Electromagnetic pulse strengthening and forming device adopting small ball cushion die

A small ball pad mold and electromagnetic pulse technology, which is applied in the field of electromagnetic pulse strengthening and forming devices, plate strengthening and forming, can solve the problems of no practical application, etc., and achieve the prevention of centralized deformation, easy relative position, and dispersed deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

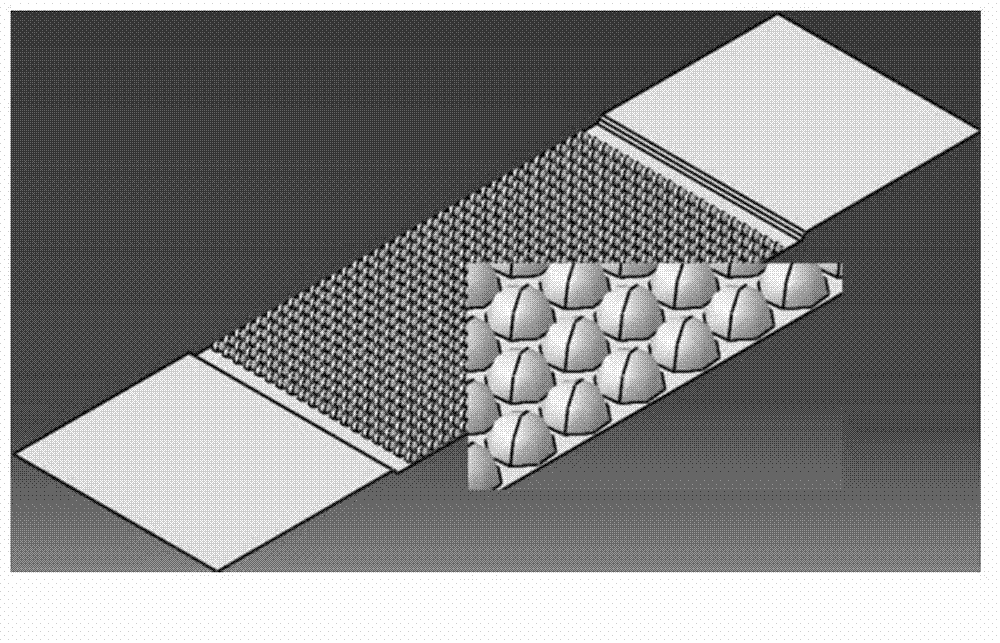

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

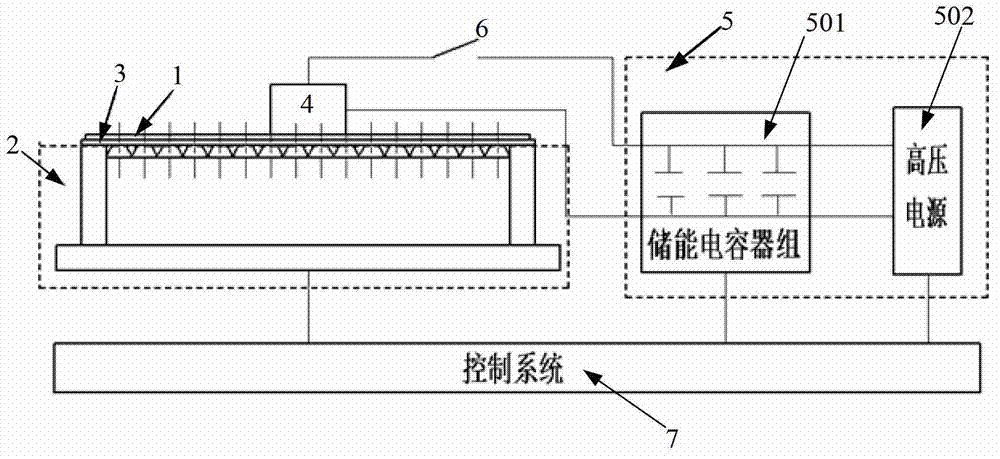

[0027] Electromagnetic pulse forming is a high-rate forming method that uses magnetic field forces to deform metal blanks. In electromagnetic pulse forming, a metal blank is placed between an electromagnetic coil and a die. The electromagnetic coil is connected to an energy storage capacitor bank, the energy storage capacitor bank is charged by the charging circuit, and then the electromagnetic coil is discharged through the discharge circuit, the electromagnetic coil generates a pulsed magnetic field, the pulsed magnetic field generates an induced current on the metal blank, and the induced current generates a corresponding induction magnetic field. At the moment of discharge, the induction magnetic field generated by the induced current on the metal blank interacts with the pulse magnetic field generated by the electromagnetic coil, so that the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com