Patents

Literature

38results about How to "Expand the range of processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

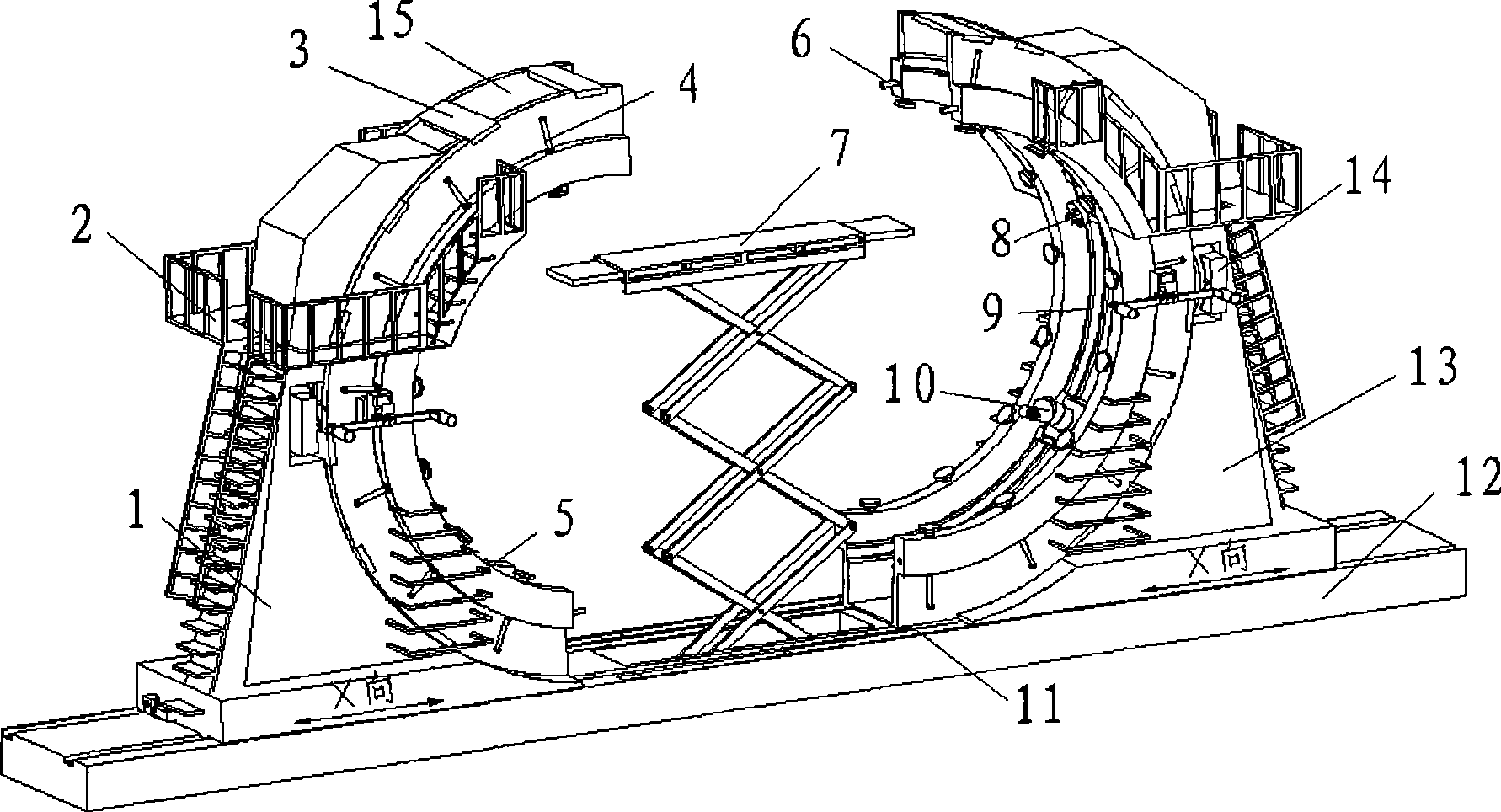

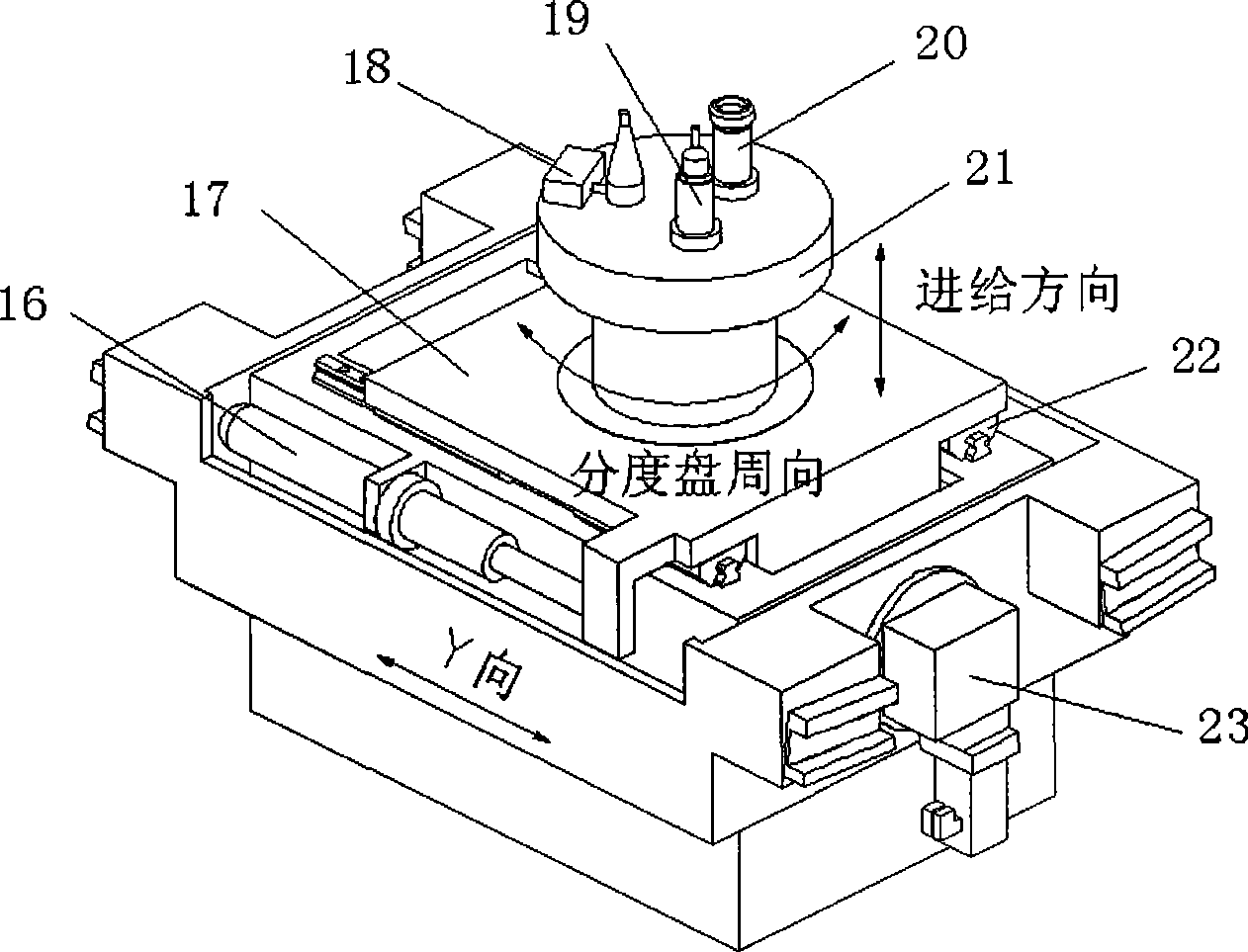

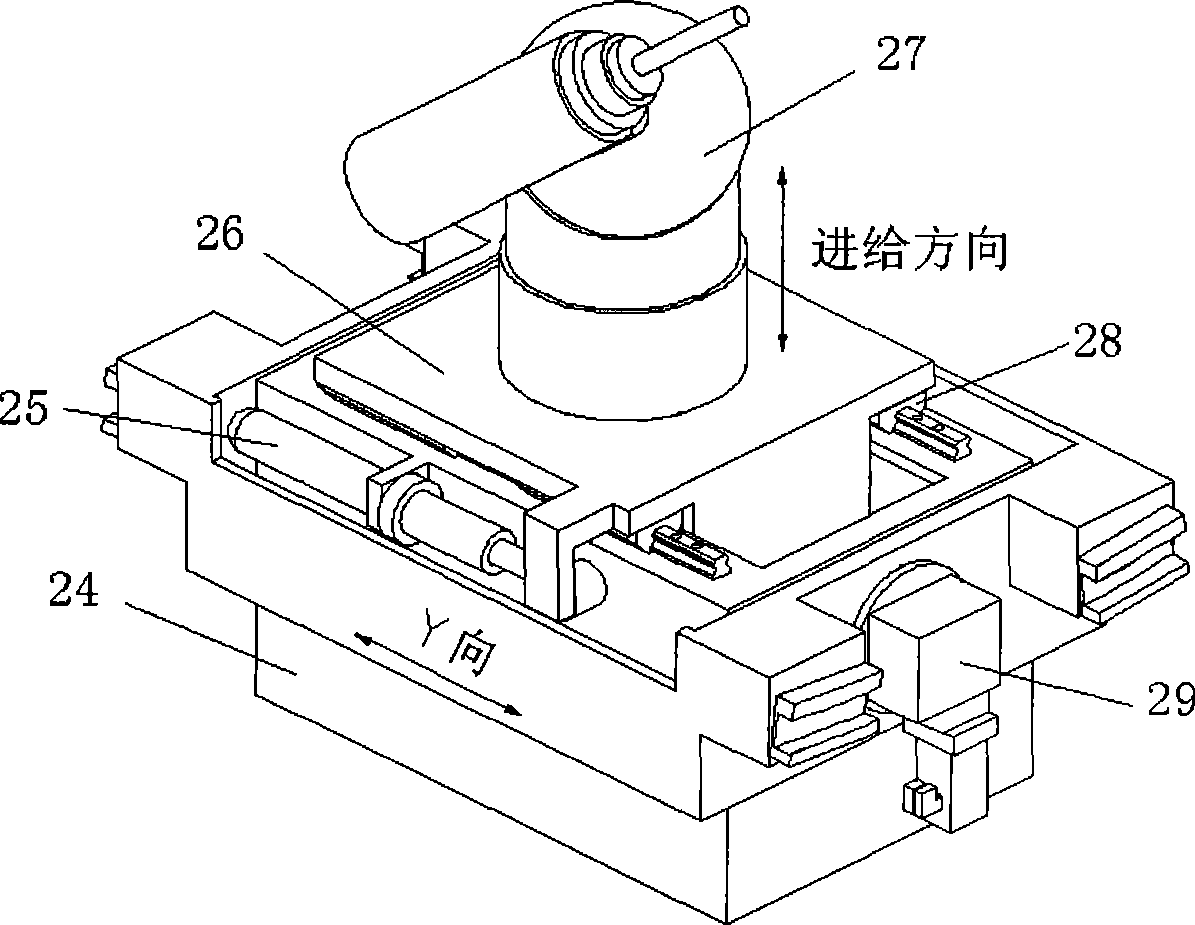

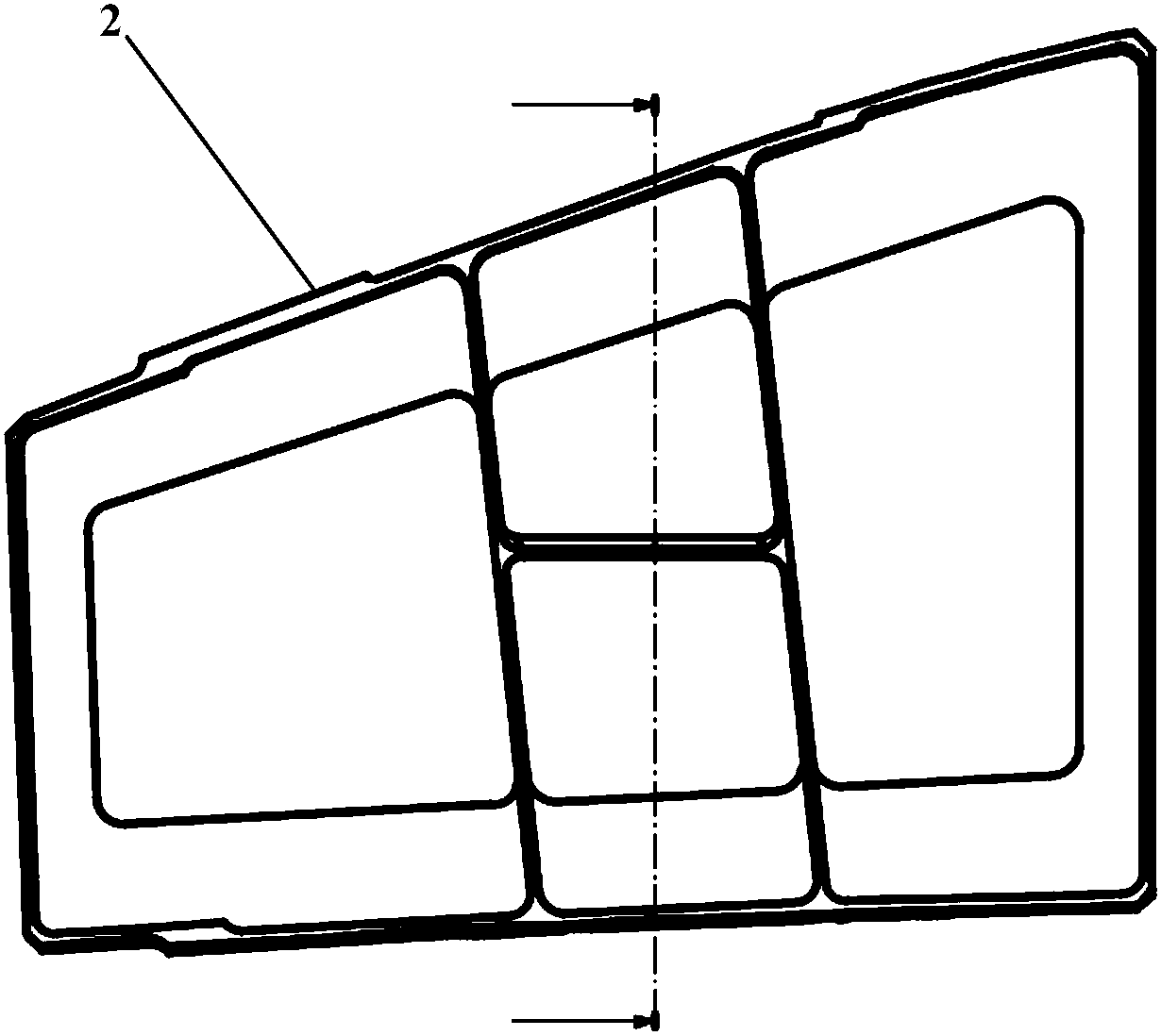

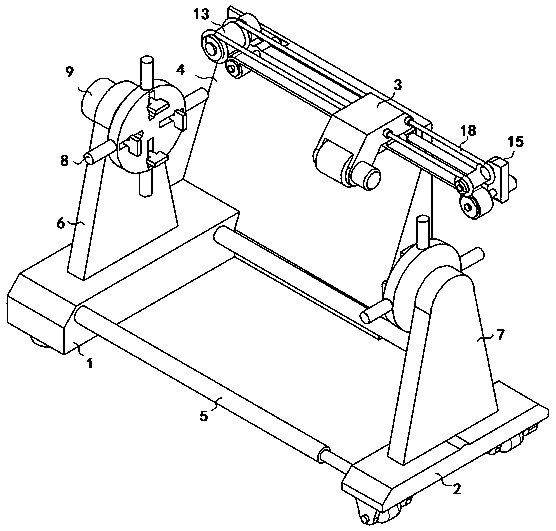

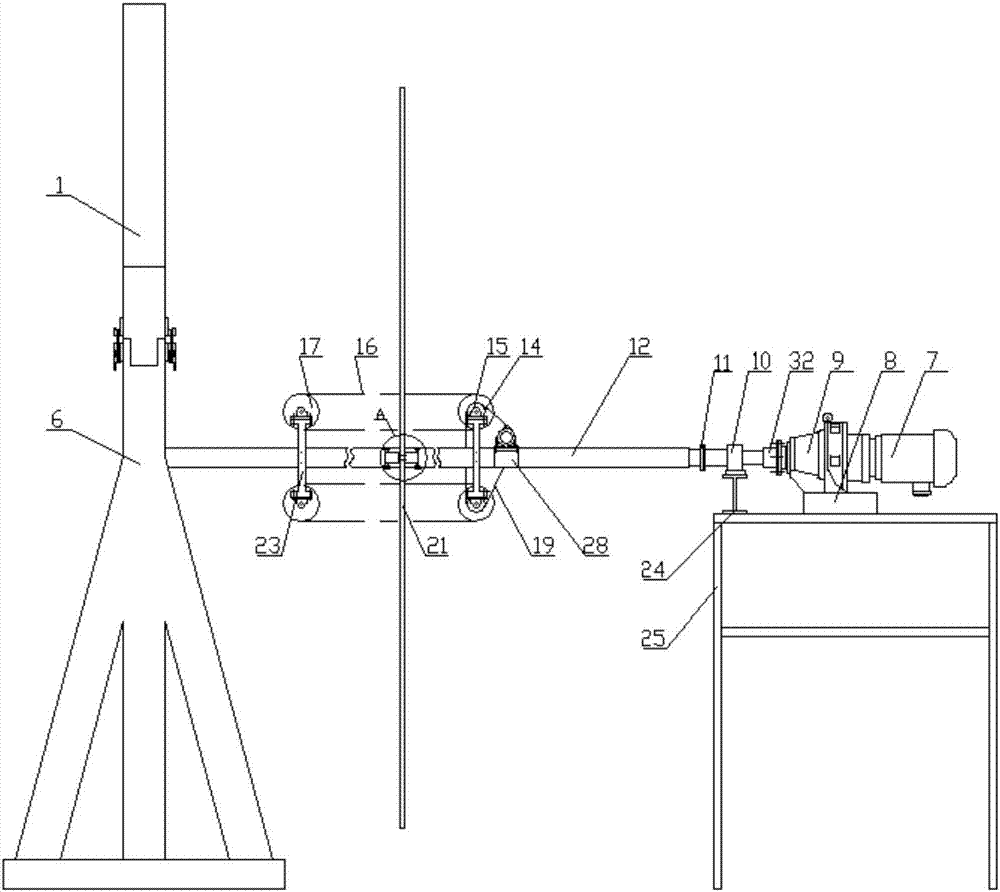

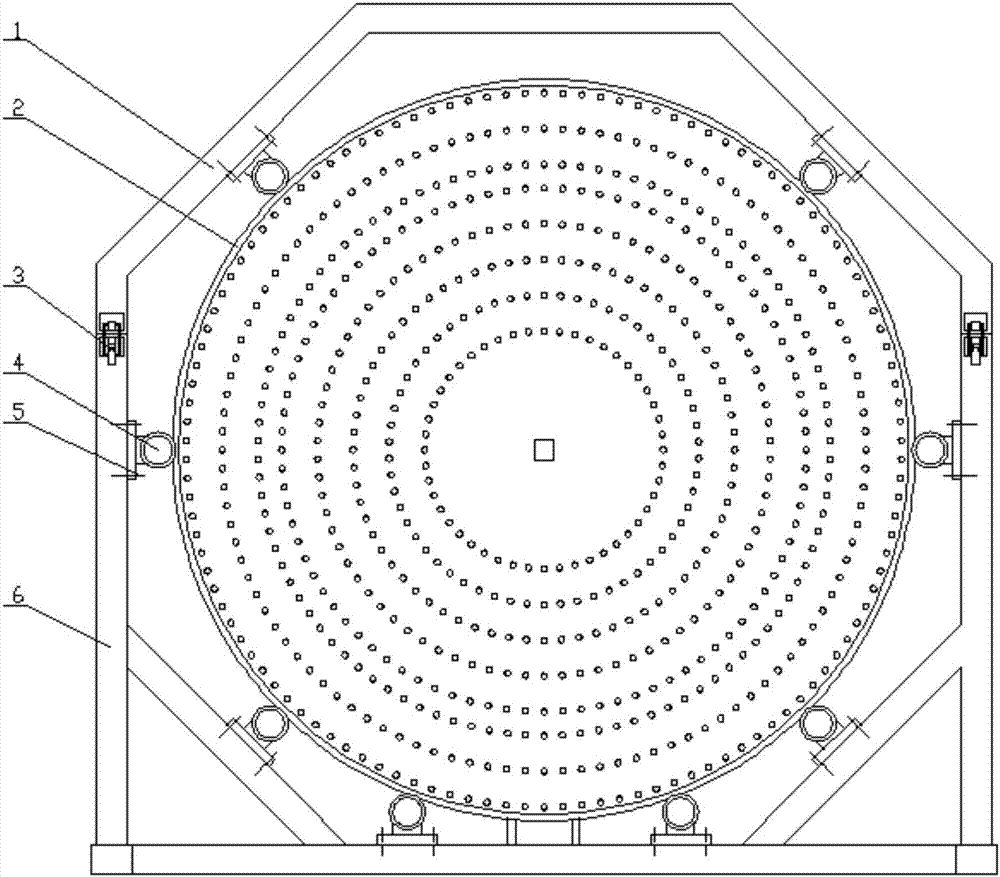

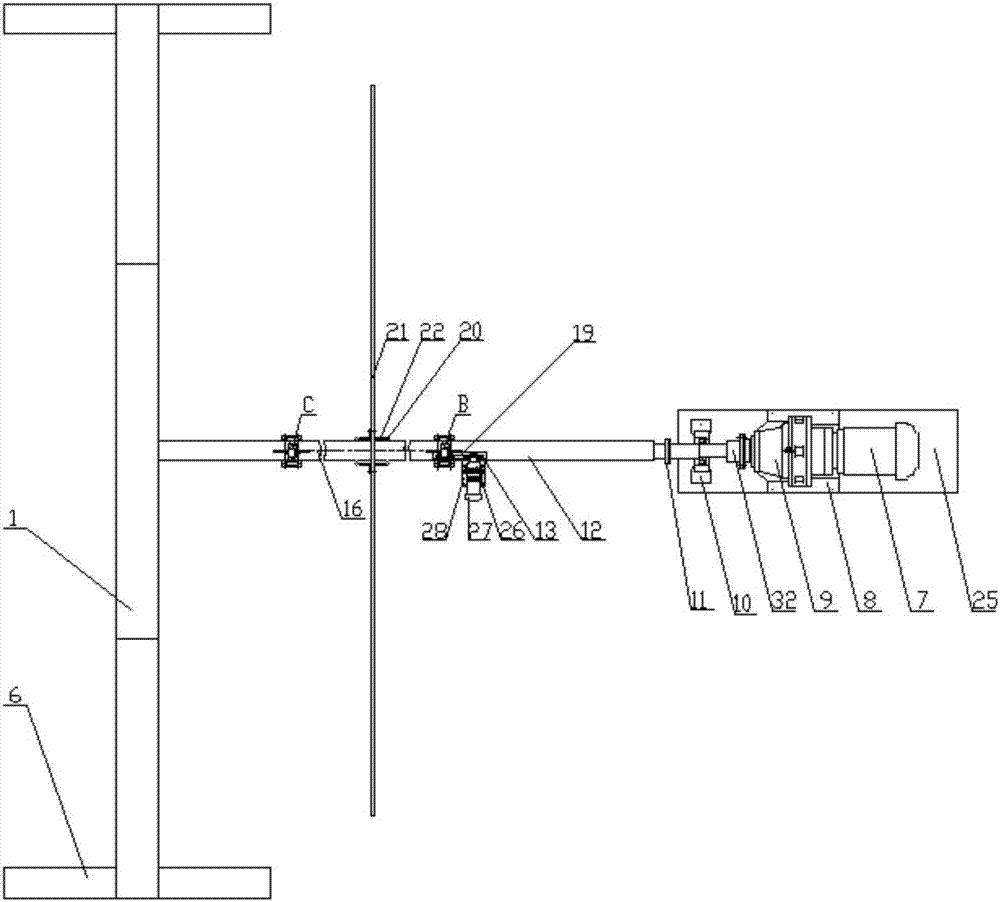

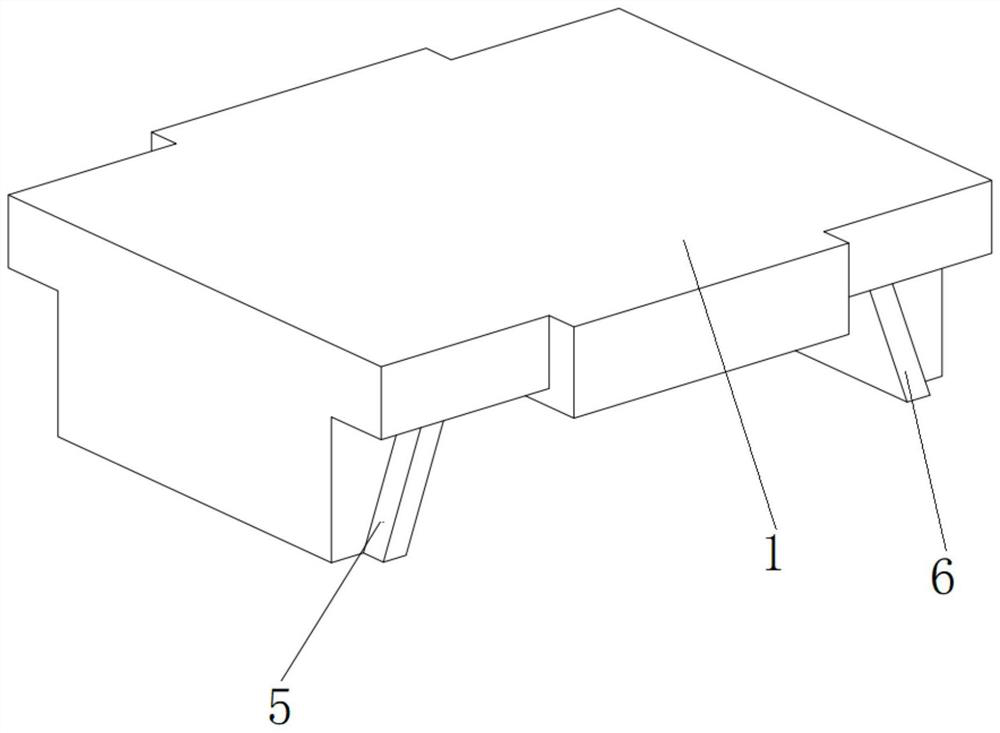

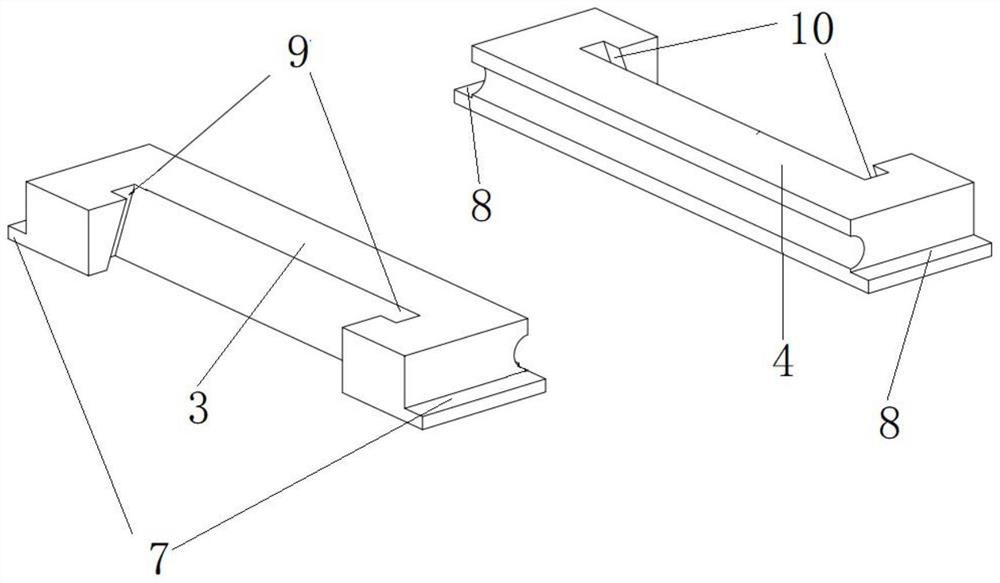

C type folded milling-drilling-riveting combined processing center and method of use thereof

InactiveCN101362302AMeet the passing requirementsExpand the range of processingLarge fixed membersPositioning apparatusSEMI-CIRCLEMachine tool

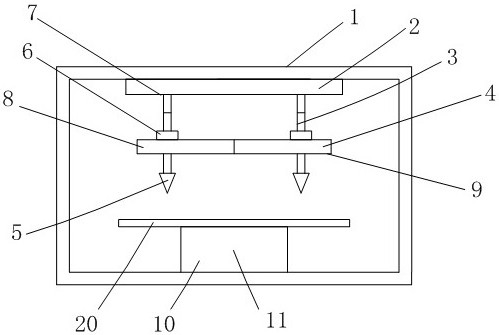

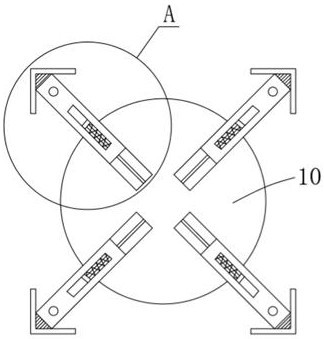

The invention discloses a working principle of a C type involutive milling, drilling and riveting combined machining center and a structure thereof. The body section of a plane can be machined by milling and drilling, and also the structure is provided with counter boring and rivet holding functions. A left machine tool body and a right machine tool body of a C type machine tool are arranged on a fixing base, two semi-circle supporting plates are arranged on the machine tool, a clamping device and a circular guide rail are uniformly distributed on the supporting plate, and a drilling and riveting device and an electric main shaft power head drilling and milling device are arranged on the circular guide rail. The working principle adopt the following machining steps: firstly, the left machine tool body and the right machine tool body are moved on the guide rail, and two semi-circumferential frames are opened; secondly, after the work piece is in position, the two semi-circumferential frames are closed, and the fixing for the work piece is realized; thirdly, after the electric main shaft power head drilling and milling device is in position, the drilling and milling for the work is finished; and fourthly, the working process of the drilling and riveting is similar to the drilling and milling device. The invention has the advantages that firstly, the automatic machining of milling, drilling and riveting of the body section of the plane can be satisfied; secondly, the work piece is ensured to have good passing ability after the machining; and thirdly, the range of circumferential machining and rivet connection range is large, and the working efficiency is high.

