Patents

Literature

32results about How to "Large axial thrust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

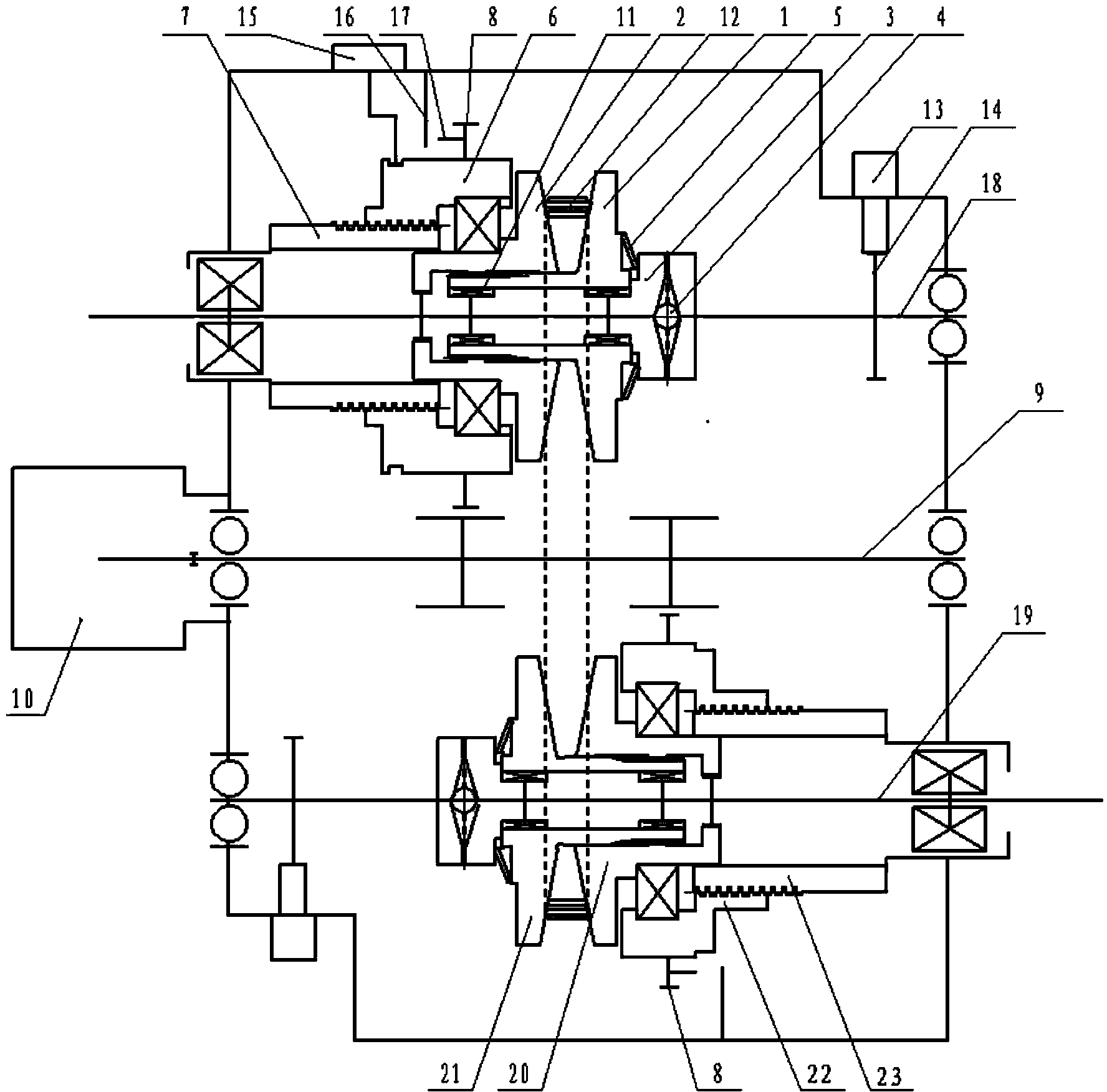

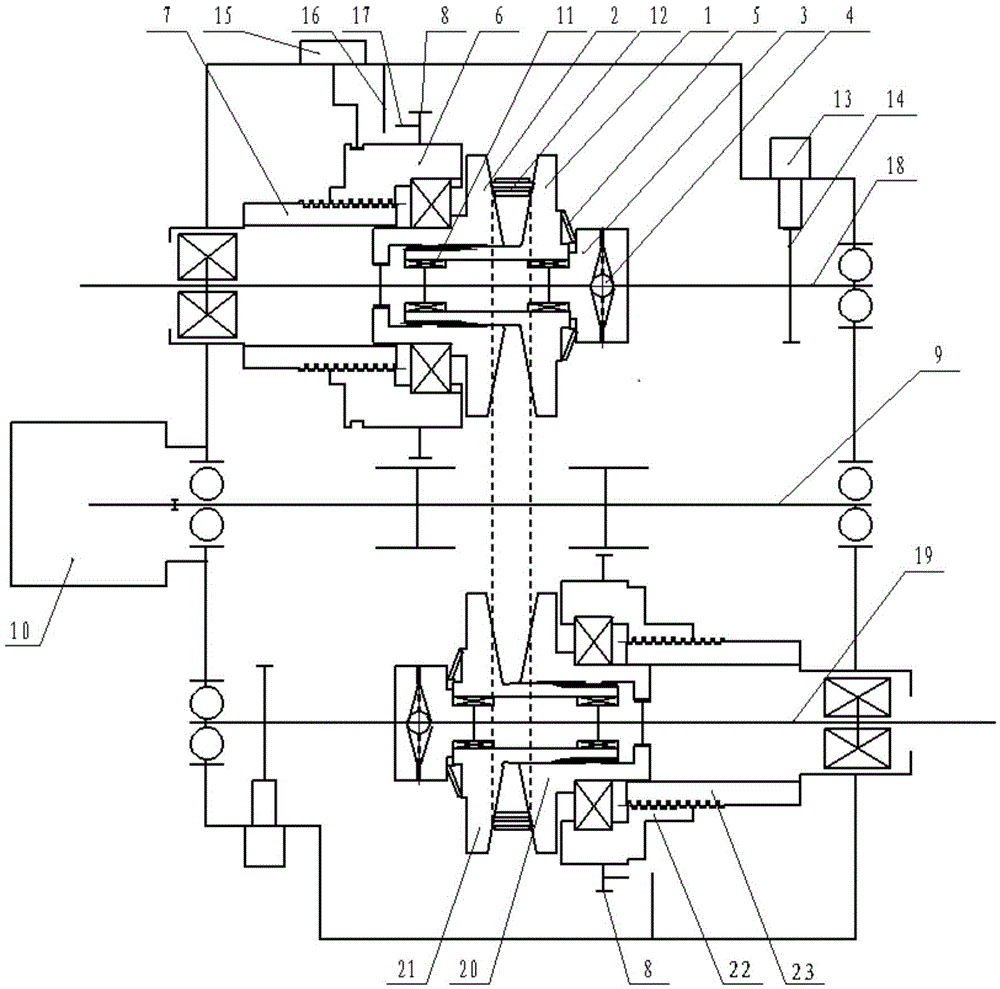

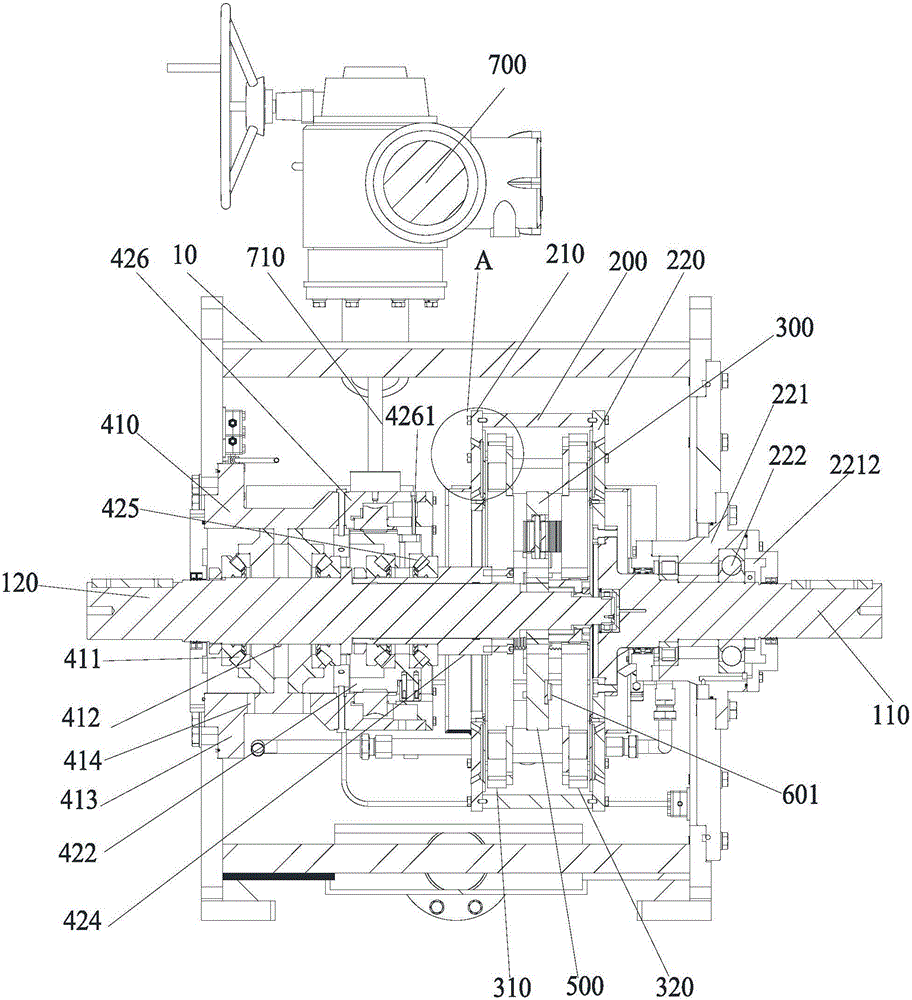

Cone plate type stepless speed changer

The invention provides a cone plate type stepless speed changer. A driving cone plate and a driven cone plate respectively consist of a pair of movable cone plates and pressurizing cone plates, a pressurizing mechanism consists of an end surface cam pressurizing mechanism arranged at the back side of at least one pressurizing cone plate in a driving shaft pressurizing cone plate and a driven shaft pressurizing cone plate, a speed regulating mechanism consists of a speed reducing shaft, a hollow screw rod and a screw nut, the hollow screw rod and the screw nut are respectively arranged at the back side of a driving shaft movable cone plate and a driven shaft movable cone plate, the hollow screw rod and the screw nut are of ball screw structures or sliding spiral structures, through a speed regulating shaft and a constant ratio transmission mechanism, the conversion relationship of the rotation of the speed regulating shaft to the axial movement of the driving shaft movable cone plate and the driven shaft movable cone plate meets a formula that i1=i2, and the driving shaft movable cone plate and the driven shaft movable cone plate are enabled to do synchronous identical-speed and identical-direction movement. The end surface cam pressurizing mechanism and the speed regulating mechanism of the speed changer are separated in space, the axial dimension of the pressurizing mechanism can be reduced, the positive and reverse two-way pressurization can be realized through the end surface cam pressurizing mechanism, the pressurizing pressure can be regulated in real time along with the transmission torque, the transmission efficiency is high, the service life of a system is long, and the reliability is high.

