A crank group driving device that can be assembled

A driving device, crank technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems such as the inability to fully exert the advantages of heavy load of gears, complicated supporting and lubricating devices, waste of resources, etc., and achieve practical value. High, simple and convenient lubrication, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

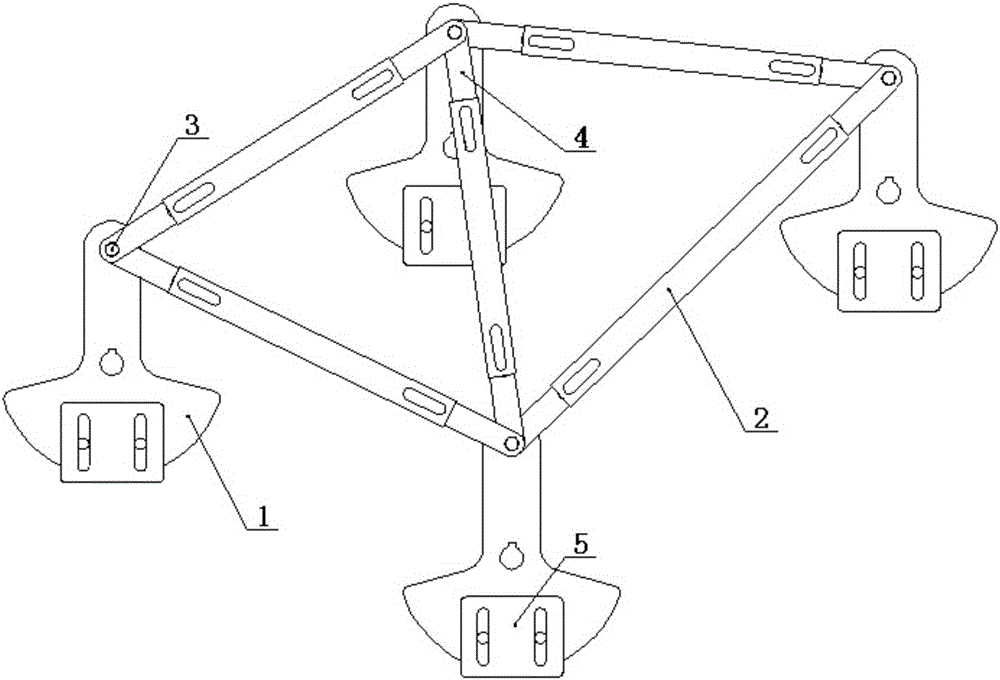

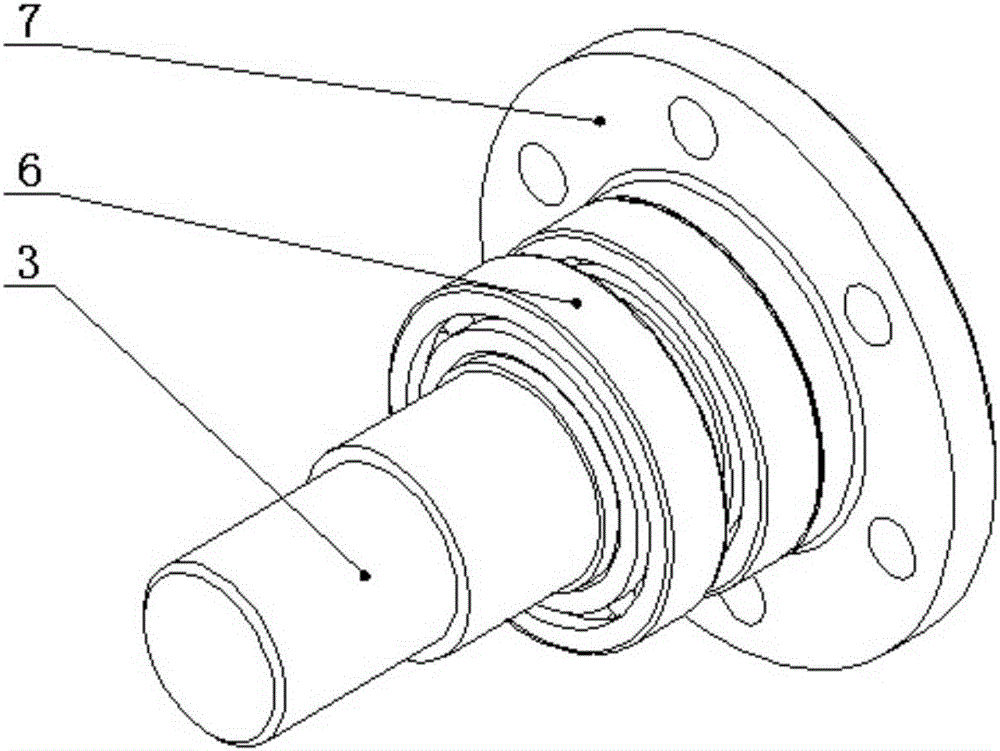

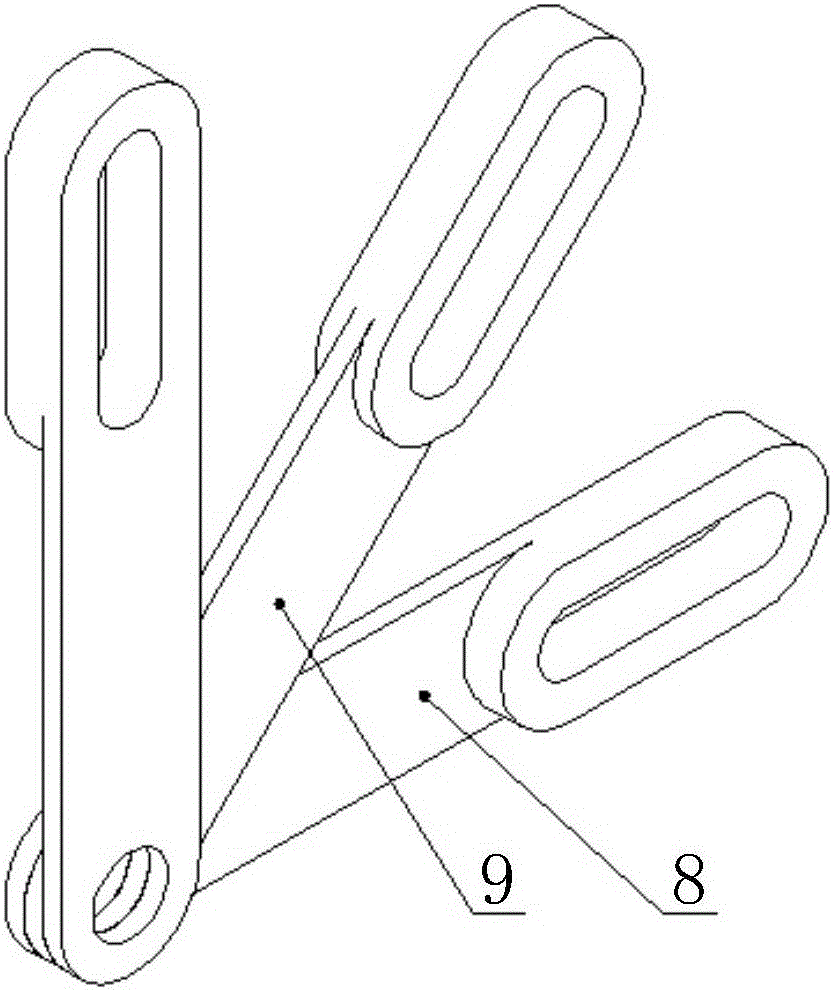

[0026] see Figure 1 to Figure 3 , the present invention includes several cranks 1, the cranks 1 are connected with the parallel shafts to be driven by flat keys; the crank 1 is fixed with a balance mass 5 by bolts, and the crank 1 is also provided with a through hole for installing the balance mass 5; Such as figure 2 As shown, each crank 1 is equipped with a connecting shaft 3, the connecting shaft 3 is covered with a connecting foot 4, a pair of bearings 6 are arranged on the connecting shaft 3 and the bearing end for fixing the connecting shaft 3 on the crank 1 Cover 7; one end of the connecting foot 4 is sleeved on the connecting shaft 3, fixed by a round nut, and the other end is inserted into the connecting rod 2 of a hollow structure, fixed by a bolt, and the connecting foot 4 can rotate around the connecting shaft 3; image 3 As shown, the connection pin 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com