor 12, gear 13, slewing bearing 14, workbench 15, controller 16, the number of which are symmetrically arranged along the sliding seat There are less than 2 sets of surface treatment mechanisms 17, the column 2 is located on the left side of the upper end of the base 1, the column 2 is screwed to the base 1, the top frame 3 is located at the upper end of the column 2, and the top frame 3 It is threadedly connected with the column 2, the first servo motor 4 is located at the lower end of the top frame 3, the first servo motor 4 is threaded with the top frame 3, and the lead screw 5 is located on the left side of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com