An alloy wire evenly distributed heat-generating cable

A heating cable and alloy wire technology, applied in electric heating devices, electrical components, ohmic resistance heating, etc., can solve problems such as unfavorable heating cable temperature control, affecting heating cable heating power feedback, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

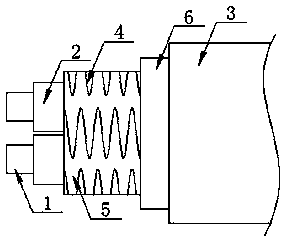

[0016] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] like figure 1 As shown, a heating cable with uniform distribution of alloy wires includes two heating wire cores and an outer sheath 3 wrapped outside the two heating wire cores, each of the heating wire cores includes a core conductor wire 1 And the core insulating sheath 2 wrapped on the outside of the core conductor wire 1, the outer sheath 3 is also provided with a uniform thermal distribution alloy wire 4, and the uniform thermal distribution alloy wire 4 is located in the core insulation Set 2 outside. It also includes an alloy wire inner film sheath 5 and an alloy wire outer film sheath 6 wrapped on the outside of the two heating wire cores, the alloy wire inner film sheath 5 and the alloy wire outer film sheath 6 are made of tetrafluoroethylene Made, the alloy wire outer membrane sheath 6 is wrapped on the outside of the alloy wire in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com