Owner:CHANGZHOU DONGFENG CVT

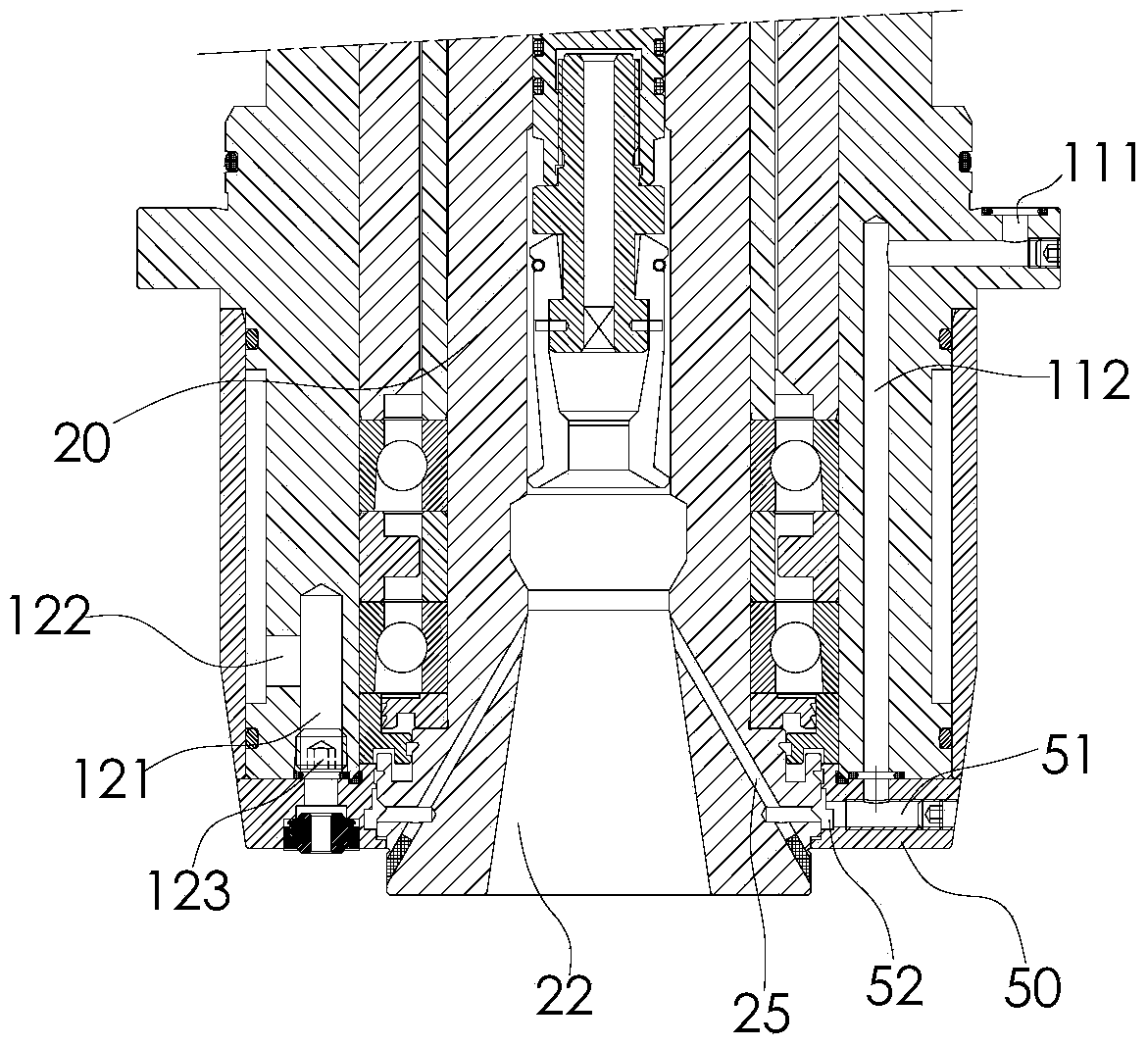

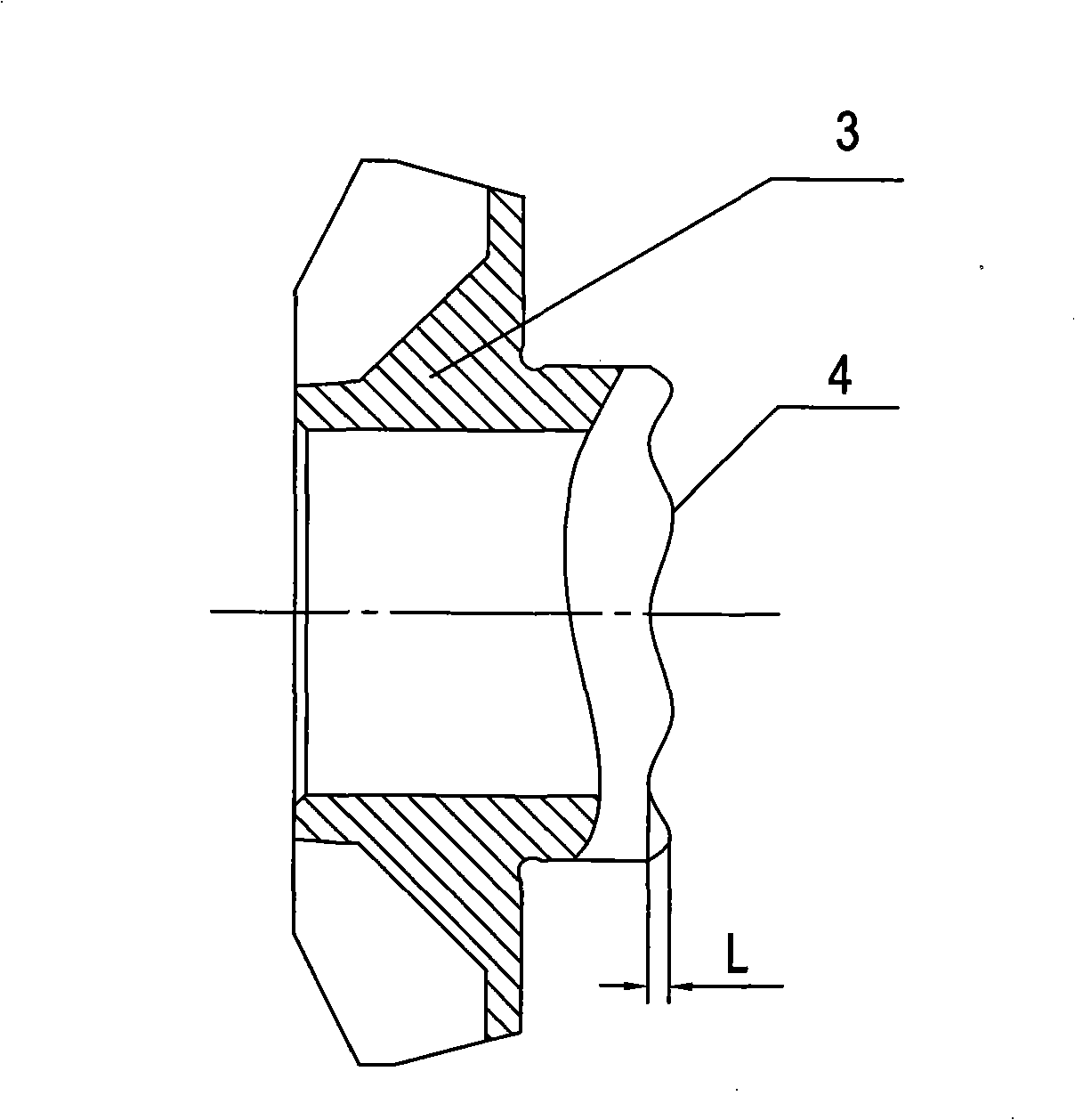

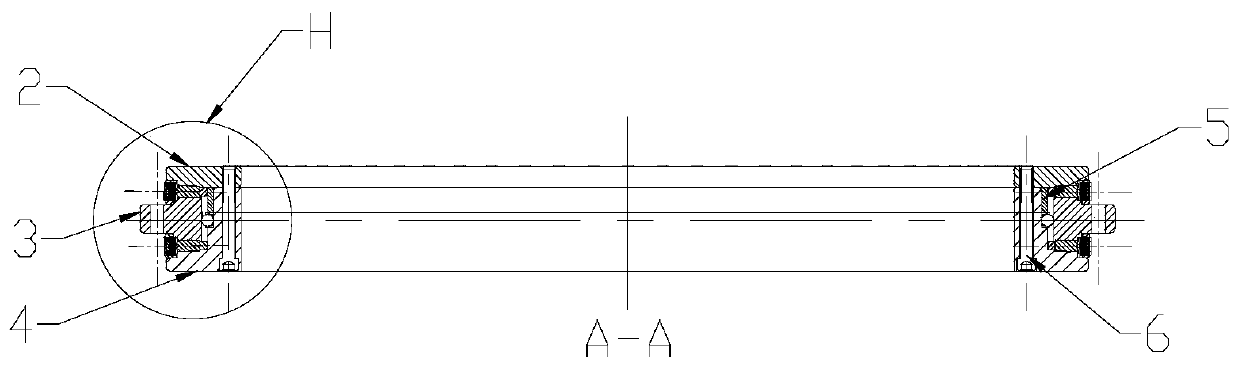

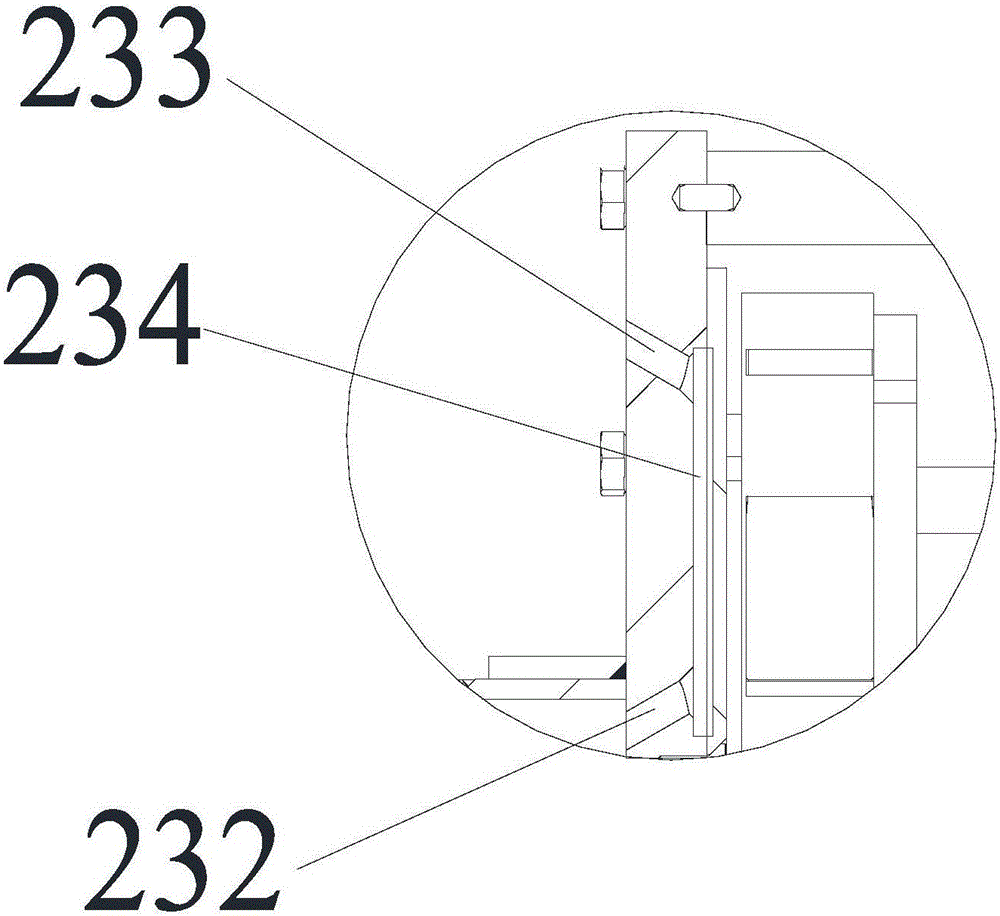

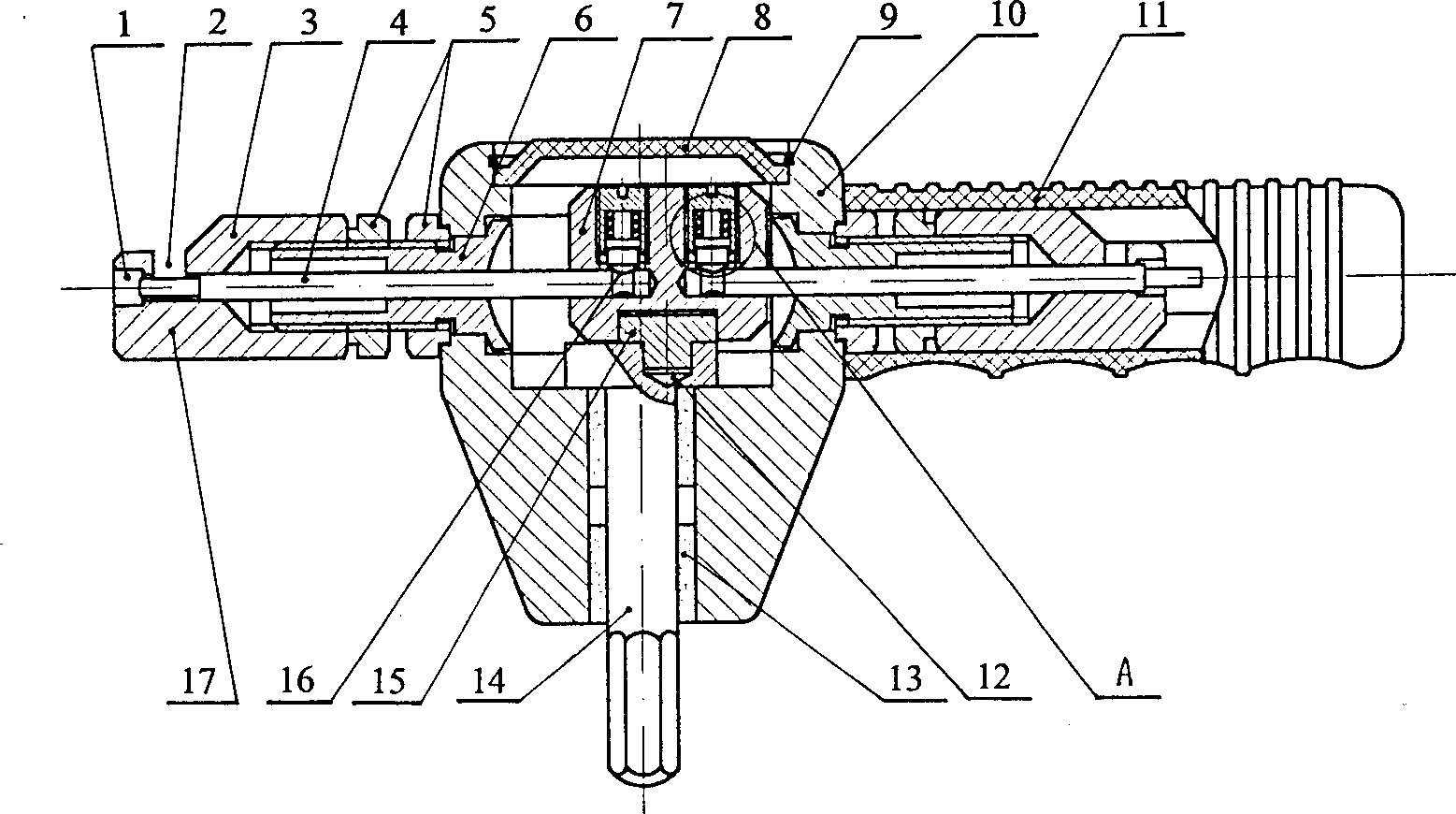

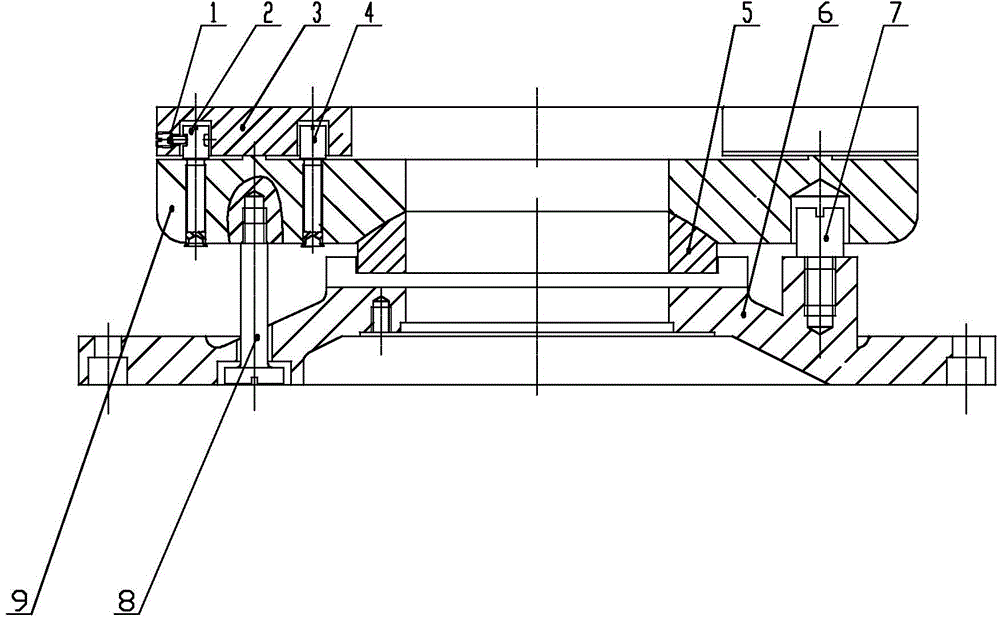

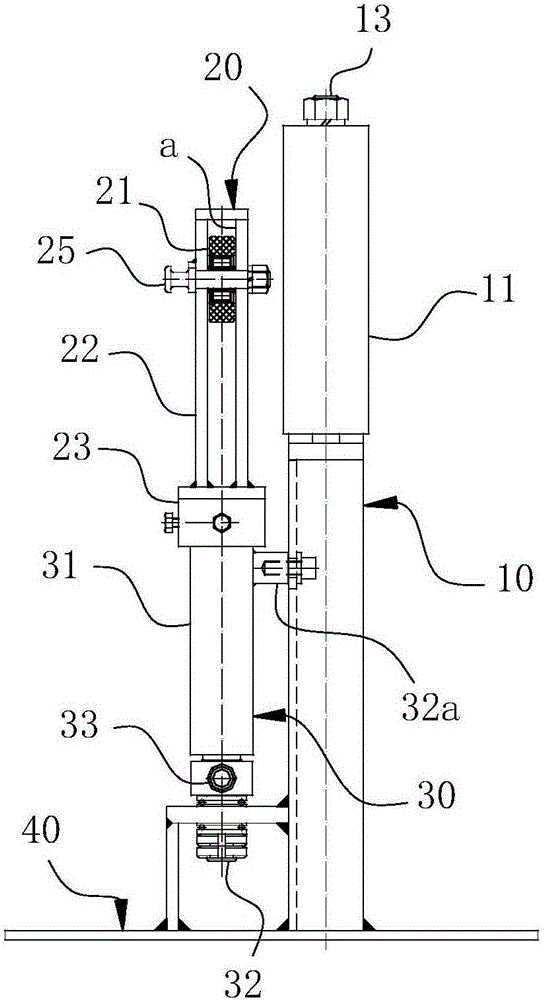

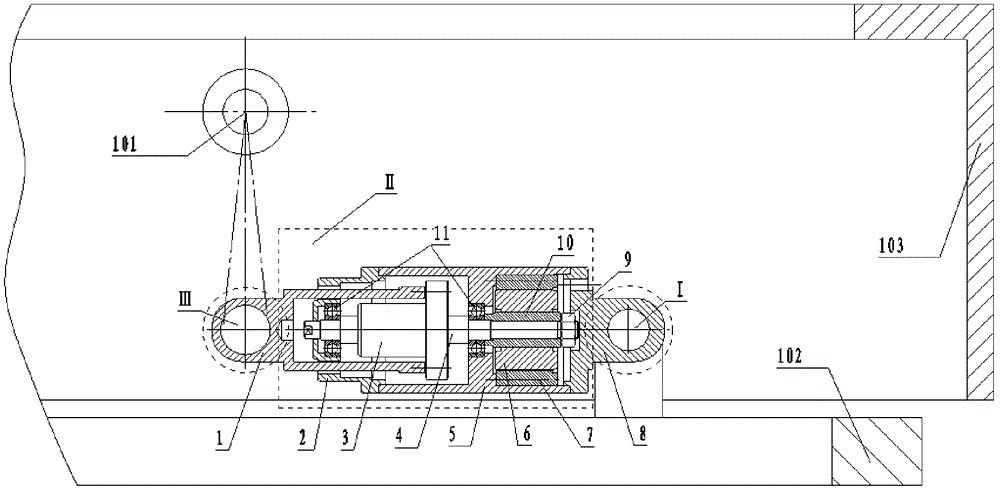

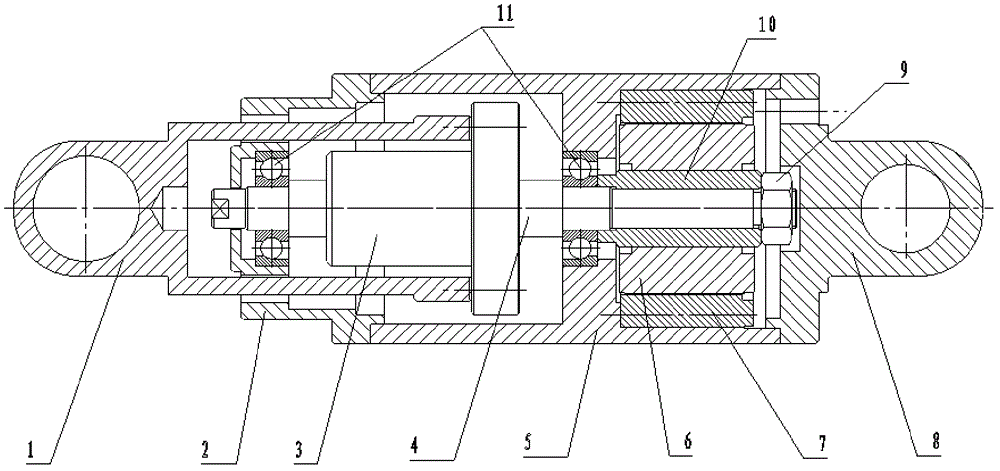

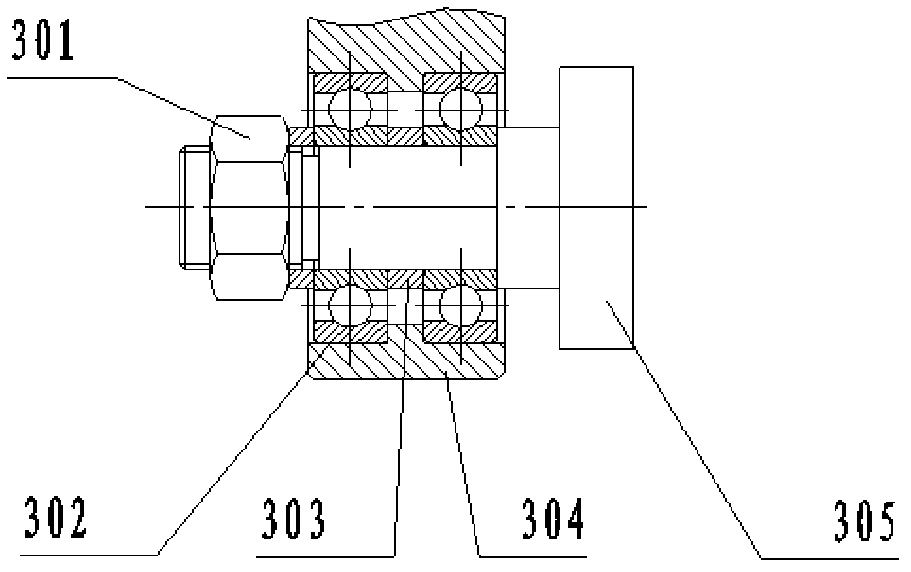

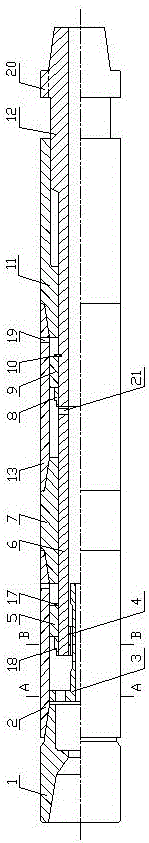

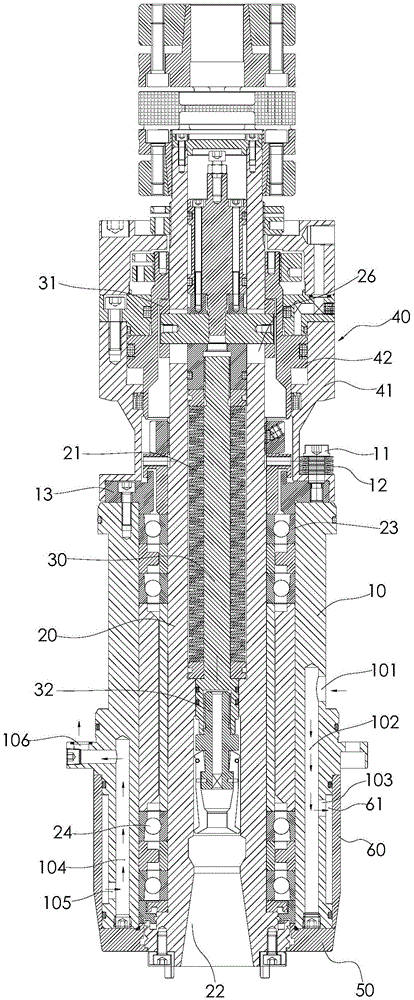

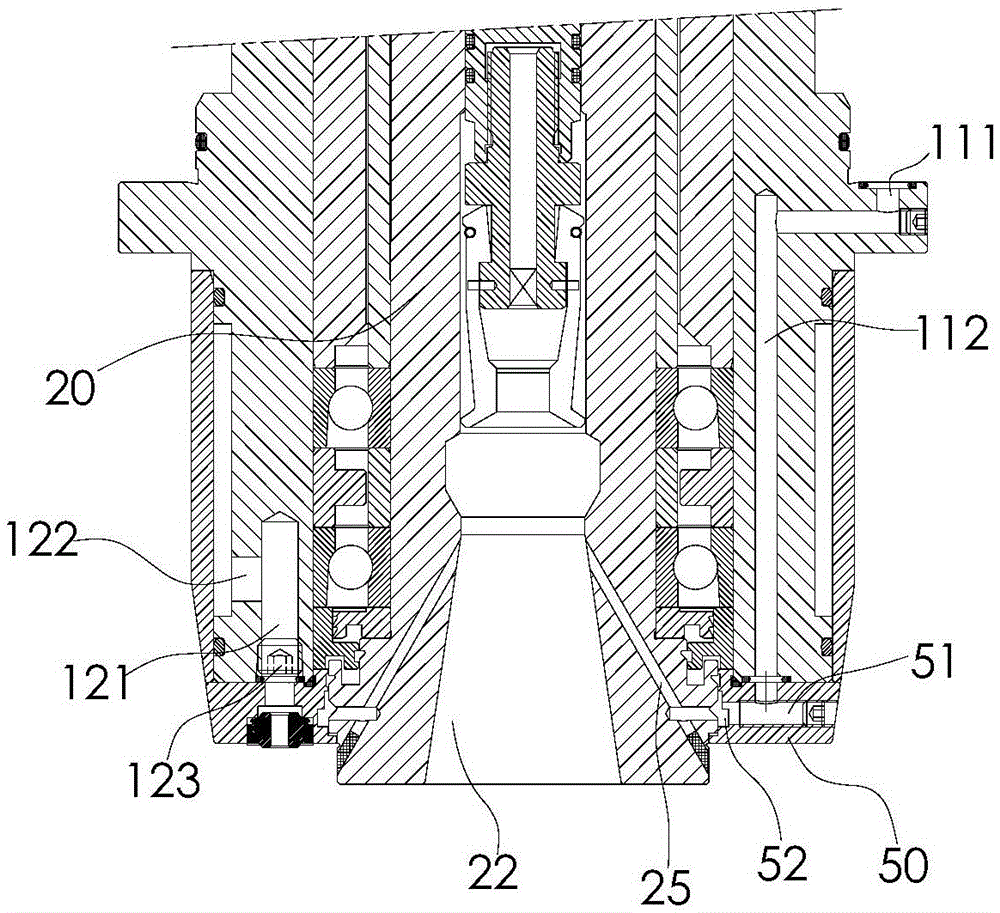

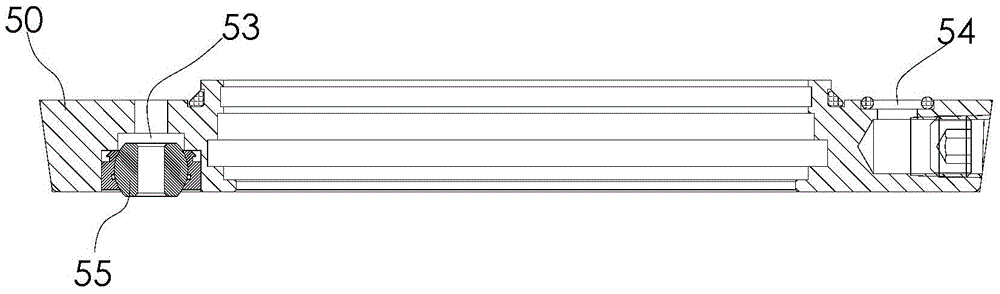

High-speed direct connection spindle

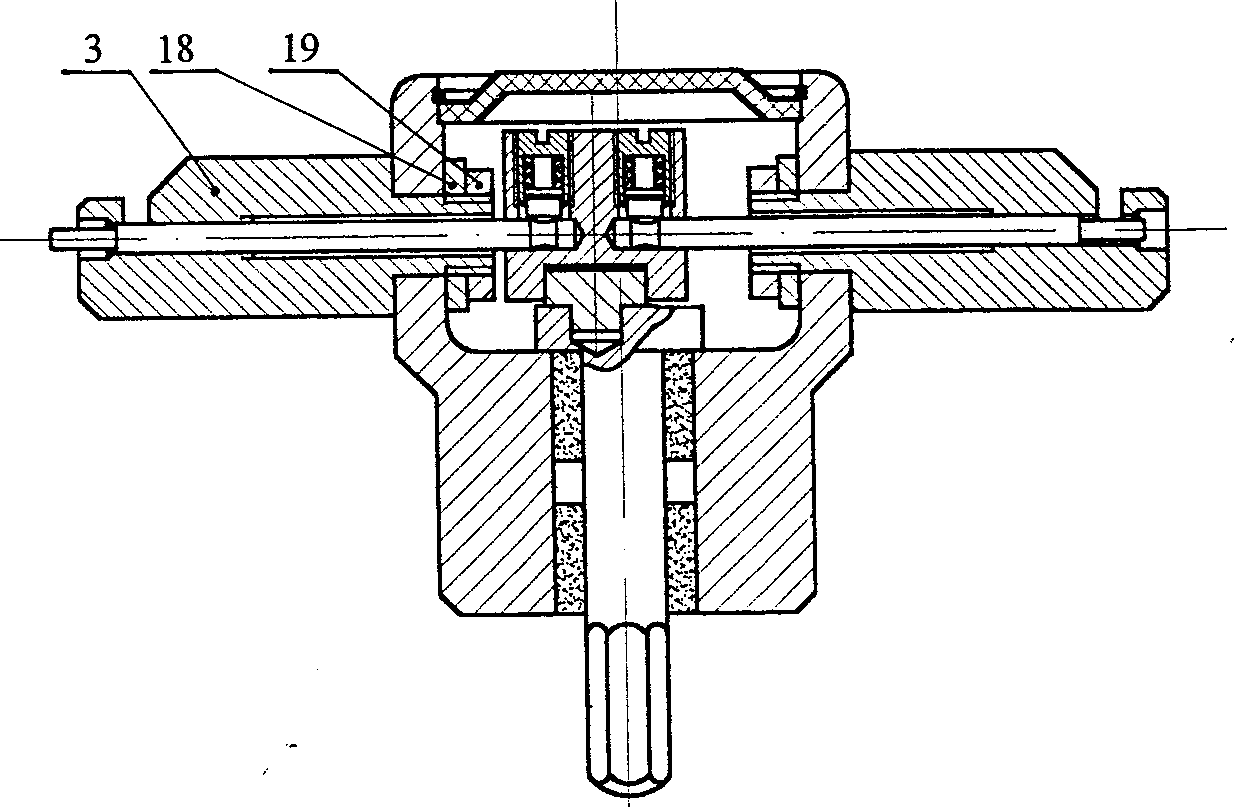

ActiveCN103737408AGuaranteed to workAvoid enteringLarge fixed membersChucksBody positionsEngineering

The invention relates to a high-speed direct connection spindle. The high-speed direction connection spindle comprises an engine body, a central spindle, a pull rod, a reset spring and an oil cylinder assembly, wherein the central spindle is pivoted in the engine body through an upper bearing and a lower bearing arranged at the upper end and the lower end of the engine body, and a conical hole is formed in the bottom end of the central spindle, wherein the diameter of the conical hole is increased from top to bottom in sequence; the lower end of the pull rod is connected with a pulling claw which is matched with the conical hole and used for fixing a cutter, and the upper end of the pull rod is fixedly provided with a cutter hitting disk; the reset spring is arranged between the central spindle and the pull rod; the oil cylinder assembly comprises a cylinder body positioned above the top of the engine body and a piston arranged at the interior of the cylinder body and used for propping against the cutter hitting disk downwards; the cylinder body is movably provided with a plurality of connecting pieces in a penetrating manner, the part, penetrating through the lower end of the cylinder body, of each connecting piece is fixedly connected to the engine body, and each connecting piece is connected with an elastic element in a sleeving manner. The cylinder body of the oil cylinder is arranged on the engine body in a floating manner, and the axial thrust applied to the central spindle when a cutter is assembled or disassembled on the oil cylinder can be counteracted, so that a bearing is protected from being damaged, and the service life of the bearing is prolonged.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

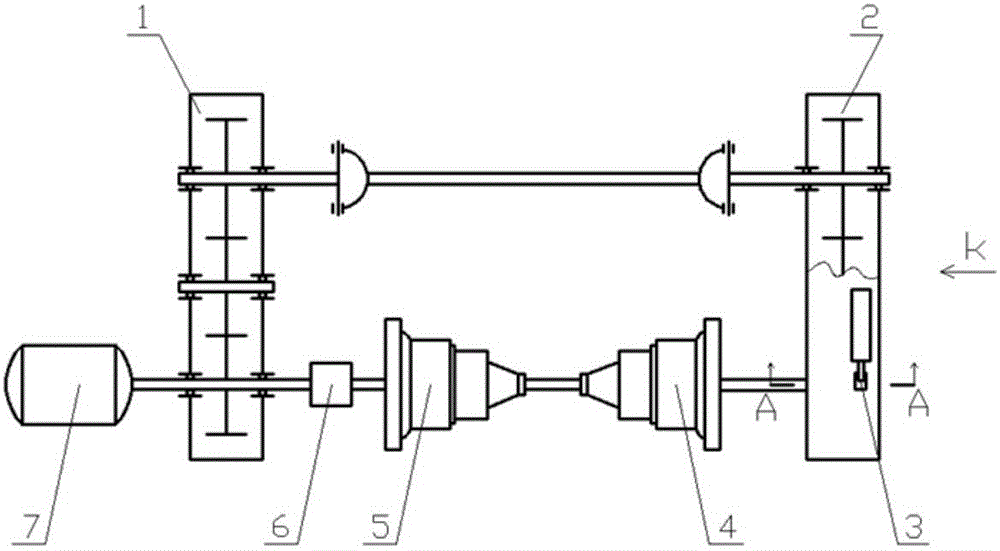

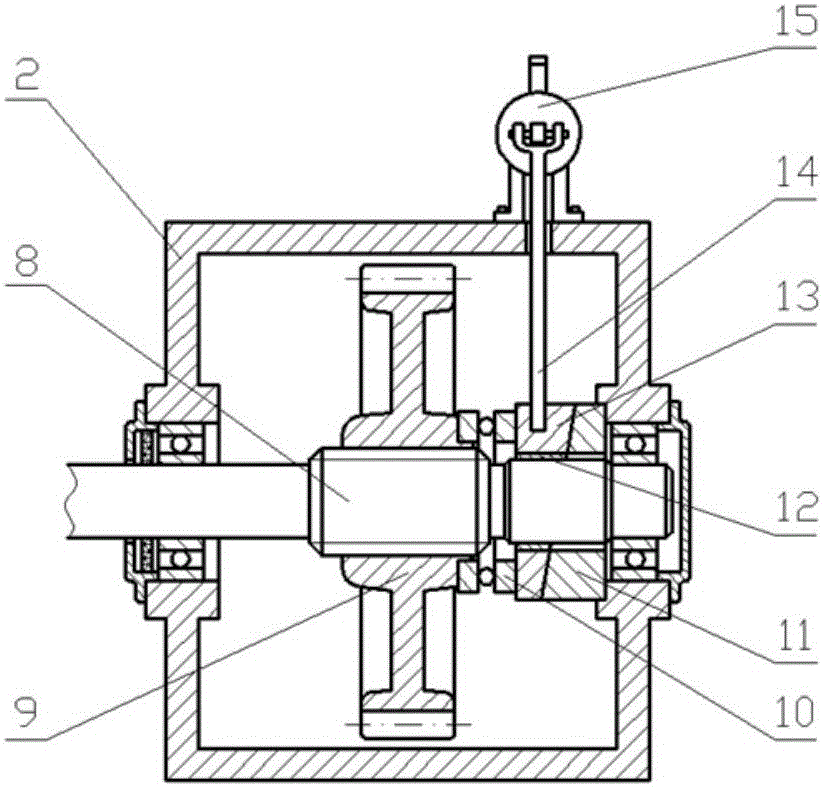

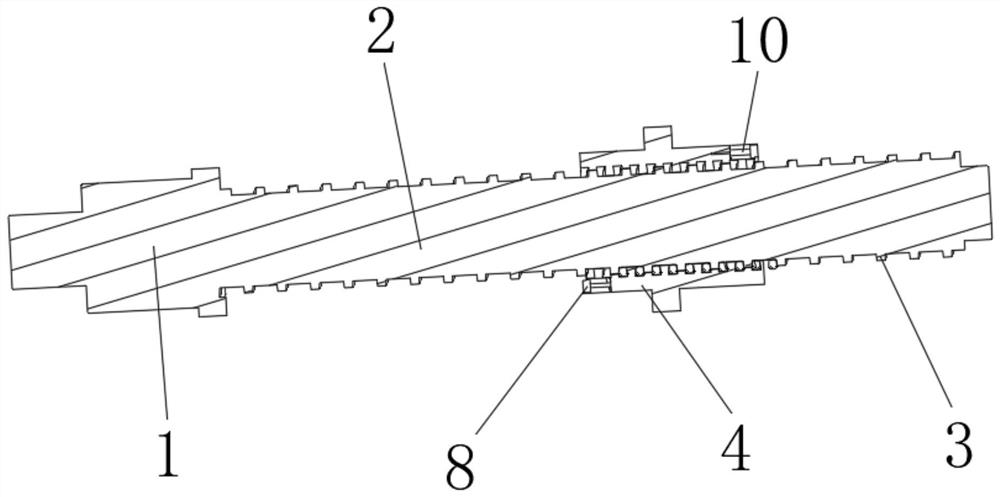

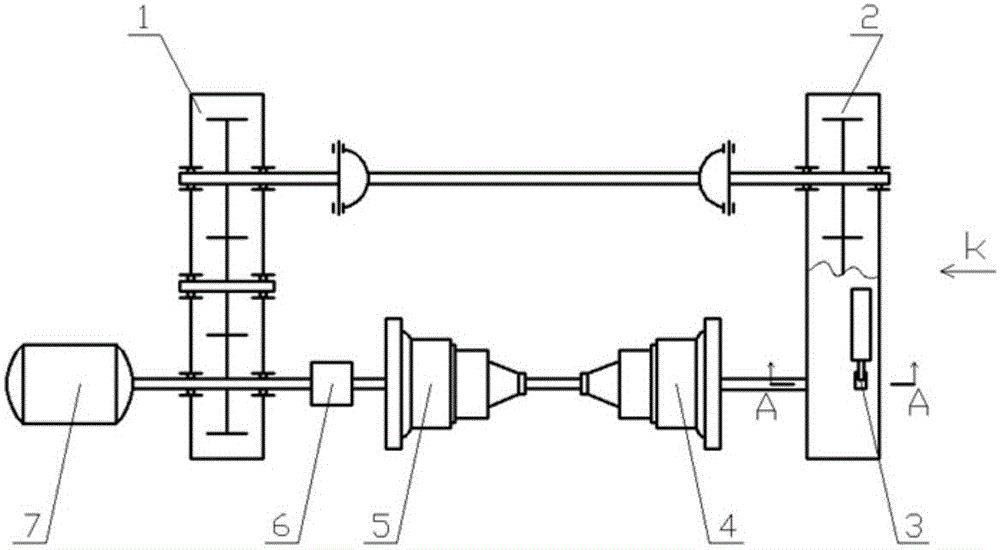

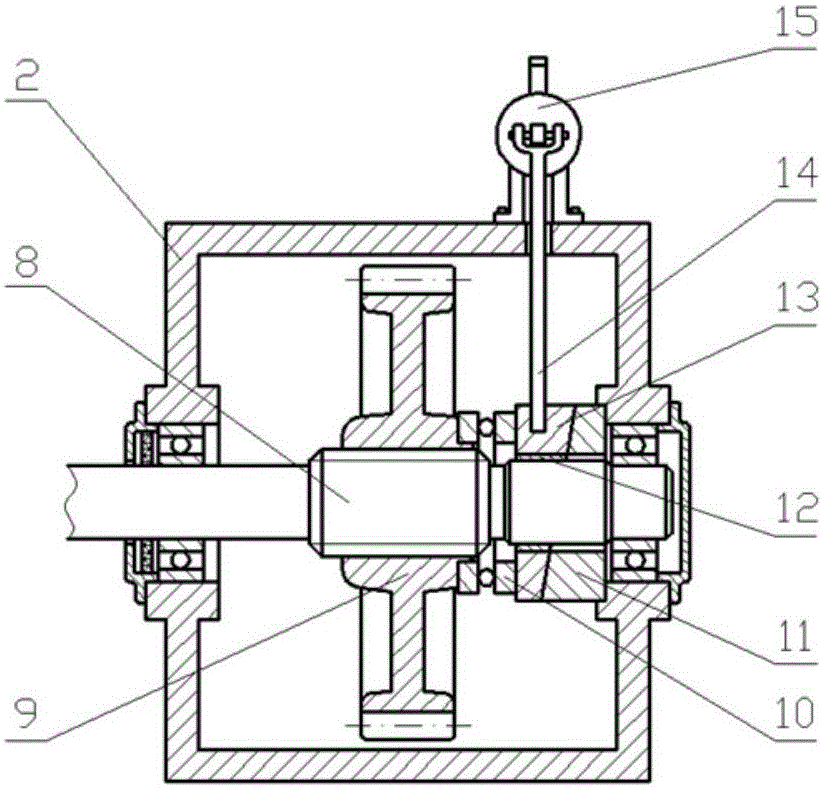

Mechanical transmission closed test bed and test method thereof

InactiveCN105784355AReduce thrustEasy to useMachine gearing/transmission testingPlain bearingWedge cushion

The invention discloses a mechanical transmission closed test bed and a test method thereof. The test bed comprises a motor, connection gear boxes, a torque and rotation speed sensor, a tested transmission, an accompanying transmission and a loader, wherein the loader comprises a spiral spline shaft, a loaded gear, a plane bearing, a pair of wedge cushion blocks, a sliding bearing, a thrust bar and an oil cylinder; the motor is connected with the left connection gear box for providing rotation power for the overall closed test bed; the two transmissions are connected in a back-to-back mode, the tested transmission is connected with the left connection gear box via the torque and rotation speed sensor and the accompanying transmission is directly connected with the right connection gear box; and the loader is arranged onto the right connection gear box for providing different loads for the overall closed test bed. A transmission fatigue life test and a reliability test can be carried out, the closed structure is adopted, the cost is low, energy is saved, the structure is compact, the use is convenient, and the test bed can be applied to transmissions of various models.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

