Method and system for adjusting and controlling exhaust steam pressure of high-pressure cylinder for steam extraction and heat supply of resteam device

A technology of exhaust pressure, steam extraction and heat supply, which is applied in the direction of steam engine device, engine start, machine/engine, etc., which can solve the problem of inability to guarantee unit power generation, safe and reliable heat supply and economical operation, and the failure of exhaust pressure of high-pressure cylinders. Quickly adjust and other issues to achieve the effect of increasing the axial thrust, increasing the exhaust pressure of the high-pressure cylinder, and avoiding the effect of too low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

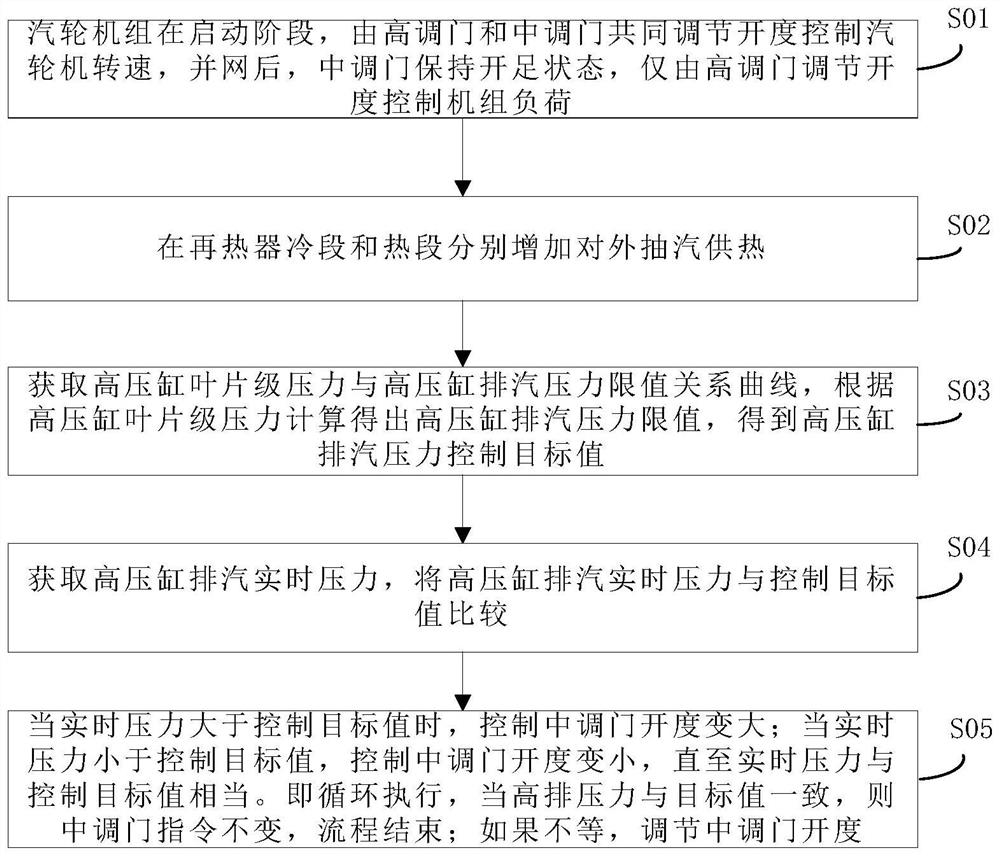

[0047] A method for adjusting and controlling the exhaust pressure of a high-pressure cylinder for steam extraction and heat supply by a resteamer, comprising the following steps:

[0048] S01: During the start-up phase of the steam turbine unit, the high-adjustment door and the middle-adjustment door jointly adjust the opening to control the turbine speed. After grid connection, the middle-adjustment door remains fully open, and only the high-adjustment door adjusts the opening to control the load of the unit;

[0049] S02: Increase external steam extraction for heat supply in the cold section and hot section of the reheater respectively;