Owner:ZHEJIANG UNIV +1

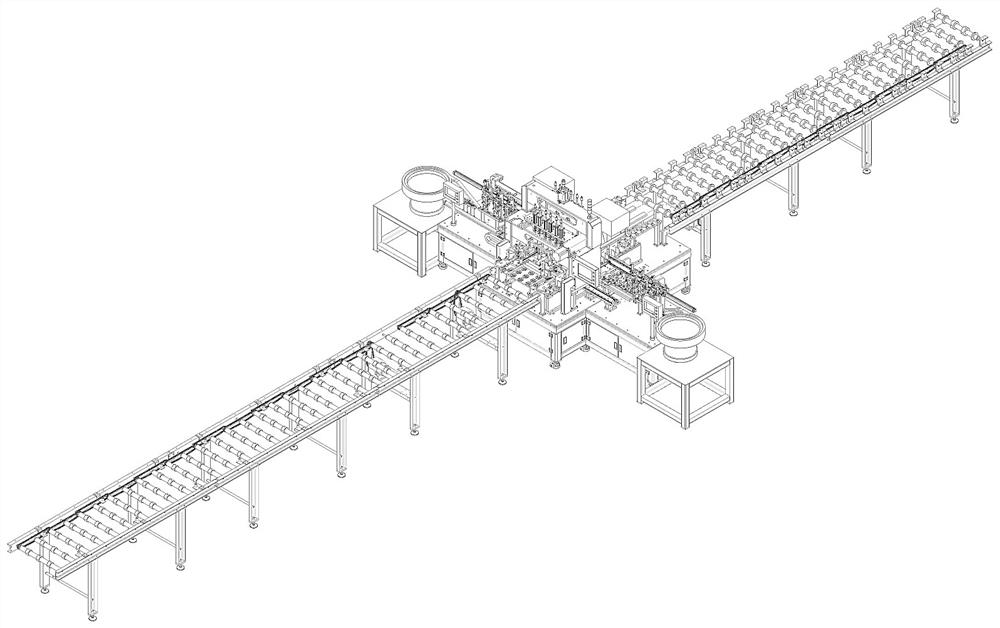

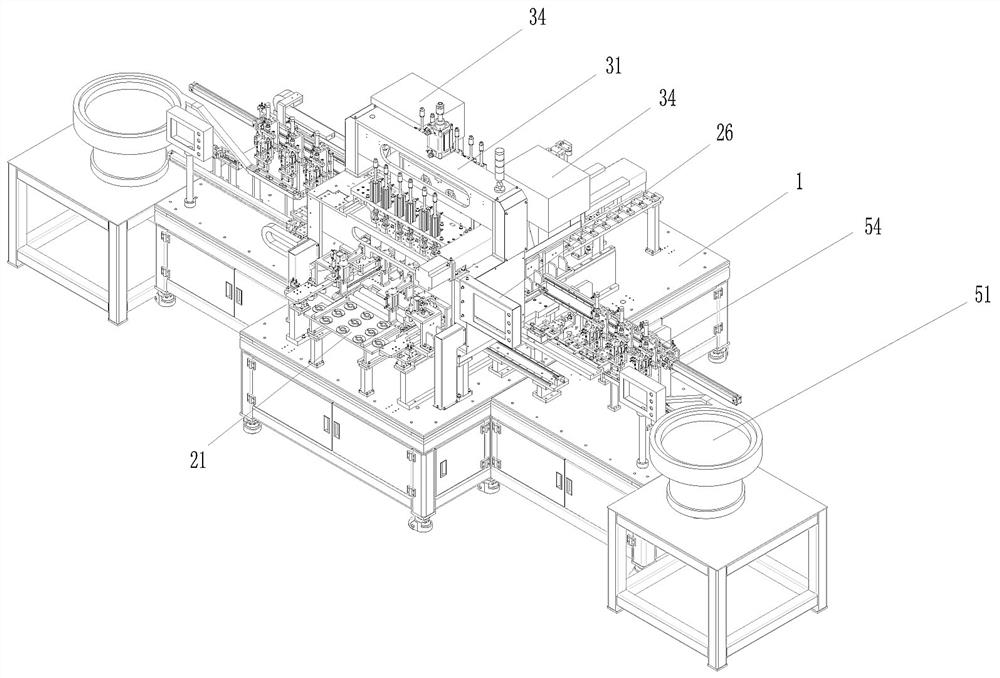

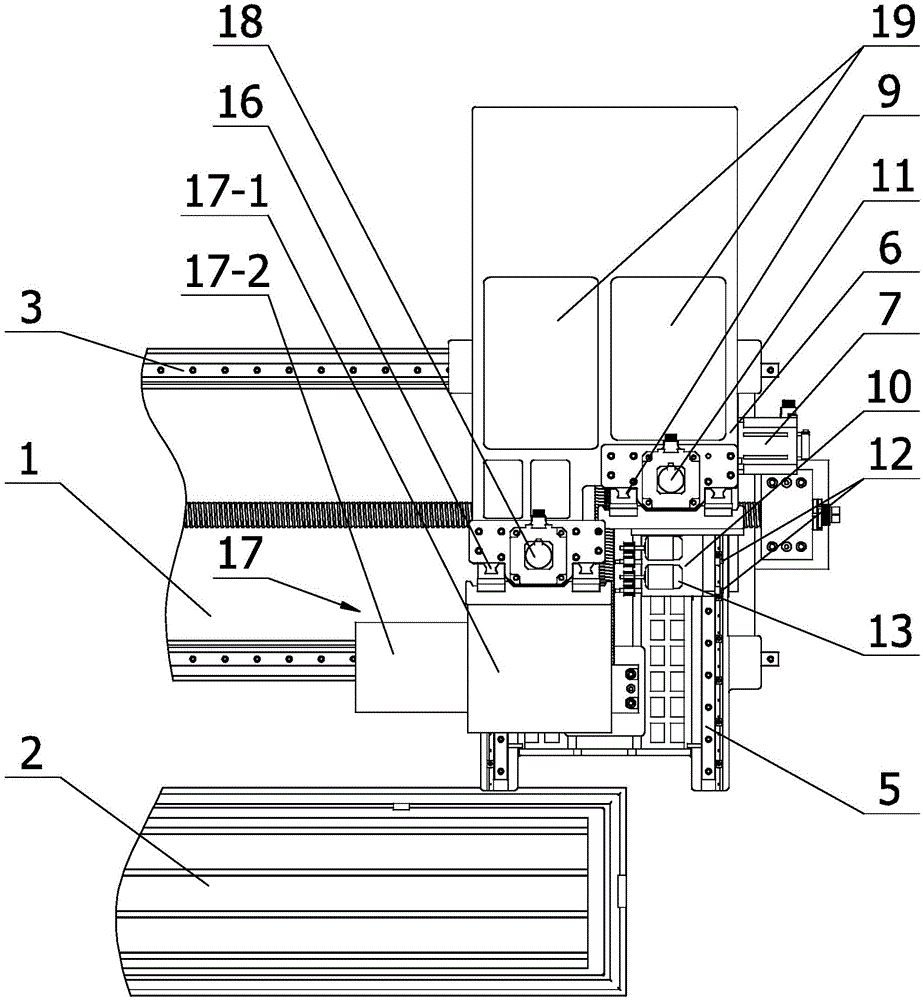

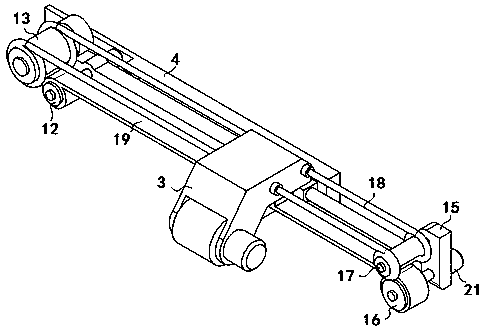

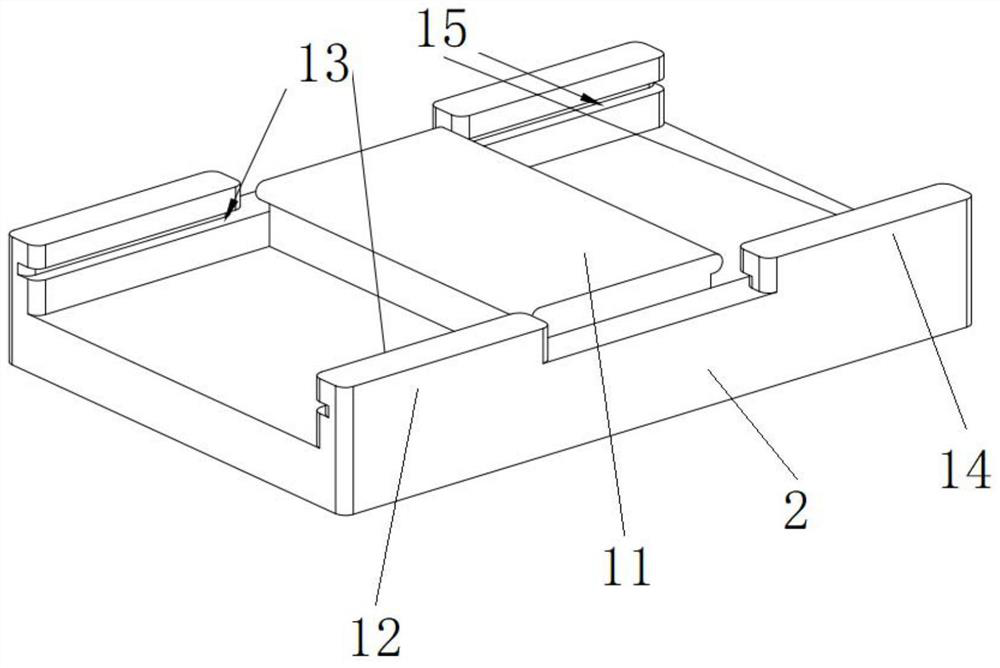

Detachable truss screw machine

ActiveCN111644834AReduce displacementReduce the situationMetal working apparatusBoring/drilling machinesPunchingStructural engineering

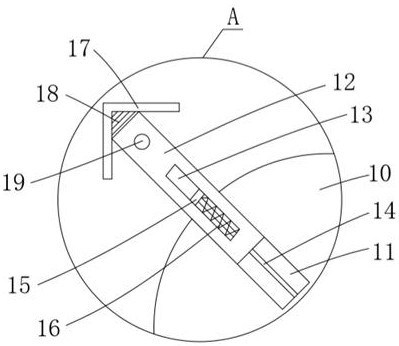

The invention relates to an assembly machine, in particular to a detachable truss screw machine. The detachable truss screw machine comprises a base, a stepping mechanism, a material sending mechanismand a processing mechanism, and the stepping mechanism comprises a stepping track and a stepping press plate device; the processing mechanism comprises a fixed frame, a punching deice, a screw loading device and a screw feeding machine; the material sending mechanism comprises a main track and a secondary track parallel to the main track, vibration discs are arranged at two ends of the main track, material placing grooves are connected to the vibration discs, transfer devices are arranged beside the material placing grooves, and moving fixtures which are matched with the transfer devices andcan move along the main track are arranged on the main track; and a push air cylinder is arranged on the secondary track, a clamp is connected to the side, facing the main track, of the push air cylinder, a control screen is arranged on the fixed frame, and the control screen is correspondingly connected with the stepping press plate device, the punching device, the screw loading device, the transfer device and the push air cylinder. According to the detachable truss screw machine, the manual process of feeding is saved, the full automation of the processing process is achieved, the processingefficiency is high, and the accuracy for processing finished products is high.

Owner:浙江亿洲机械科技有限公司

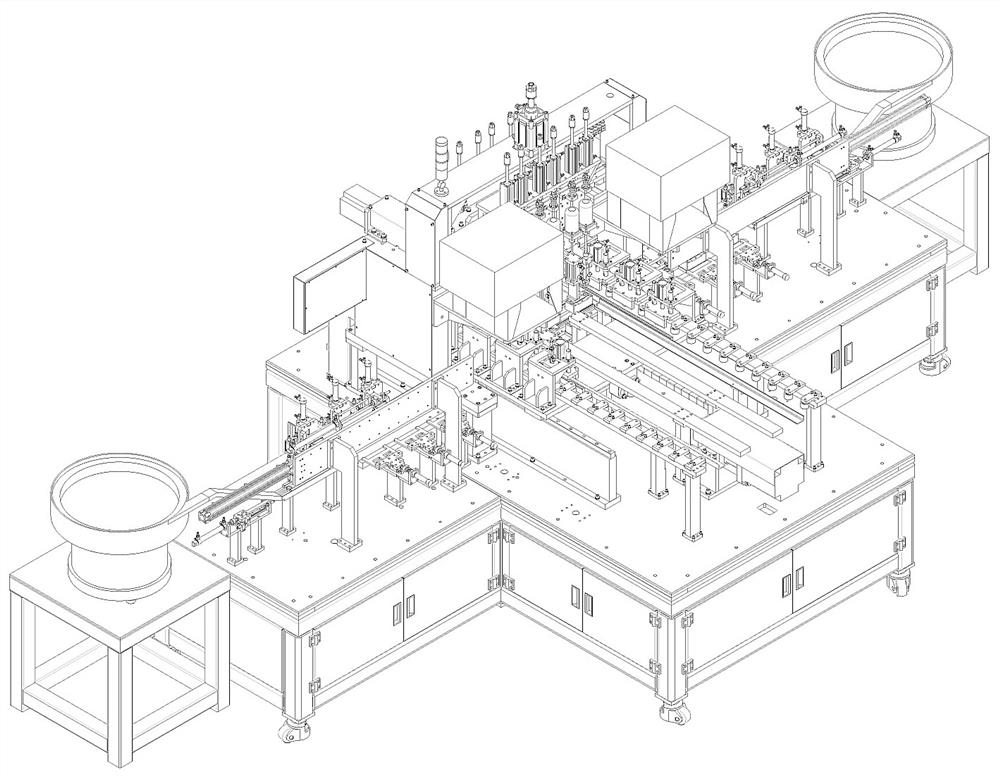

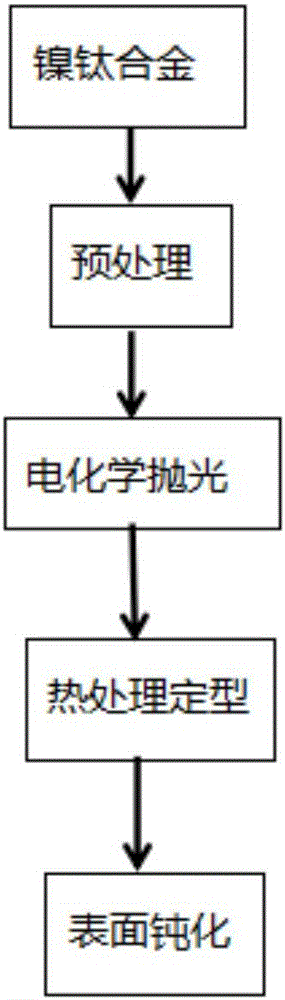

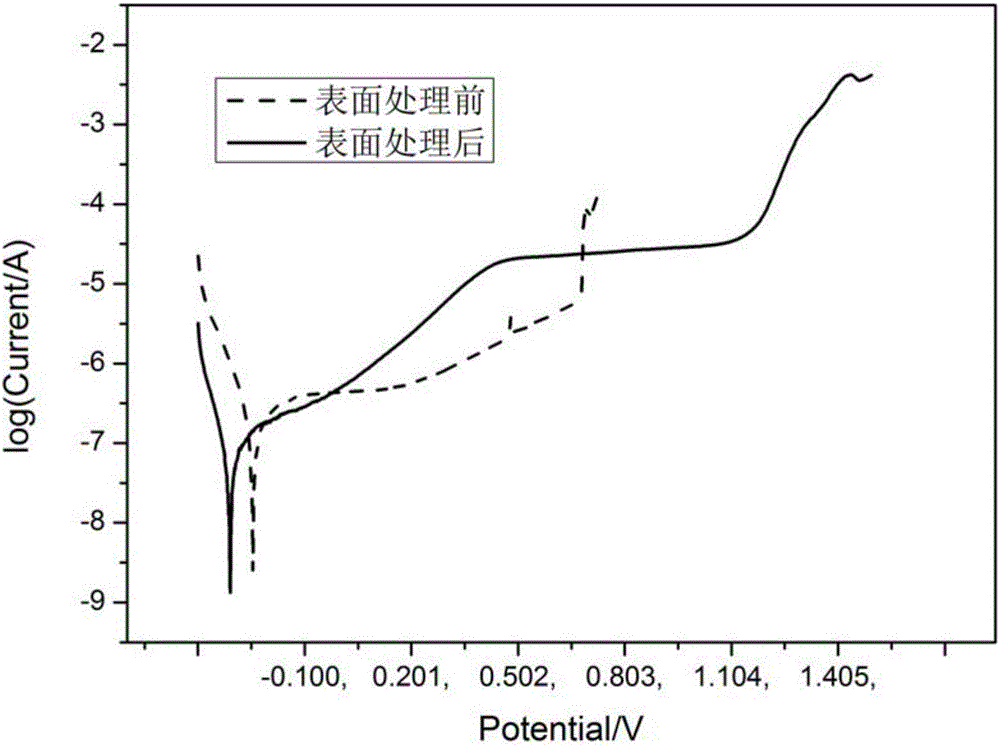

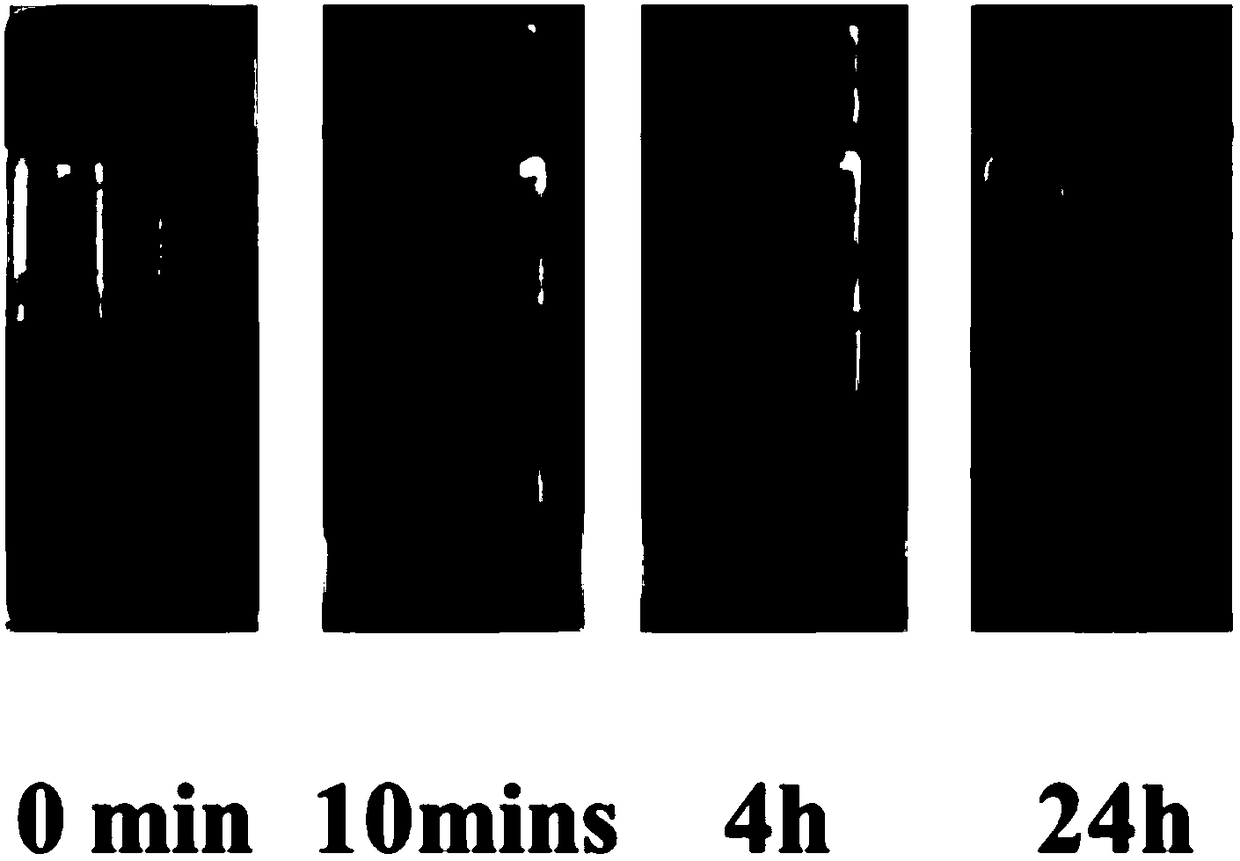

Surface treatment method for material nickel-titanium alloy for left aurcle plugging device

InactiveCN106811753AReduce surface roughnessEasy to useSurgeryPharmaceutical delivery mechanismTitaniumPre treatment

The invention discloses a method for surface treatment of a nickel-titanium alloy, a material used for a left atrial appendage occlusion device, and belongs to the technical field of medical metal surface treatment; the invention relates to a method for surface treatment of a biomedical nickel-titanium alloy, comprising the following steps and process conditions: (1) Substrate pretreatment; (2) Electrochemical polishing; (3) Product heat treatment setting; (4) Surface passivation process. Compared with the prior art, the process can significantly improve the surface treatment quality, improve the corrosion resistance of the nickel-titanium plug, and can expand the scope of the process treatment, especially suitable for the surface treatment of small pieces and complex-structured nickel-titanium products, with low cost and low cost. Simple and convenient for factory production and use of nickel-titanium products.

