Automatic packaging and discharging device

An automatic packaging and discharge port technology, applied in the field of packaging, can solve problems such as easily damaged packaging products, and achieve the effect of improving practicability, reducing impact force and improving packaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

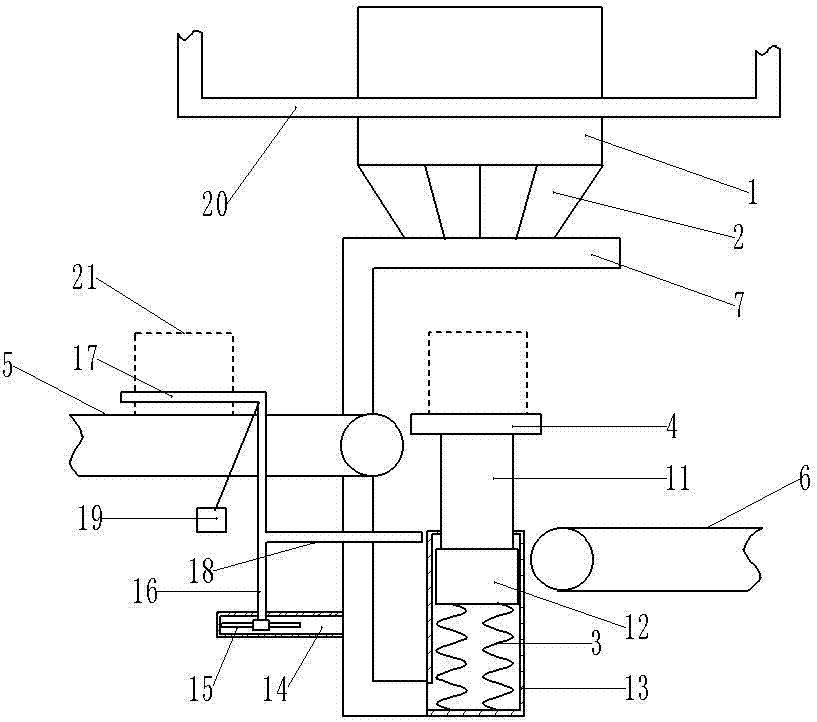

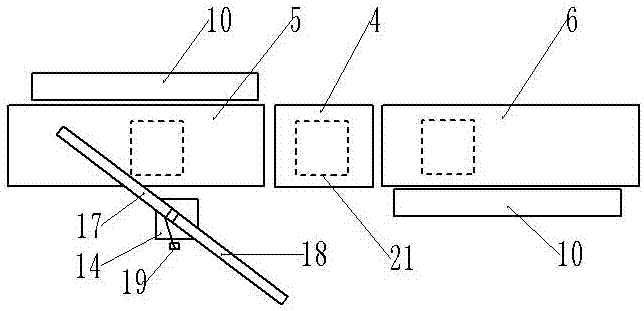

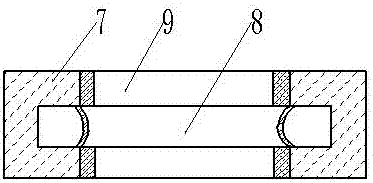

[0018] The reference signs in the drawings of the description include: feed hopper 1, discharge plate 2, spring 3, press table 4, first conveyor belt 5, second conveyor belt 6, annular pipe 7, elastic layer 8, splint 9, baffle plate 10. Compression column 11, piston 12, pipeline 13, bellows 14, impeller 15, rotating rod 16, upper strut 17, lower strut 18, hanging block 19, suspension 20, packing box 21.

[0019] The embodiment is basically as figure 1 and figure 2 Shown: an automatic packaging and unloading device, including a feed hopper 1, which is placed on a suspension 20 on the upper wall, and a plurality of discharge plates 2 are hinged at the lower end of the feed hopper 1, and a plurality of discharge plates 2 are hinged. The plate 2 is enclosed to form a discharge port, and a press table 4 is provided directly below the discharge port, and a first transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com