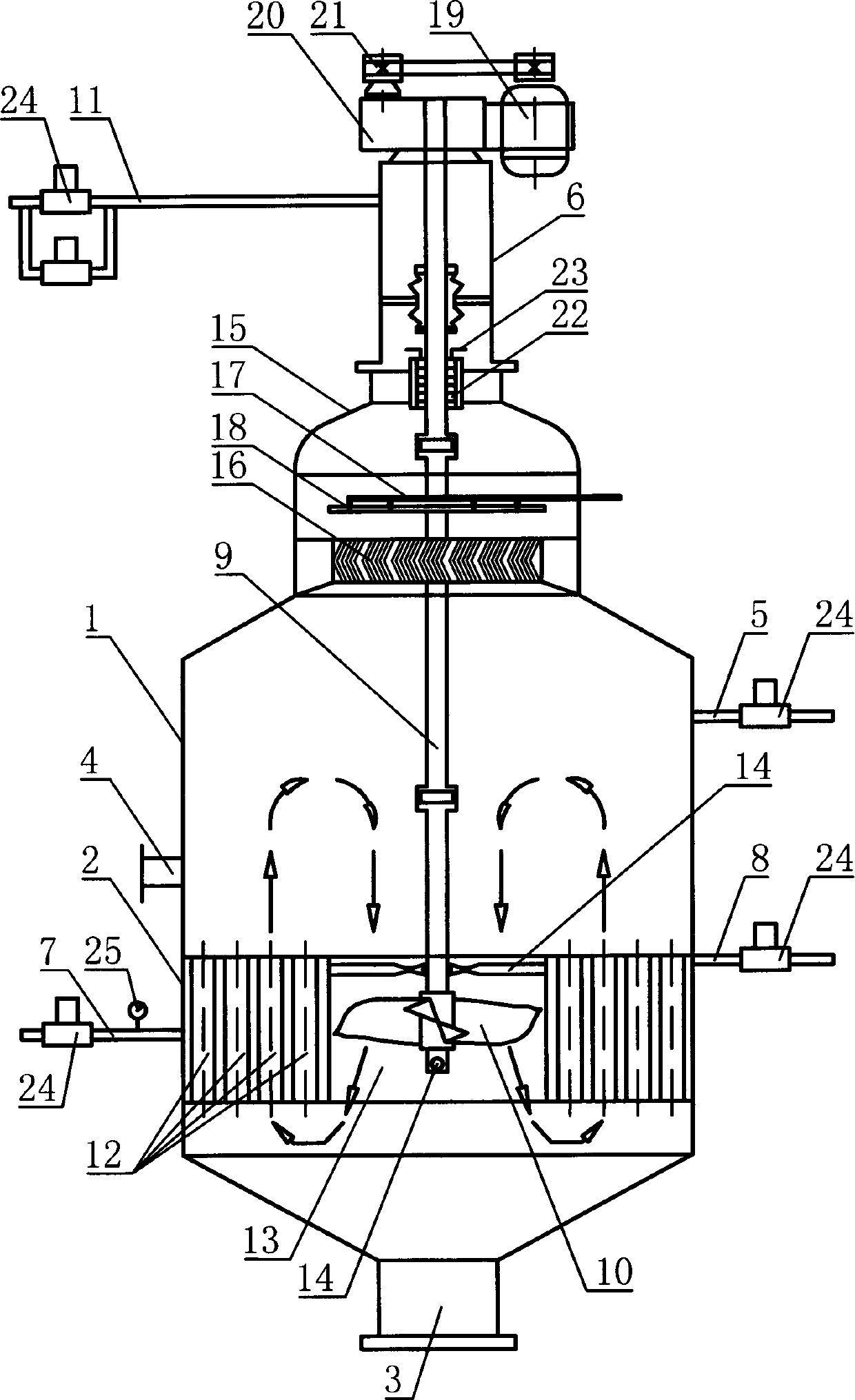

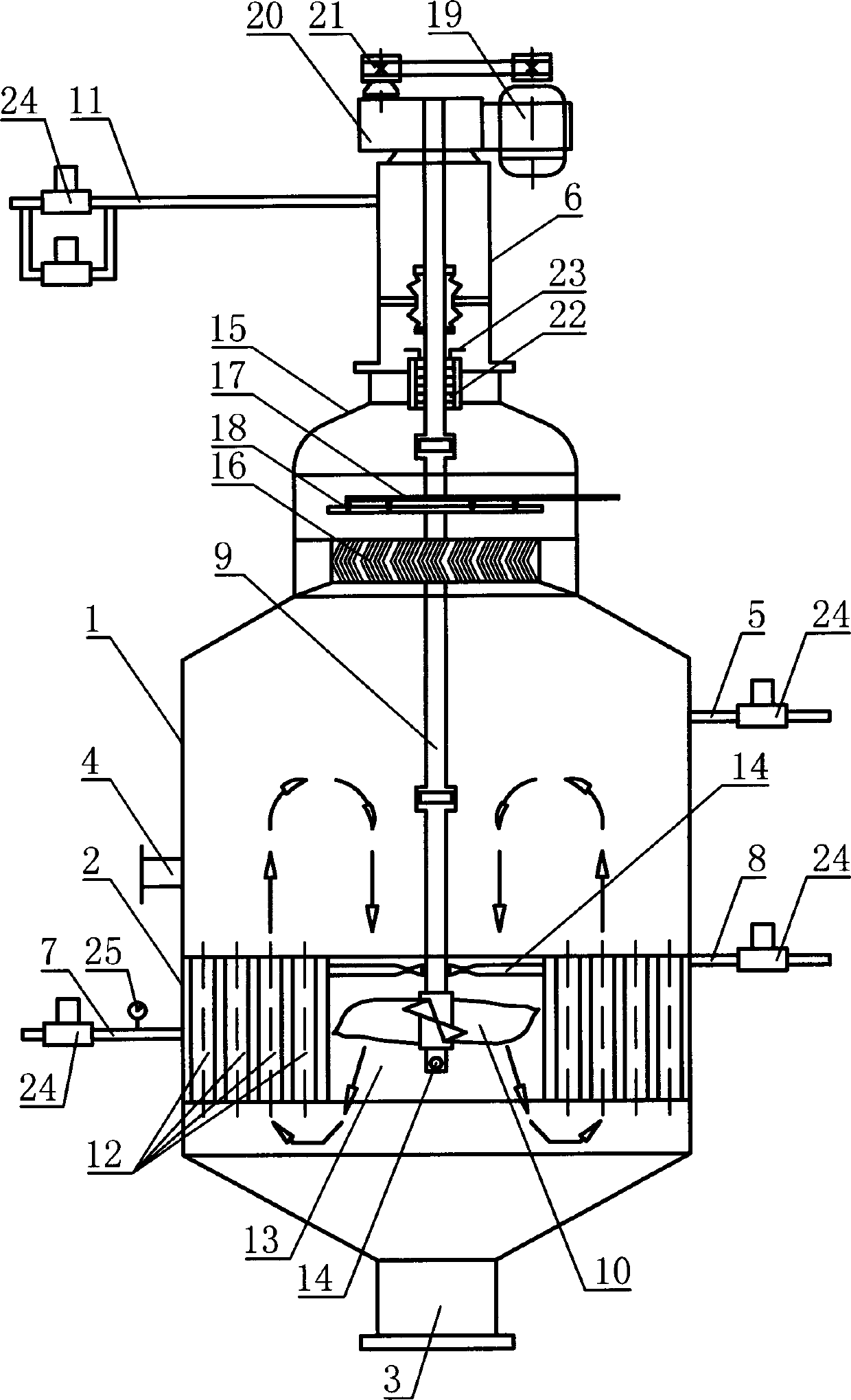

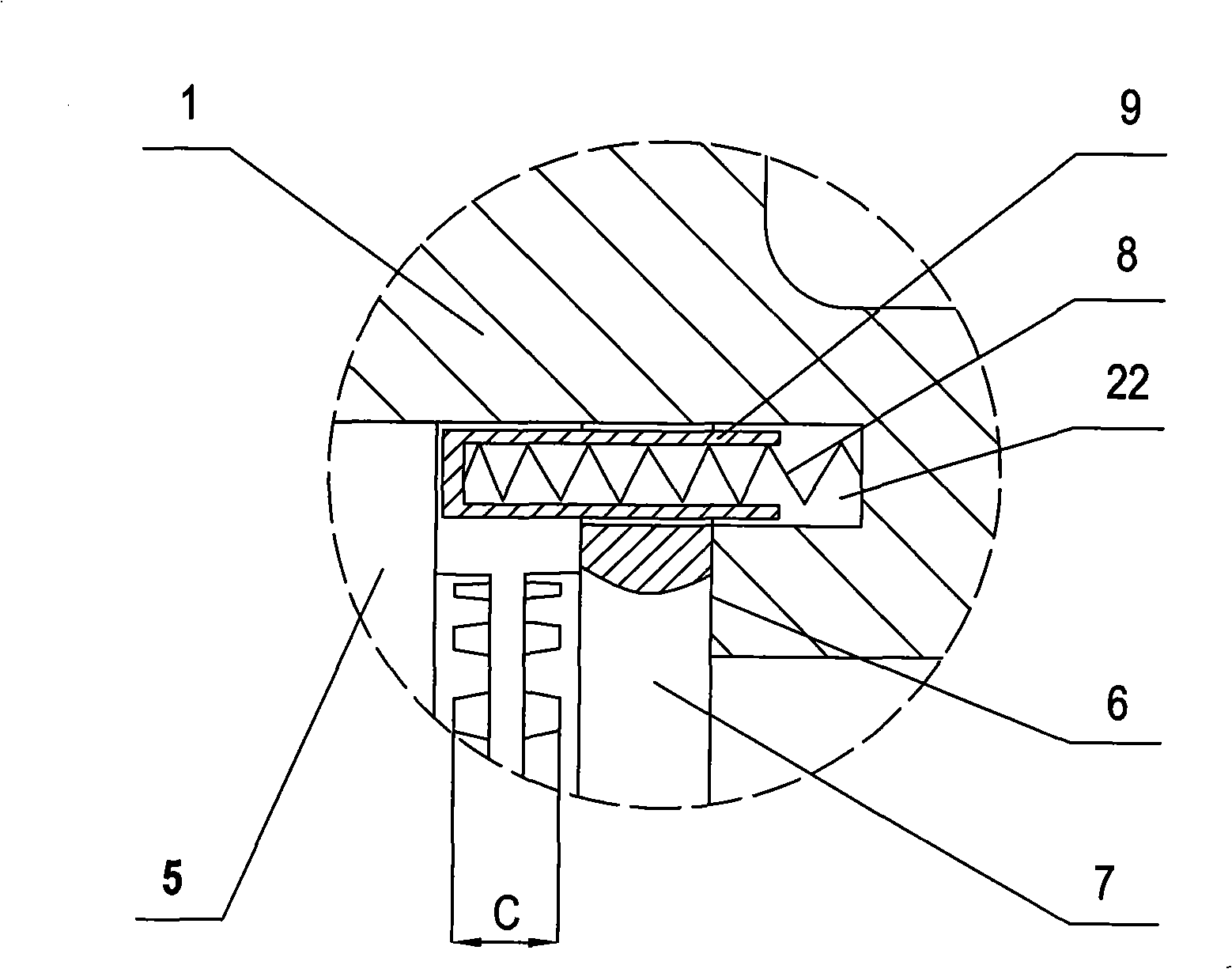

Crystallizing tank for boiling sugar

InactiveCN102676704AAvoid wear and tearLarge design angleSugar crystallisationBiochemical engineeringSugar

The invention relates to the field of sugar-producing devices and particularly relates to a crystallizing tank for boiling sugar which is smooth in operation, good in sealing performance, good in massecuite circulation, uniform in concentration, little in sugar crystal grain abrasion and capable of effectively saving the time of sugar boiling. The crystallizing tank comprises a tank body (1), wherein an evaporator (2) is arranged inside the tank body (1), a discharging port (3) is arranged at the bottom of the tank body (1), a feeding port (4) and a blow-down pipe (5) are arranged on the side wall of the tank body (1), and a driving device is arranged on the upper portion of the tank body (1) through a supporting seat (6); a heating chamber is arranged on a position inside the tank body (1), the position corresponds to the evaporator (2), and an evaporating chamber is arranged on the upper portion of the evaporator (2); the heating chamber is provided with and respectively communicated with a steam input pipe (7) and a seed input pipe (8); the driving device is connected with a main shaft (9) extending to the inside of the tank body (1); a forced-circulation blade (10) arranged inside the center of the evaporator (2) is installed at the end of the main shaft (9) which extends to the inside of the tank body (1); and one side of the supporting seat (6) is connected with a vacuum tube (11).

Owner:郑凯锋

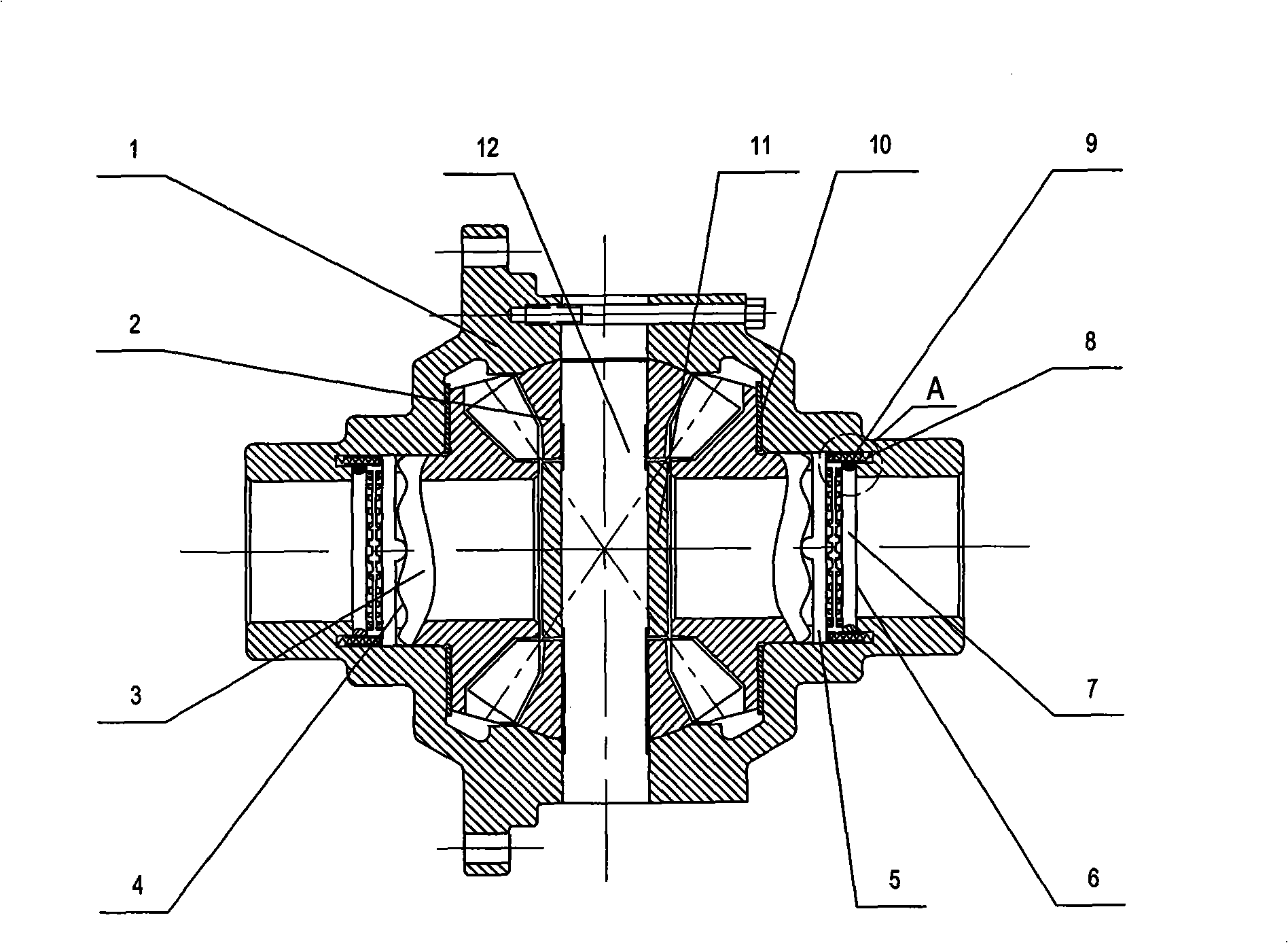

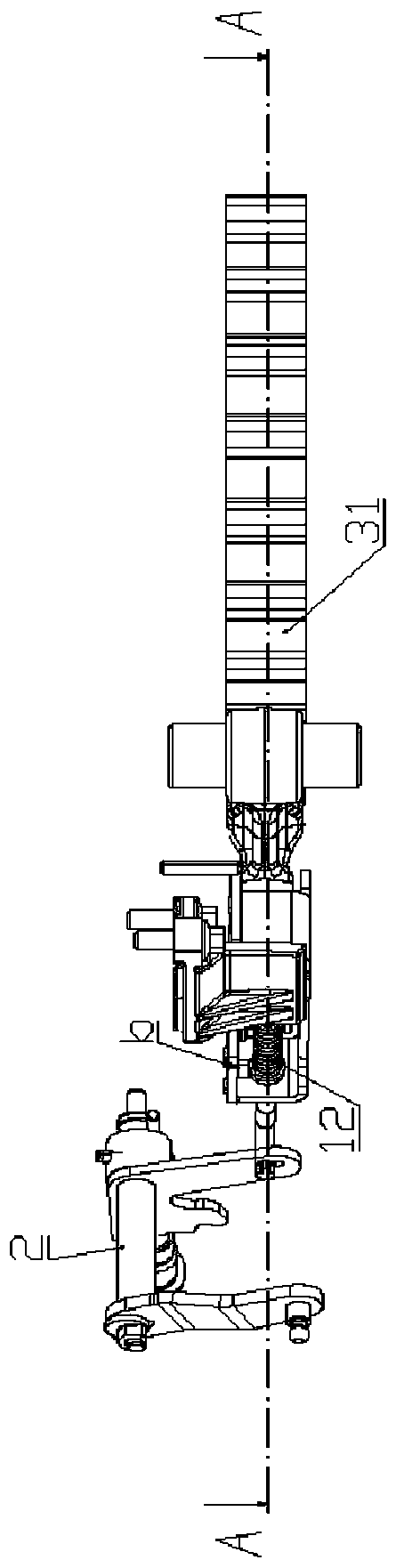

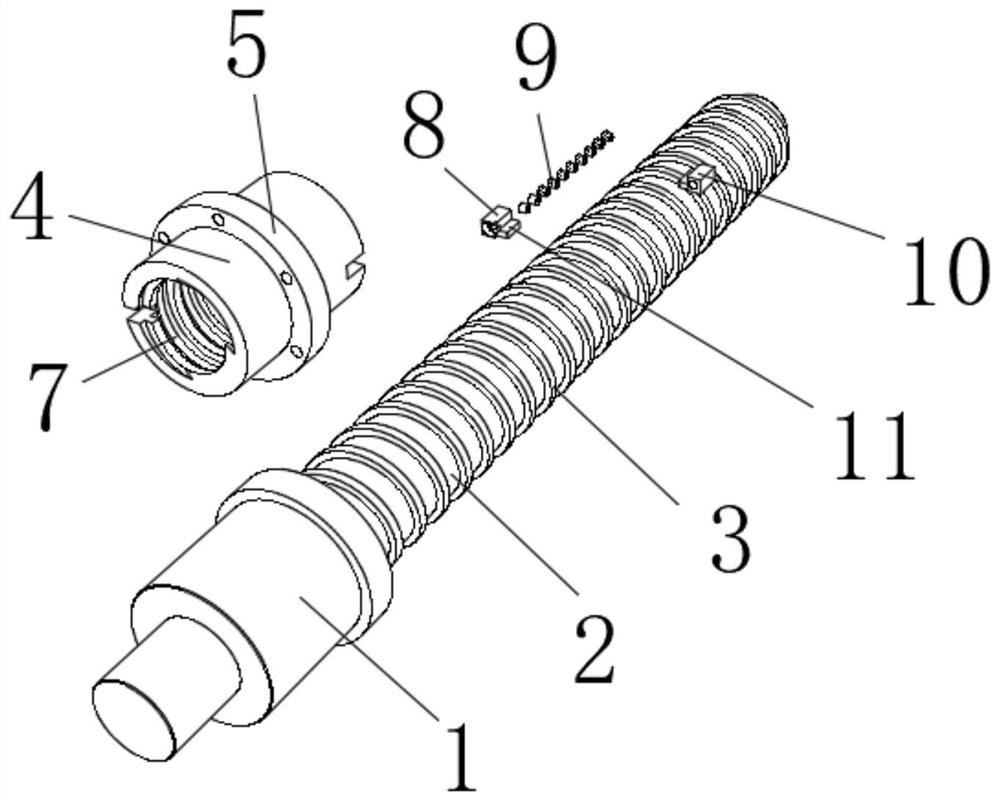

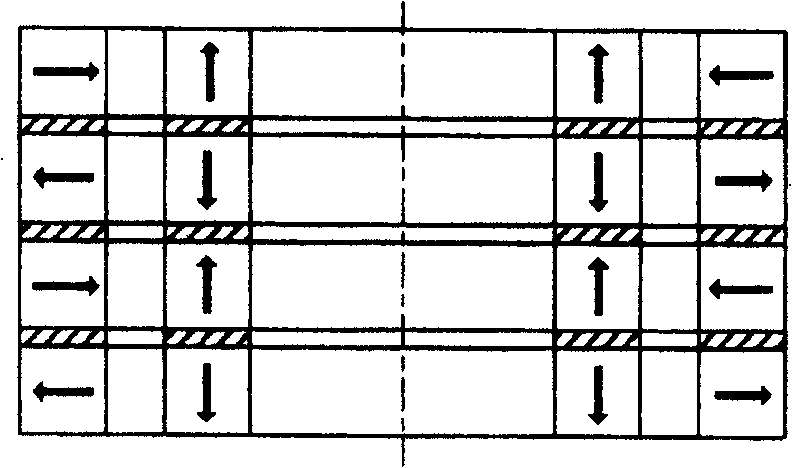

Transmitting ratio variable slip-limiting speed differentiator

InactiveCN101265965ASimple structureSimple mechanical structureDifferential gearingsControl devicesDifferentiatorGear wheel