Owner:XIANGTAN UNIV

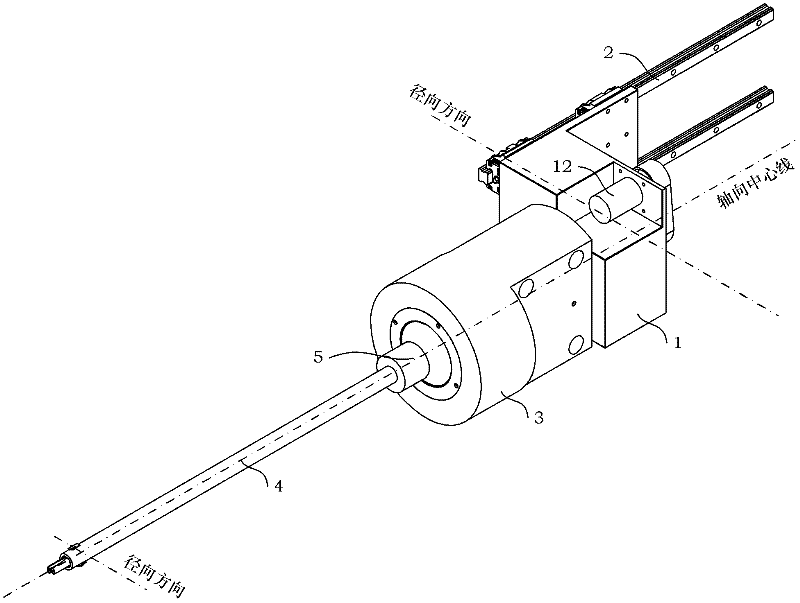

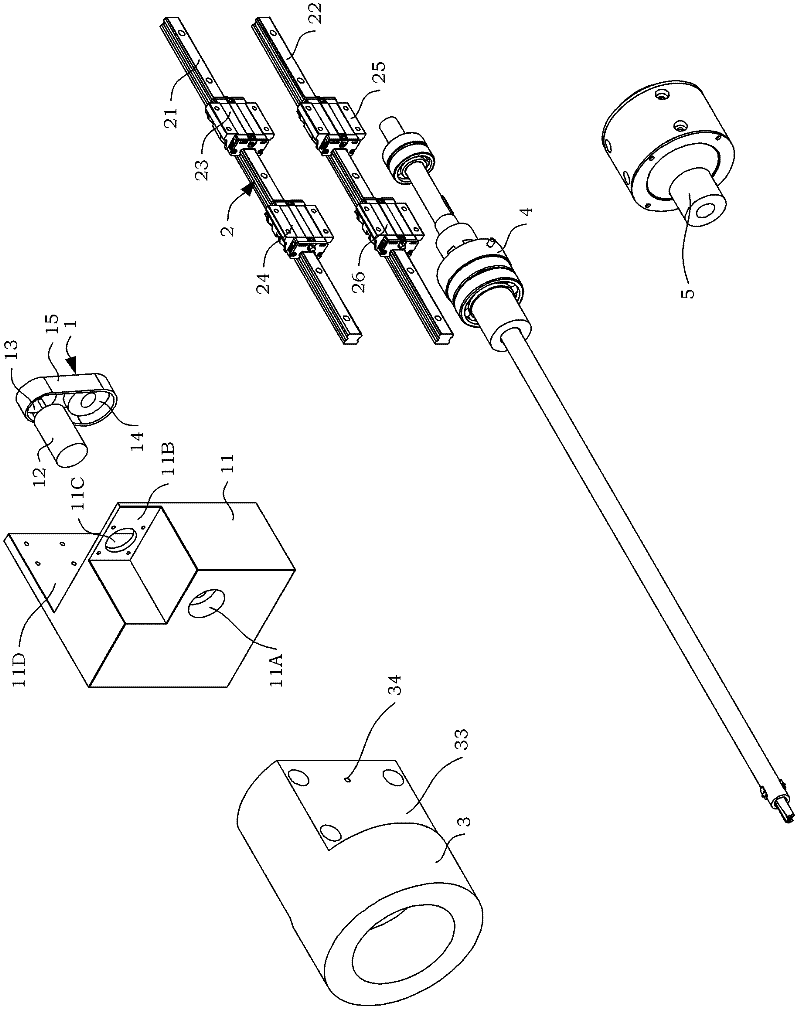

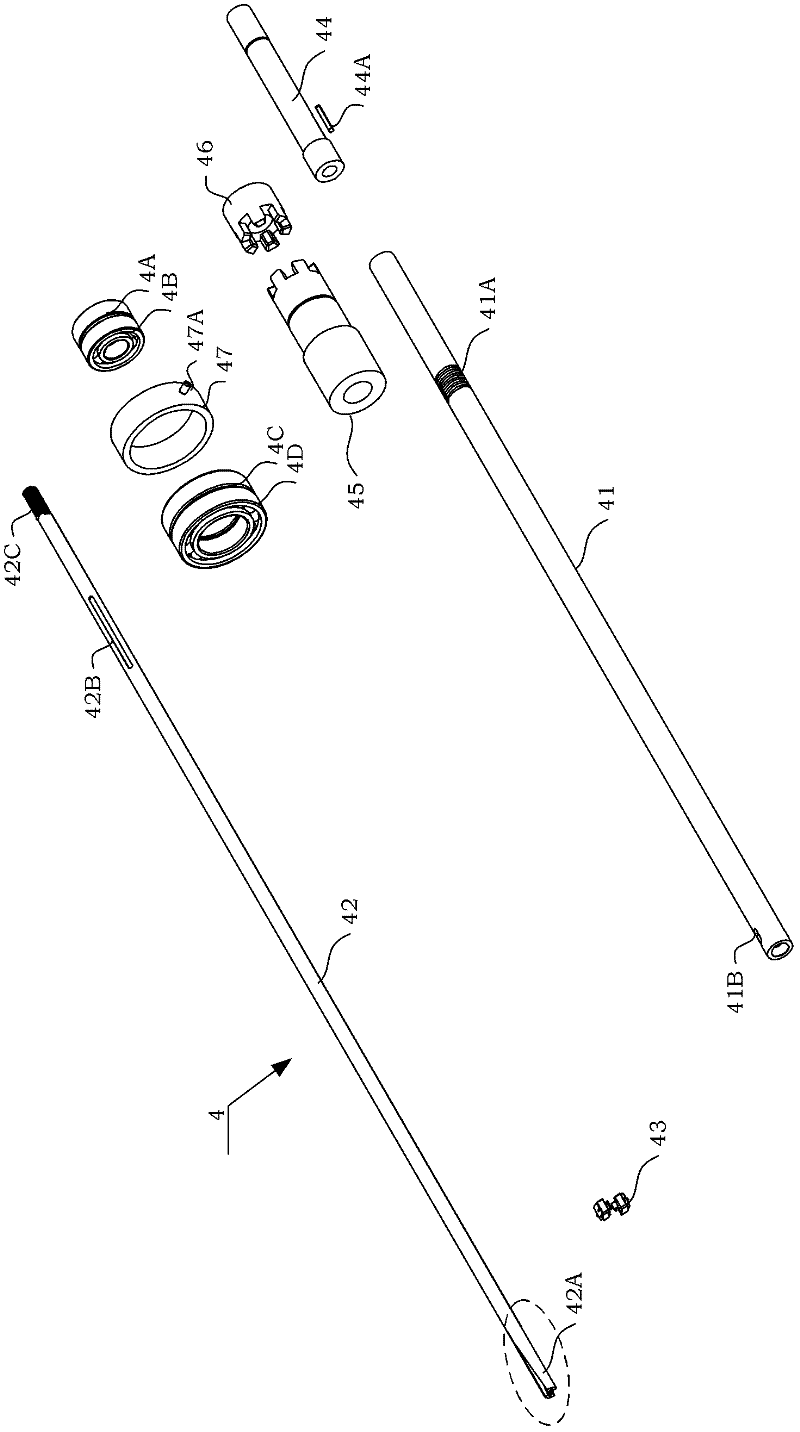

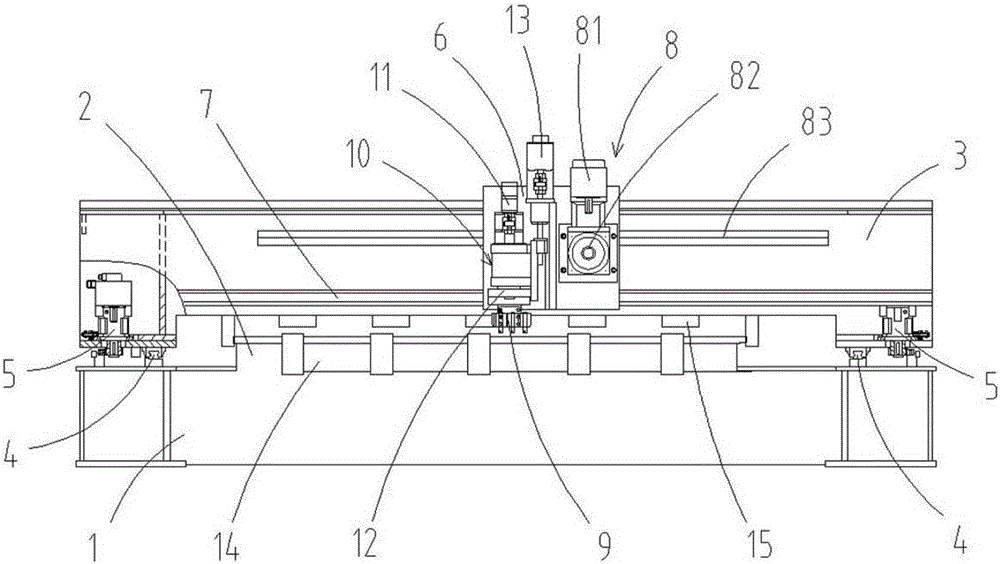

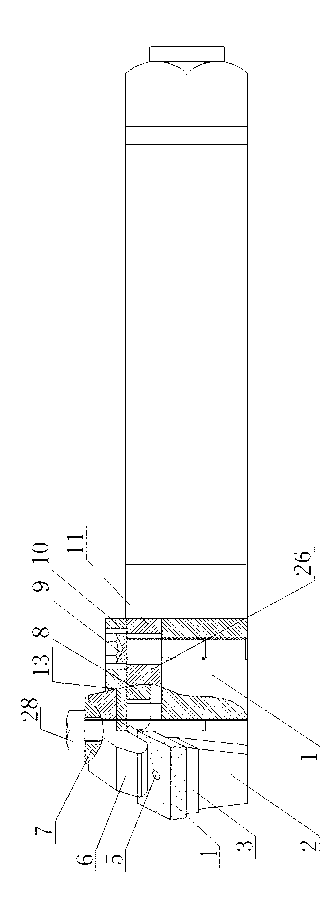

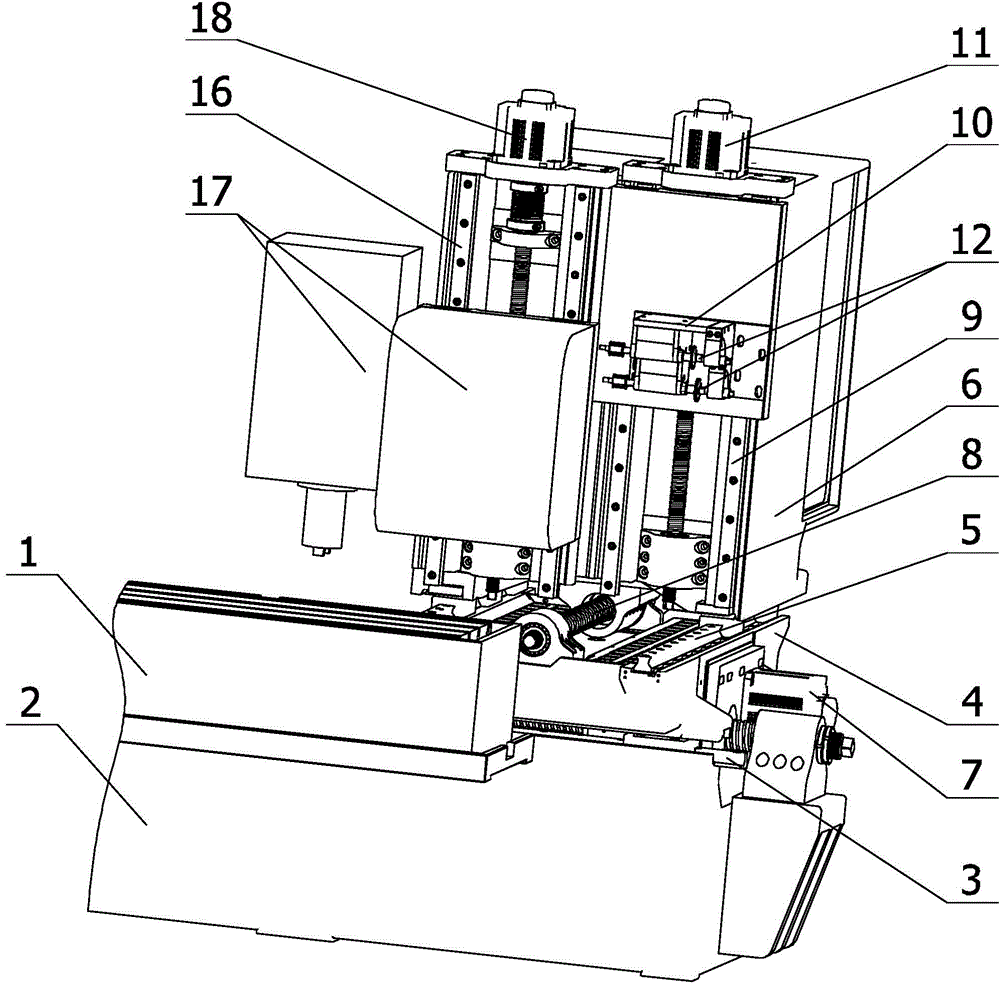

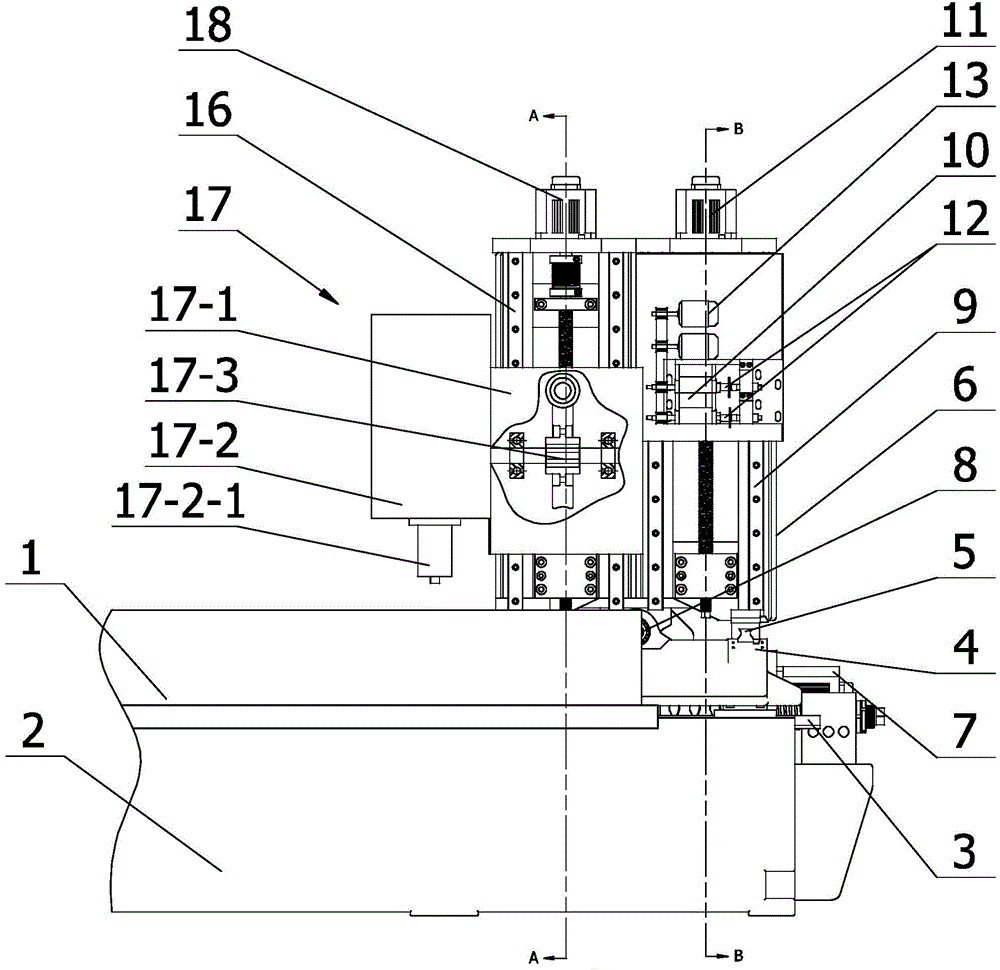

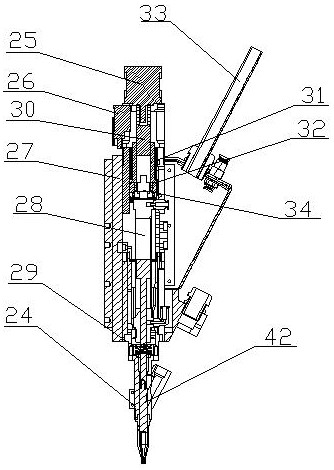

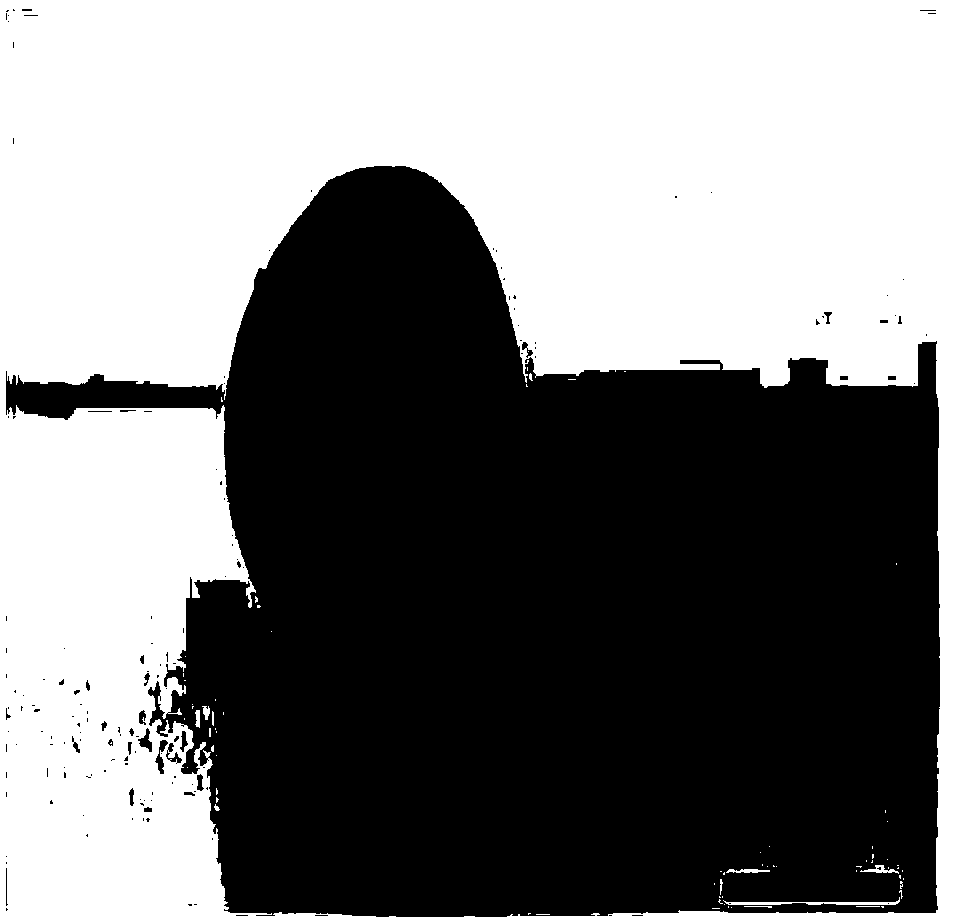

Numerical control and reducing ultrasonic vibration device for machining complicated inner cavity of deep hole

InactiveCN102500775AImprove rigidityImprove machining accuracyTurning toolsMechanical vibrations separationNumerical controlEngineering

The invention discloses a numerical control and reducing ultrasonic vibration device for machining a complicated inner cavity of a deep hole. The device comprises a driving subassembly, a sliding subassembly, a knife sheath, a reducing boring rod subassembly and an ultrasonic transduction subassembly, wherein the ultrasonic transduction subassembly is mounted in the knife sheath and the knife sheath is mounted on a knife tower; a sliding block of the sliding subassembly is mounted on a base of the driving subassembly and a guide rail of the sliding subassembly is mounted on a box of a machinetool; and the reducing boring rod subassembly is connected with the sliding subassembly. According to the numerical control and reducing ultrasonic vibration device provided by the invention, the machining efficiency and the machining precision of the complicated inner cavity of the deep hole are improved by utilizing a numerical control and reducing way. The application range of ultrasonic vibration boring is enlarged.