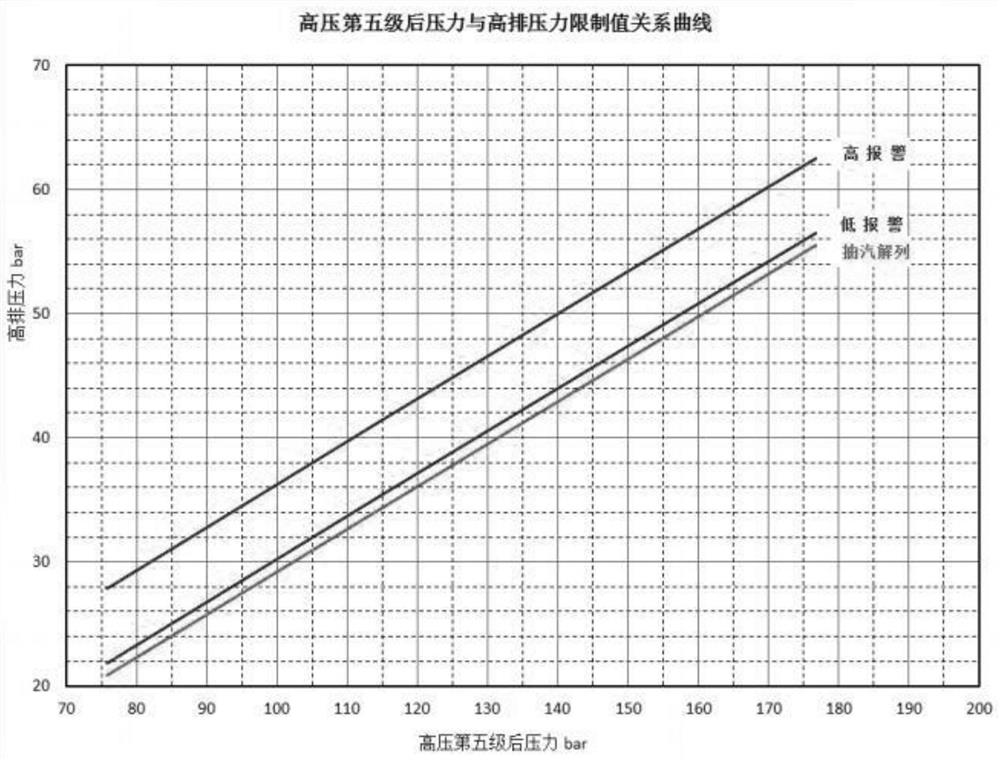

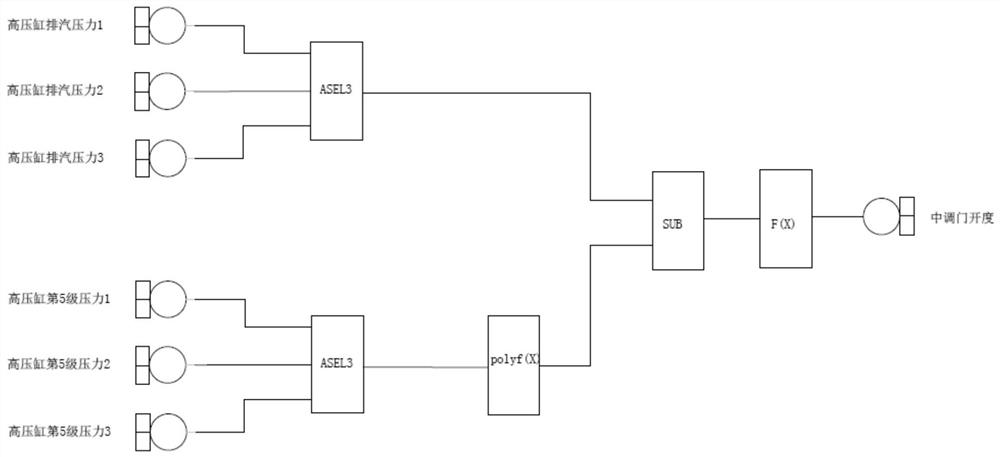

[0050] S03: Obtain the relationship curve between the blade stage pressure of the high pressure cylinder and the exhaust pressure limit of the high pressure cylinder, calculate the exhaust pressure limit of the high pressure cylinder according to the blade stage pressure of the high pressure cylinder, and obtain the exhaust pressure control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com