Mechanical seal performance testing device

A technology of mechanical seal and test device, which is applied in the direction of machine seal ring test, fluid tightness test, measuring device, etc., can solve the problems of incompatibility, low accuracy, small shaft strain, etc., and achieve accurate measurement and guarantee The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0040] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

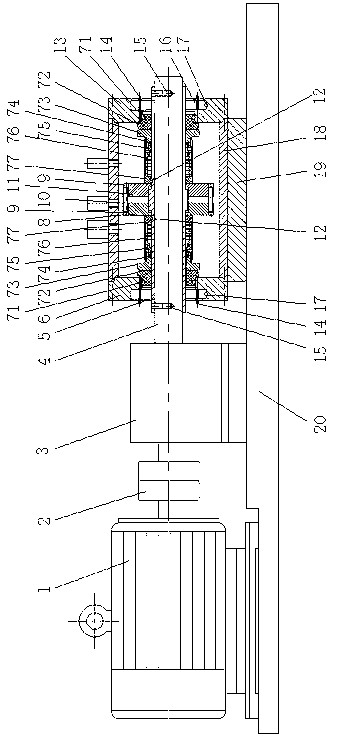

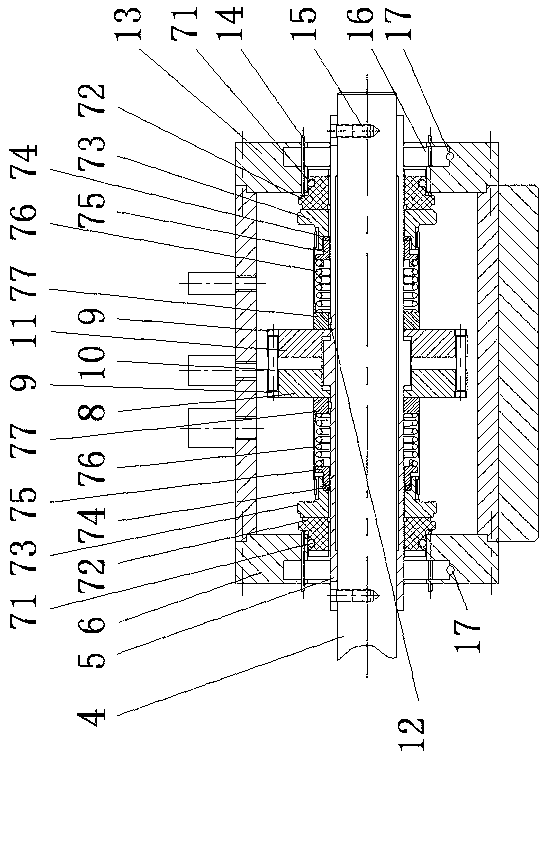

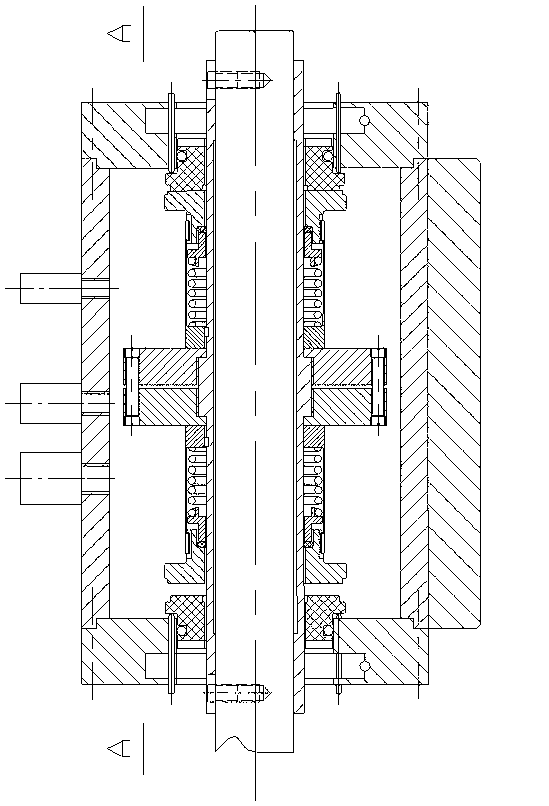

[0041] figure 1 , 2 A mechanical seal performance test device is shown, including motor 1, shaft coupling 2, bearing housing 3, main shaft 4, transmission pin 15, shaft sleeve 5, left end cover 6, process hole plug 24, process shaft 22, shaft Force sensor 14, mechanical seal to be tested (static ring O-ring 71, static ring 72, moving ring 73, moving ring O-ring 74, support ring 75, spring 76, moving ring seat 77), guide flat key 12, Left nut 8, right nut 11, short pin 10, short pin hole plug 9, working chamber 18, right end cover 13, carriage 19, support 20.

[0042] The shaft sleeve 5 is a symmetrical structure abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com