Auxiliary stocking propelling device and propelling method thereof

A technology of auxiliary propulsion and socks, applied in the direction of packaging, etc., can solve the problems of being stuck at this critical point, affecting the process operation, interrupting the handling of socks, etc., and achieving the effect of convenient maintenance of the transmission belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

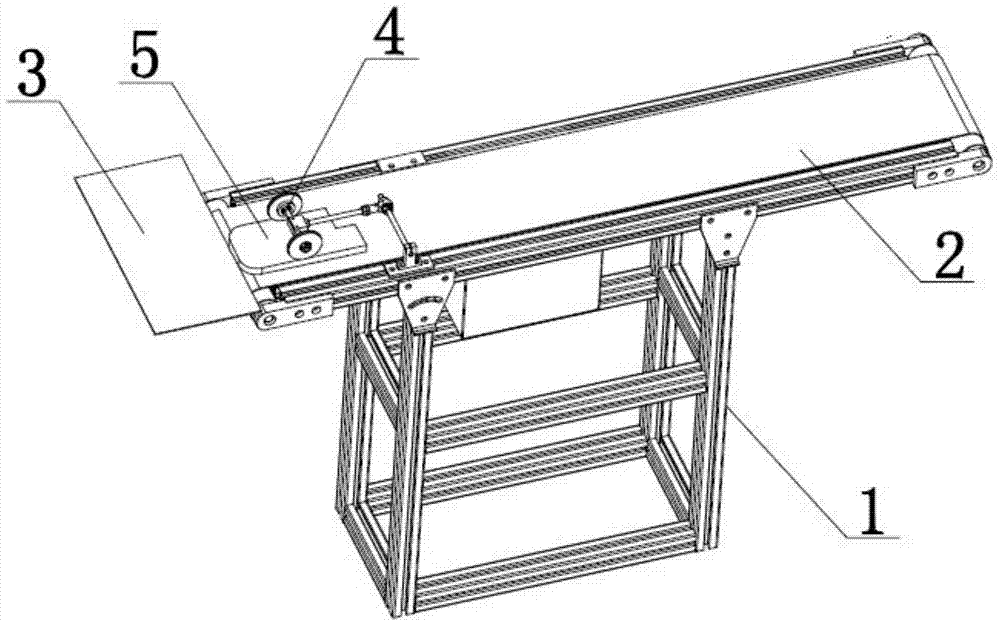

[0017] Example: such as figure 1 As shown, a sock auxiliary propulsion device includes a frame 1, a conveyor belt 2 is arranged on the frame 1, a working panel 3 is arranged at the end of the transmission belt 2, the working surface of the working panel 3 is flush with the belt surface of the transmission belt 2, and the transmission belt 2 is provided with a propeller 4, and the propeller 4 is located near the side where the working panel 3 is located.

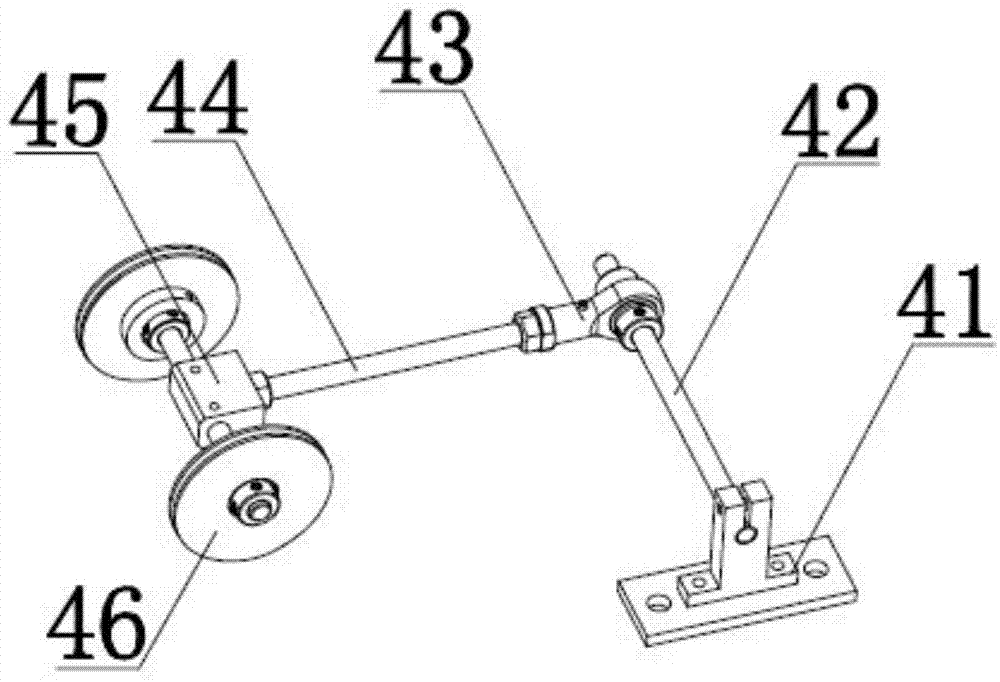

[0018] Such as figure 2 As shown, the propeller 4 includes a base 41, a connecting rod 42, a fish-eye joint 43, a swing rod 44, a bearing seat 45, a rotating shaft (the position in the figure is limited and the number is not given) and a pair of rollers 46, and the base 41 is fixed on the transmission belt. 2 On the frame 1 on one side, one end of the connecting rod 42 is hinged to the base 41, and the free end of the other end of the connecting rod 42 spans directly above the belt center of the transmission belt 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com