Owner:BEIHANG UNIV

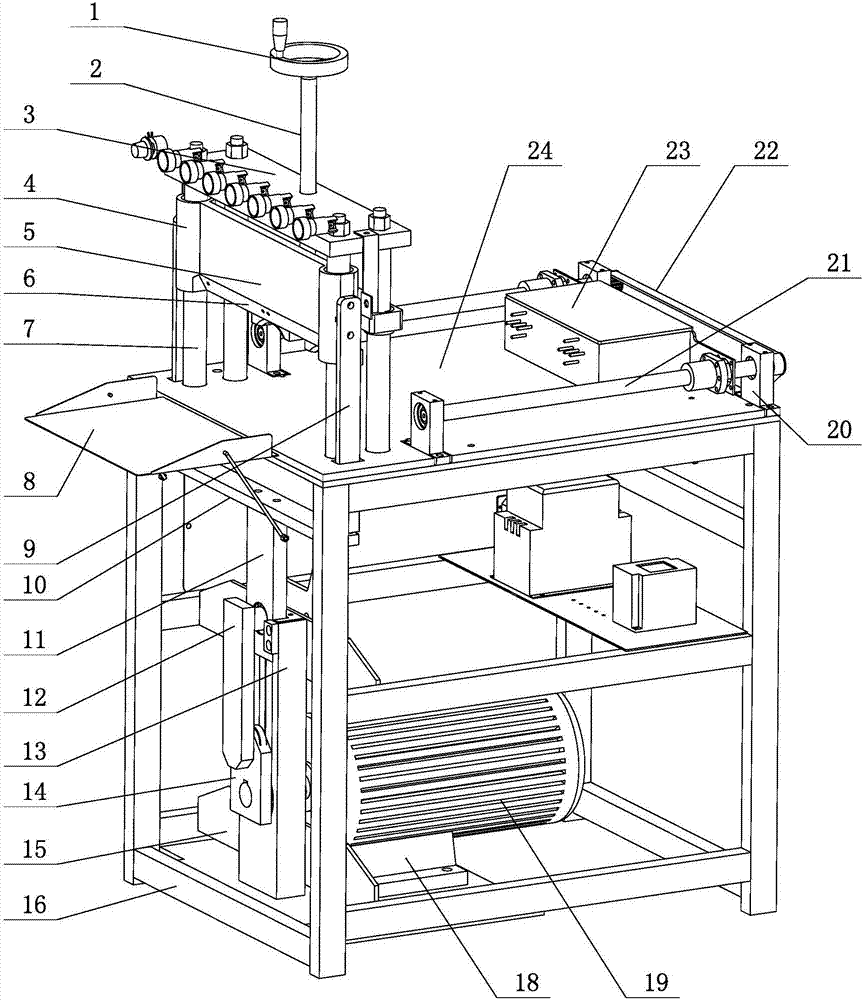

Meat slice processing equipment

PendingCN107950626AImprove power densityExpand the range of processingMeat processing devicesEngineeringFace sheet

The invention is mainly used for processing meat into slices, and particularly relates to meat slice processing equipment. The meat slice processing equipment comprises a machine frame; a face plate is arranged at the top of the machine frame; a driving mechanism is arranged on the lower part of the machine frame; the driving mechanism is connected with a cutting mechanism; the cutting mechanism comprises a transmission assembly; the top of the transmission assembly is connected with a guide assembly; the guide assembly is connected with a cutting assembly; the cutting assembly is positioned above one end of the face plate; a propulsion mechanism is arranged at the other end of the face plate; a discharging plate is arranged on the outer side of the cutting assembly; a clamping mechanism is arranged on the inner side of the cutting assembly; the transmission assembly comprises a crank connected with the driving mechanism; the top end of the crank is hinged with a rocking rod; the top of the rocking rod is connected with a sliding block; the sliding block is arranged in a guide groove body; the guide groove body is fixed on the machine frame; the top of the sliding block is connected with the guide assembly. The meat slice processing equipment is stable in transmission and small and exquisite in mechanism, enables an action force to be closed into the mechanism and only outputsa main action force for moving up and down to the outside. The adverse influence that the previous machine has a serious deflection force is overcome.

Owner:刘洪柱

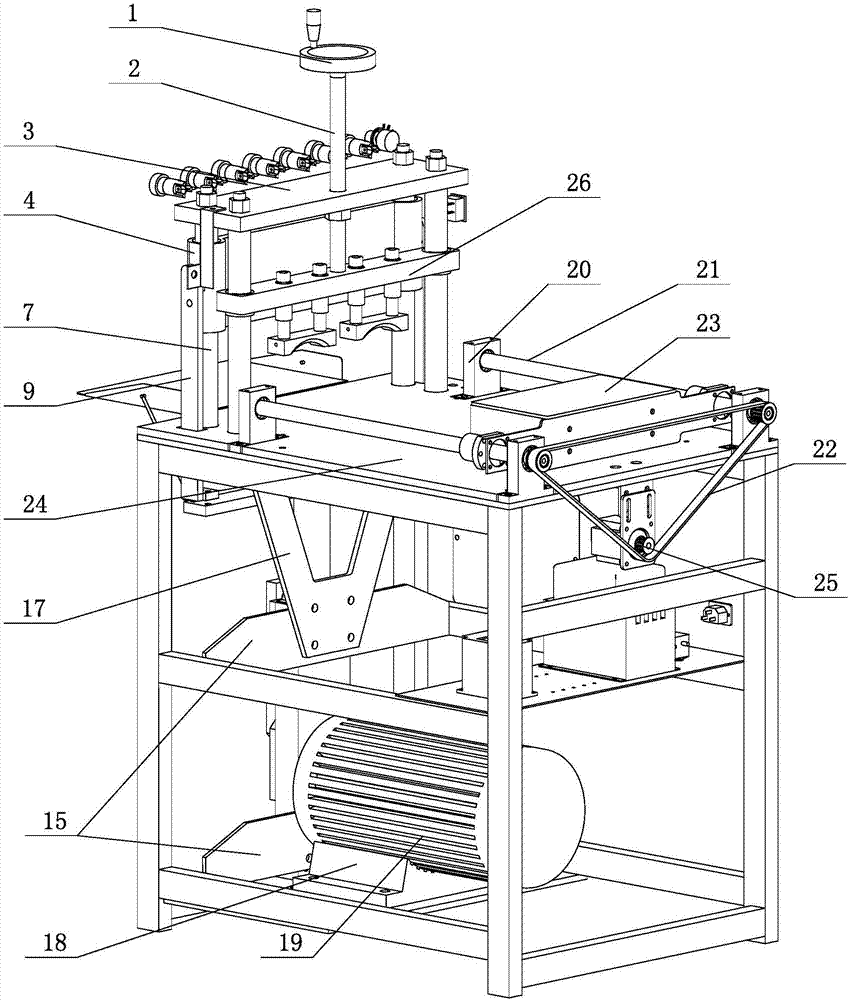

All-dimensional planar planing equipment with intelligent pressing system

ActiveCN106077784AReduce contact surfaceAutomatic height adjustmentPlaning/slotting machinesPositioning apparatusSlide plateEngineering

The invention discloses all-dimensional planar planing equipment with an intelligent pressing system. The all-dimensional planar planing equipment comprises a machine frame, a work table arranged on the upper surface of the machine frame and a moving beam suspended above the work table, wherein the two ends of the moving beam are connected to the machine frame through transverse guide rails and transverse drive devices are arranged at the two ends of the machine frame; a longitudinal sliding plate device is arranged on one side of the moving beam and is connected to the moving beam through a longitudinal guide rail; and a longitudinal driving device is arranged on one side of the longitudinal sliding plate device, a cutter box is arranged at the lower end of the longitudinal sliding plate device, and a set of cutters are arranged inside the cutter box. According to the design, bidirectional planing and slotting in the longitudinal direction and the transverse direction can be realized, inclined planing and slotting can be realized through simultaneous moving of the moving beam and the longitudinal sliding plate device, and inclined planing and slotting at different angles can be realized by controlling the moving speed of the moving beam and the moving speed of the longitudinal sliding plate device.

Owner:施泰德精密机械(太仓)有限公司

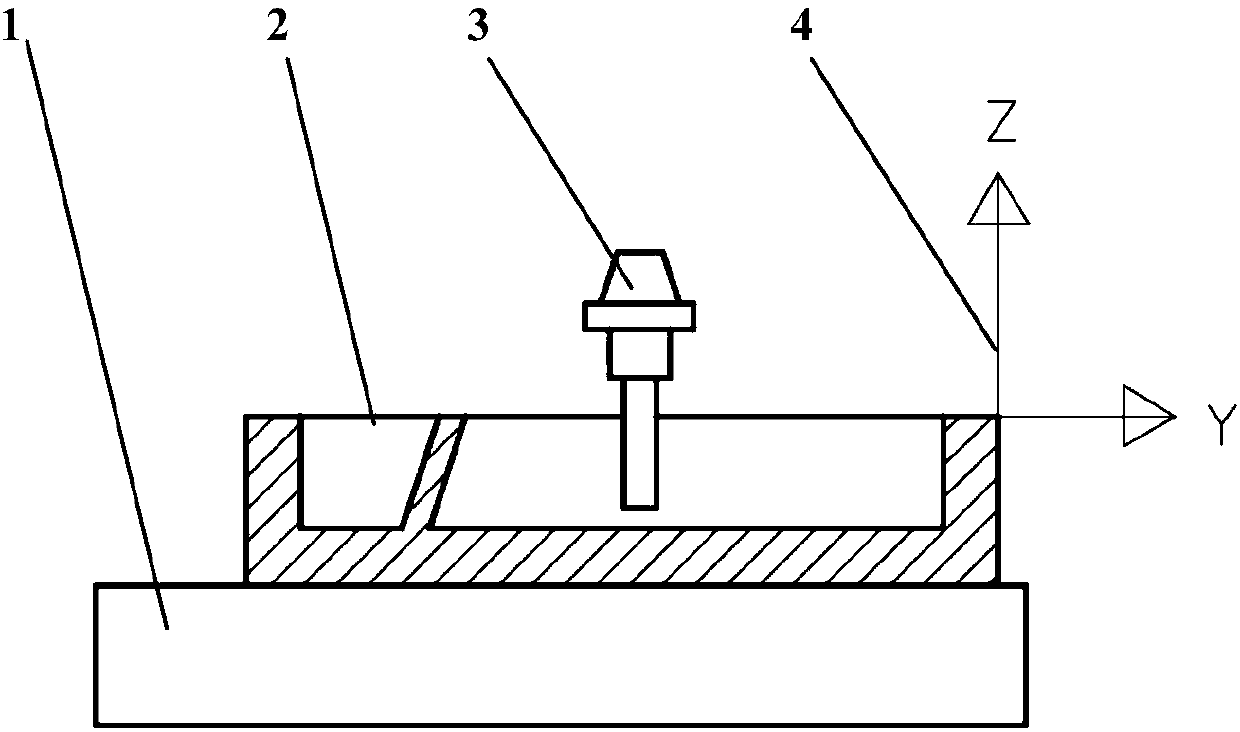

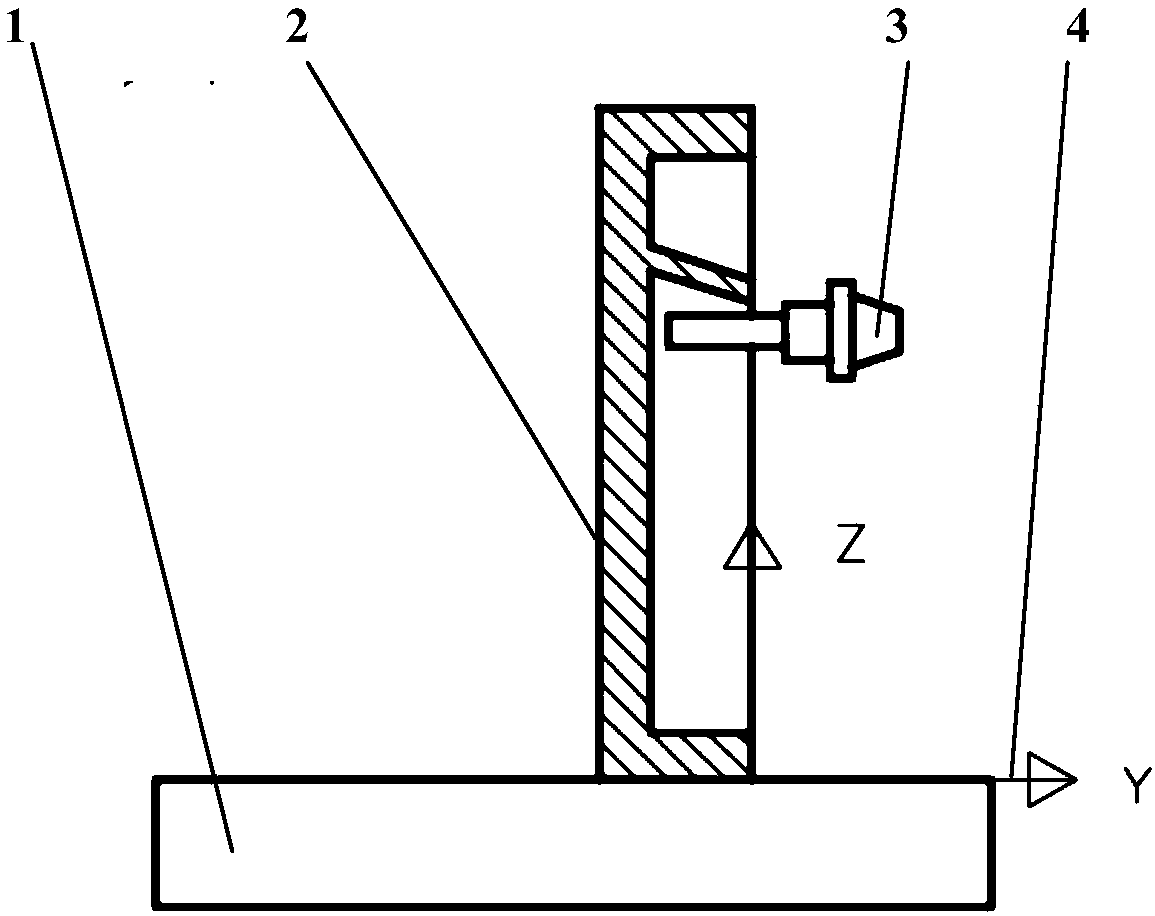

Method and clamping device for numerical control machining of component closed corner

PendingCN107649904ASolve the lack of travel in the Y directionSolve processabilityLarge fixed membersPositioning apparatusNumerical controlRight trapezoid

The invention discloses a method and a clamping device for numerical control machining of a component closed corner. The cross section of the clamping device is in a right trapezoid shape. The clamping device comprises a top plane and a bottom plane which are parallel to each other, and further comprises an oblique plane. The angle formed between the oblique plane and the vertical direction is larger than the maximum closed corner angle on a component. Two positioning holes and a plurality of bolt holes are distributed in the oblique plane. The top plane is provided with a vertical datum hole,and a reference edge perpendicular to the bottom plane is arranged below the oblique plane. The clamping device is arranged on a platform of a numerical control machine tool, the bottom plane is attached to the machine tool platform, the reference edge is parallel to the X direction of the machine tool, and the component is positioned and installed on the oblique plane of the clamping device. A machining coordinate system is established by utilizing the relative relation of the datum hole and the positioning holes in the clamping device, and the original point of the machining coordinate system coincides with the center of the datum hole. Five-axis oscillating angle machining of a workpiece is finished through the numerical control machining program established under the machining coordinate system.

Owner:XIAN AIRCRAFT IND GROUP

Method for processing circuit board by means of laser direct structuring technology

ActiveCN103917052AHigh precisionLow costConductive material chemical/electrolytical removalLaser etchingEngineering

The invention relates to a method for processing a circuit board by means of the laser direct structuring technology. A conducting layer with which a substrate material is covered is thinned firstly and then selectively and directly removed after being processed through through-hole plating and electroplating thickening procedures so that a conductive pattern structure meeting the design requirements can be obtained. The method includes the steps that firstly, a monitoring disc is manufactured, namely the conducting layer is removed from a monitoring pattern area through laser in an etched mode; secondly, the material covered with the conducting layer is thinned through micro etching liquid, and micro etching thinning is carried out until a base material is exposed at patterns of the monitoring disc; ultimately, after drilling and through-hole plating are carried out on the thinned substrate material and the material covered with the conducting layer, a part of the conducting layer with which the substrate material is covered is removed through laser direct structuring, and a needed conducting layer is left. According to the method, the processing problem that in the prior art, the conducting layer is too thick after undergoing the through-hole plating and accordingly it is improper that the conducting layer is directly removed through laser or a mechanical method, and meanwhile the application range of a PCB processed through a laser etching method is widened.

Owner:德中(天津)技术发展股份有限公司

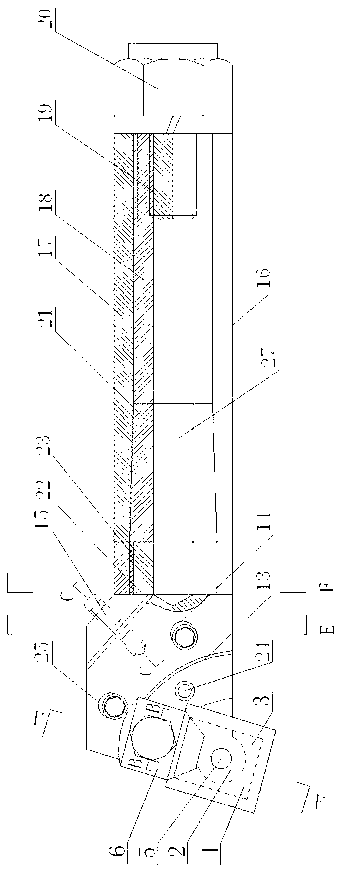

Lathe type roughing feed finish-machining adjustable cutter comprehensive tool system with finishing edge

ActiveCN103264172ALarge adjustment spaceExpand the range of processingTurning toolsTool holdersEngineeringMechanical engineering

A lathe type roughing feed finish-machining adjustable cutter comprehensive tool system with a finishing edge comprises a cutter bit subsystem, a cutter bar subsystem, a clamping subsystem and a cutter pad subsystem. A main body of the cutter bit subsystem is a cutter bit, a circular-arc-shaped adjusting face is arranged on the lower end face of the cutter bit, a circular-arc-shaped cutter stand, an upper press plate and a lower press plate are arranged on the cutter bit, and the upper press plate and the lower press plate are connected with the cutter bit through press pads. One end of the upper press plate and one end of the lower press plate are respectively connected with an upper blocking plate and a lower blocking plate to form a vector adjusting oblique table, and the vector adjusting oblique table is fixedly connected with the cutter bit through an adjustable positioning hole to form the clamping subsystem. A cutter pad and a transposition blade are clamped between the upper press plate and the circular-arc-shaped cutter stand to form the cutter pad subsystem. The lathe type roughing feed finish-machining adjustable cutter comprehensive tool system can adjust the cutter clamping position in multidirectional and multi-angle modes and is large in adjustment feeding mount and wide in range, different types of cutters can be replaced, and an accurate systematized cutter system can be formed by configuring a small quantity of cutters.