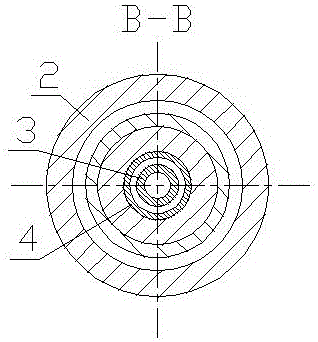

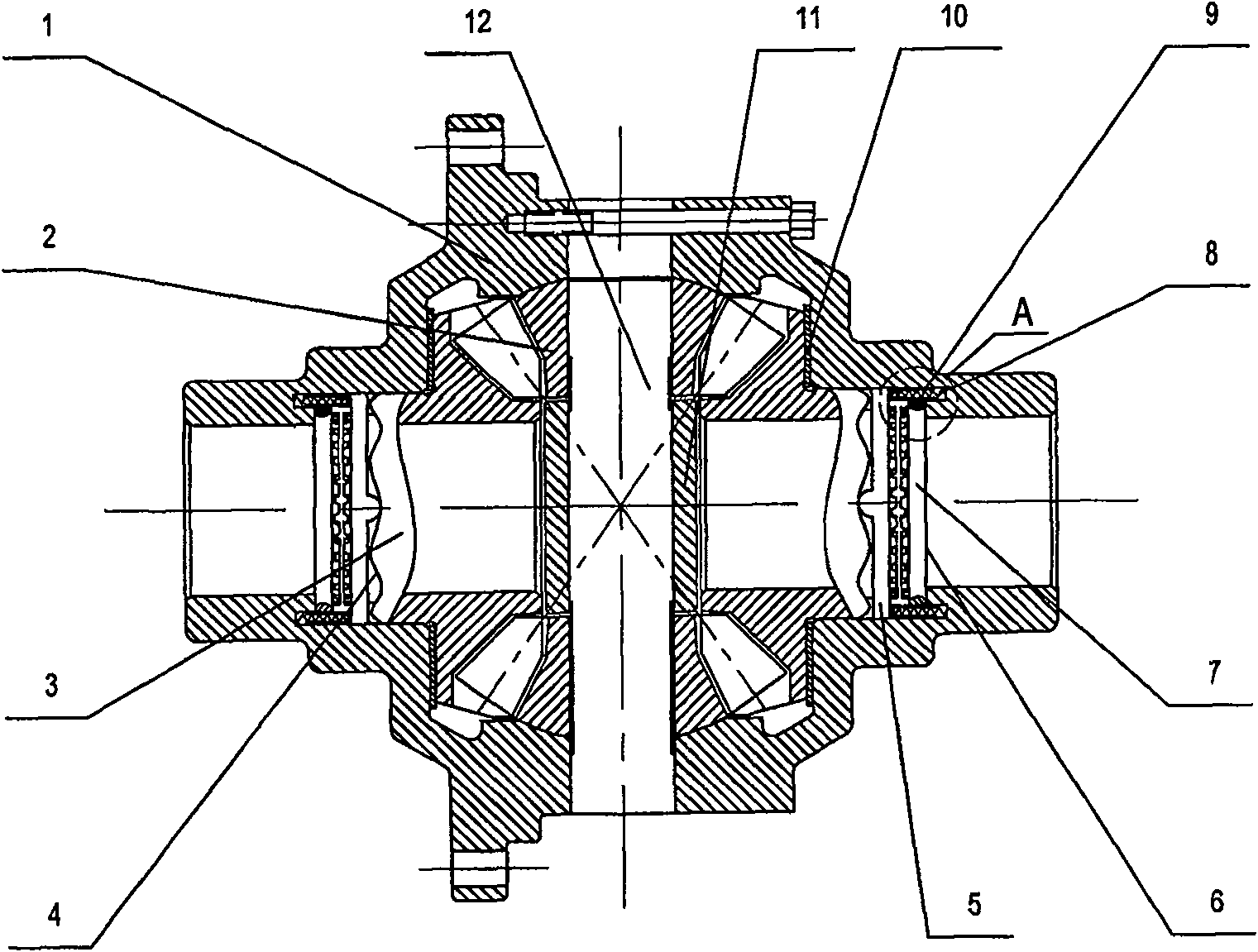

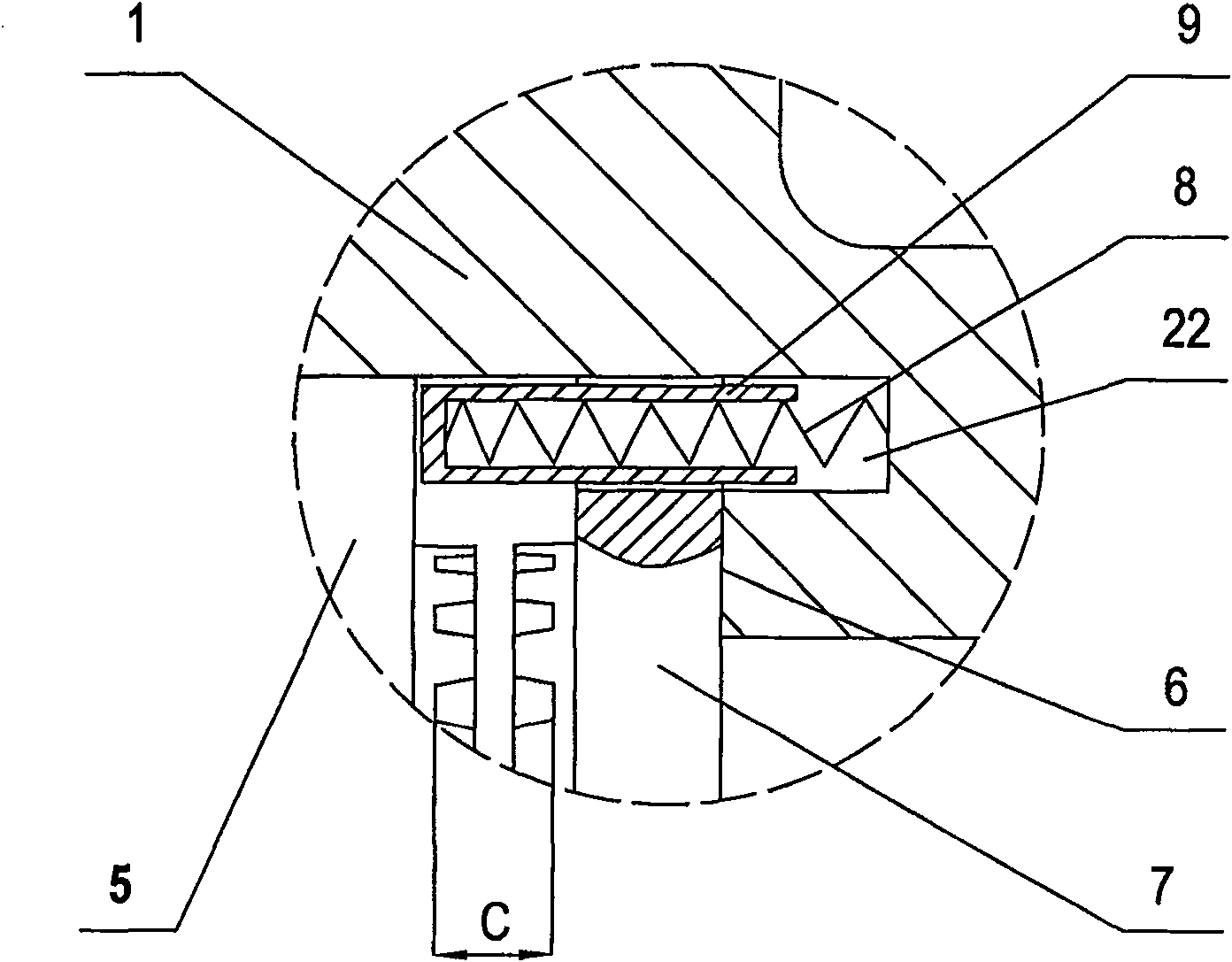

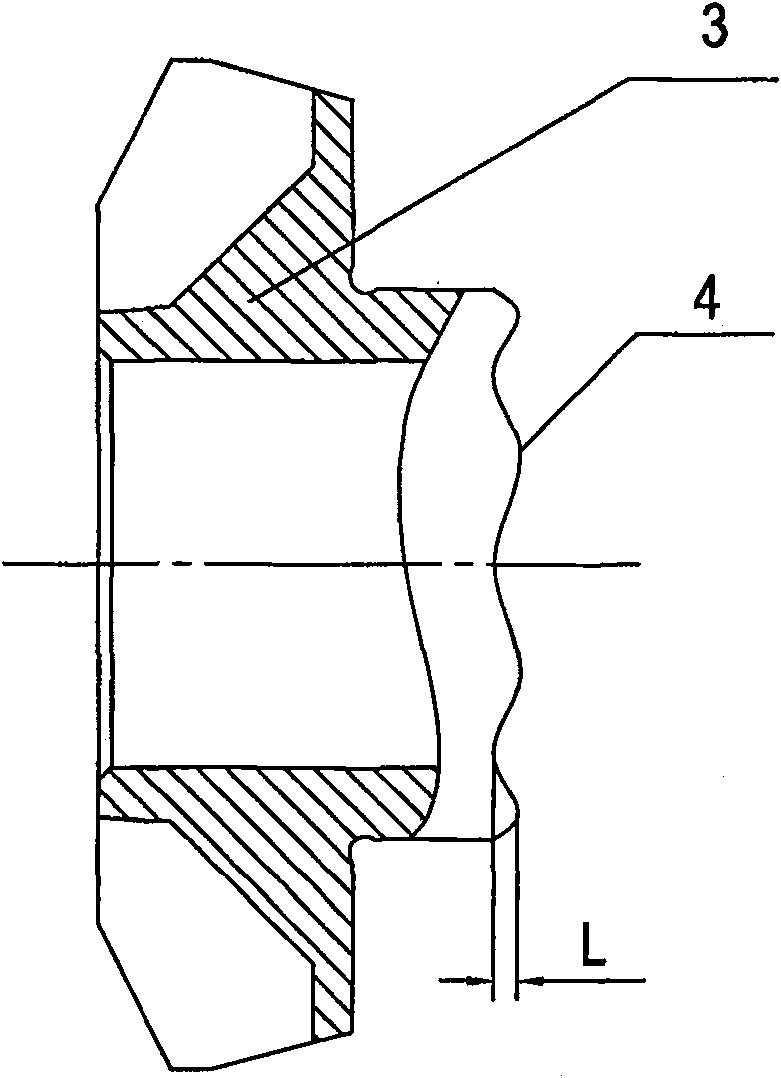

The invention relates to a variable transmission ratio limited-slip differential with self-locking function, which comprises a differential case (1), a variable transmission planet gear (2) and a differential side gear (3) arranged in the differential case, a cam ring (5), a locking ring (7), a returning spring (8) and a spring shield (9) arranged between a back end face (4) of the differential side gear and the back end face (6) of the differential case, a friction plate (10) arranged on outside the differential side gear (3), a central block (1) and a cross shaft (12) arranged in the middle of the differential. The parts constitute a self-locking mechanism. The invention provides a limited-slip differential which can realize self-locking on an extreme road and be automatically unlocked when coming off the extreme road, thereby improving the trafficability and the safety of vehicles. The variable transmission ratio limited-slip differential is particularly suitable for cross-country vehicles and various wheeled engineering machinery, such as dump trucks, wheel loaders, bulldozers and so on.

Owner:BEIJING JIAOTONG UNIV

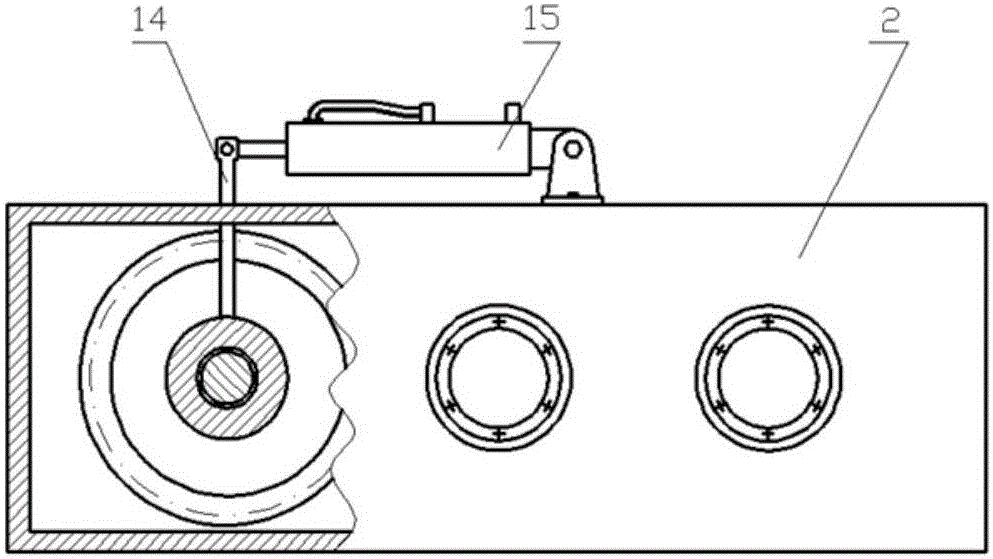

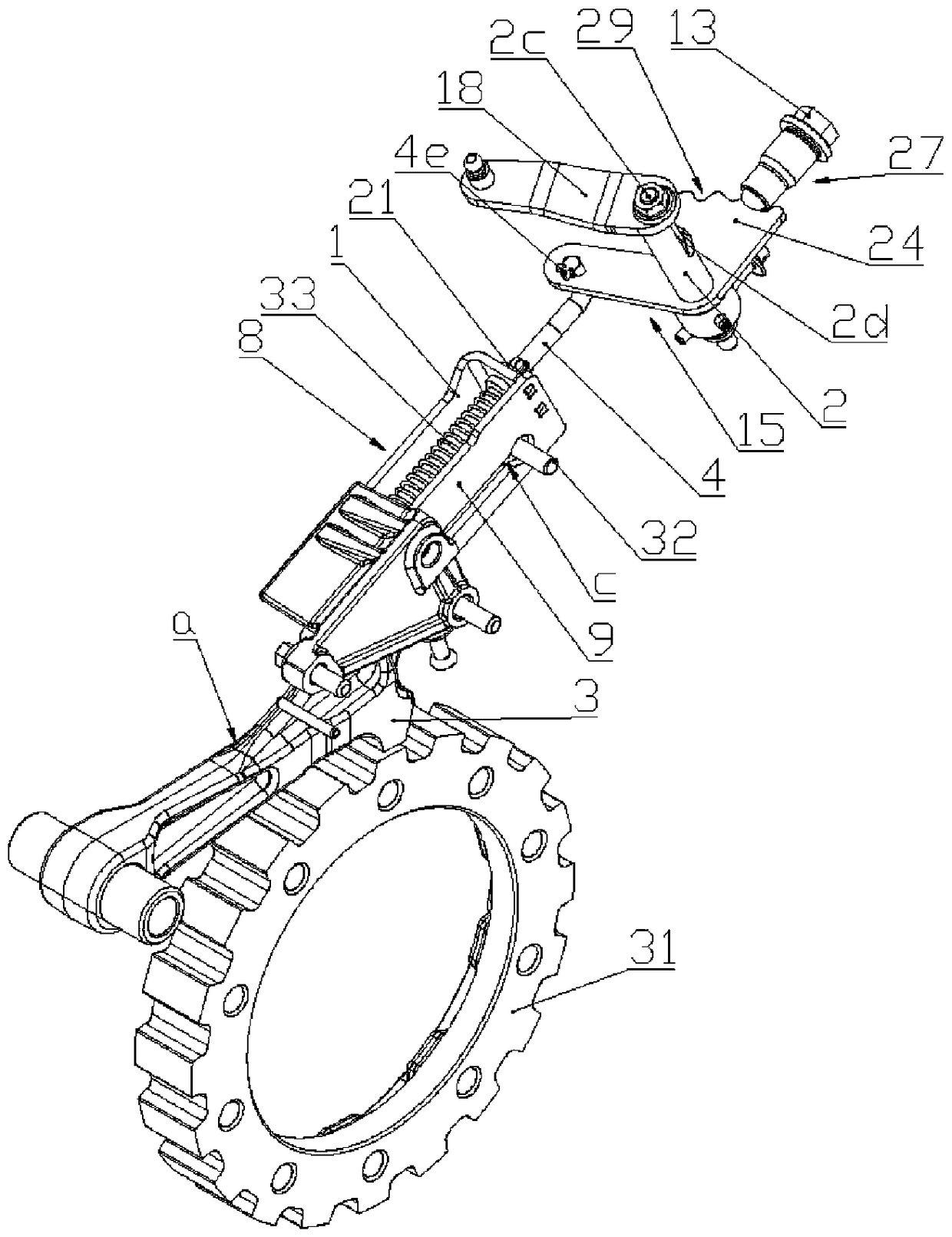

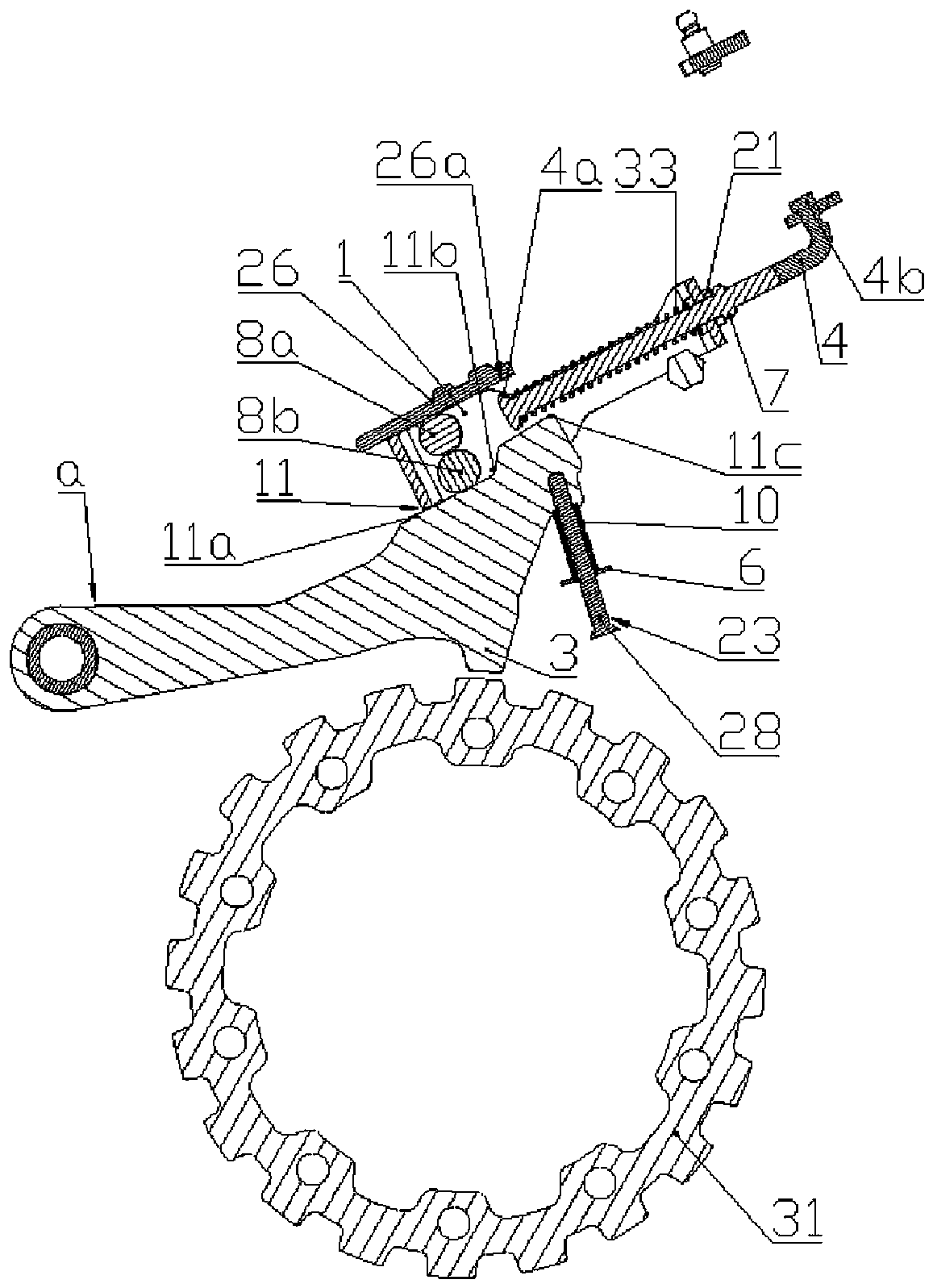

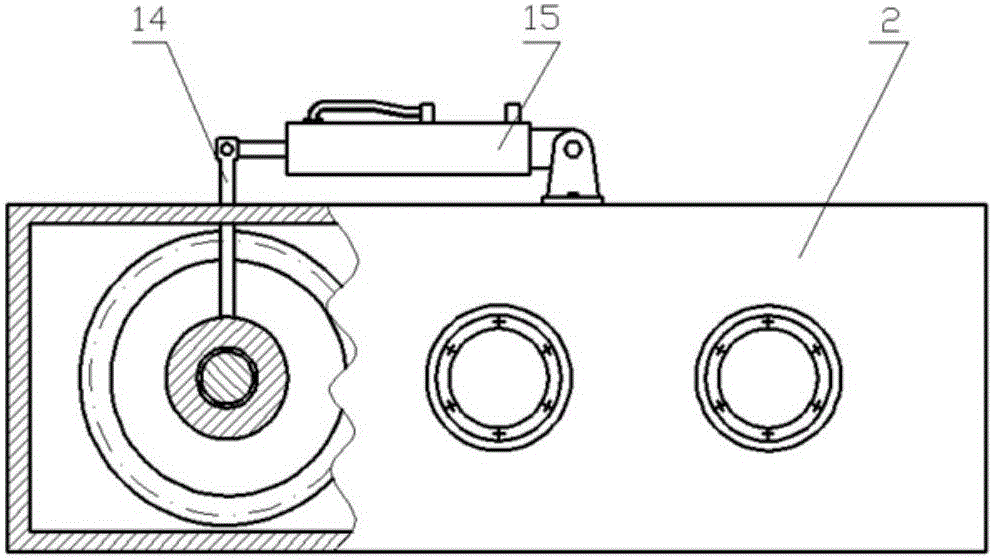

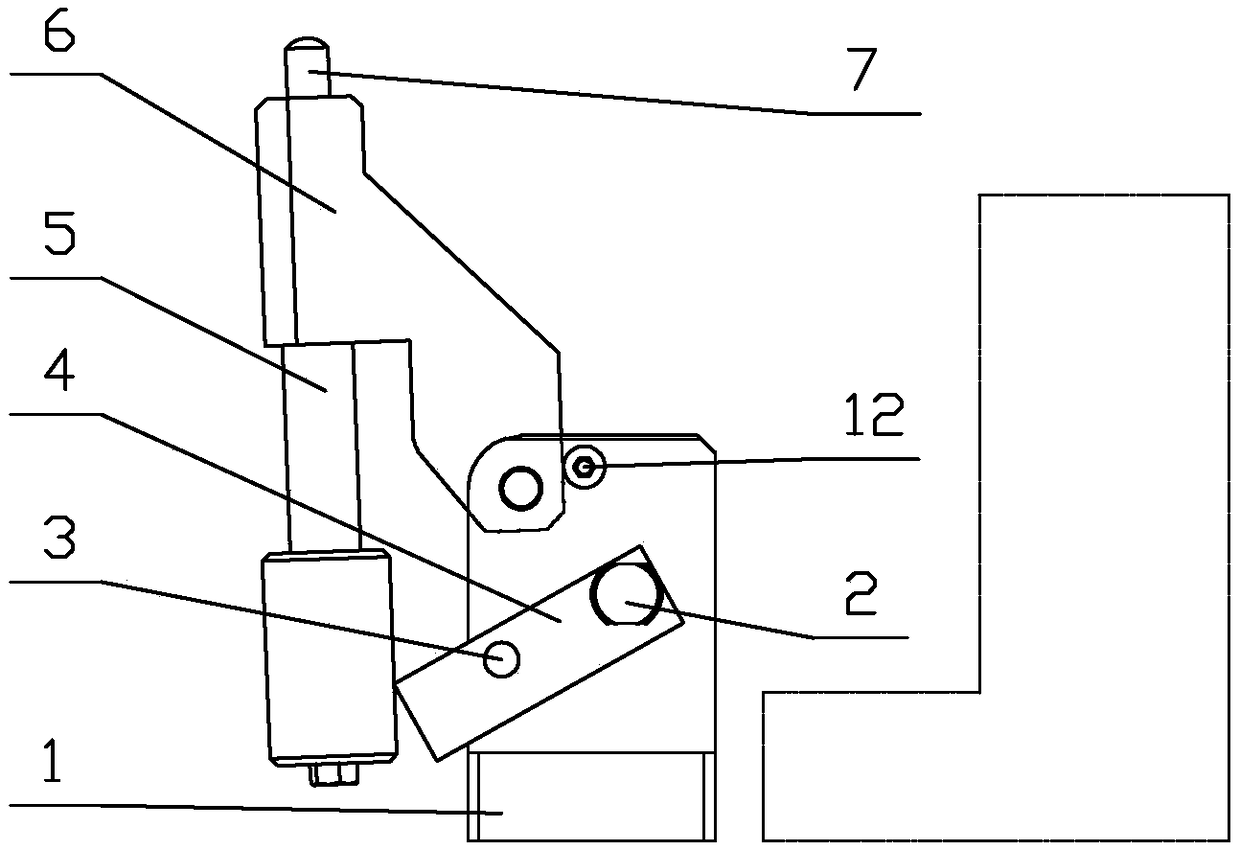

Automatic transmission mechanical parking mechanism

The invention relates to an automatic transmission mechanical parking mechanism. The automatic transmission mechanical parking mechanism comprises a parking ratchet wheel circumferentially fixed to atransmission shaft system. A gear shifting rotary shaft is arranged on a transmission box. One end of the gear shifting rotary shaft is fixedly connected with a gear shifting rotary arm, and the otherend of the gear shifting rotary shaft is fixedly connected with a parking rotary arm. The parking rotary arm is in an L shape. The short arm end of the L-shaped parking rotary arm is provided with sectored teeth. An elastic compression lock pin is arranged on the transmission box. The long arm end of the L-shaped parking rotary arm is hinged to a parking push-pull rod. The extension end of the parking push-pull rod is inserted into a parking driving frame which is in sliding fit with the transmission box. The extension end, inserted into the parking driving frame, of the parking push-pull rodis sleeved with a push rod compression spring. One end of the push rod compression spring is limited by a convex edge of the extension end of the parking push-pull rod, and the other end of the pushrod compression spring is limited by an end plate of the parking driving frame. A first roller makes rolling contact with the lower end face of a guide plate, and a second roller makes rolling contactwith the free end of a parking detent. The transmission box is provided with a reset device corresponding to the free end of the parking detent.

