A high-speed direct-coupled spindle

A technology of direct coupling and main shaft, which is applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of reducing the service life of bearings, reducing the service life of bearings, affecting the matching accuracy of inner rings and outer rings of bearings, etc., so as to prolong the service life, Improves accuracy and protects against damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

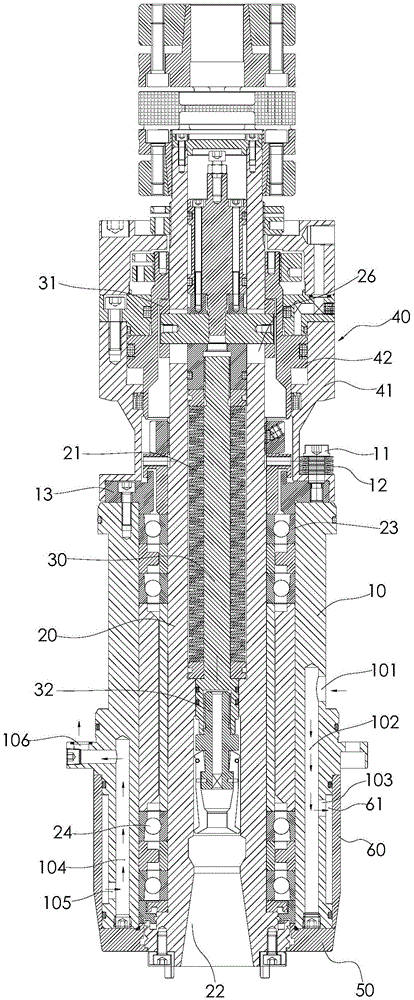

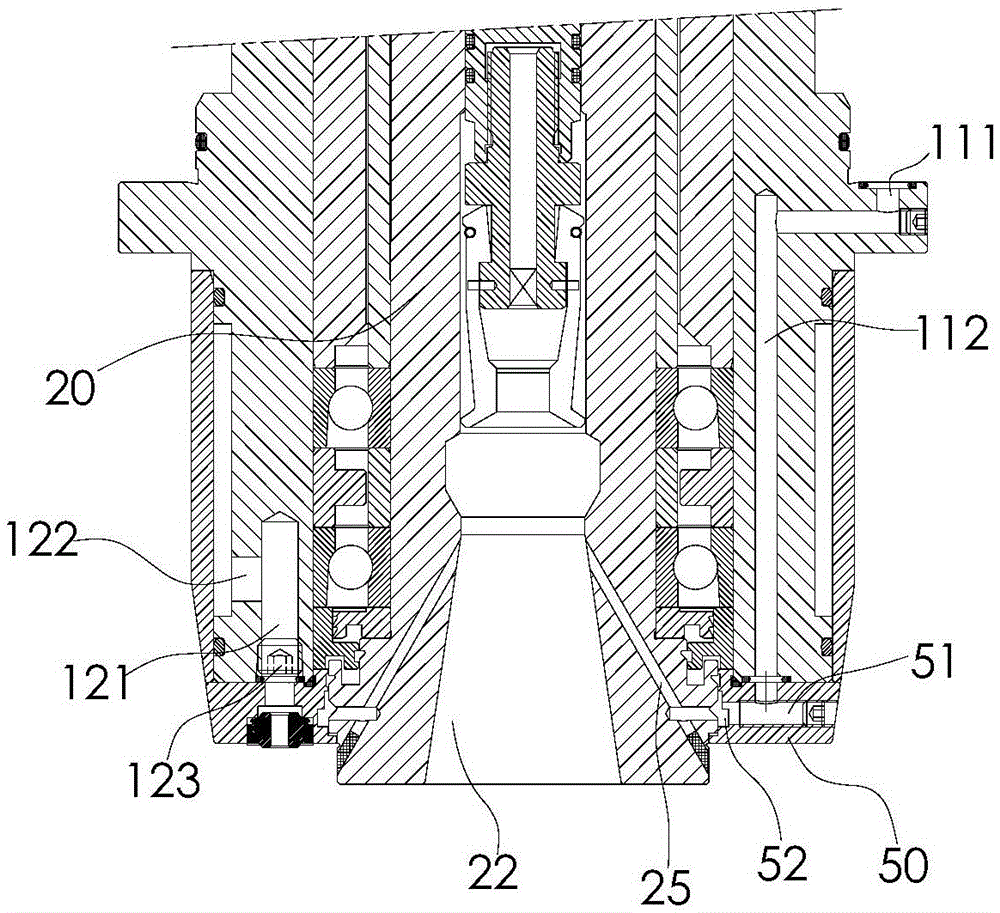

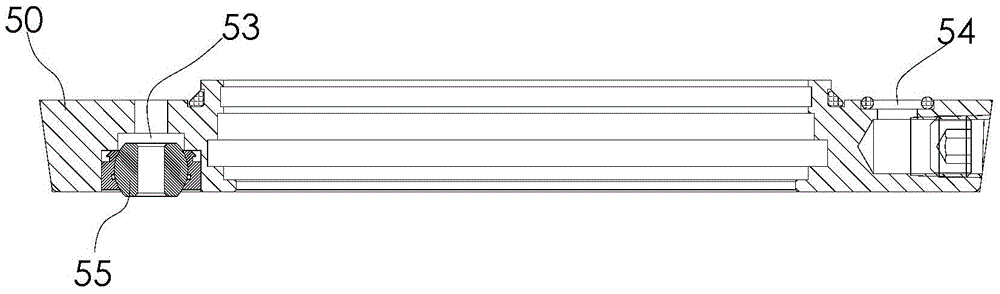

[0026] Such as figure 1 , 2 , 3, it is a high-speed direct-coupled main shaft of the present invention, which includes a body 10, a shaft core 20, a pull rod 30, and an oil cylinder assembly 40, wherein the shaft core 20 is connected inside the body 10, and the shaft core 20 is respectively set by The upper bearing 23 and the lower bearing 24 at the upper and lower ends of the body 10 are pivotally connected inside the body 10, and the bottom end of the shaft core 20 is provided with a tapered hole 22 whose diameter increases from top to bottom, and the pull rod 30 is movable Inside the shaft core 20, the bottom end of the pull rod 30 is connected with a pull claw 32 for fixing the tool. The pull claw 32 cooperates with the above-mentioned tapered hole 22 to realize loading and unloading of the knife. When the pull claw 32 moves upward along the taper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com