A method for improving corrosion resistance and fatigue resistance of aluminum alloys

An aluminum alloy and anti-fatigue technology, which is applied to the improvement of process efficiency, coating, surface reaction electrolytic coating, etc., can solve the problems of weakening the effect of shot peening on the fatigue performance of aluminum alloy, so as to improve the quality and performance of equipment , improve the overall performance, improve the effect of surface treatment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

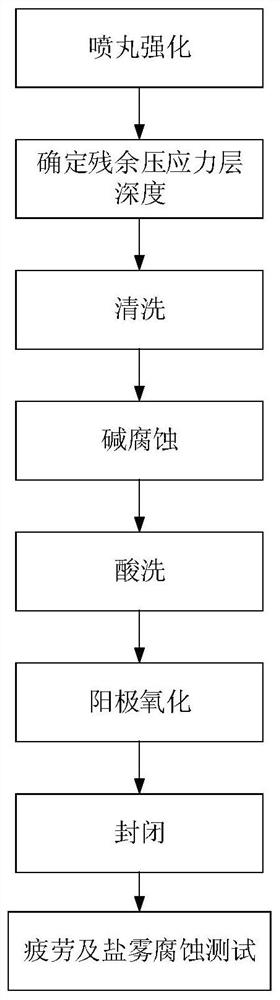

[0032] Please refer to figure 1 As shown, Example 1 provides a method for improving the corrosion resistance and fatigue resistance of aluminum alloys. The 7150 aluminum alloy is subjected to shot peening treatment with a shot peening strength value of 0.143 mmN, and the residual stress is carried out by the small hole method after shot peening For the distribution test, the depth of the compressive stress layer is 100 μm. The preparation method includes at least the following steps (1) to (7):

[0033] (1) Shot peening, the surface of 7150 aluminum alloy is subjected to shot peening treatment with a shot peening strength value of 0.143 mmN, and residual compressive stress is generated on the surface.

[0034] (2) Determine the depth of the residual compressive stress layer. After shot peening, based on the relationship between the shot peening intensity parameter and the depth of the residual compressive stress layer, from the preset shot peening intensity parameter of 0.143...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com