Owner:CHONGQING TSINGSHAN IND

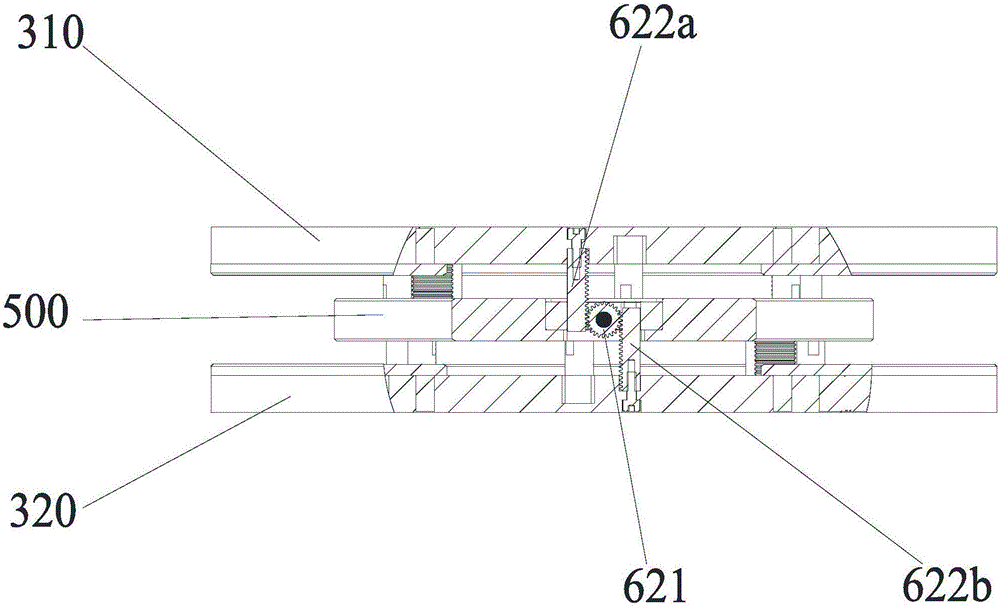

A cone-disk continuously variable transmission

Owner:CHANGZHOU DONGFENG CVT

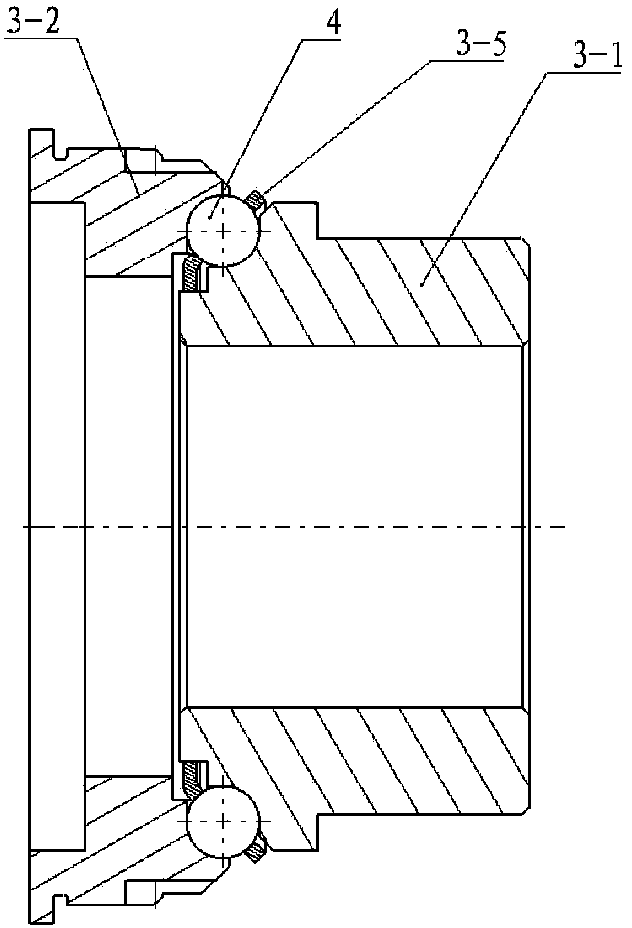

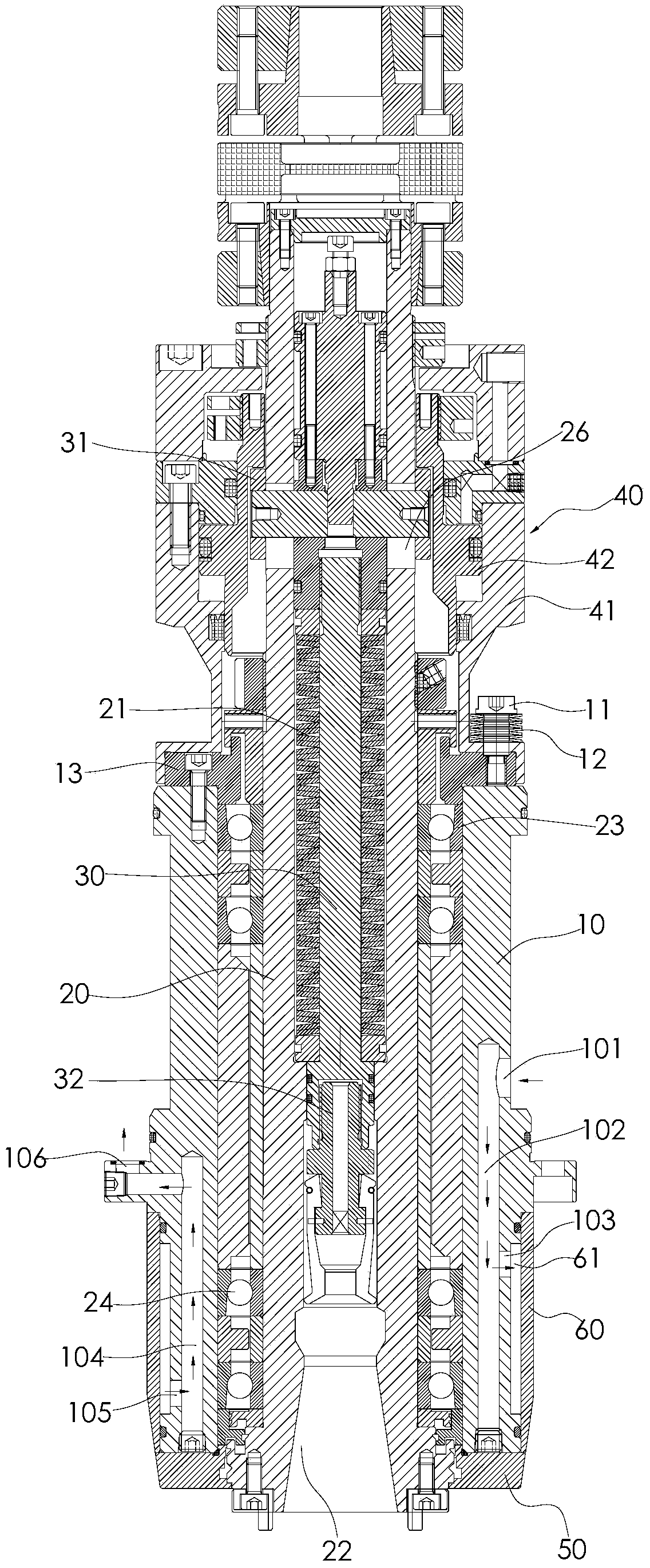

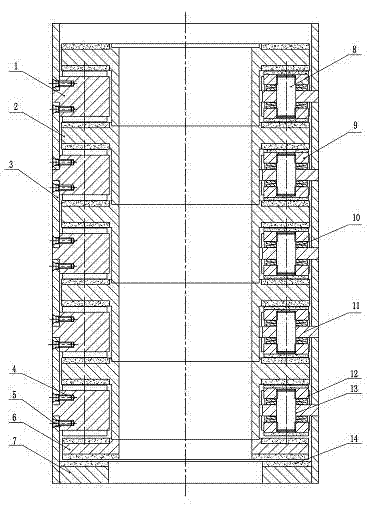

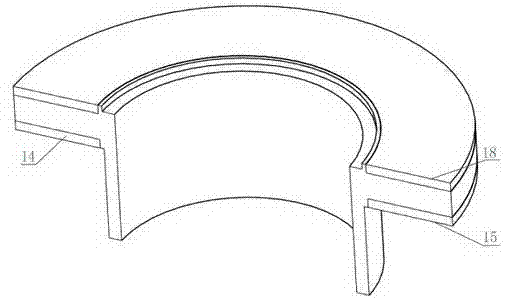

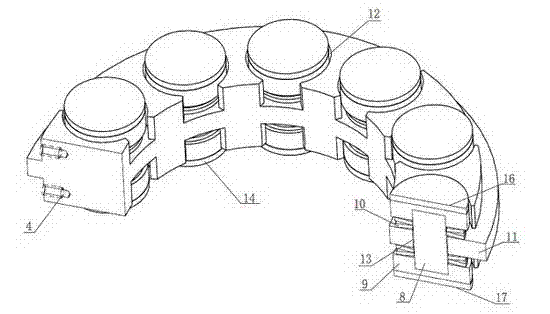

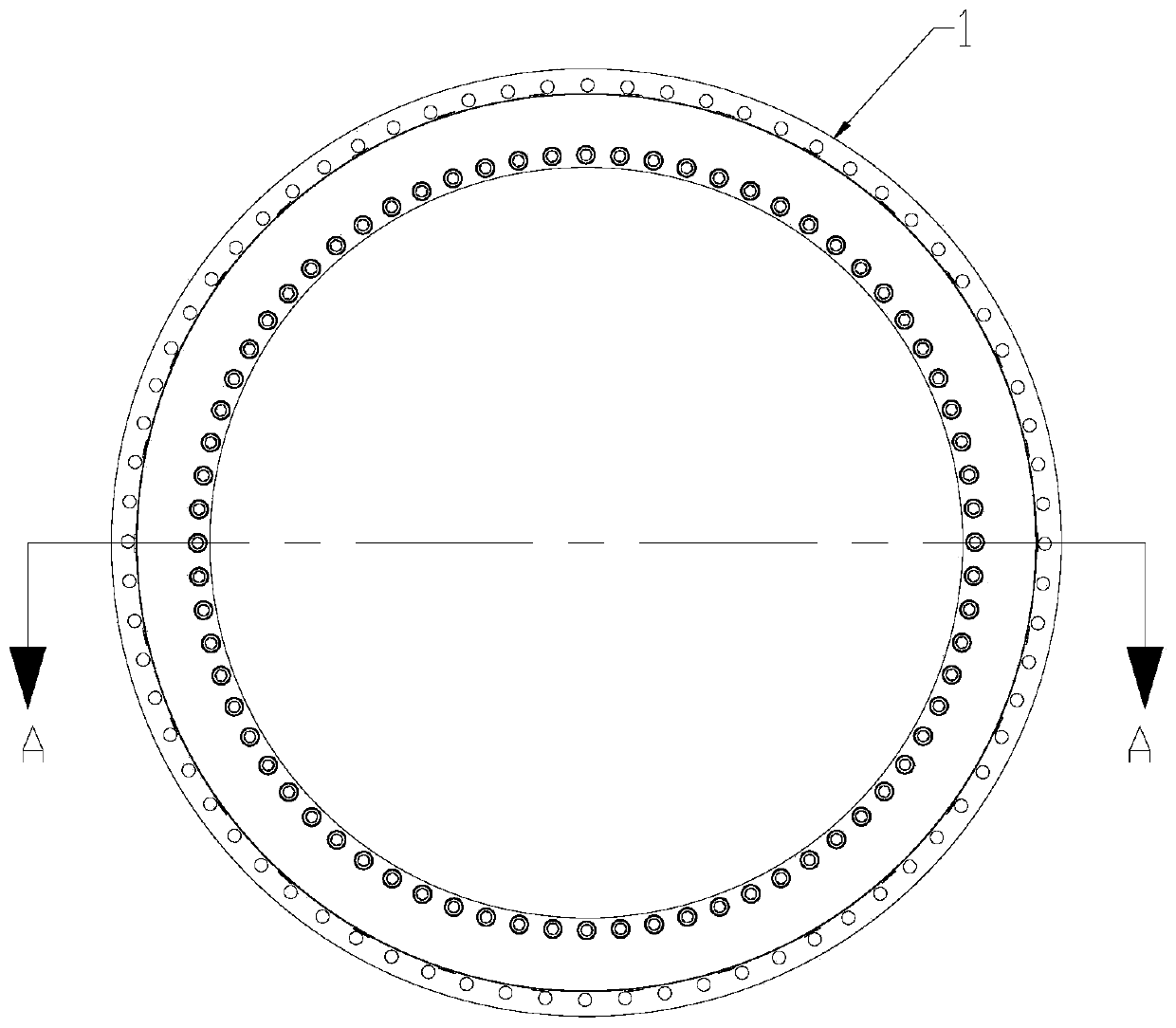

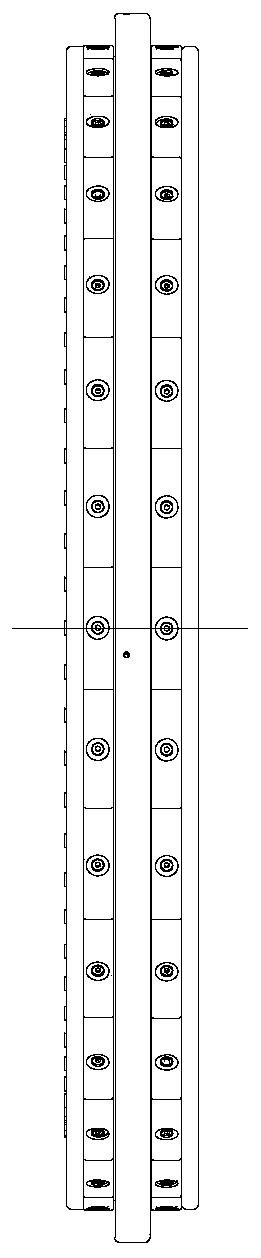

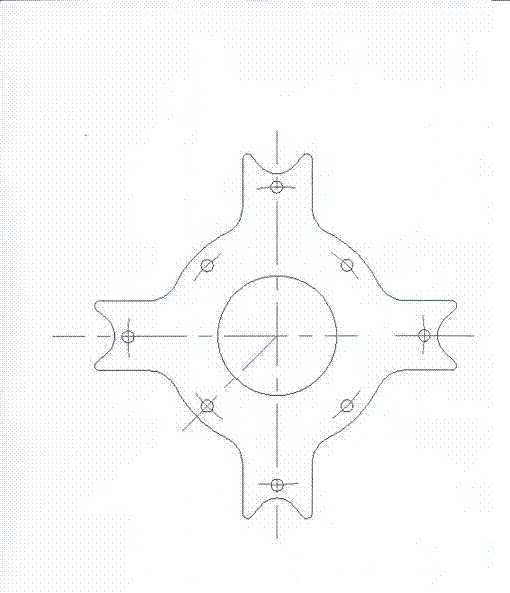

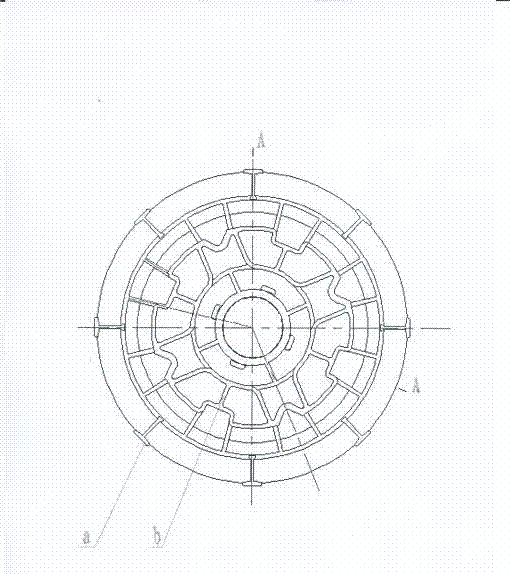

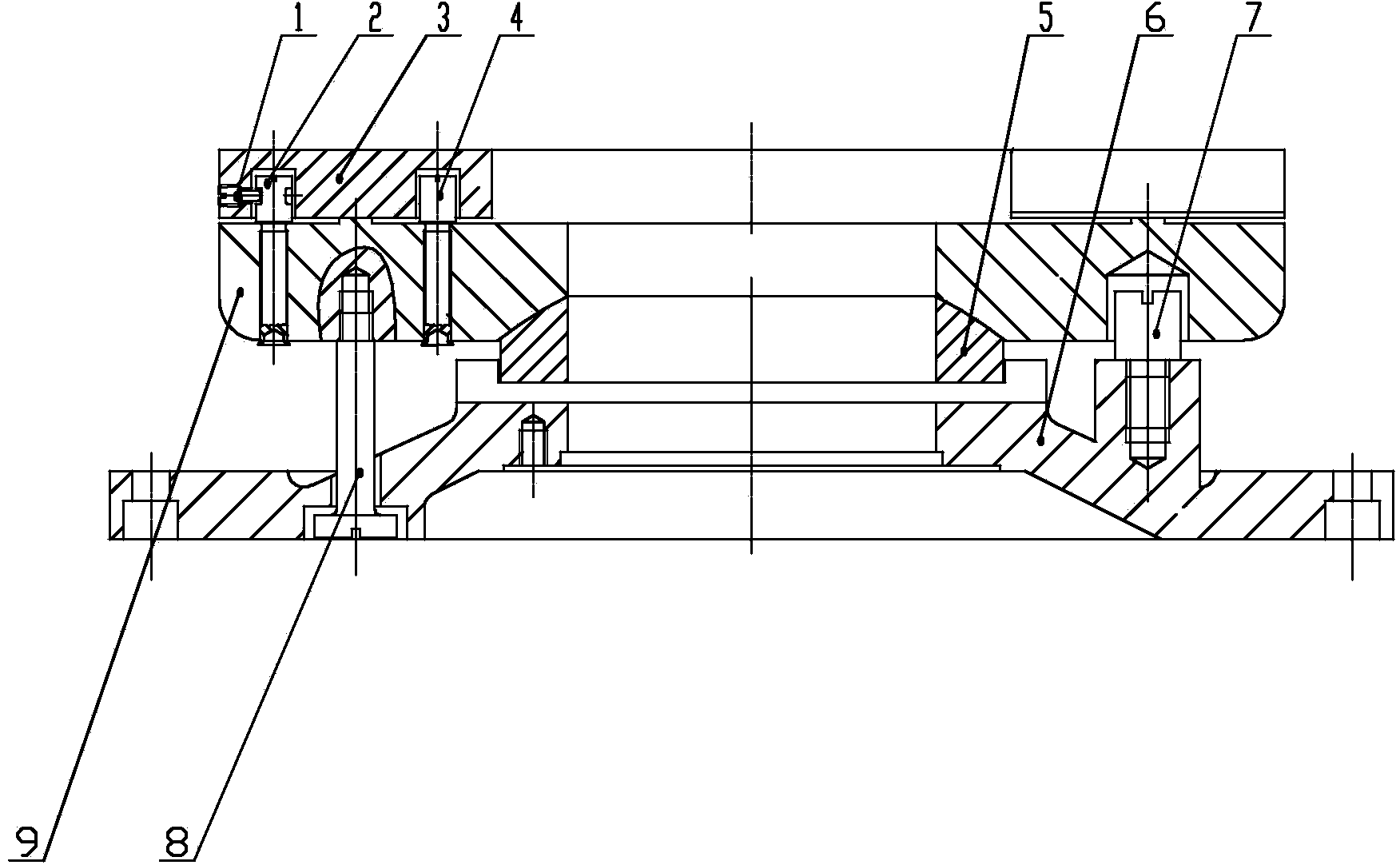

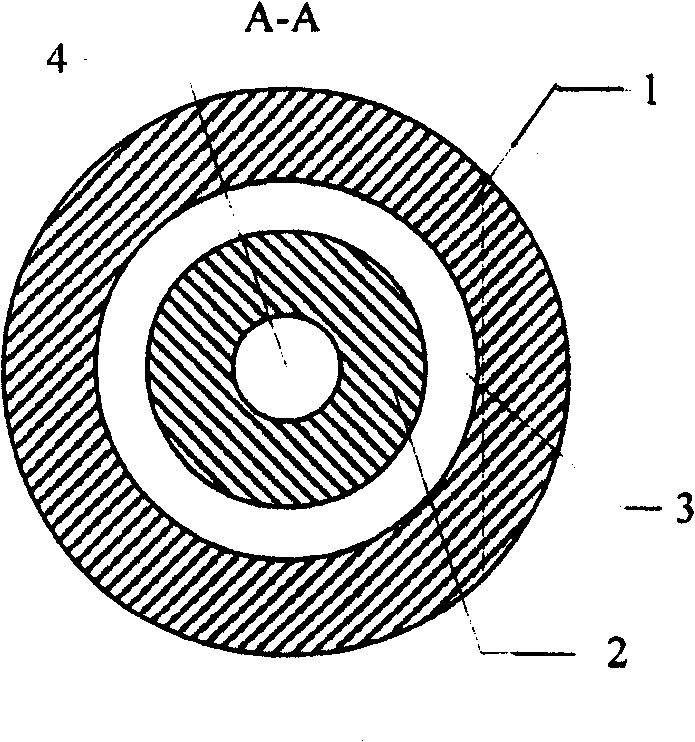

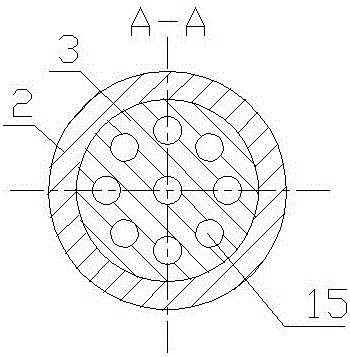

Uniform-load thrust sliding bearing group for downhole power drilling tools

InactiveCN102537032AUniform load distributionAvoid damageBearing componentsSliding contact bearingsStructural engineeringOil drilling

The invention relates to a uniform-load thrust sliding bearing group for downhole power drilling tools, belonging to the technical field of downhole equipment for oil drilling. The uniform-load thrust sliding bearing group is mainly composed of a static ring, a moving ring, an outer sleeve, an overload protection moving ring and an overload protection static ring; wherein the static ring is composed of a connection stud, a thrust pad, a disk spring and a static ring base; 10-16 counter bores are uniformly distributed in the circumferential directions of the positive and negative surfaces of the static ring base; through holes are arranged at the centers of the counter bores; the connection stud passes through the through holes to be in threaded connection with the thrust pad so as to fix the disk spring between the thrust pad and the static ring base; the disk spring is arranged in a shutting form; 3-8 threaded holes are distributed on the static ring base in the radial direction; the static ring base and the outer sleeve are fixed together by a bolt; and the moving ring and the static ring are connected in series to form the bearing group. According to the uniform-load thrust sliding bearing group, drilling fluid dynamic pressure lubrication can be formed, so that the abrasion of friction surfaces is decreased; the friction surface is made of high-temperature ceramic abrasion resistant materials and has the characteristics of abrasion resistance and corrosion resistance; and the bearing group has a compact structure, so that the mounting, the overhauling and the change of the bearing group are simplified.

Owner:SOUTHWEST PETROLEUM UNIV

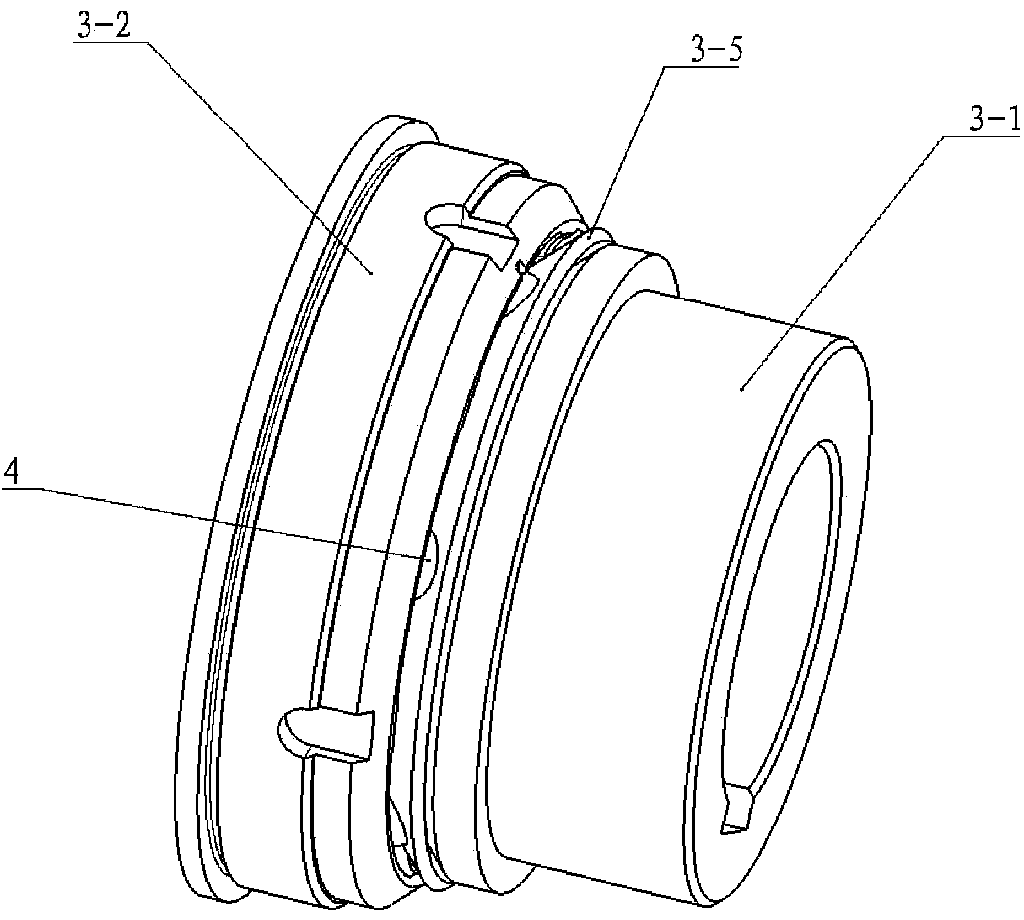

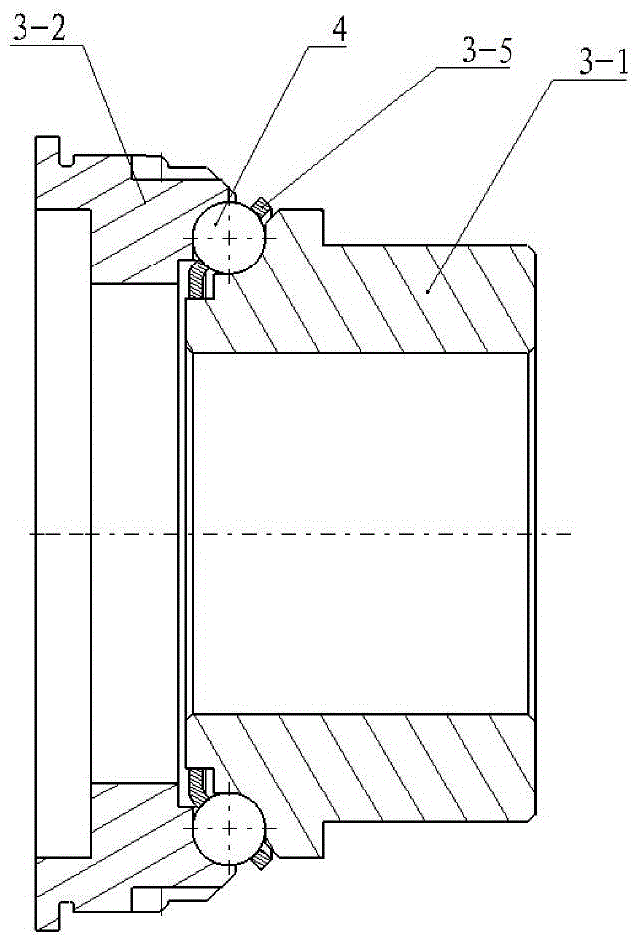

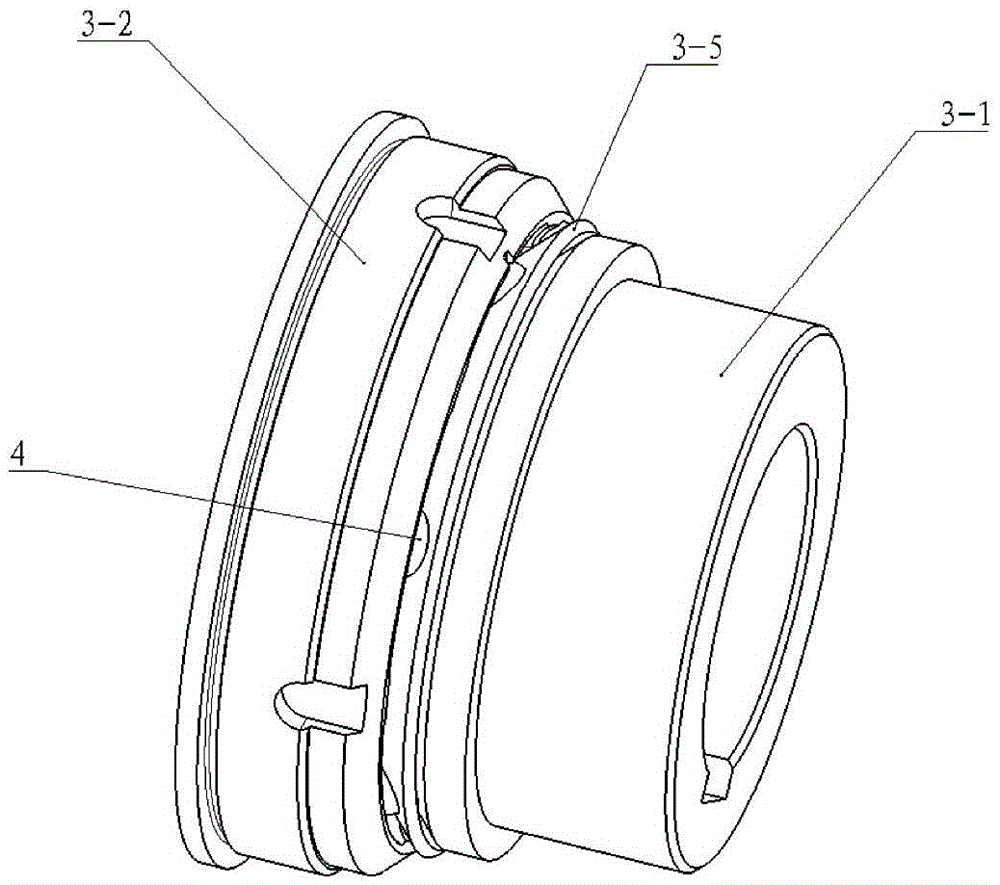

Precise combination bearing with adjustable pre-tightening force

PendingCN110566577ASmooth runningHigh precisionBall and roller bearingsBearing componentsEngineeringMechanical engineering

The invention relates to a precise combination bearing with adjustable pre-tightening force. The precise combination bearing with adjustable pre-tightening force comprises a small inner ring, a largeinner ring, an outer ring, an axial retainer, axial rollers and a radial roller, wherein the small inner ring is arranged on the small inner ring; the axial rollers are tapered rollers, and the linearspeeds of the two ends of each axial roller are consistent; tapered grooves matched with the axial rollers in size and shape are formed in the axial retainer; the axial rollers are mounted in the tapered grooves; the surfaces, correspondingly contacted with the axial rollers, of the small inner ring and the large inner ring are inclined surfaces matched with the tapered surfaces of the axial rollers; the outer end of each axial roller is provided with a pre-tightening device capable of adjusting pre-tightening force, and the pre-tightening devices are arranged outside the axial retainer; theradial roller is a spherical roller; each pre-tightening device comprises a piston, a spring and a small threaded plug; and the springs are connected with the axial rollers through small ball bodies.The precise combination bearing with the adjustable pre-tightening force has the advantages of high transmission rigidity, stable transmission, convenient mounting, high precision of machine operationand the like, and is not influenced by the speed difference of long-time operation.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

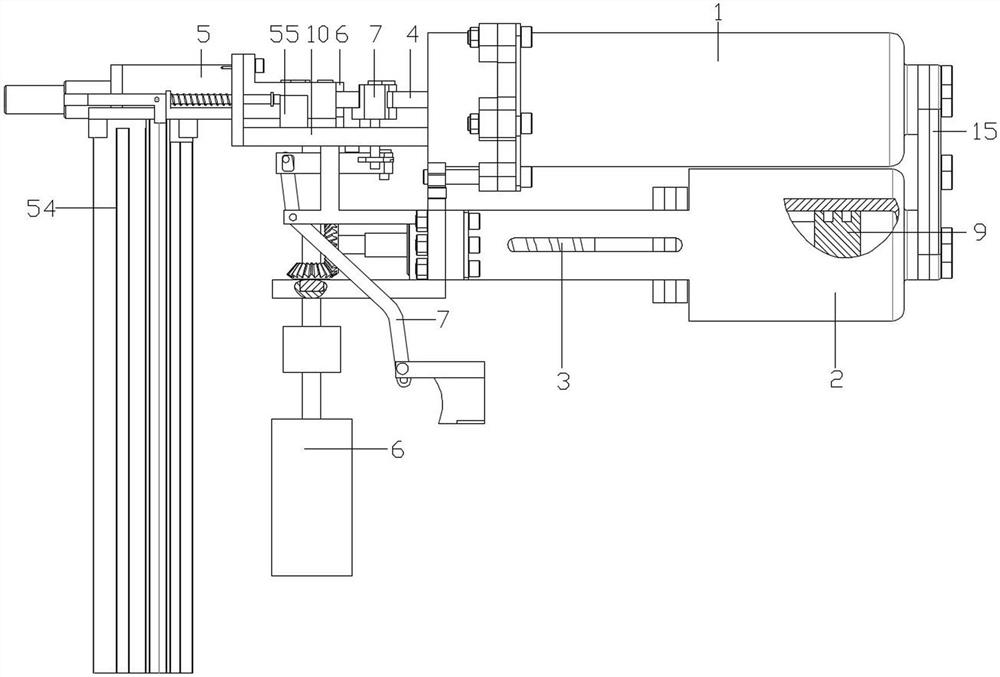

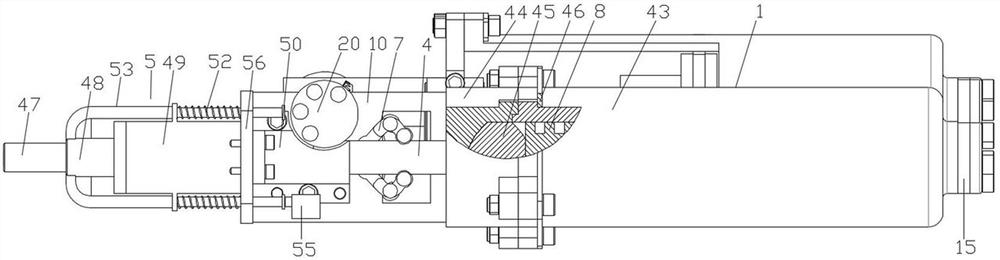

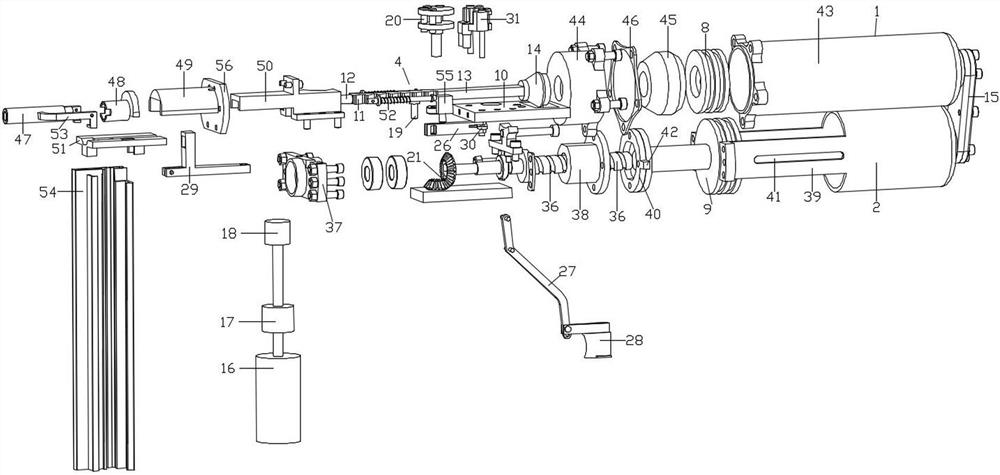

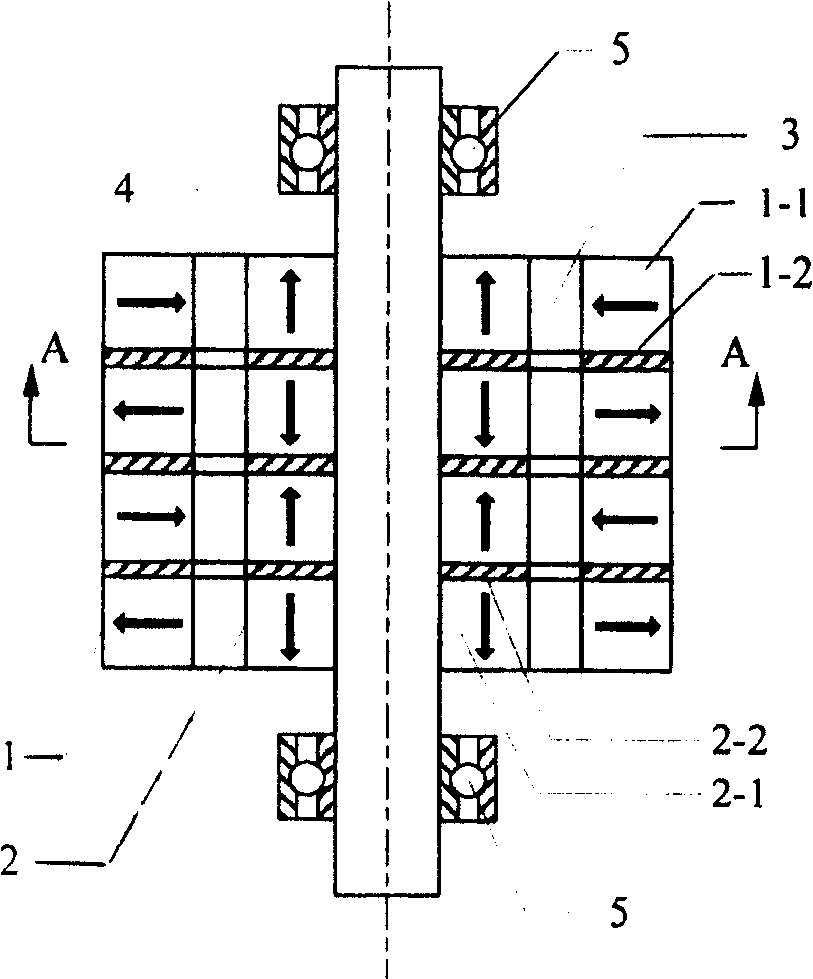

Horizontal type oil-cooled permanent magnetic speed regulator

The invention discloses a horizontal type oil-cooled permanent magnetic speed regulator. The horizontal type oil-cooled permanent magnetic speed regulator comprises an external rotor connected with a first shaft, an internal rotor connected with a second shaft and a speed regulating mechanism connected with the internal rotor, and the first shaft and the second shaft are horizontally arranged; a third rotor disc is fixedly connected with the speed regulating mechanism; and the speed regulating mechanism comprises a speed regulating portion bearing pedestal and a worm gear assembly, the horizontal type oil-cooled permanent magnetic speed regulator further comprises a casing, and the casing is provided with a cooling coil inlet and an oil outlet. According to the invention, the worm gear assembly is adopted, the worm gear assembly can generate larger axial thrust, the precision is higher, the delay is smaller, accurate control can be realized, the worm gear assembly adjusts axial displacement of the rotors by use of a thread sleeve with a threaded structure, and the requirement for accurately adjusting an air gap is realized.

