All-water-based rubber treating agent for shoe making industry

A fully water-based, shoe-making technology, applied in the field of leather preparation, can solve the problems of non-compliance, non-environmental protection, flammability and explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

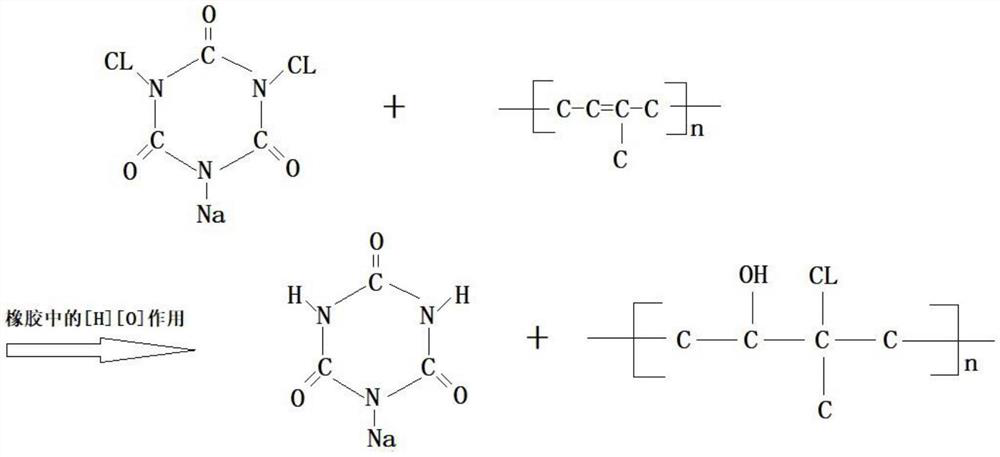

Method used

Image

Examples

Embodiment 1

[0022] The all-water-based rubber treatment agent for the shoe industry, including the following raw materials in weight percentage: 95% deionized water, 0.1‰ of hydrophilic chlorinated rubber resin, 0.1‰ of hydrophilic vinyl resin, and 0.1‰ of modified organic acid , Inorganic acid 0.1‰, silicone surfactant 0.5%, polysiloxane wetting agent 0.5% and indicator 0.1‰;

[0023] The preparation of the all-aqueous rubber treatment agent for footwear industry comprises the following steps:

[0024] Step 1: Weigh deionized water, silicone surfactant and polysiloxane wetting agent by weight percentage, put the deionized water into the stirring tank at normal temperature, and put the silicone surfactant and polysiloxane into the stirring tank in sequence Polysiloxane wetting agent, open the stirring tank, make the stirring tank rotate at a speed of 50rpm / min, stir and disperse for 10-20min, so that the organic silicon surfactant and polysiloxane wetting agent are completely dissolved in...

Embodiment 2

[0028] The all-water-based rubber treatment agent for the shoe industry, including the following raw materials in weight percentage: 97% deionized water, 0.25‰ of hydrophilic chlorinated rubber resin, 0.25‰ of hydrophilic vinyl resin, and 0.25‰ of modified organic acid , Inorganic acid 0.25‰, silicone surfactant 1.25%, polysiloxane wetting agent 1.252% and indicator 0.25‰;

[0029] The preparation of the all-aqueous rubber treatment agent for footwear industry comprises the following steps:

[0030] Step 1: Weigh deionized water, silicone surfactant and polysiloxane wetting agent by weight percentage, put the deionized water into the stirring tank at normal temperature, and put the silicone surfactant and polysiloxane into the stirring tank in sequence Polysiloxane wetting agent, open the stirring tank, make the stirring tank rotate at a speed of 50rpm / min, stir and disperse for 10-20min, so that the organic silicon surfactant and polysiloxane wetting agent are completely diss...

Embodiment 3

[0034] The all-water-based rubber treatment agent for the shoe industry, including the following raw materials in weight percentage: deionized water 99%, hydrophilic chlorinated rubber resin 0.4‰, hydrophilic vinyl resin 0.4‰, modified organic acid 0.4‰ , Inorganic acid 0.4‰, silicone surfactant 2%, polysiloxane wetting agent 2% and indicator 0.4‰;

[0035] The preparation of the all-aqueous rubber treatment agent for footwear industry comprises the following steps:

[0036] Step 1: Weigh deionized water, silicone surfactant and polysiloxane wetting agent by weight percentage, put the deionized water into the stirring tank at normal temperature, and put the silicone surfactant and polysiloxane into the stirring tank in sequence Polysiloxane wetting agent, open the stirring tank, make the stirring tank rotate at a speed of 50rpm / min, stir and disperse for 10-20min, so that the organic silicon surfactant and polysiloxane wetting agent are completely dissolved in deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com