Owner:南京能新电力高科实业有限公司

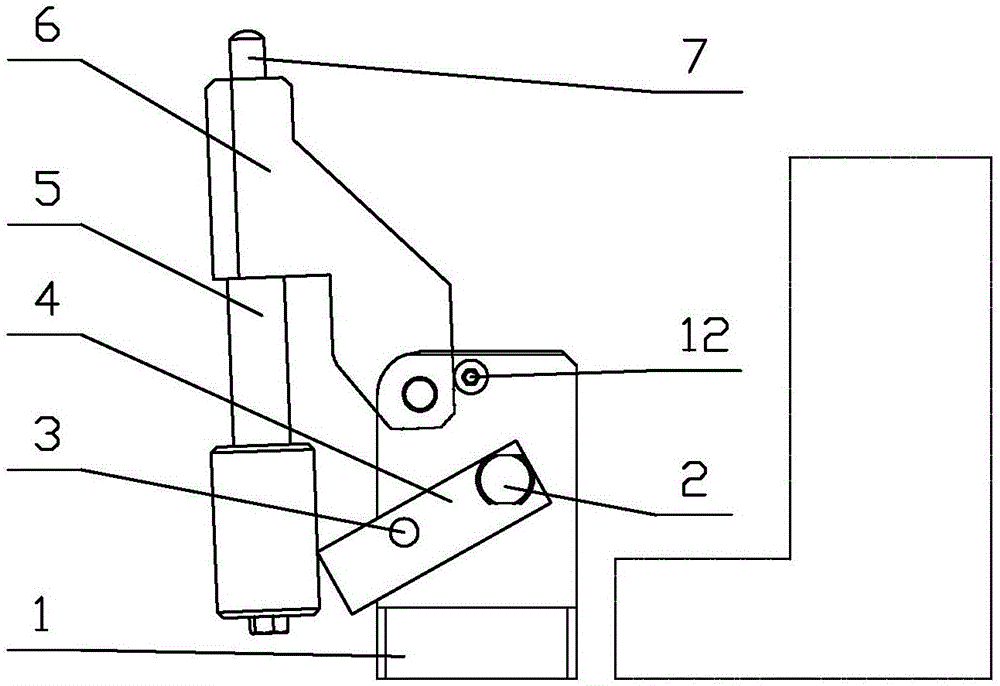

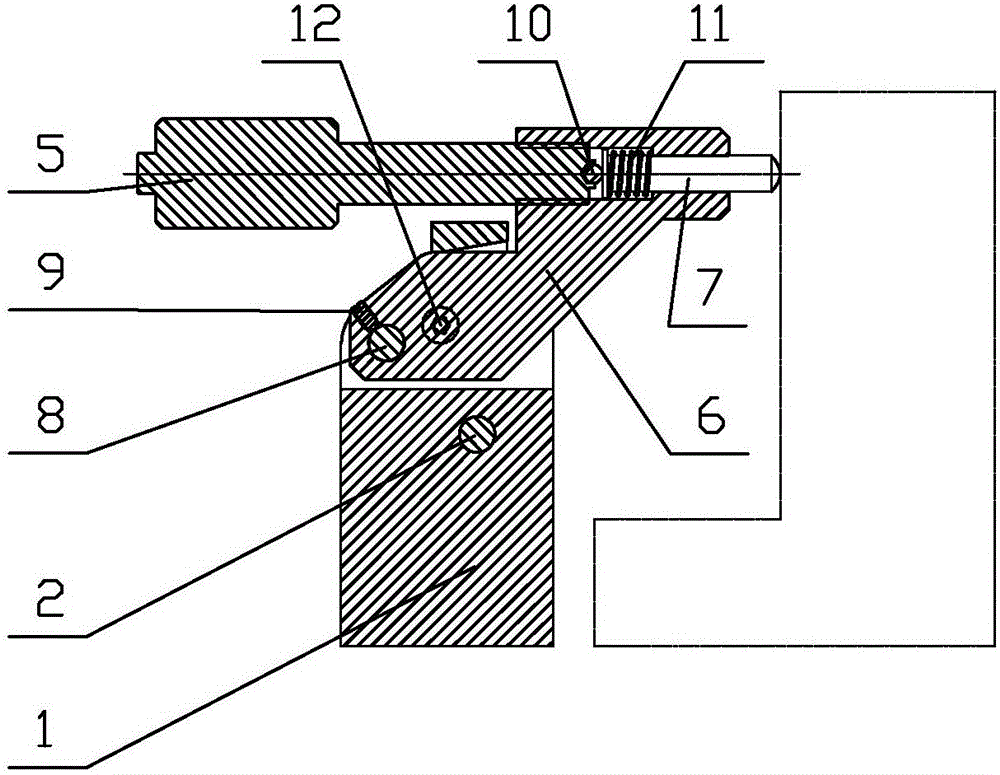

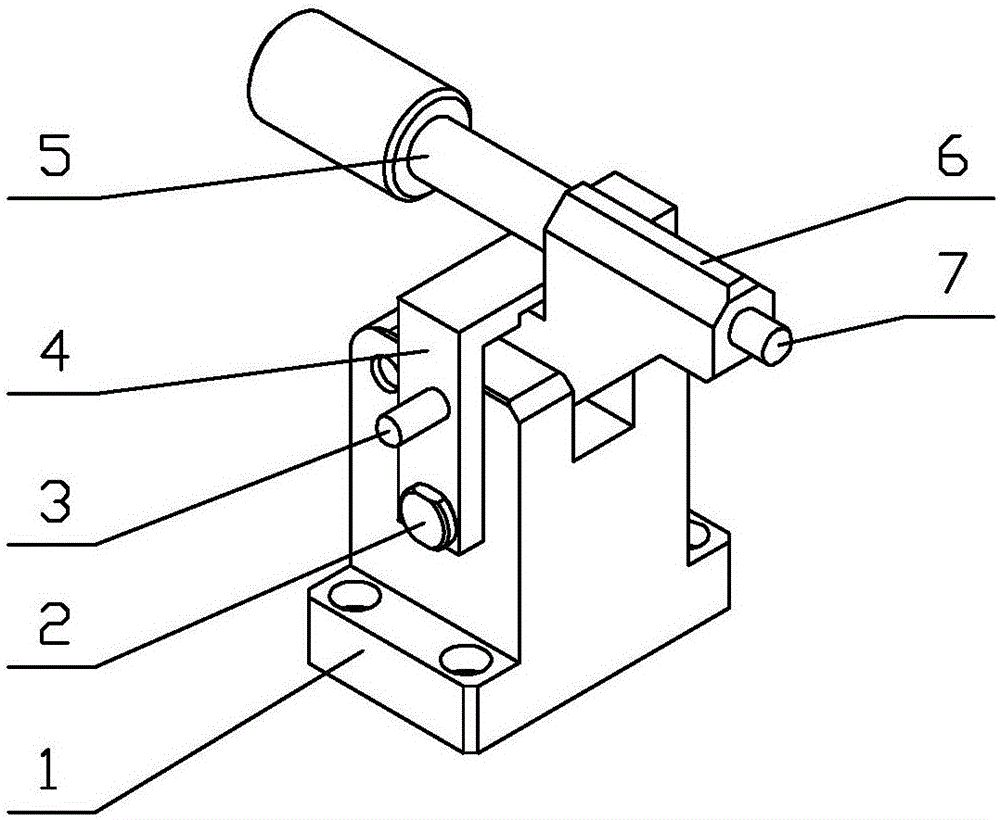

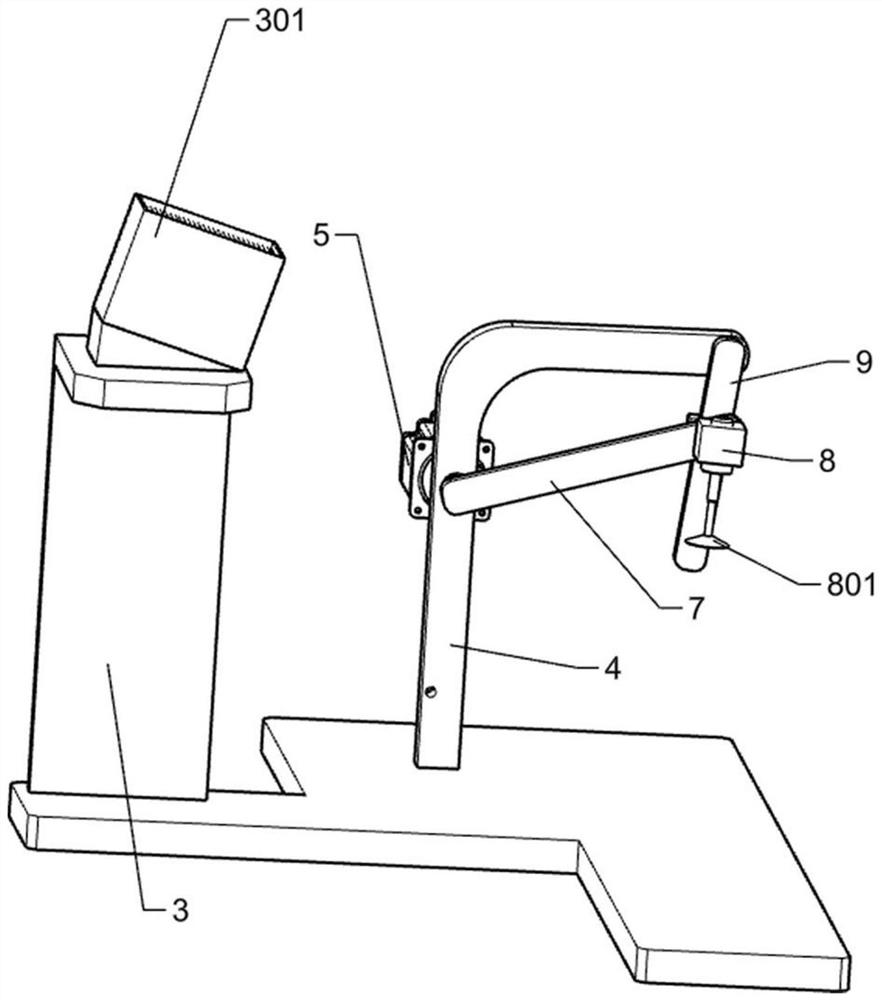

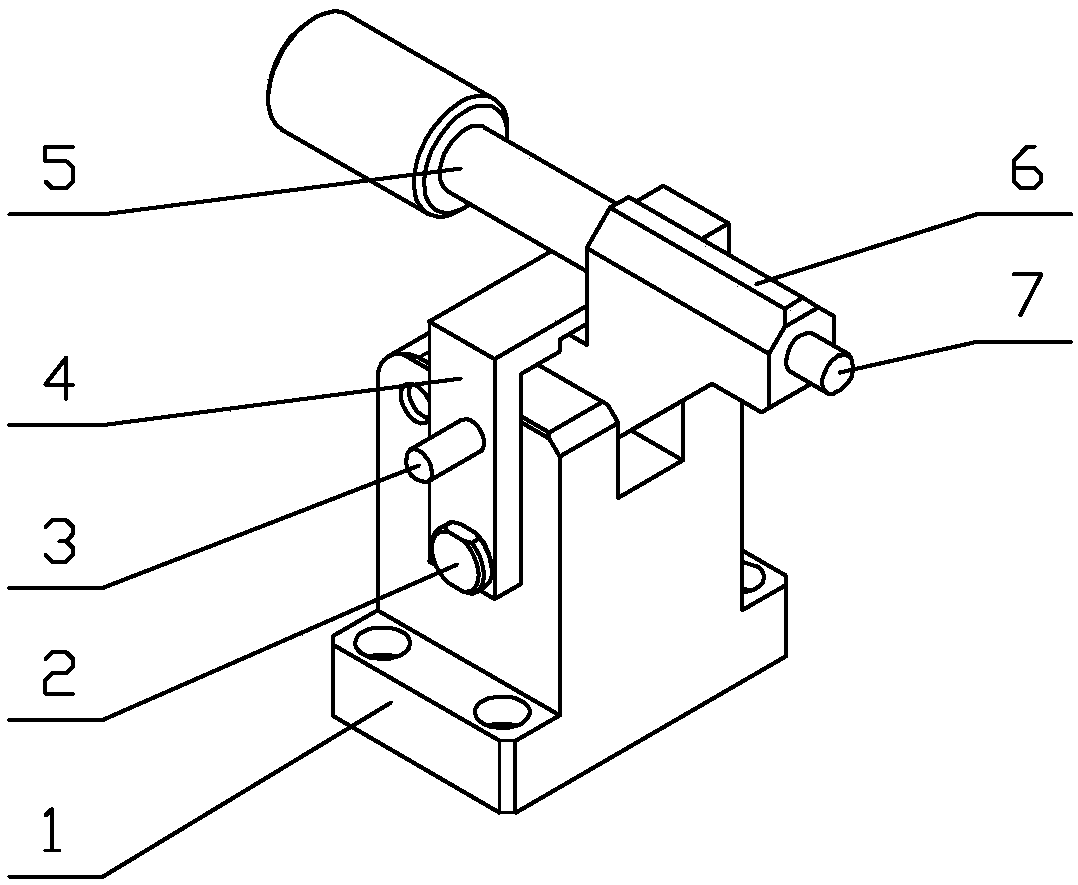

Rapid overturning and tightly-abutting mechanism

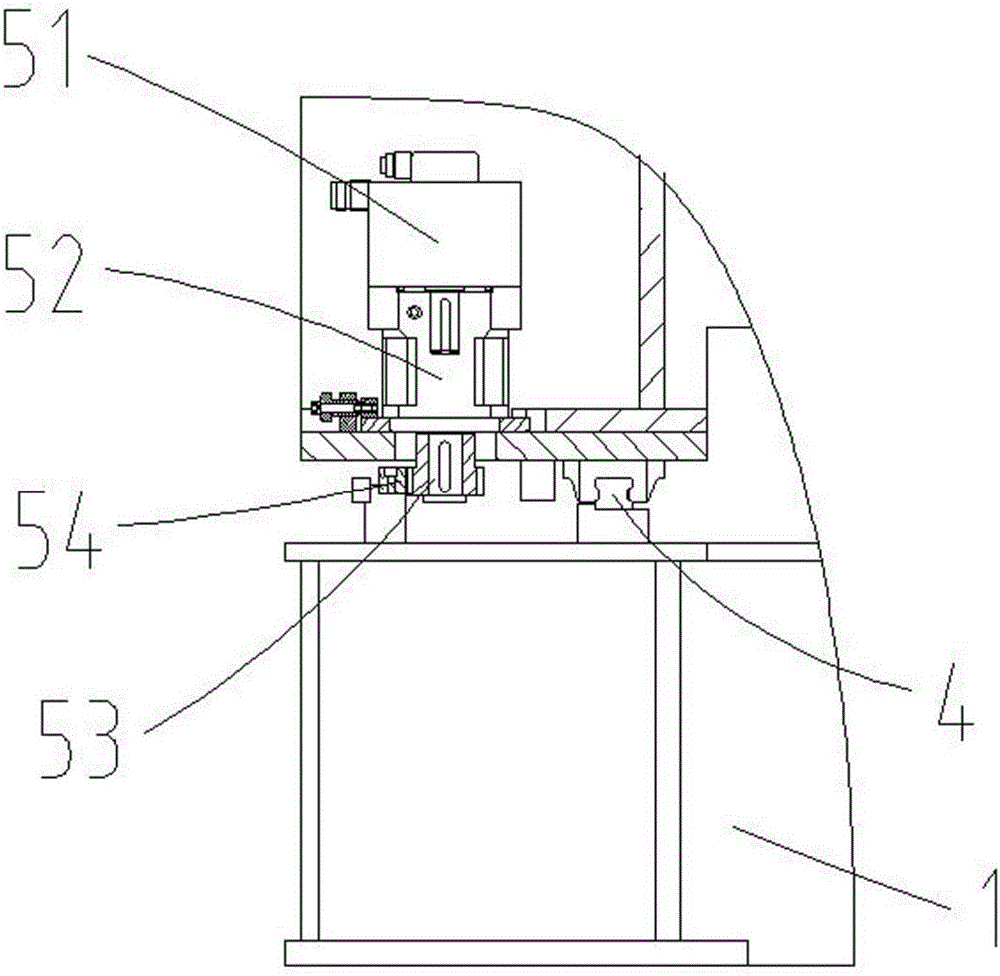

ActiveCN106624958ATight and reliableExpand the range of processingMetal working apparatusHinge angleEngineering

The invention relates to a rapid overturning and tightly-abutting mechanism. An installation groove is formed in the top of the installation seat. An overturning block is hinged to the installation seat through small hinge shafts installed on side plates on the two edges of the installation groove. The small hinge shafts are installed on the side plates on the two edges of the installation groove. The overturning block can freely rotate with the small hinge shafts as the rotation center. When the overturning block is overturned to a limiting position, the overturning block abuts against the bottom of the installation groove. The overturning block is provided with a pin hole. A tightly-abutting shaft is assembled in the pin hole and can axially and freely move in the pin hole. A screwing-down handle is connected to threads at the left end of the pin hole in a threaded manner. The right end of the screwing-down handle is connected with the tightly-abutting shaft. The right end of the tightly-abutting shaft is used for tightly abutting against a workpiece and locating the workpiece. An overturning frame is hinged to the installation seat through hinge shafts. The hinge shafts are installed on the installation seat. The overturning frame can freely rotate with the hinge shafts as the rotation center. When overturning to the limiting position upwards, the overturning frame presses the overturning frame without exerting force. The rapid overturning and tightly-abutting mechanism is convenient to operate and capable of reliably and tightly abutting against the workpiece, rapidly leaving a workpiece machining area, expanding the machining range and shortening the operation time.