Owner:ANHUI WOLF POWER TECH

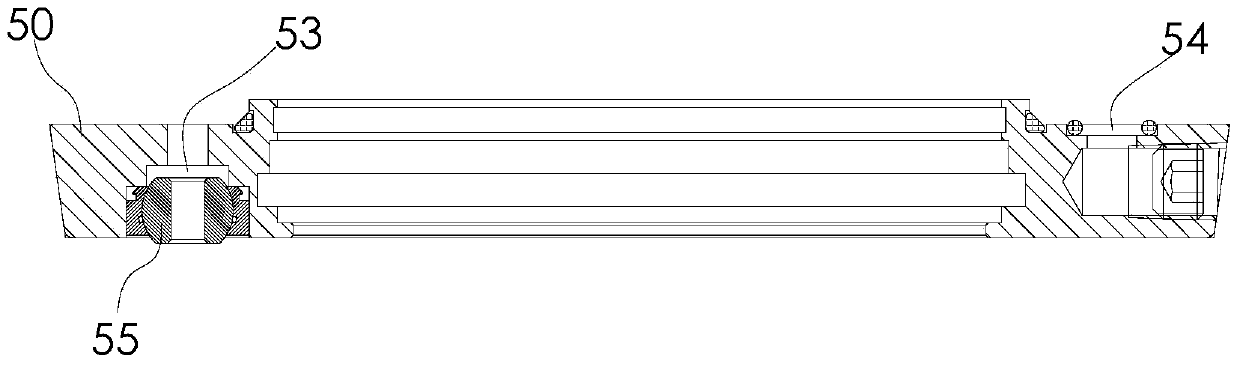

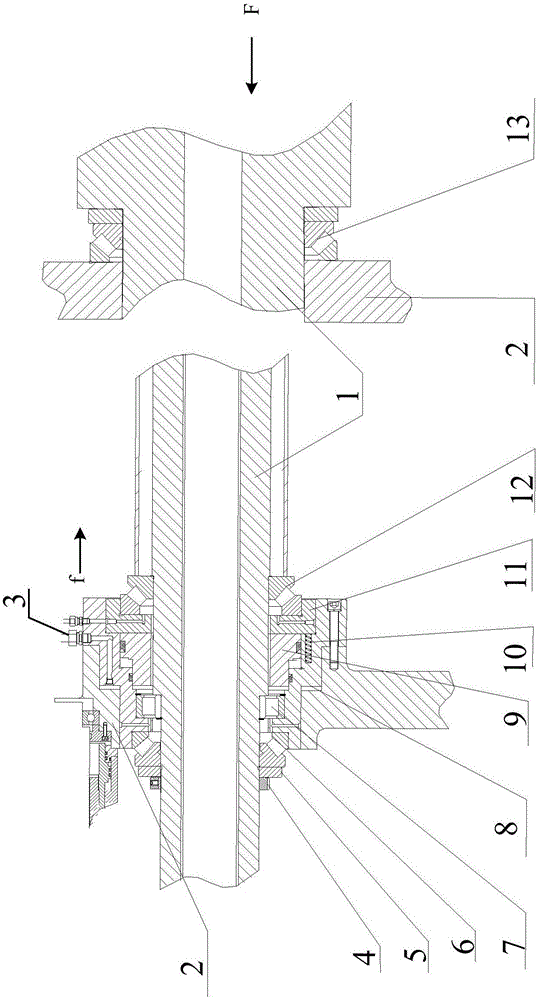

Friction welding machine and spindle force balancing assembly thereof

InactiveCN106334871ALarge axial forceLarge axial thrustNon-electric welding apparatusFriction weldingAxial thrust

The invention relates to a spindle force balancing assembly of a friction welding machine. The assembly comprises a spindle and a spindle box and further comprises a balancing device which is assembled on the spindle box and used for exerting axial force on the spindle; and the direction of the force exerted on the spindle by the balancing device is opposite to that of the axial force on the spindle during working. After the balancing device is added, the axial force exerted on the spindle by the balancing device can partially or completely offset the axial force on the spindle during working, so that the axial force on a bearing of the spindle is reduced, and correspondingly, the axial thrust capable of being borne by the friction welding machine is remarkably increased; and meanwhile, the axial force on the spindle is remarkably reduced, and the service life of the bearing of the spindle is correspondingly prolonged. The invention further discloses the friction welding machine provided with the spindle force balancing assembly.

Owner:CHONGQING TURBO FLOW MACHINERY MFG

New-type sheet cutter

InactiveCN1360989ALarge axial thrustEasy to change and adjustNibbling shearing machinesSet screwReciprocating motion

The sheet cutter is used in making sheet product, field decoration, repairing, etc. It consists of frame, eccentric shaft, upper sliding block, lower sliding block, guide sleeve, cutter seat, cutter rod and other parts and features the cutter rod separated into two parts set axially and oppositely and with fixed inner end and moving outer end inside the cutter seat, which is connected to the frame via the symmetrical guide structure. Driven by outer force, the eccentric shaft rotates at high speed to drive via the upper sliding block the upper sliding block and the cutter rod to reciprocate and thus to shear and cut sheet in either linear or curvilinear mode.

Owner:俞岳皋

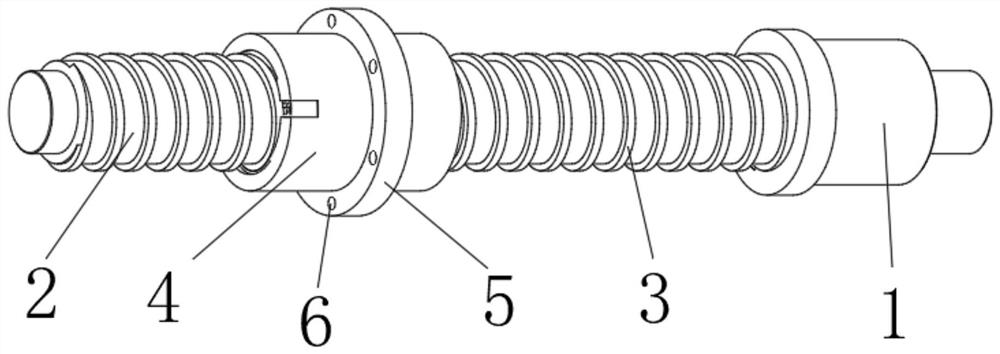

Novel roller lead screw transmission device and using method thereof

The invention provides a novel roller lead screw transmission device and a using method thereof, and relates to the technical field of mechanical transmission parts. The roller lead screw transmission device comprises a mounting base, first threaded grooves which are evenly distributed are fixedly connected to the outer diameter of the periphery of a lead screw, second threaded grooves which are evenly distributed are fixedly connected to the inner wall of the periphery of a nut, and a front reverser and a rear reverser are arranged in the middles of the rear end of the right side and the front end of the left side of the nut respectively. Conical rollers which are uniformly distributed are connected in the second threaded grooves in a sliding manner. The lead screw rotates to drive the nut to move forwards on the lead screw through the first threaded grooves and the second threaded grooves, and meanwhile the conical rollers are driven to circulate in an inner circulation closed loop formed by the lead screw, the nut, the front reverser and the rear reverser, so that the nut moves relative to the lead screw; and the conical rollers serve as transmission media, so that the contact area between the nut and the lead screw is increased, and the device can bear larger axial thrust, and the device is worthy of being vigorously popularized.

Owner:威海市精彩永恒体育用品有限公司

Switchable mechanical coolant pump

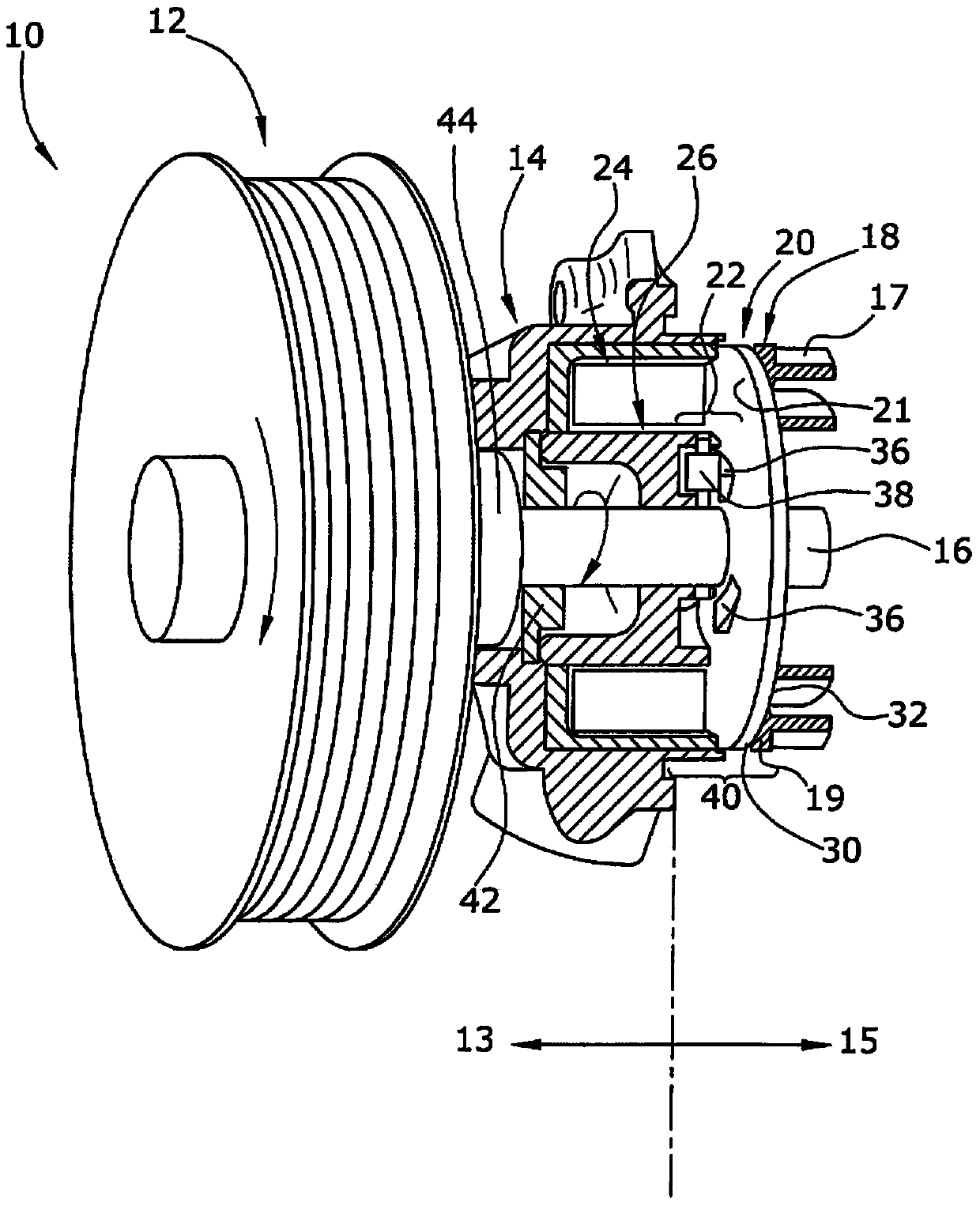

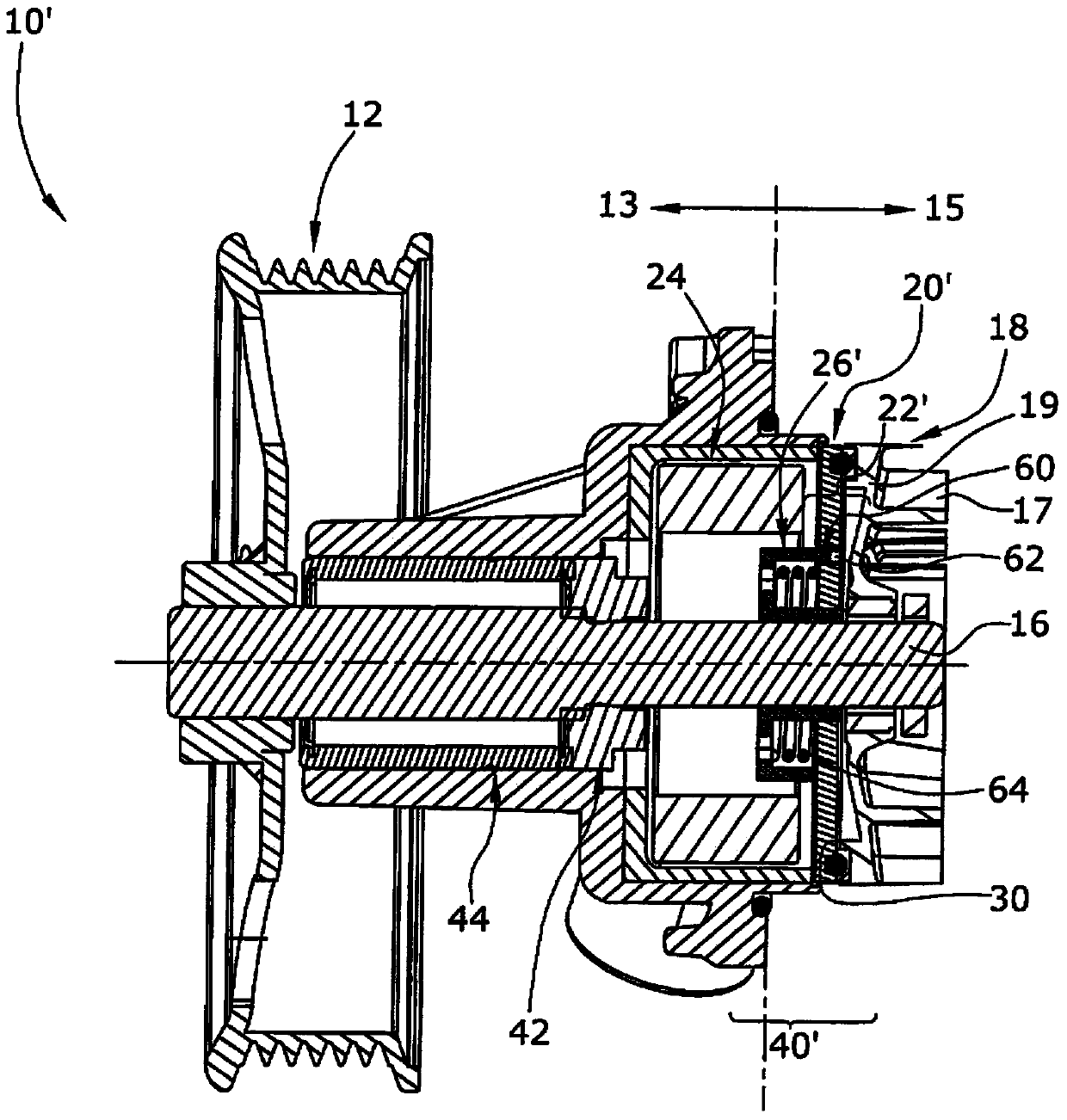

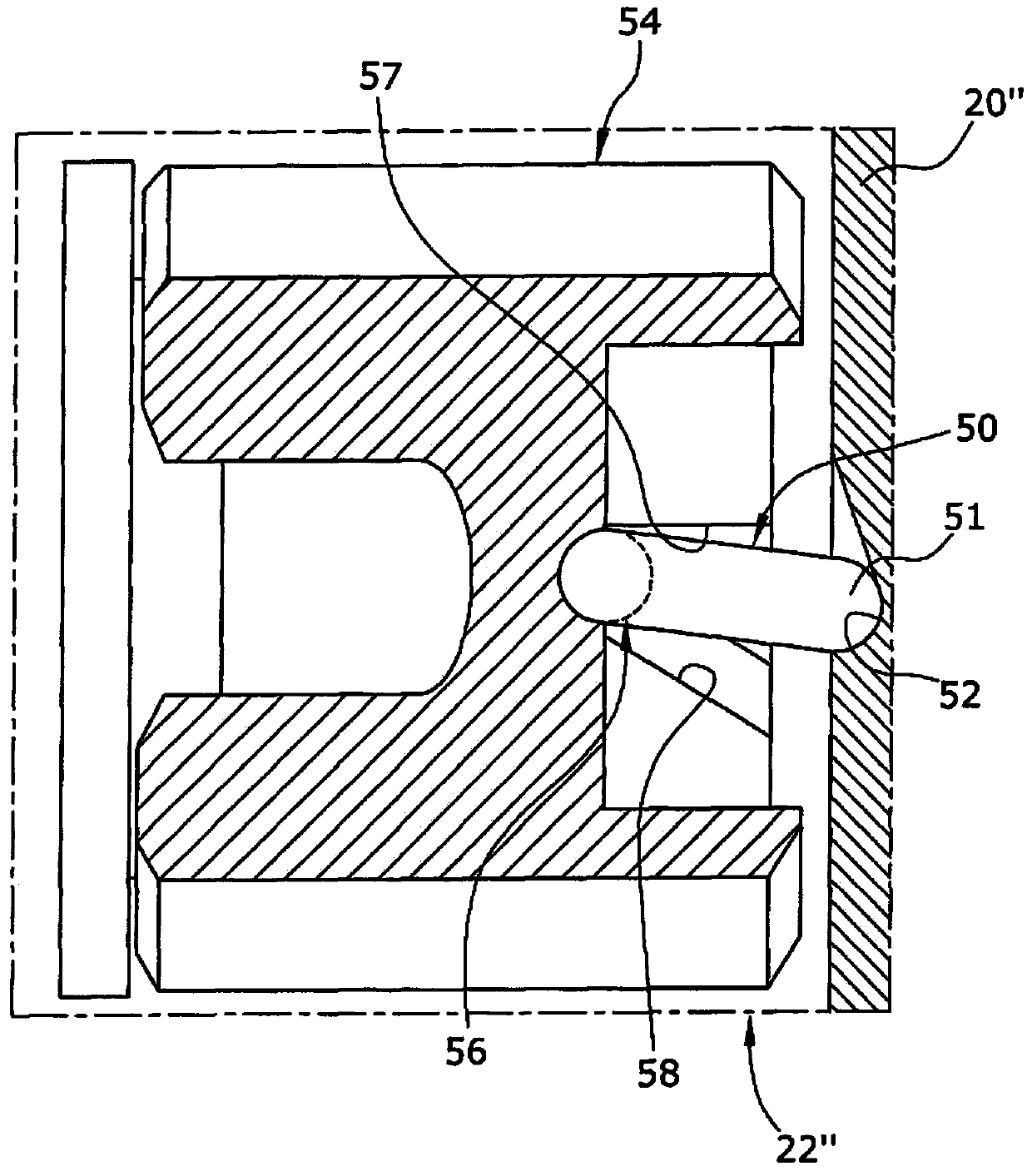

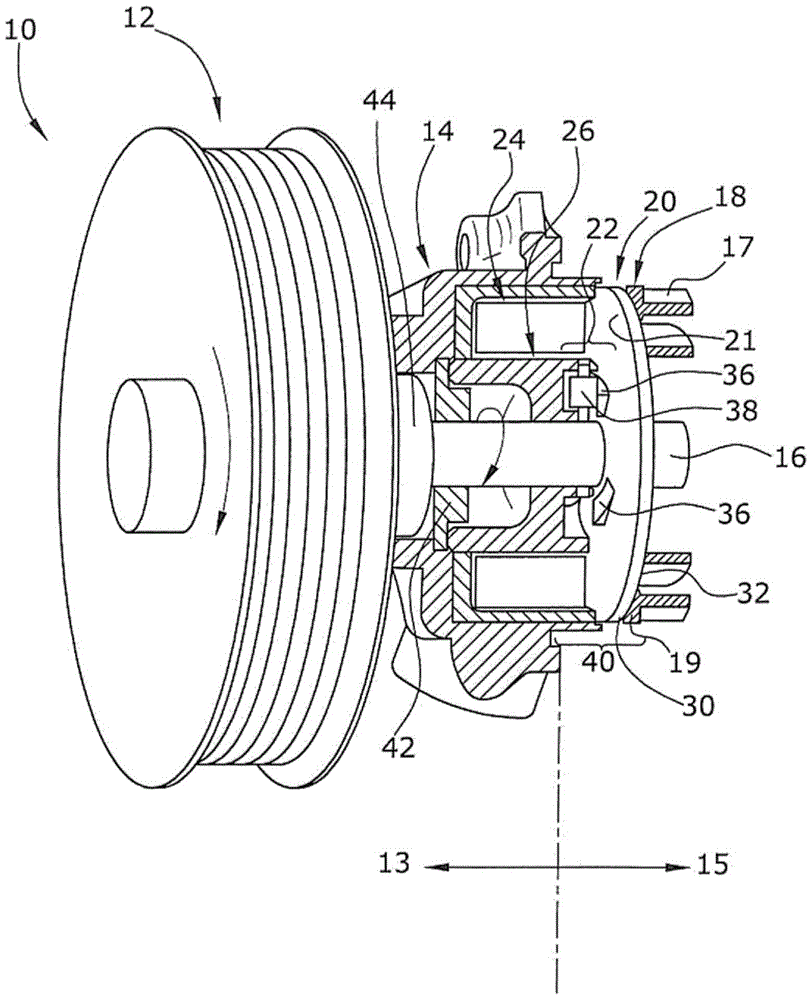

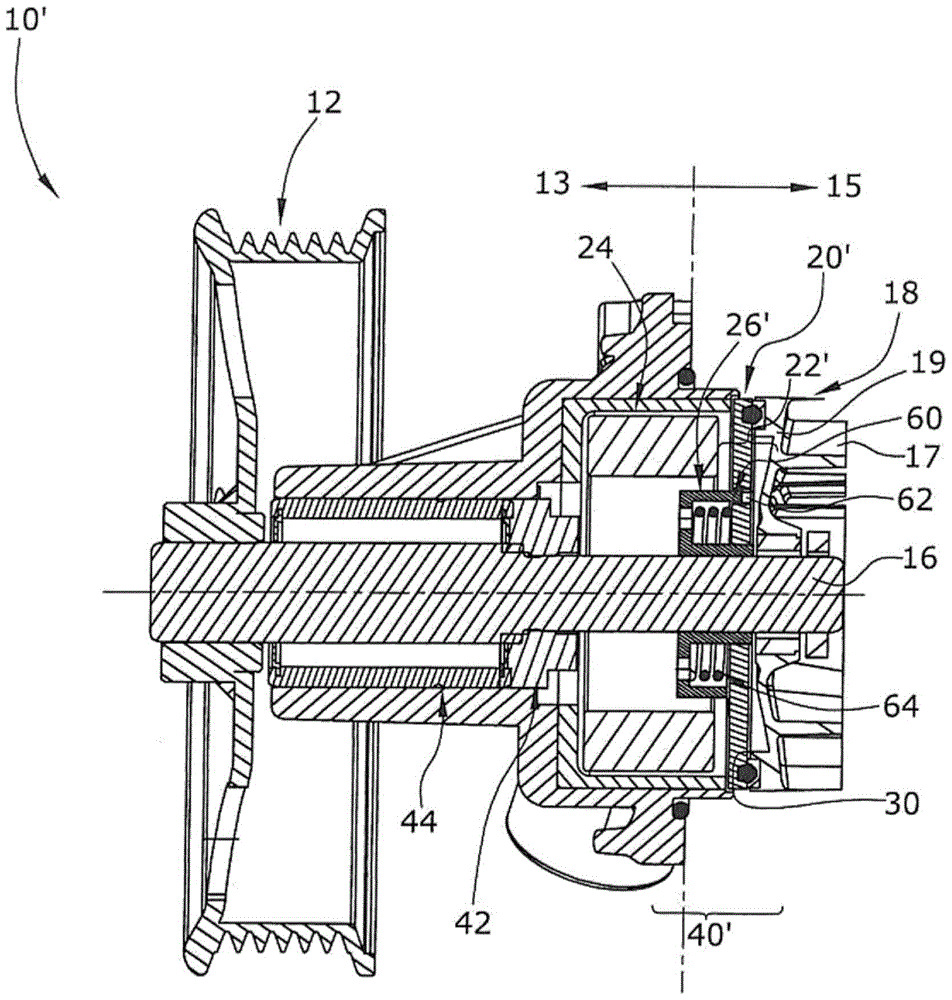

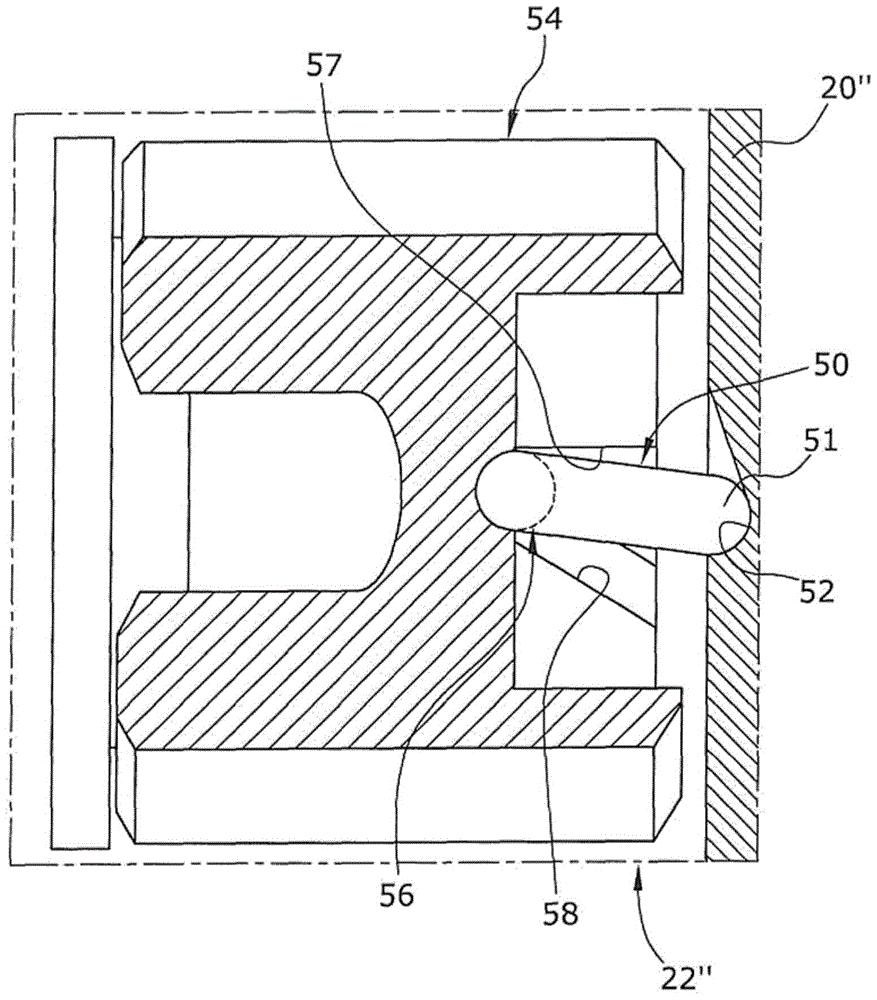

InactiveCN103827502AIncrease fluid resistanceLarge axial thrustMechanical actuated clutchesMagnetically actuated clutchesCombustionEngineering

The invention refers to a switchable mechanical coolant pump (10) comprising a pulley wheel (12) co-rotating with and supported by a rotatable rotor shaft (16), the pulley wheel (12) being directly drivable by a combustion engine, a pump wheel (18) rotatably supported at the rotor shaft (16), an electrically switched wedge-coupled wet friction clutch (40) with a clutch support (26) being fixed to the rotor shaft (16), a clutch ring (30) at the proximal side of the pump wheel (18), and a separate clutch disk (20) rotatably and shiftably supported by the rotor shaft (16), the clutch disk (20) comprising a ferromagnetic element (21) and being arranged axially between the clutch support (26) and the clutch ring (30), a static electromagnet (24) axially pulling the clutch disk (20) to the clutch support (26) into a disengaged position when energized, and a wedge coupling mechanism (22); defined at the proximal side of the clutch disk (20) and the distal side of the clutch support (26), the wedge coupling mechanism (22) comprising: a wedge element (36) and a counter-wedge element (38).

