Structural improvement of engine connecting rod

A technology of engine connecting rods and connecting rods, which is applied in the direction of connecting rods, mechanical equipment, shafts and bearings, etc., can solve the problems of reducing the service life of piston pins, difficult lubrication of lubricating oil, and large impact force of crankshaft, etc., to achieve impact force small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

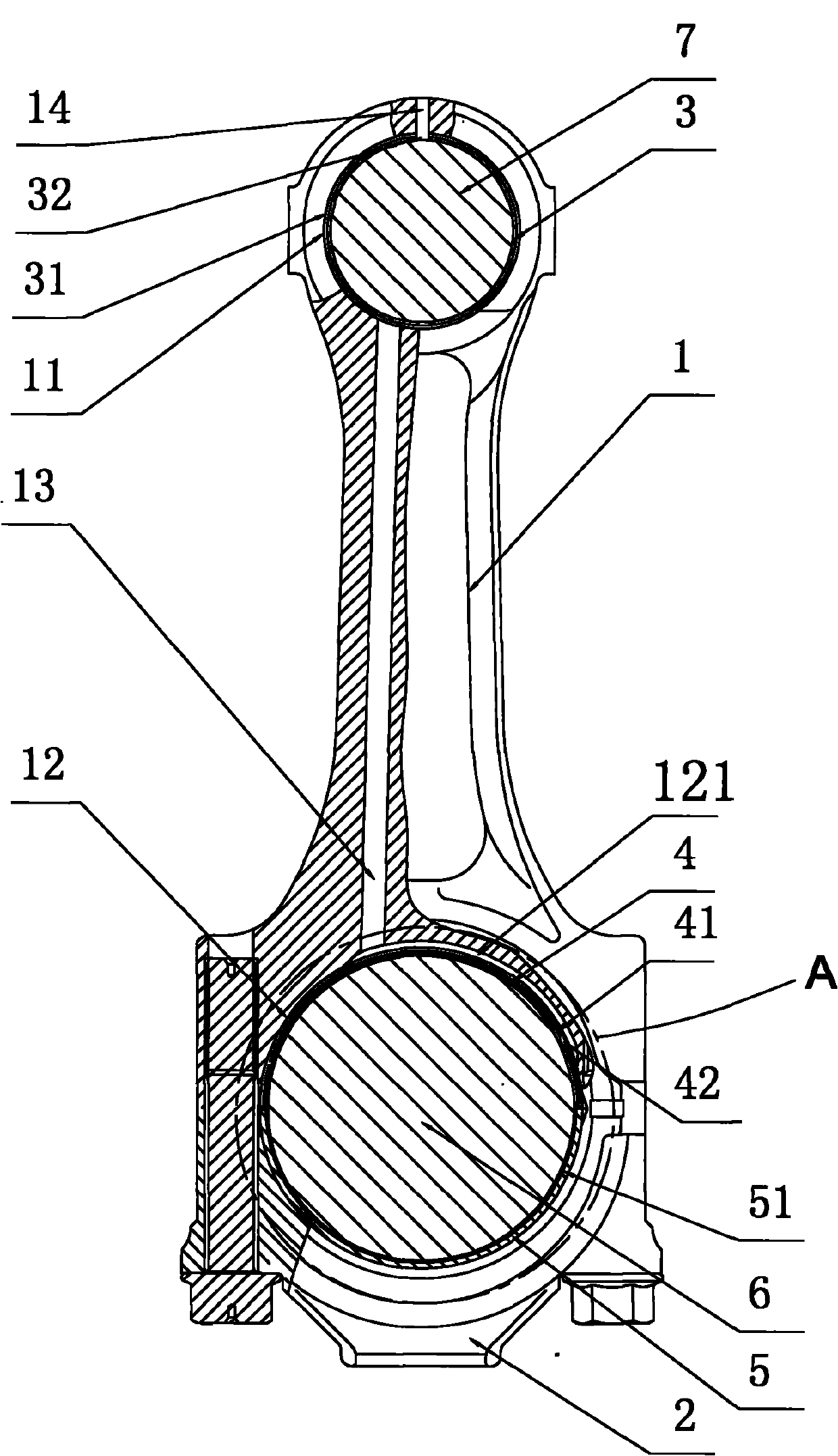

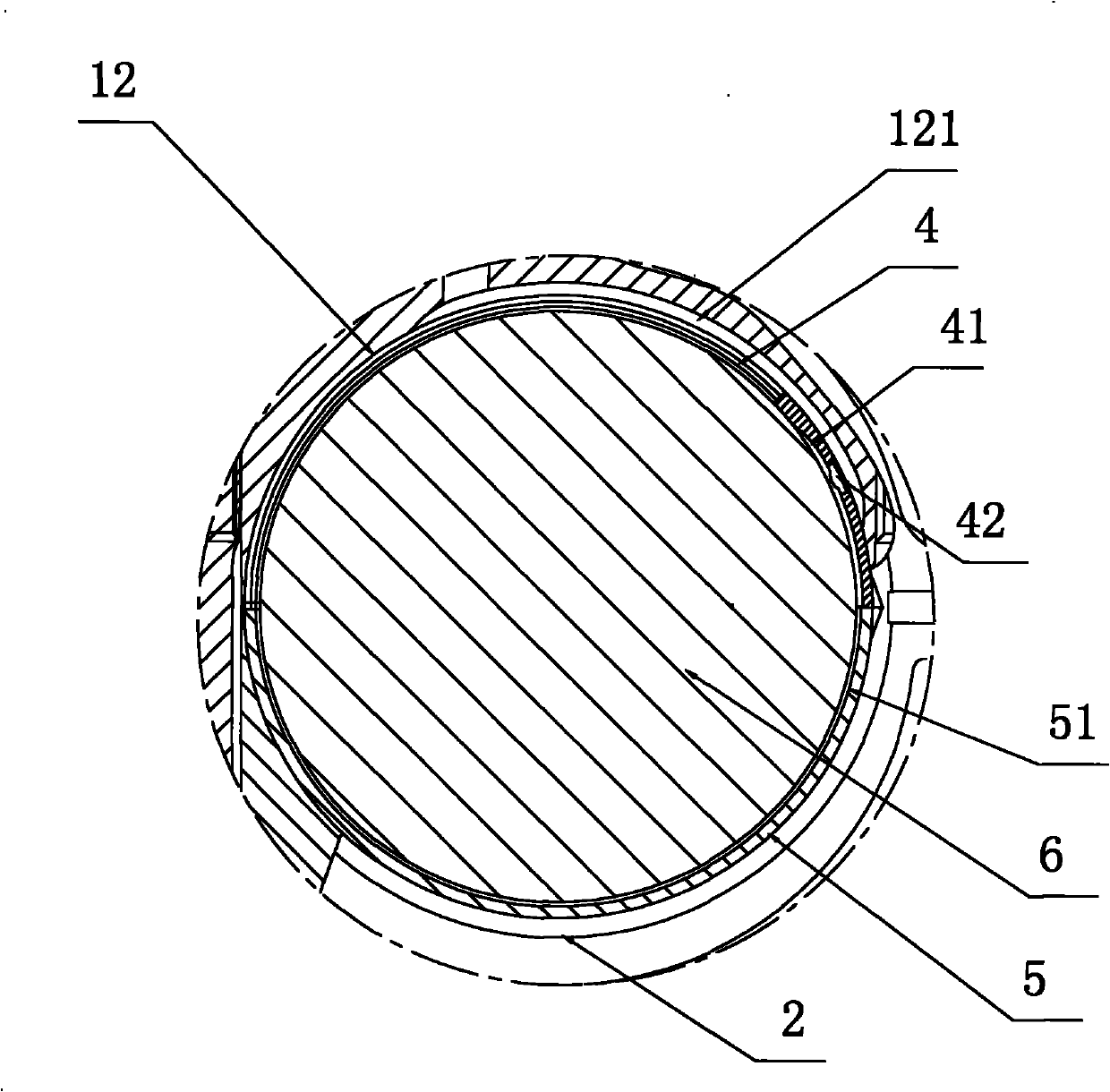

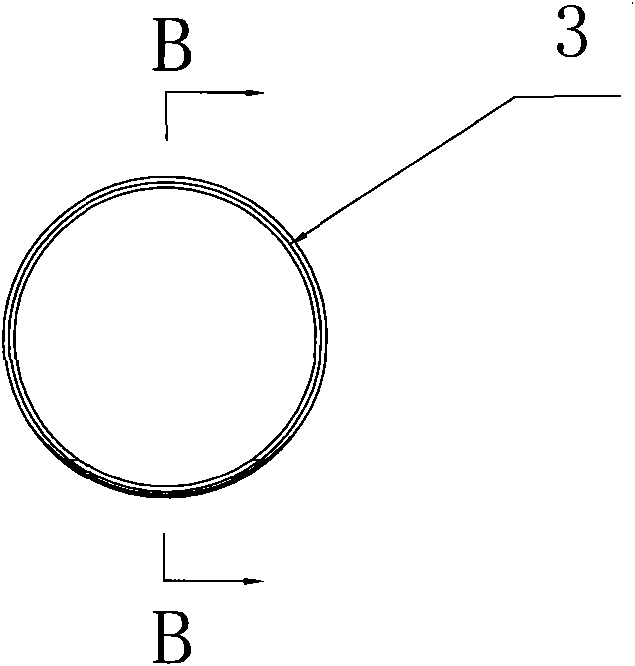

[0015] Embodiment: An improved engine connecting rod structure. The connecting rod includes a connecting rod body 1, a connecting rod cover 2, a bushing 3, an upper bearing bush 4, and a lower bearing bush 5. Based on the direction of use, the big end of the connecting rod body is far away from the small end The end side is detachably connected with the connecting rod cover 2, the small end of the connecting rod body 1 is provided with a piston pin hole 11, the large end and the connecting rod cover together form a crank shaft hole 12 in the same direction as the piston pin hole 11, and the bushing 3 Fixedly inserted into the piston pin hole 11 at the small end of the connecting rod body, the upper bearing bush 4 and the lower bearing bush 5 are radially combined to form a ring shape and inserted into the crank shaft hole 12 at the big end of the connecting rod body, the lower bearing bush 5 The inner side wall is provided with a semicircular concave first oil groove 51, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com