Owner:WUXI BEST PRECISION MACHINERY

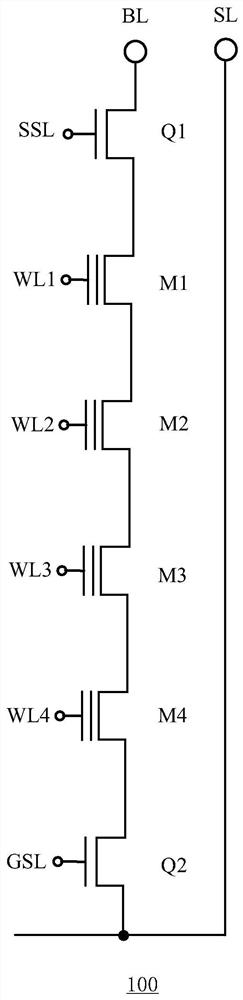

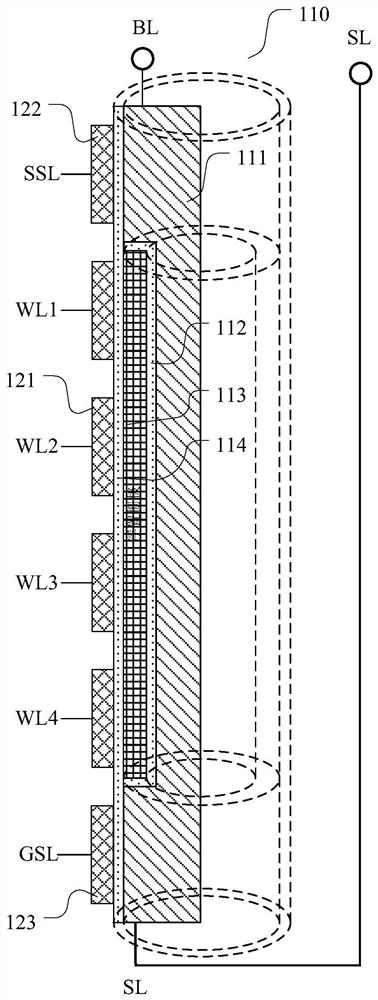

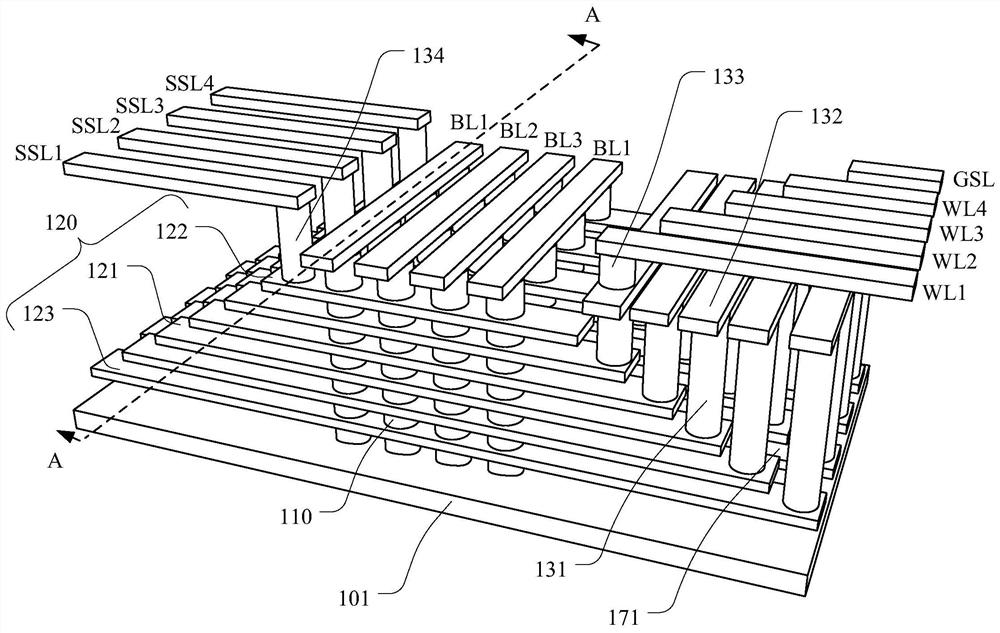

3D memory device and manufacturing method thereof

ActiveCN112420729BSmall cavity sizeReduce the overall heightSolid-state devicesSemiconductor devicesEngineeringDeposition process

The present application discloses a 3D memory device and a method for manufacturing the same. The memory device includes a substrate; a stacked structure on the substrate, the stacked structure includes a plurality of gate conductors and a plurality of interlayer insulating layers stacked alternately ; a channel hole penetrating the stack structure; a channel structure located in the channel hole and a filling layer covering the channel structure; wherein, the filling layer is formed by multiple depositions, and is formed after multiple depositions Gas etching is performed between deposition processes, so that the top of the cavity in the filling layer is located below the uppermost interlayer insulating layer in the stacked structure, so as to further reduce the size of the cavity in the filling layer and reduce the seam at the top of the cavity The height of the 3D memory device increases the thickness of the filling layer above the seam, so as to meet the subsequent processing requirements and improve the yield and reliability of the 3D memory device.

Owner:YANGTZE MEMORY TECH CO LTD

Double-milling head machining device

ActiveCN104148713AGuaranteed positioning accuracyImprove processing efficiencyMilling machinesEngineeringUltimate tensile strength

The invention relates to a double-milling head machining device. The device comprises a working table, an X-axle machine body, an X-axle guide rail pair, a tray, a Z-axle guide rail pair, a stand column, an X-axle driving device and a Z-axle driving device, wherein a Y-axle guide rail pair 1 is arranged on the stand column, and is in sliding connection with a horizontal milling head mounting base; a Y1-axle driving device is additionally mounted on the stand column; two cutter shafts with parallel axles in an X-axle direction and rotationally connected to the horizontal milling head mounting base and cutter shaft driving devices for driving the cutter shafts to rotate are arranged on the horizontal milling head mounting base; the positions of the two cutter shafts in a Y-axle direction and a Z-axle direction are staggered from each other; and the distance from the cutter shaft at the lower side in the Y-axle direction to the working table is further in the Z-axle direction. The device can guarantee the position preciseness of each set of corresponding machining positions of two workpieces having the machining position cooperative relationship, and has the prominent advantages of high machining efficiency and low labor intensity.

Owner:CHANGLE WANDA TEXTILE MACHINERY

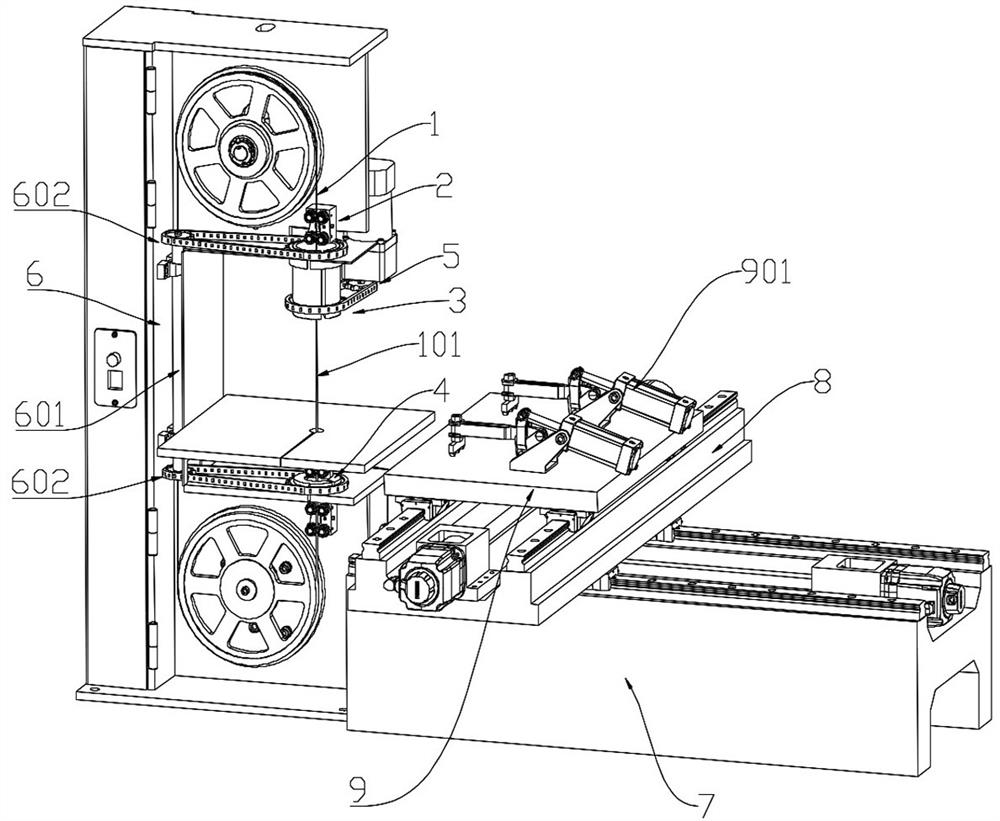

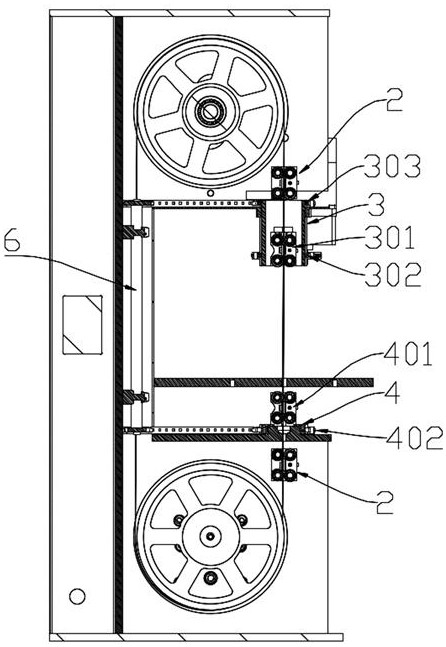

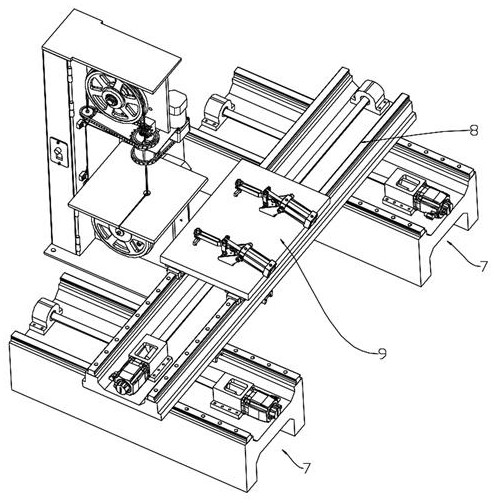

Arc-shaped saw for cutting arc-shaped wood

The invention relates to the technical field of wood cutting machine tools, in particular to an arc-shaped saw for cutting arc-shaped wood. The arc-shaped saw comprises a saw belt which is tensioned through a lower driving wheel and an upper driving wheel, a follow-up corner mechanism is arranged at the two ends of a cutting action end of the saw belt in a sleeving manner and comprises an upper rotating drum and a lower rotating seat, an upper saw belt clamping roller and a lower saw belt clamping roller are fixed in the upper rotating drum and the lower rotating seat respectively, and a lower chain wheel is arranged at the bottom of the upper rotating drum in a sleeving mode. The lower chain wheel is connected with a servo driving mechanism through a chain, the upper rotating drum and the lower rotating seat synchronously rotate through an arranged linkage mechanism, a servo sliding supporting plate used for clamping plates is arranged on the front portion of the cutting action section, and the servo sliding supporting plate and the servo driving mechanism are electrically connected with a numerical control system. The servo driving mechanism drives the follow-up corner mechanism to rotate, so that the width direction of the saw belt is always tangent to a curved knife edge, the accuracy of a cutting arc is ensured, meanwhile, unnecessary friction of the saw belt is avoided, and the service life of the saw belt is prolonged.