Owner:PIERBURG PUMP TECH

Combined structure for magnetic steel and magnetic loop of motor

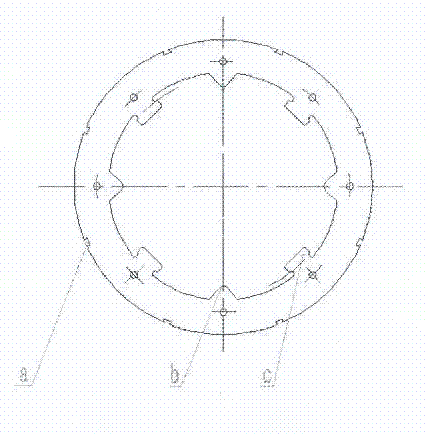

InactiveCN102480182AGuaranteed coaxialityBlock flowMagnetic circuit rotating partsMagnetic polesStructural engineering

The invention relates to a combined structure for magnetic steel and magnetic loop of a motor, consisting of a magnetic loop, a support core, a fixed end plate and a rotating shaft, wherein a corresponding number of dovetail grooves are arranged according to the number of magnetic poles by the periphery of the magnetic circuit, V-shaped teeth bearing the radial torque are designed on the internal circular surface and supported on the external diameter of the core, a plurality of equal support arms are arranged, double dovetail locking pieces having the same number as that of the magnetic poles are arranged on the fixed end plate and on the external diameter of the plate. The method for processing the magnetic isolating piece into V shape by using the magnetic isolating material through a die can effectively overcome the drawbacks of the old-fashioned products during the production. The structure is simple and convenient to produce and process.

Owner:环宇平

Highly-thrust-resistant pin structure for connecting constructional steel column with constructional steel pipe truss

ActiveCN103046650AKeep Basic Link FunctionalityImprove performanceBuilding constructionsEngineeringSteel columns

The invention discloses a highly-thrust-resistant pin structure for connecting a constructional steel column with a constructional steel pipe truss. The highly-thrust-resistant pin structure comprises a pin, a truss node and a pin connecting seat, the truss node is integrally formed by casting, the truss node and the constructional steel pipe truss are welded mutually, the pin connecting seat is fixedly connected with the constructional steel column, the truss node and the pin connecting seat are of mutually folded lug plate butting structures and are provided with pin holes for the pin to penetrate through, and after the truss node and the pin connecting seat are folded, the pin is inserted into the pin holes to hinge the truss node and the pin connecting seat integrally, so that integrity and thrust-resistant rigidity of the pin structure are enhanced. The constructional steel pipe truss is in swing connection with the constructional steel column through the pin structure. The pin structure is capable of achieving swing connection of the constructional steel pipe truss with the constructional steel column and has the advantages of high thrust-resistant rigidity, good integrity, attractive appearance and more stable and reliable connection and force transfer.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

Double-cylinder electric nail fixing device

ActiveCN114750111APower dynamic adjustmentExtend the gas cycleStapling toolsNailing toolsEngineeringHigh pressure gas

The invention discloses a double-air-cylinder electric nail fixing device which comprises a main air cylinder, an auxiliary air cylinder, a linear motion mechanism, a firing pin, a needle tube assembly, a driving mechanism and a limiting releasing mechanism. The main air cylinder is fixedly connected with the auxiliary air cylinder, and an inner cavity of the main air cylinder is communicated with an inner cavity of the auxiliary air cylinder; a main piston and an auxiliary piston are arranged in the main air cylinder and the auxiliary air cylinder respectively, the needle tube assembly is fixedly connected with the main air cylinder through a connecting piece, one end of the firing pin is movably arranged in the needle tube assembly, and the other end of the firing pin is fixedly connected with the main piston. The limiting and releasing mechanism used for limiting or releasing the firing pin is arranged beside the firing pin, the linear motion mechanism is fixedly connected with the auxiliary piston, and the driving mechanism is connected with the firing pin and the linear motion mechanism. Compression of high-pressure gas in the cylinder can be achieved under the condition that the bearing capacity is small, and the micro leakage amount of the gas in the cylinder can be automatically compensated and the nailing power can be automatically adjusted by adjusting the stroke of the driving mechanism.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

Convertible mechanical coolant pump

InactiveCN103827502BIncrease fluid resistanceLarge axial thrustMechanical actuated clutchesMagnetically actuated clutchesCombustionEngineering

The invention relates to a switchable mechanical coolant pump (10), comprising: a pulley (12) co-rotating with and supported by a rotatable rotor shaft (16), which can be driven directly by an internal combustion engine; rotatably supported on the rotor shaft (16) Pump wheel (18) at 16); electrically converted wedge-coupled wet friction clutch (40) with clutch support (26) fixed to the rotor shaft (16), clutch ring (26) proximal to the pump wheel (18) 30) and a separate clutch disk (20) rotatably and movably supported by the rotor shaft (16), which includes a ferromagnetic element (21) and is arranged axially between the clutch support (26) and the clutch ring ( 30); a fixed electromagnet (24) that axially pulls the clutch disk (20) to the clutch support (26) into the disengaged position when energized; and a fixed electromagnet (24) defined proximal to the clutch disk (20) and the clutch support A wedge-shaped coupling mechanism (22) distal to the member (26), which includes a wedge-shaped element (36) and a counter wedge-shaped element (38).

Owner:PIERBURG PUMP TECH

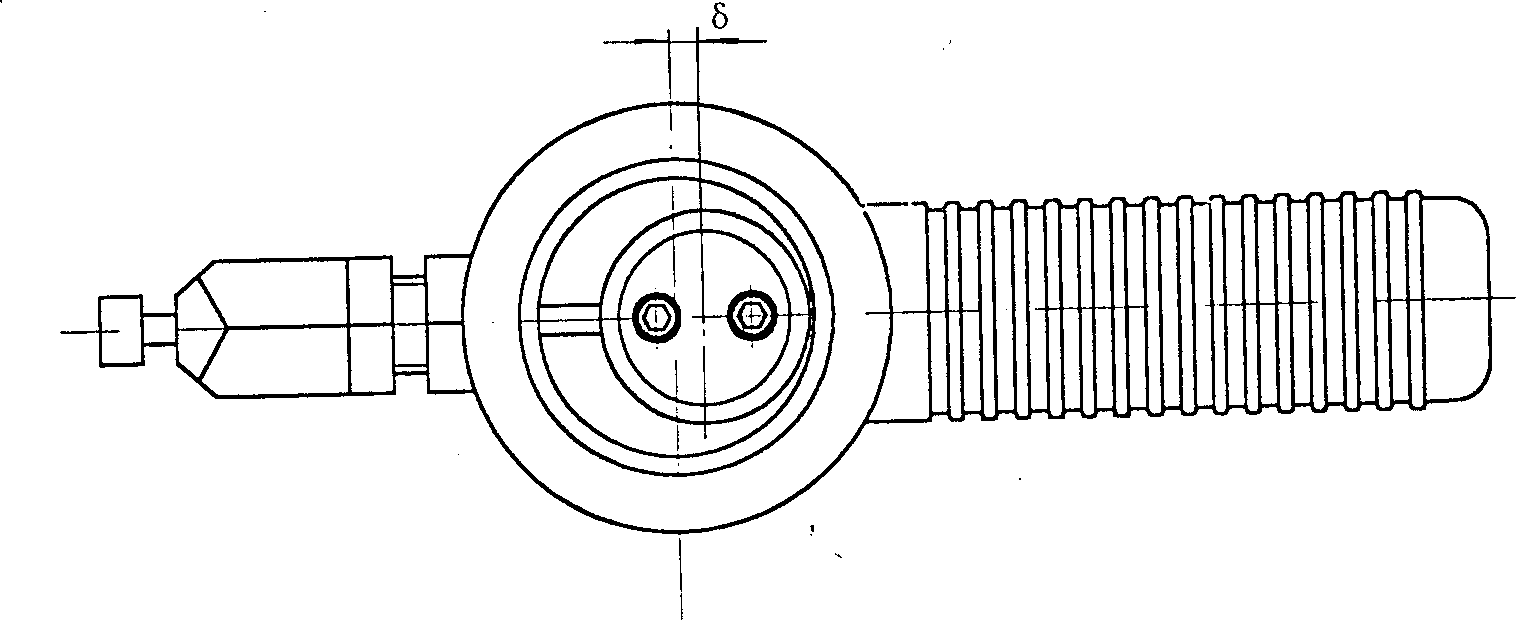

Water Lubricated Axial Thrust Bearings

InactiveCN103410849BProcessing levelSurface Aurora Low Coefficient of FrictionSliding contact bearingsBearing unit rigid supportThrust bearingOil free

The invention relates to thrust bearings and particularly relates to a water-lubricated axial thrust bearing. The water-lubricated axial thrust bearing comprises a bracket, wherein a thrust bearing block is arranged on the top end face of the bracket, a mounting hole is formed in the bottom center of the bracket, the end face of the mounting hole is provided with a chamfer, a retaining rack is arranged at the bottom of the mounting hole in a matching manner, an inclined face of the top end of the retaining rack is clung to the chamfer face of the mounting hole, and the bottom of the retaining rack is connected with a thrust bearing seat. The water-lubricated axial thrust bearing can work in oil-free lubrication water; and the principle is that a sliding friction surface is machined to be smooth, is extremely smooth, is small in friction coefficient and can withstand enormous axial thrust, so that the water-lubricated axial thrust bearing can be widely applied to oil-free lubrication working environment of water feeding motors.

Owner:WUXI XISHAN ANDA EXPLOSION PROOF ELECTRIC EQUIP

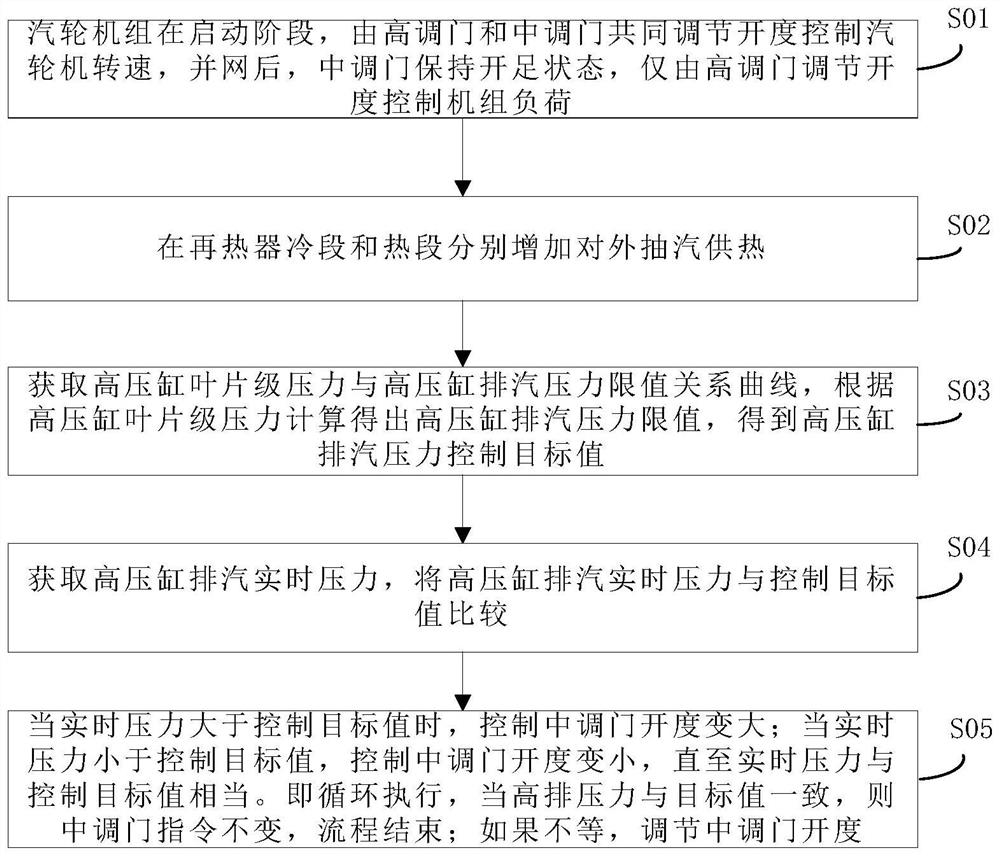

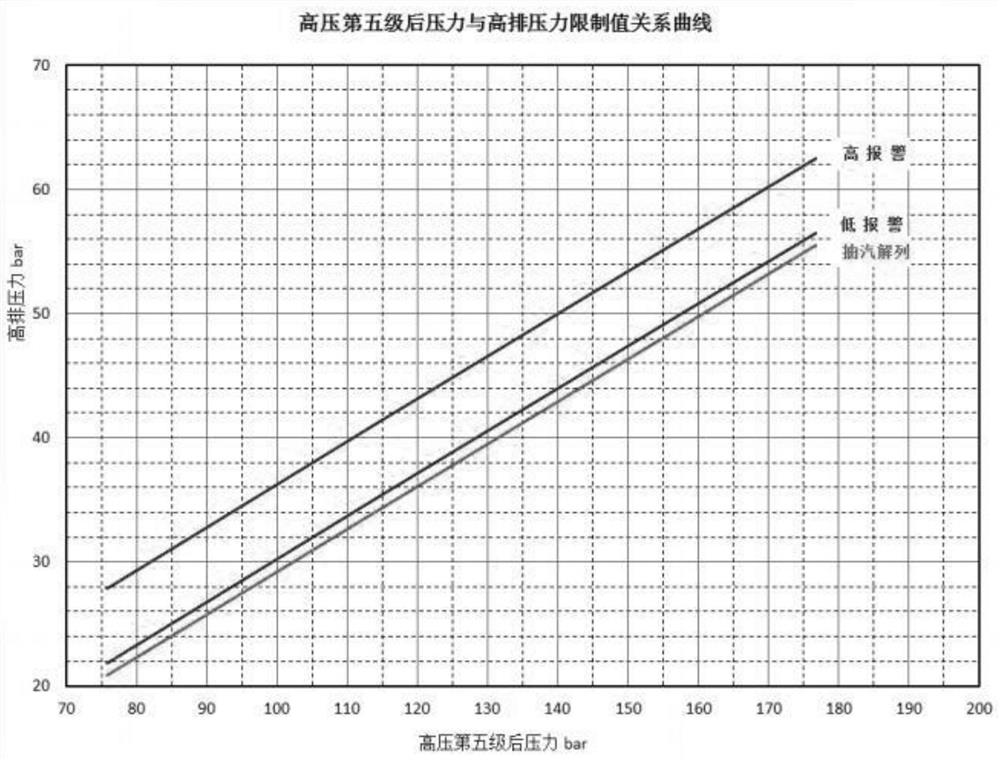

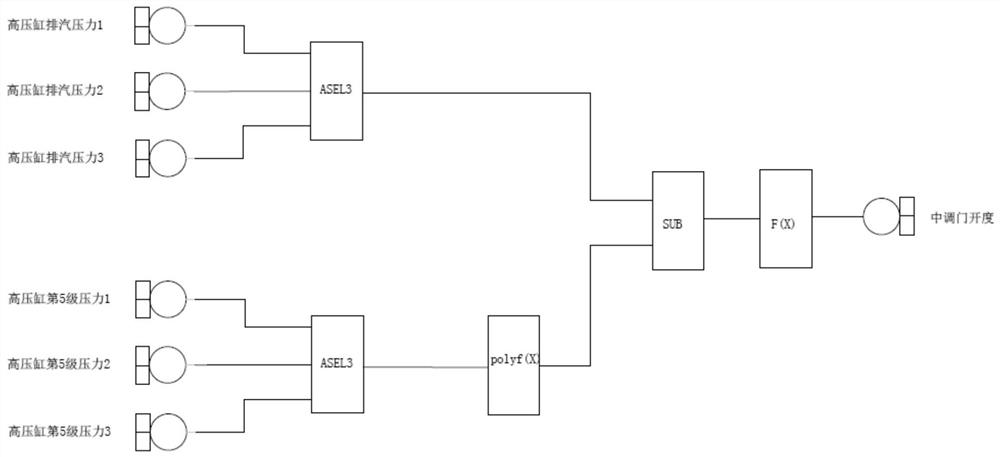

Method and system for adjusting and controlling exhaust steam pressure of high-pressure cylinder for steam extraction and heat supply of resteam device

ActiveCN113339083AGuaranteed safe operationIncreased exhaust pressureEngine startersSteam engine plantsSteam pressureControl objective

The invention discloses a method for adjusting and controlling exhaust steam pressure of a high-pressure cylinder for steam extraction and heat supply of a resteam device. The method comprises the following steps that in a starting stage of a steam turbine unit, the opening degree is adjusted by a high regulating valve and a middle regulating valve together to control the rotating speed of a steam turbine, after grid connection, the middle regulating valve is kept in a sufficient opening state, and only the high regulating valve adjusts the opening degree to control the load of the unit; external steam extraction and heat supply are added to a cold section and a hot section of a reheater respectively; a relation curve of high-pressure cylinder blade-level pressure and a high-pressure cylinder exhaust steam pressure limit value is obtained, the high-pressure cylinder exhaust steam pressure limit value is calculated according to the high-pressure cylinder blade-level pressure, and a high-pressure cylinder exhaust steam pressure control target value is obtained; high-pressure cylinder exhaust steam real-time pressure is obtained, and the high-pressure cylinder exhaust steam real-time pressure is compared with a control target value; when the real-time pressure is larger than the control target value, the opening degree of the middle regulating valve is controlled to be increased; and when the real-time pressure is smaller than the control target value, the opening degree of the middle regulating valve is controlled to be smaller until the real-time pressure is equal to the control target value. Through pressure building control of the middle regulating valve, the high-pressure cylinder exhaust steam pressure can be rapidly adjusted.

Owner:SHANGHAI HUADIAN ELECTRIC POWER DEV CO LTD

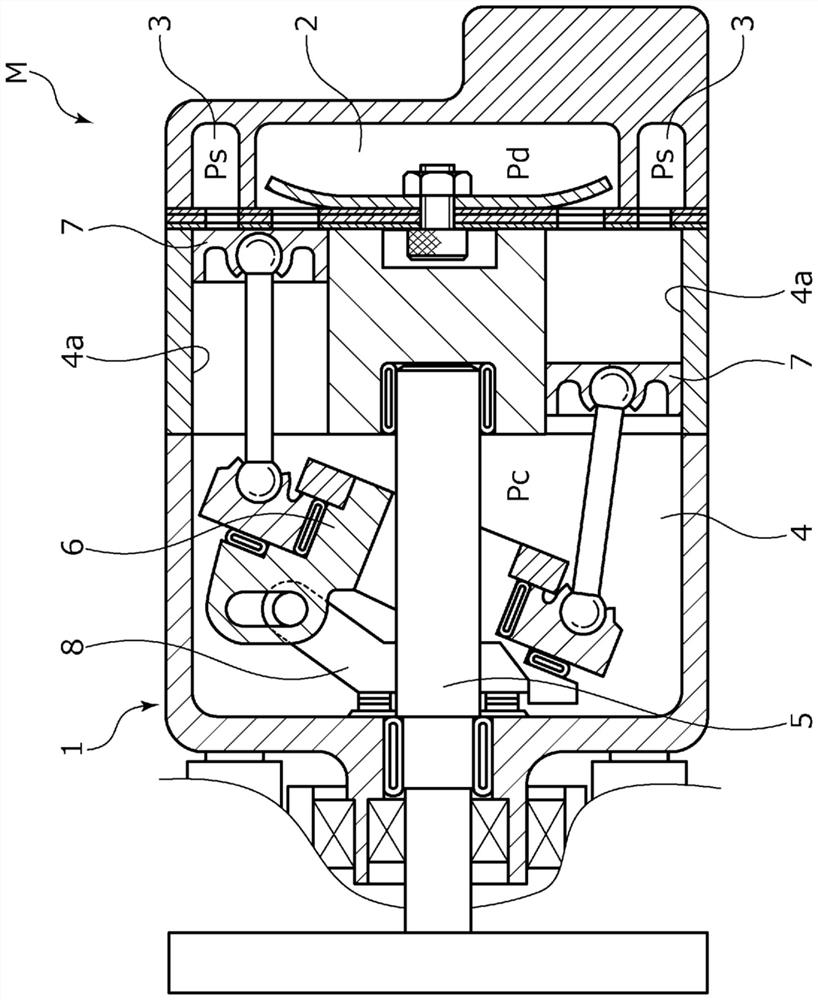

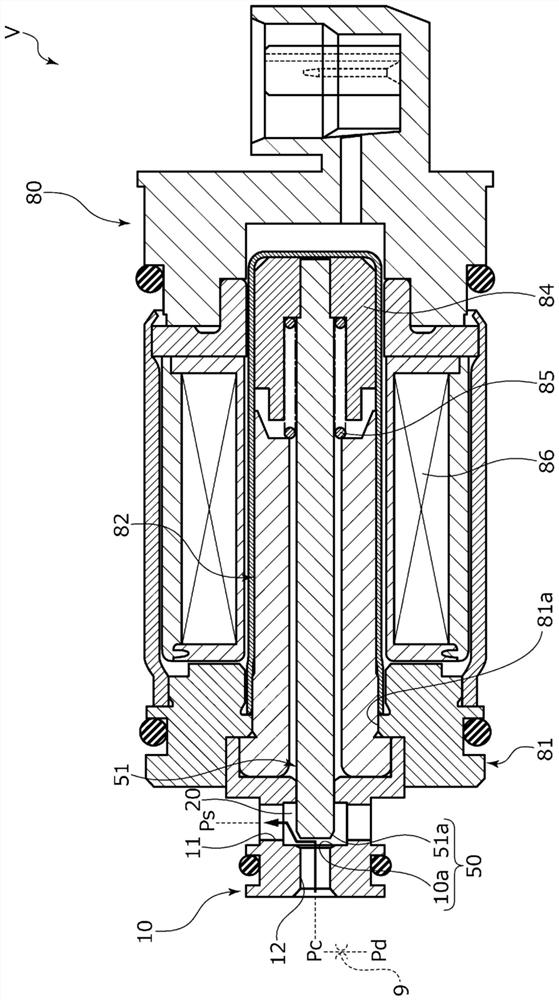

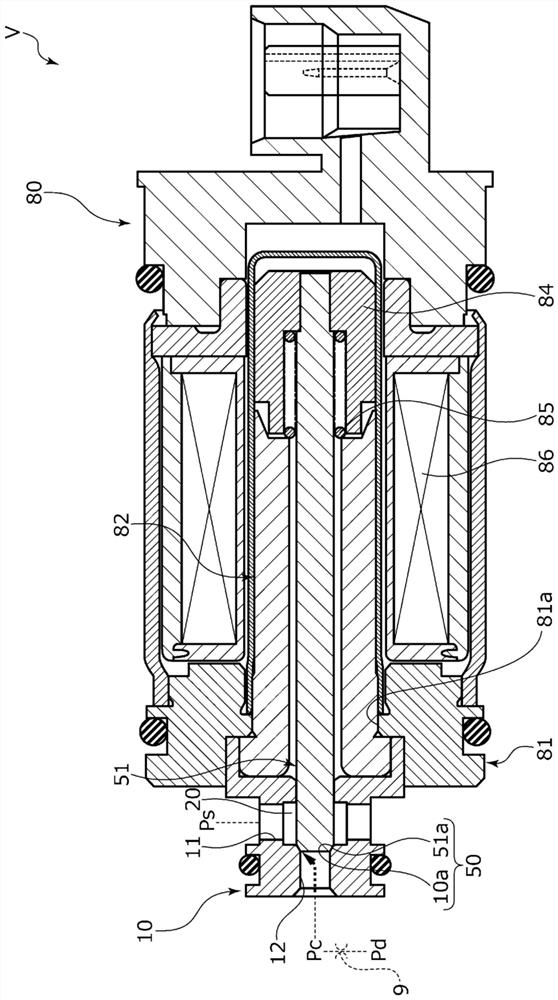

Capacity control valve

PendingCN113661323AStable controlAxial thrust is stableOperating means/releasing devices for valvesPositive displacement pump componentsMagnetic tension forceEngineering

The objective of the present invention is to provide a capacity control valve in which a valve body can be controlled smoothly, and in which the valve body can be held stably in a maximum stroke position. In a capacity control valve (80) in which energization of an electromagnetic coil (86) causes a movable iron core (84) to move toward a fixed iron core (82) due to the attraction of a magnetic force, thereby causing the position of a valve body (51) to change. One iron core (82) is provided with a protruding portion (90) on the diametrically outer side thereof; the other iron core (84) is provided with a protruding portion (92) on the diametrically inner side thereof; the protruding portions are capable of fitting loosely together when moved by attraction. An effective magnetic force surface (90a) of a tip end of one protruding portion (90) is formed to be smaller than an opposing surface (93) facing the opposing iron core (84), and is formed with a tapered shape.

