Preparation method of ceramic filled polytetrafluoroethylene microwave composite dielectric substrate

A technology of polytetrafluoroethylene and composite media, applied in the field of copper clad laminates, can solve the problems of low dielectric constant, low thermal expansion coefficient, small dielectric constant temperature coefficient, etc., and achieve good modification effect, small thermal expansion coefficient and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of polytetrafluoroethylene composite microwave ceramic substrate comprises the following steps:

[0030] Step 1: Prefabrication of silica powder. Include the following specific steps:

[0031] Step 1-1: Dry in an oven to remove physically adsorbed water from the silica ceramic powder, and dry at a temperature of 120-150°C for 8-12 hours;

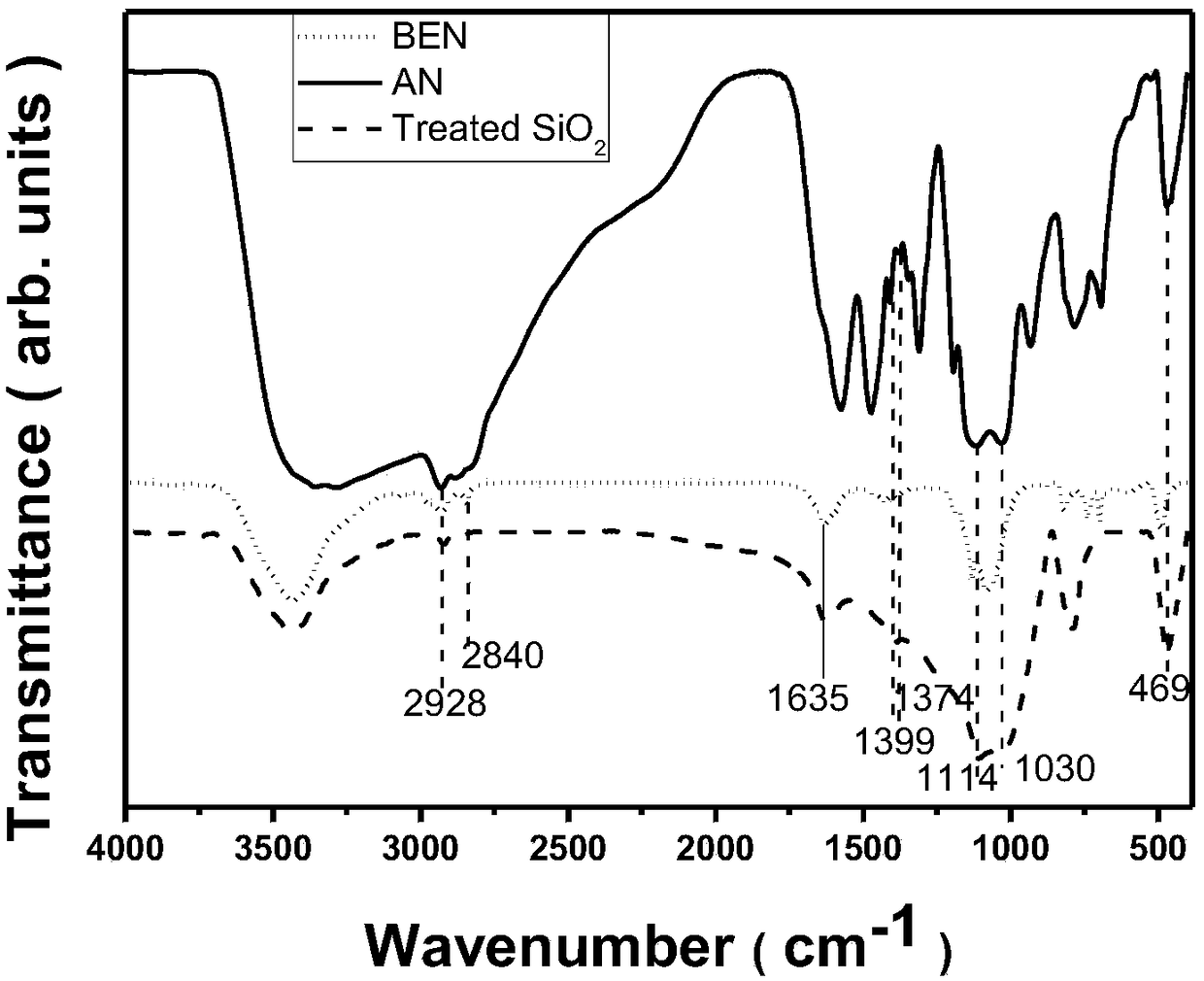

[0032] Step 1-2: Add the raw materials prepared in step 1-1 to the mixture of hydrogen peroxide and concentrated hydrochloric acid (20:80-40:60) by mass ratio, boil at 50-70°C while stirring for 1-2 hours to increase The surface hydroxyl group is convenient to react with the silane coupling agent behind.

[0033] Step 1-3: Suction filter the suspension obtained in Step 1-2, and then dry it under vacuum at 105-120°C for 12-24 hours. ;

[0034] Step 2: Surface treatment of silica powder. Include the following specific steps:

[0035] Step 2-1: Weigh a certain amount of agate balls and add them to the ball mi...

Embodiment approach

[0043] A more specific implementation is as follows:

[0044] The preparation method of the polytetrafluoroethylene-based microwave composite dielectric substrate material of the present invention comprises the following steps:

[0045] a. Prefabricated silica powder: dry the silica in an oven to remove physically adsorbed water, then add the silica to the mixture of hydrogen peroxide and concentrated hydrochloric acid to activate and increase the hydroxyl effect on the surface of the silica, and suction filter , then dry.

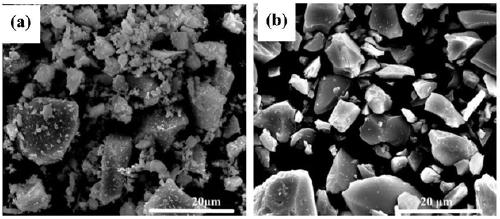

[0046] b. Using a ball milling process, modifying and hydrophobicizing the surface of the silica with a silane coupling agent, and finally drying and sieving to obtain the treated silica powder.

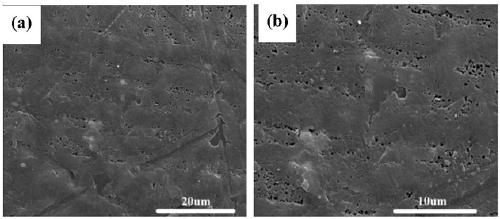

[0047] c. Using a ball milling process, mix silica powder, chopped glass fiber and polytetrafluoroethylene in proportion, and then demulsify with a demulsifier to obtain dough.

[0048] d. Obtain a green sheet through a calendering process, pre-baked, cut, coat...

Embodiment 1

[0066] a) Weigh 200g of silicon dioxide, dry the silicon dioxide in an oven at 120-150°C for 8-12 hours to remove physically adsorbed water, and prepare 150ml of a mixture of hydrogen peroxide and concentrated hydrochloric acid in a three-necked reflux flask (hydrogen peroxide: concentrated hydrochloric acid =20:80~40:60), then add silicon dioxide into the mixed solution and boil at 50~70°C while stirring for 1~2h to activate and increase the hydroxyl effect on the surface of silicon dioxide, then filter the silicon dioxide with suction, Dry at 105-120°C for 12-24 hours in a vacuum environment.

[0067] b) Weigh 0.8 g of KH550 coupling agent and 2.2 g of phenyltrimethoxysilane coupling agent. Weigh 58.5 g of deionized water and 136.5 g of alcohol, then add glacial acetic acid to the mixed liquid of deionized water and alcohol to adjust pH=4. Weigh 300g of cleaned agate balls of 8-14mm, add the agate balls, pH adjusting mixture, coupling agent and activated silica ceramic powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com