Owner:EAGLE INDS

A mechanical transmission closed test bench and its test method

InactiveCN105784355BReduce thrustEasy to useMachine gearing/transmission testingPlain bearingEnergy conservation

The invention discloses a mechanical transmission closed test bed and a test method thereof. The test bed comprises a motor, connection gear boxes, a torque and rotation speed sensor, a tested transmission, an accompanying transmission and a loader, wherein the loader comprises a spiral spline shaft, a loaded gear, a plane bearing, a pair of wedge cushion blocks, a sliding bearing, a thrust bar and an oil cylinder; the motor is connected with the left connection gear box for providing rotation power for the overall closed test bed; the two transmissions are connected in a back-to-back mode, the tested transmission is connected with the left connection gear box via the torque and rotation speed sensor and the accompanying transmission is directly connected with the right connection gear box; and the loader is arranged onto the right connection gear box for providing different loads for the overall closed test bed. A transmission fatigue life test and a reliability test can be carried out, the closed structure is adopted, the cost is low, energy is saved, the structure is compact, the use is convenient, and the test bed can be applied to transmissions of various models.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

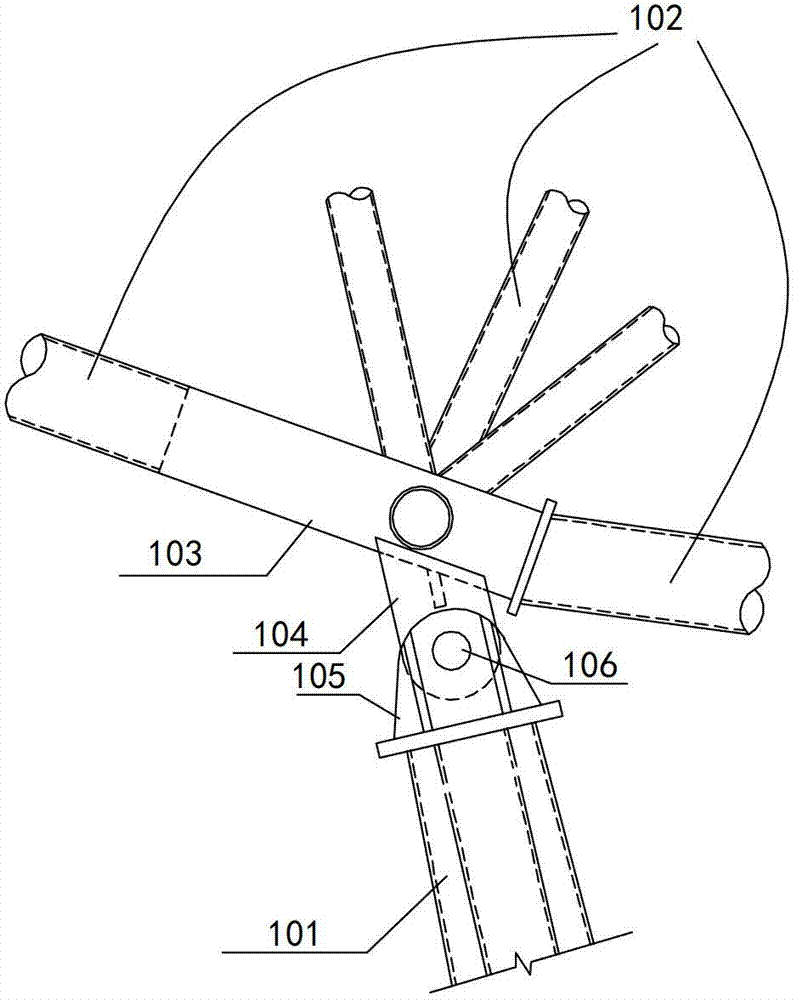

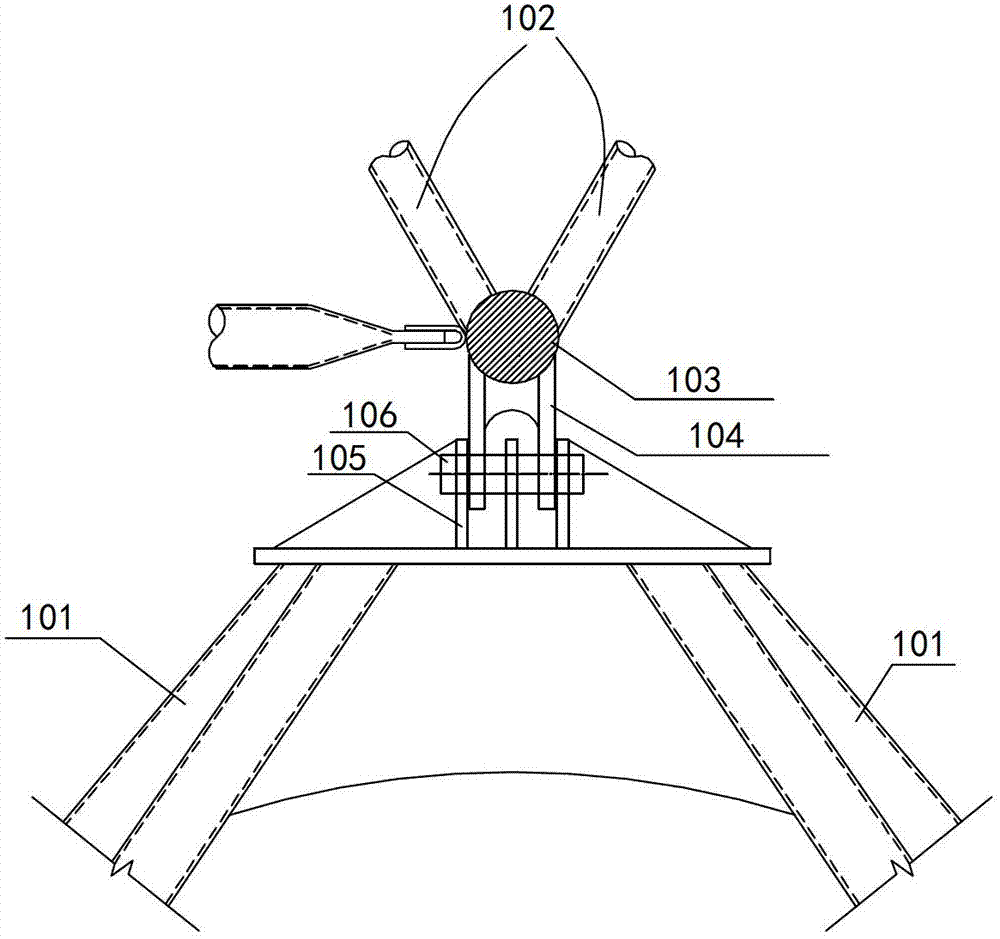

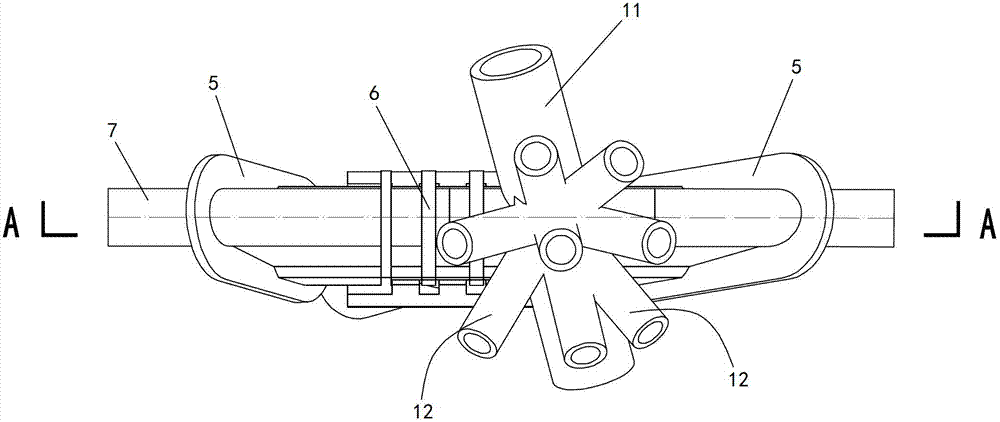

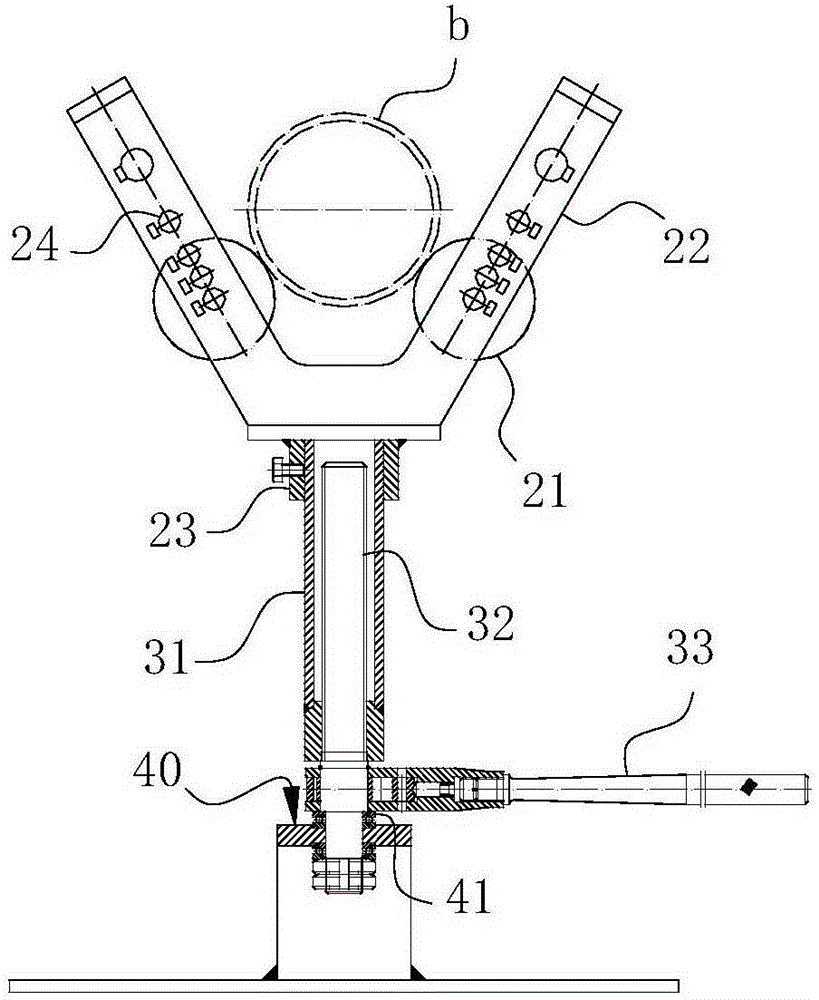

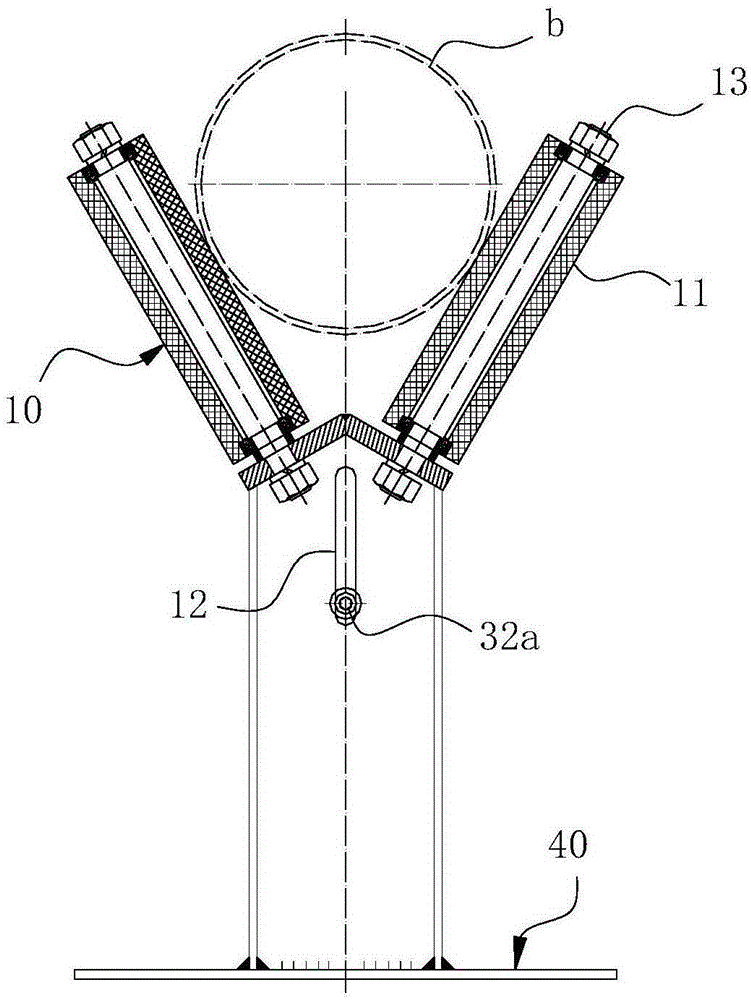

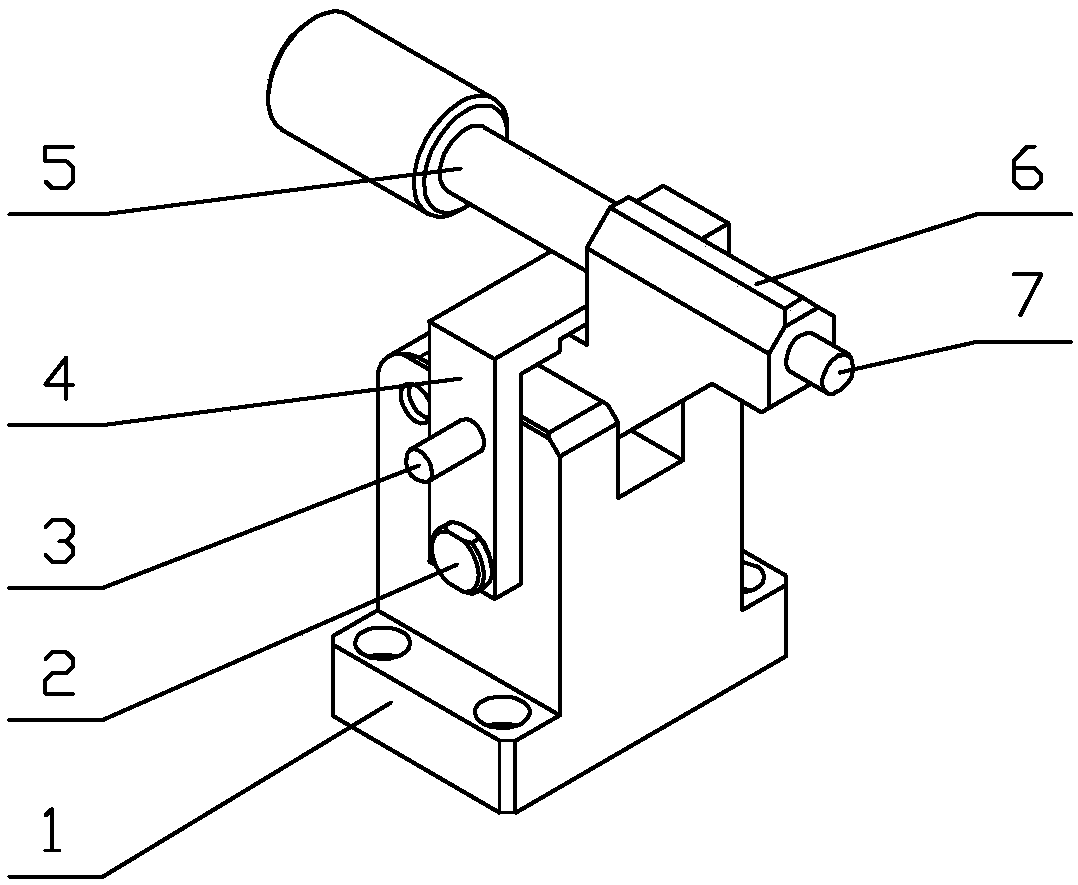

Universal adjustable pipe female welding bracket

ActiveCN104368943BRealize the purpose of one-time online weldingEasy butt-to-endWelding/cutting auxillary devicesArc welding apparatusEngineeringPipe welding

The invention belongs to the field of tubular bus welding process attachment devices, and particularly relates to a universal adjustable tubular bus welding bracket. The universal adjustable tubular bus welding bracket comprises an axial supporting base. A plurality of axial guide wheels are distributed on the axial supporting base. Tubular buses are erected on the axial guide wheels, and the outer rims of all the axial guide wheels are matched to form a supporting part. The universal adjustable tubular bus welding bracket further comprises a lifting mechanism. A rotation supporting base is arranged on the lifting mechanism. The roll surfaces of a plurality of circumferential wheels on the rotation supporting base form a contact face. The minimum height of the contact face is lower than the supporting height of the tubular buses on the supporting part of the axial supporting base after the lifting mechanism falls. The maximum height of the contact face is higher than the supporting height of the tubular buses on the supporting part of the axial supporting base after the lifting mechanism rises. The universal adjustable tubular bus welding bracket achieves the online rotation and frontward-backward axial movement capacity in the tubular bus welding process, and therefore the aim of the one-time online welding is achieved under the condition that no mechanical hoisting is needed, the welding speed can be obviously increased, and the welding quality can be obviously improved.

Owner:STATE GRID CORP OF CHINA +1

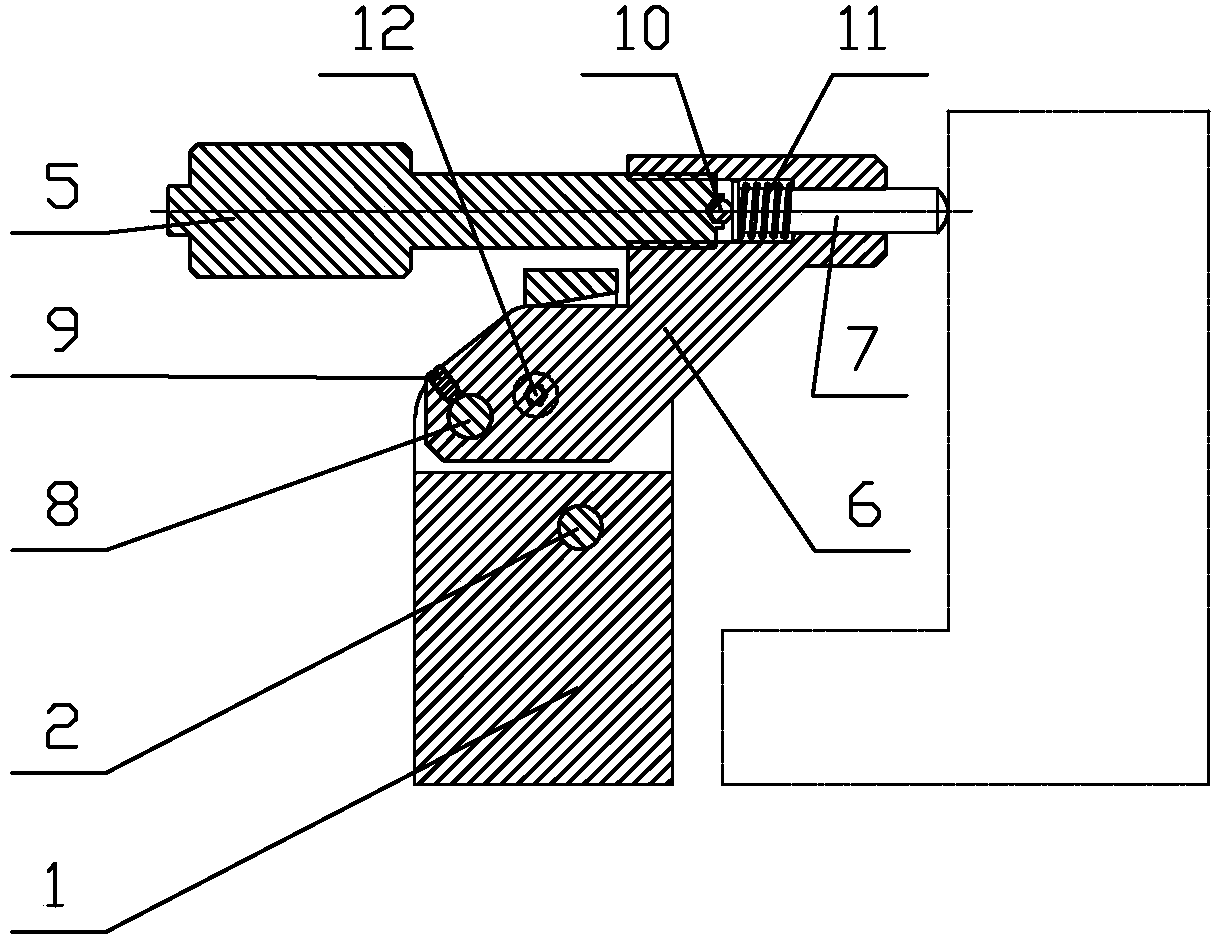

Quick turn top tightening mechanism

ActiveCN106624958BTight and reliableExpand the range of processingMetal working apparatusFree rotationEngineering

The invention relates to a rapid overturning and tightly-abutting mechanism. An installation groove is formed in the top of the installation seat. An overturning block is hinged to the installation seat through small hinge shafts installed on side plates on the two edges of the installation groove. The small hinge shafts are installed on the side plates on the two edges of the installation groove. The overturning block can freely rotate with the small hinge shafts as the rotation center. When the overturning block is overturned to a limiting position, the overturning block abuts against the bottom of the installation groove. The overturning block is provided with a pin hole. A tightly-abutting shaft is assembled in the pin hole and can axially and freely move in the pin hole. A screwing-down handle is connected to threads at the left end of the pin hole in a threaded manner. The right end of the screwing-down handle is connected with the tightly-abutting shaft. The right end of the tightly-abutting shaft is used for tightly abutting against a workpiece and locating the workpiece. An overturning frame is hinged to the installation seat through hinge shafts. The hinge shafts are installed on the installation seat. The overturning frame can freely rotate with the hinge shafts as the rotation center. When overturning to the limiting position upwards, the overturning frame presses the overturning frame without exerting force. The rapid overturning and tightly-abutting mechanism is convenient to operate and capable of reliably and tightly abutting against the workpiece, rapidly leaving a workpiece machining area, expanding the machining range and shortening the operation time.

Owner:WUXI BEST PRECISION MACHINERY

Water-lubricated axial thrust bearing

InactiveCN103410849AProcessing levelSurface Aurora Low Coefficient of FrictionSliding contact bearingsBearing unit rigid supportThrust bearingEngineering

The invention relates to thrust bearings and particularly relates to a water-lubricated axial thrust bearing. The water-lubricated axial thrust bearing comprises a bracket, wherein a thrust bearing block is arranged on the top end face of the bracket, a mounting hole is formed in the bottom center of the bracket, the end face of the mounting hole is provided with a chamfer, a retaining rack is arranged at the bottom of the mounting hole in a matching manner, an inclined face of the top end of the retaining rack is clung to the chamfer face of the mounting hole, and the bottom of the retaining rack is connected with a thrust bearing seat. The water-lubricated axial thrust bearing can work in oil-free lubrication water; and the principle is that a sliding friction surface is machined to be smooth, is extremely smooth, is small in friction coefficient and can withstand enormous axial thrust, so that the water-lubricated axial thrust bearing can be widely applied to oil-free lubrication working environment of water feeding motors.

Owner:WUXI XISHAN ANDA EXPLOSION PROOF ELECTRIC EQUIP

Driving device for triaxial inertially stabilized platform

ActiveCN102664488BSimple drive structureSmall structure sizeMechanical energy handlingSupports/enclosures/casingsEngineeringMechanical engineering

The invention discloses a driving device for a triaxial inertially stabilized platform. The device is suitable for driving the swing of a roll frame and an elevation frame of the triaxial inertially stabilized platform. Different from a traditional sector gear transmission or a cog belt transmission, the device adopts a link mechanism to realize the swing of the roll frame and the elevation frame. The driving device is composed of a fixed end hinge pair, a motor-lead screw movable pair and a swing end hinge pair. When the motor bi-directionally rotates to drive the lead screw to axially move forwards and backwards, a swing hinge shaft mounted on a swing frame drives the swing frame to rotate around the center of rotation to swing back and forth. Compared with the traditional sector gear transmission or the cog belt transmission, the structure has the advantages of large transmission ratio, good transmission rigidity, light and small driving unit, simple structure and the like. The device disclosed by the invention is suitable for driving the roll frame and the elevation frame of inertially stabilized and photoelectric servo platforms for aerial remote sensing, target tracking and the like.

Owner:BEIHANG UNIV

Rotor weight self-adaptive type permanent magnet thrust bearing

Owner:ZHEJIANG UNIV

Pressure-adjustable hydraulic thruster

The invention relates to a pressure-adjustable hydraulic thruster, and belongs to the technical field of petroleum drilling tools and machines. The pressure-adjustable hydraulic thruster comprises an upper connector, a core shaft, a middle connector, a first-stage secondary cylinder body, a second-stage secondary cylinder body and a flow plug, wherein a main cylinder body is installed on the core shaft in a sliding mode; one side of the main cylinder body is provided with the first-stage secondary cylinder body and the second-stage secondary cylinder body in a threaded mode through the middle connector; one end of the second-stage secondary cylinder body is connected with the main cylinder body in a threaded mode; an end socket of the first-stage secondary cylinder body is provided with the upper connector in a threaded mode; and the flow plug is arranged on the inner side of the upper connector. By means of the pressure-adjustable hydraulic thruster, the problems that when an existing drilling tool is put down too fast, a liquid cylinder is pressed tightly, and when the drilling tool is put down too slowly, a drill bit is in an idle state, and the drilling efficiency is lowered are solved effectively. The pressure-adjustable hydraulic thruster has the characteristics of being simple in structure and good in practicability. A drilling work operator can guide normal conduction of well drilling by observing the change of the pressure read number of drilling liquid, and the pressure-adjustable hydraulic thruster is particularly suitable for installation and use of drilling wells such as horizontal wells and large-displacement extending wells.

Owner:YANGTZE UNIVERSITY

Transmitting ratio variable slip-limiting speed differentiator with self-locking function

InactiveCN100567771CSimple structureSimple mechanical structureDifferential gearingsControl devicesDifferentiatorGear wheel

The invention relates to a variable transmission ratio limited-slip differential with self-locking function. Including the differential case (1), the variable transmission ratio planetary gear (2) and the side gear (3) arranged in it, and the cam between the rear end surface of the side gear (4) and the rear end surface of the differential case (6) ring (5), locking ring (7), return spring (8) and spring cover (9), the side gear (3) is provided with a friction plate (10), and a central square (11) is arranged in the middle of the differential ) and cross shaft (12), they form a self-locking mechanism. The invention provides a limited-slip differential that realizes self-locking under extreme road conditions and quickly and automatically unlocks when leaving extreme road conditions, thereby improving the passability and safety of the vehicle. The invention is especially suitable for all kinds of wheeled engineering machinery such as off-road vehicles, dump trucks, wheel loaders, bulldozers and the like.

Owner:BEIJING JIAOTONG UNIV

A high-speed direct-coupled spindle

ActiveCN103737408BGuaranteed to workAvoid enteringLarge fixed membersChucksAxial thrustHigh velocity

A high-speed direct connection spindle. The high-speed direct connection spindle comprises: a machine body (10); a spindle core (20), the spindle core (20) being pivotally connected in the machine body (10) through an upper bearing (23) and a lower bearing (24) respectively arranged at the upper end and the lower end of the machine body (10), and a conical hole (22) being provided in the bottom end of the spindle core (20), the diameter of the conical hole (22) being gradually increased from bottom to top; a pull rod (30), the lower end of the pull rod (30) being connected to a pull claw (32) that matches the conical hole (22) and is used for fixing a cutter, and the upper end of the pull rod (30) having a cutter hitting disk (31) fixed thereto; a reset spring (21), mounted between the spindle core (20) and the pull rod (30); and an oil cylinder assembly (40), comprising a cylinder body (41) positioned above the top end of the machine body and a piston (42) mounted inside the cylinder body and used for pushing against the cutter hitting disk (31) downwards. The cylinder body (41) is movably provided with a plurality of connecting pieces penetrating therethrough, the part, penetrating through the lower end of the cylinder body (41), of each connecting piece is fixedly connected to the machine body (10), and each connecting piece has an elastic element sleeved thereon. The cylinder body (41) of the oil cylinder is mounted on the machine body (10) in a floating manner, and the axial thrust applied by the oil cylinder to the spindle core (20) when the cutter is assembled or disassembled can be counteracted, so that the bearings are protected from being damaged, and the service life of the bearings is prolonged.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com