Owner:HEBEI BLUEBIRD FURNITURE CO LTD

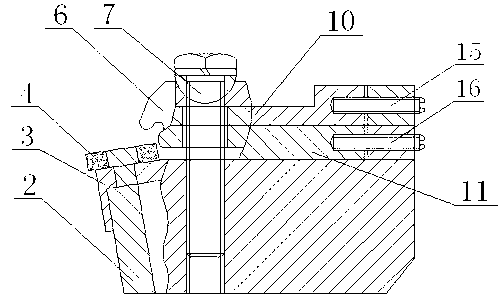

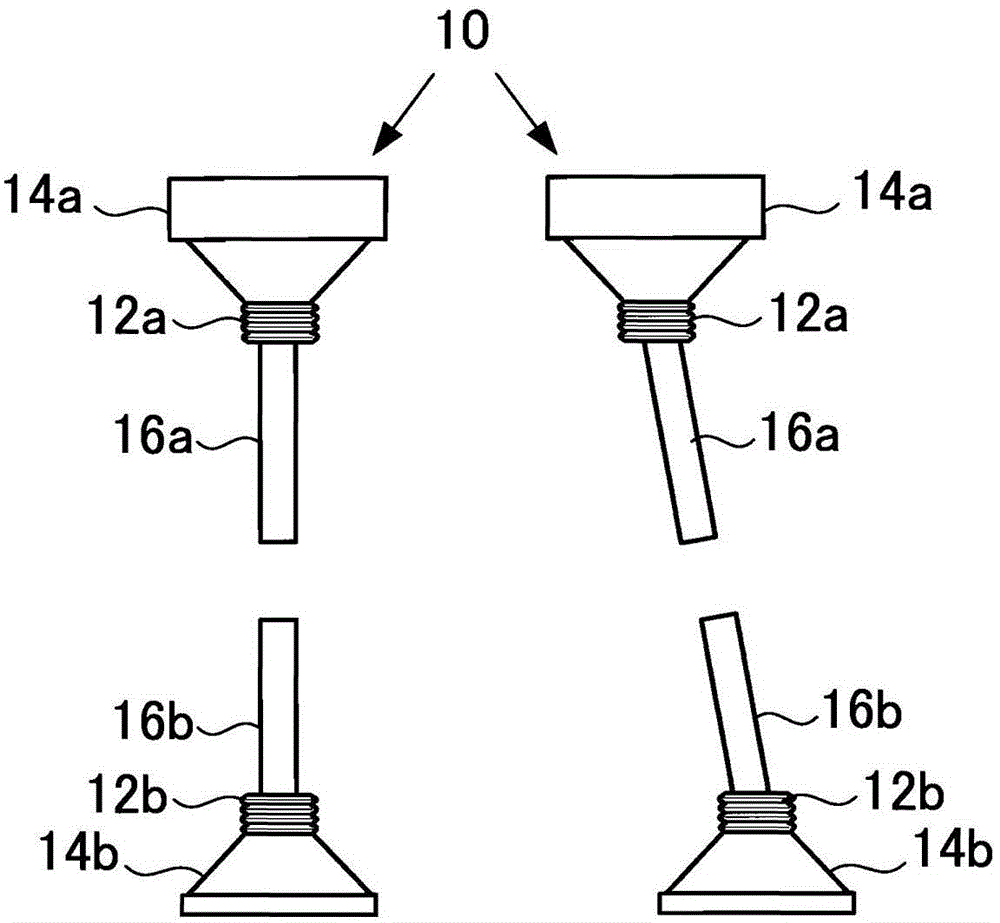

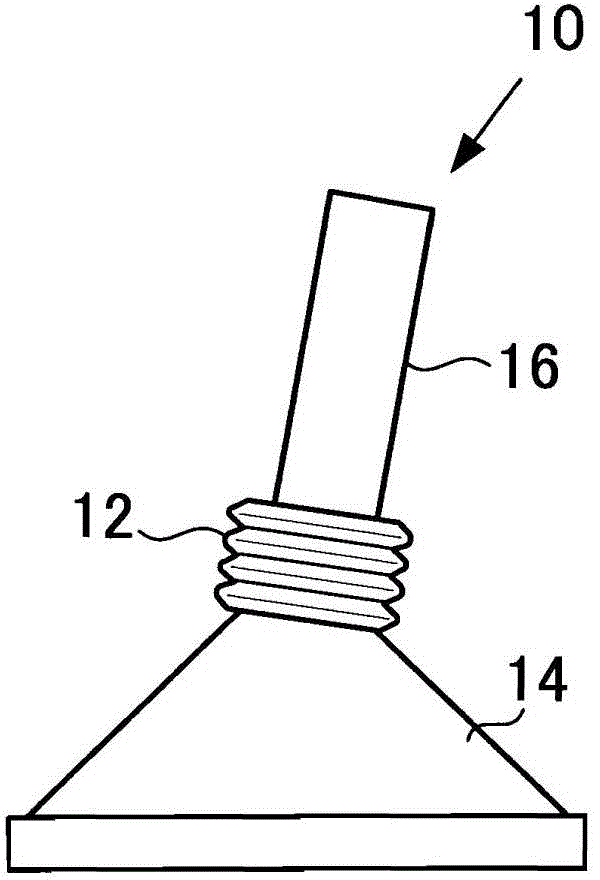

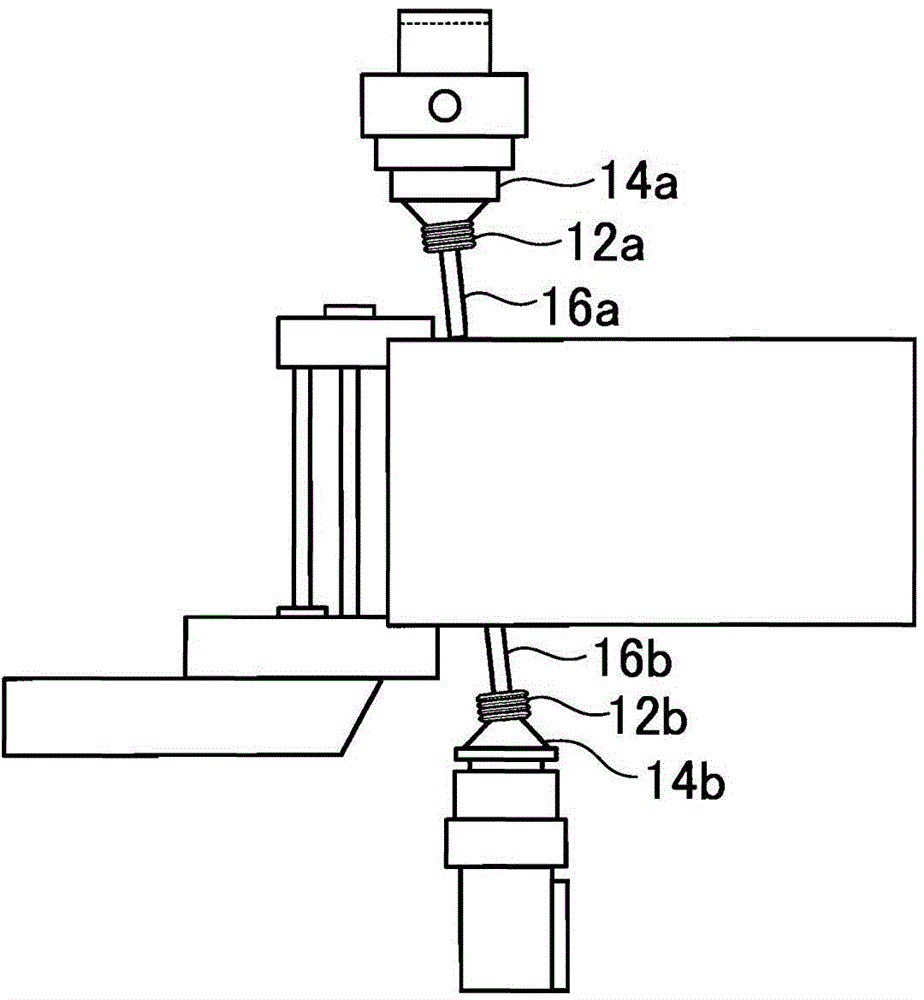

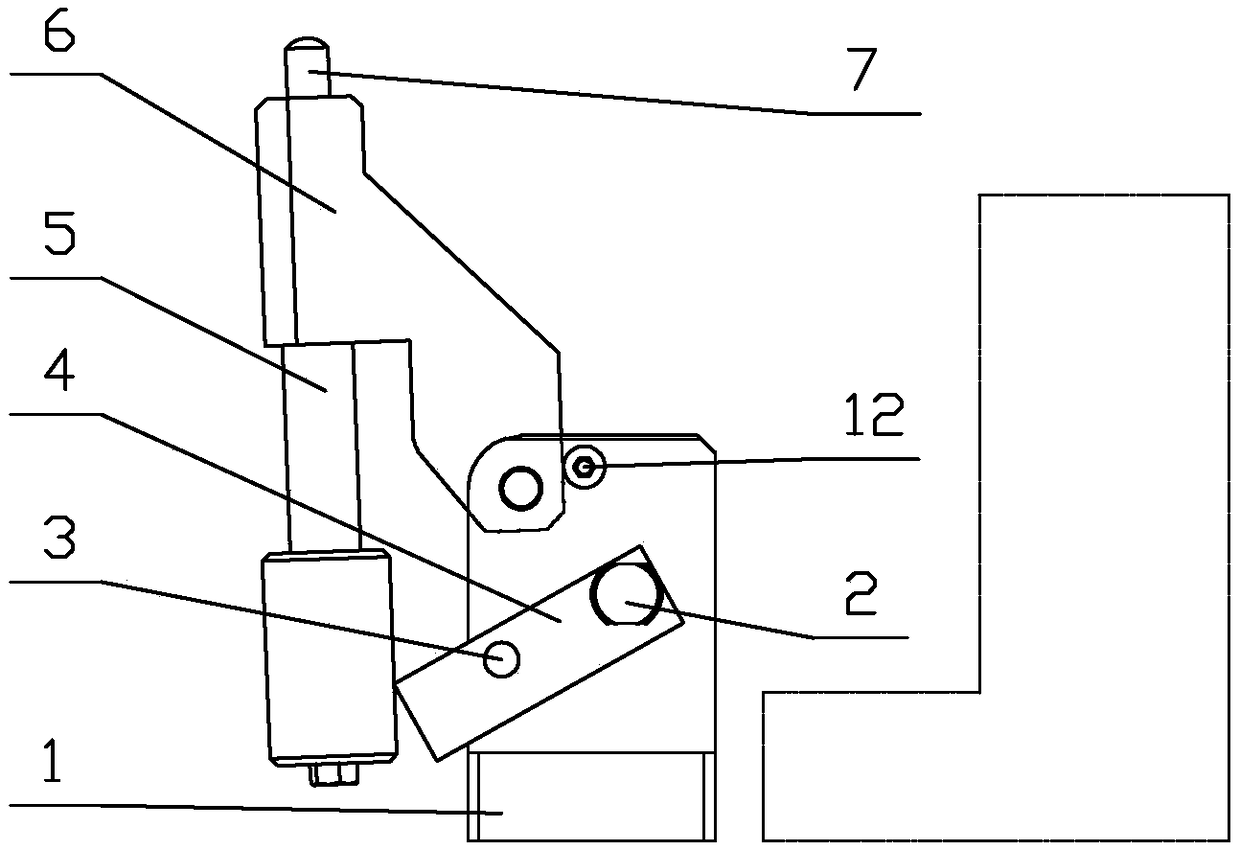

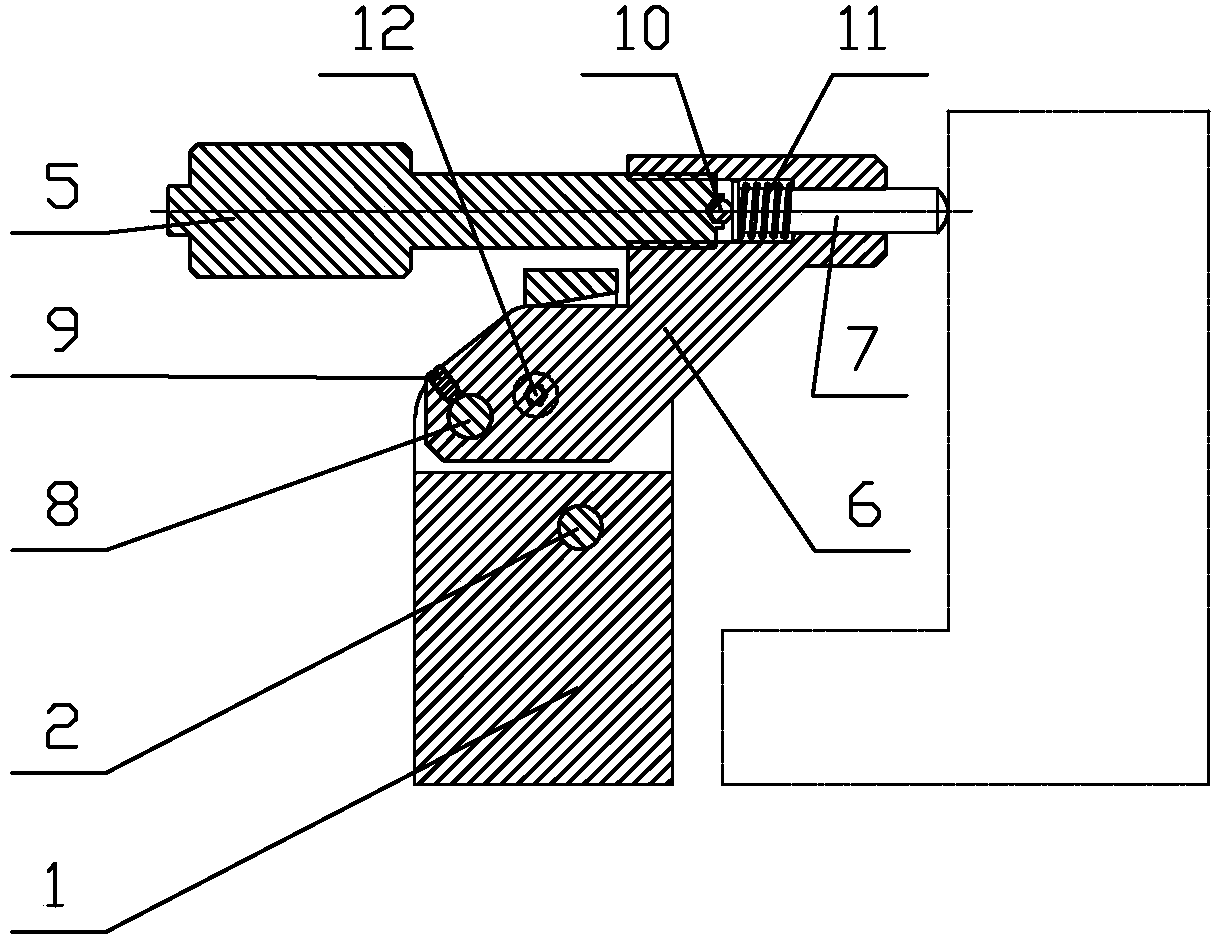

Processing liquid ejection device of wire electrical discharge machine

InactiveCN104801797AProcessing speed is slowExpand the range of processingElectrical-based machining electrodesElectrical-based auxillary apparatusEngineeringMechanical engineering

A processing liquid ejection device of a wire electrical discharge machine includes: a processing liquid ejection portion (16); a holding portion (14) of which the diameter decreases as the holding portion (14) approaches the processing liquid ejection portion (16); and an angle changing member (12) that is provided in a connection portion between the processing liquid ejection portion and the holding portion so as to change the relative angle between the processing liquid ejection portion and the holding portion.

Owner:FANUC LTD

Feed device for a polishing machine

ActiveCN110561257BExpand the range of processingImprove practicalityPolishing machinesGrinding drivesPolishingElectric machinery

The invention discloses a feeding device of a polishing machine, and relates to the technical field of polishing machines. The device comprises a supporting seat, a first moving seat and a polishing assembly, wherein a side plate is fixedly connected to one surface of the supporting seat, two first linear feeding push rods are fixedly connected between the opposite surfaces of the supporting seatand the first moving seat, one surfaces of the supporting seat and the first moving seat are fixedly connected with a first connecting plate and a second connecting plate respectively, one surfaces ofthe first connecting plate and the second connecting plate are rotationally connected with clamps, and one surface of the first connecting plate is also fixedly connected with a first transmission motor. According to the device, through the design of a first winding wheel, a second winding wheel, a first driving wheel and a second driving wheel, the feeding device of the polishing machine can synchronously perform the change of the stroke of a feeding mechanism in an adjustable range according to the length of a steel pipe to be polished, and the working range of the polishing machine is improved through the change of the stroke of the feeding mechanism, so that the practicability and universality of the feeding device are improved.

Owner:SHANDONG BUSINESS INST

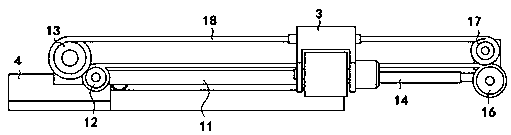

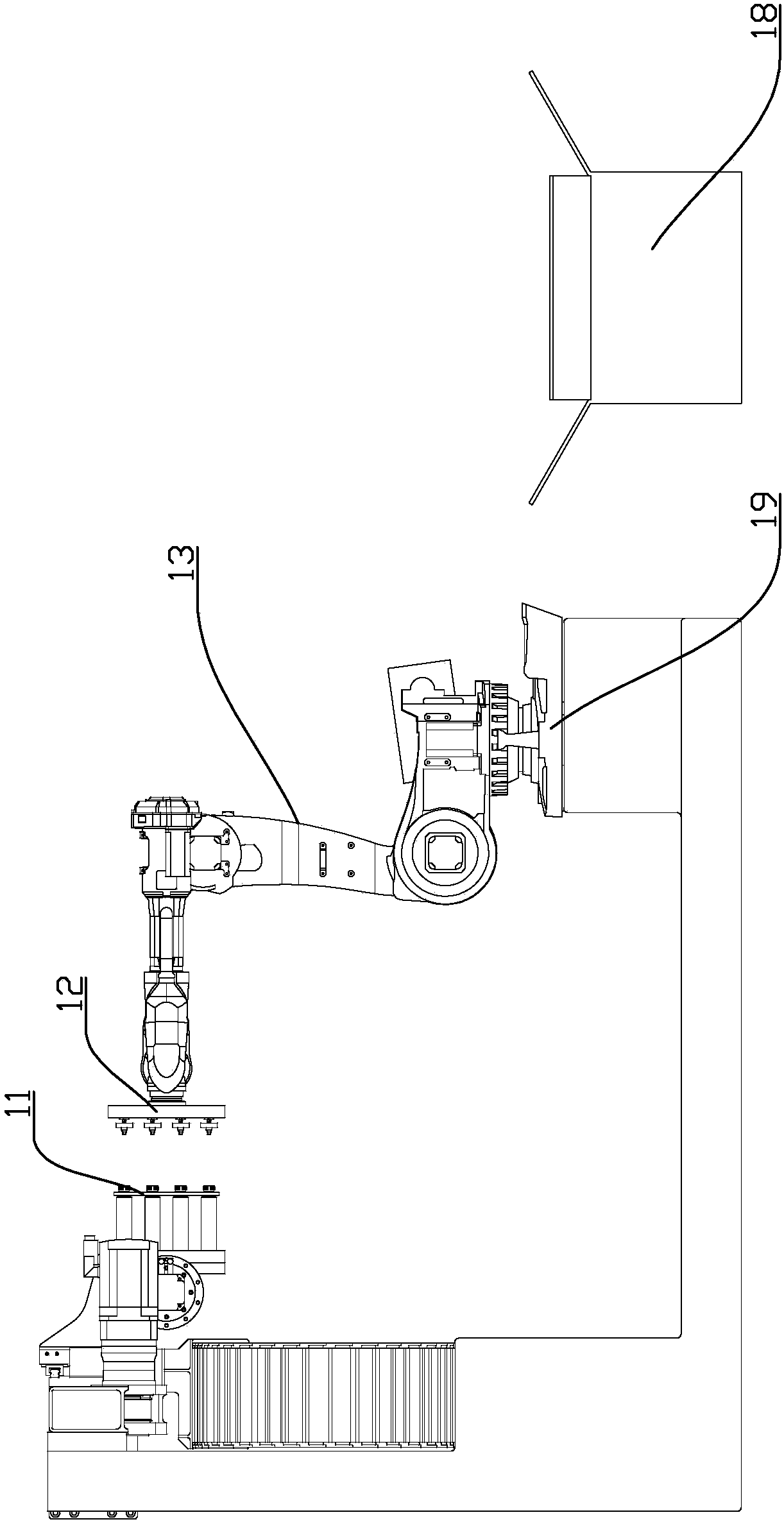

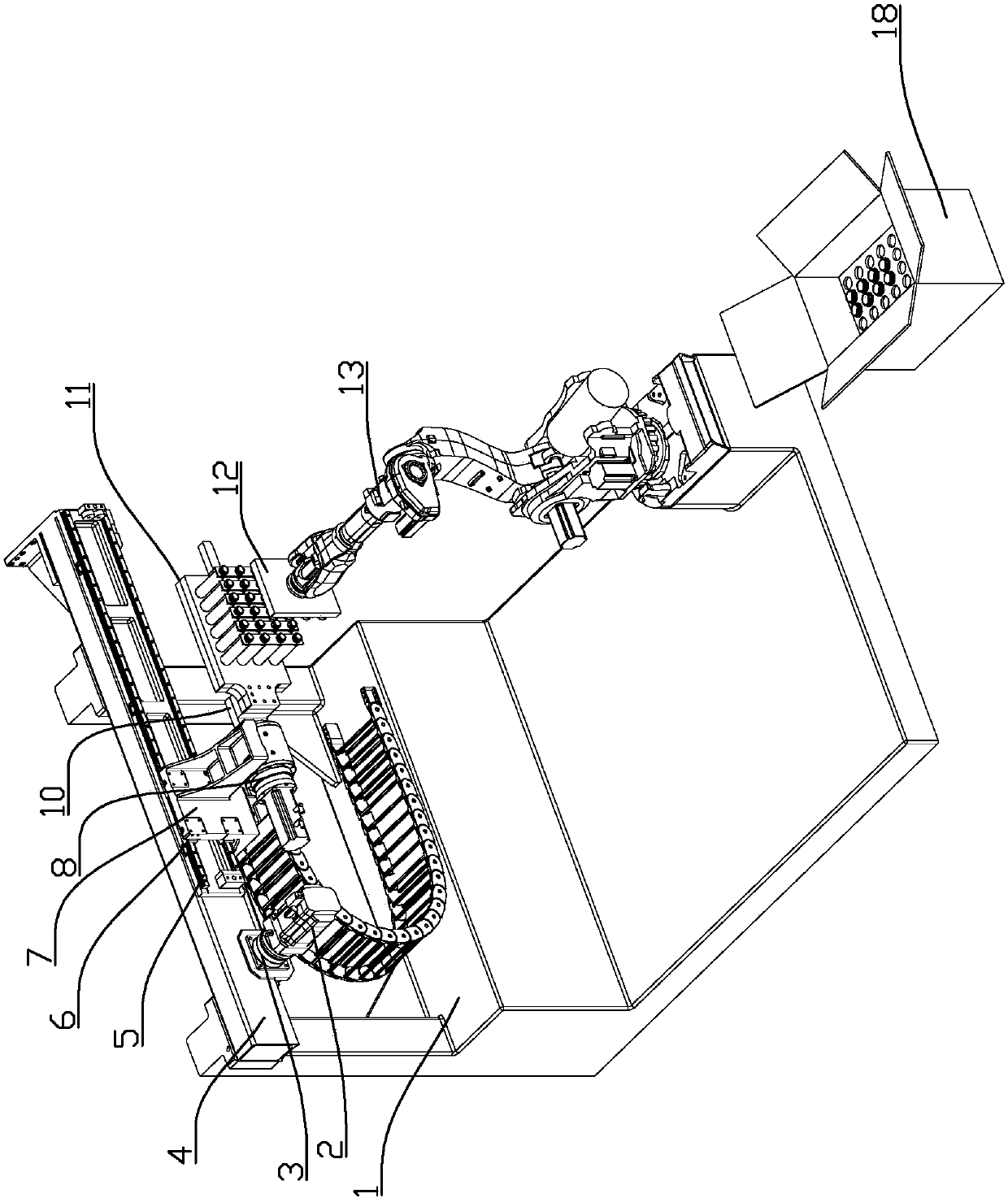

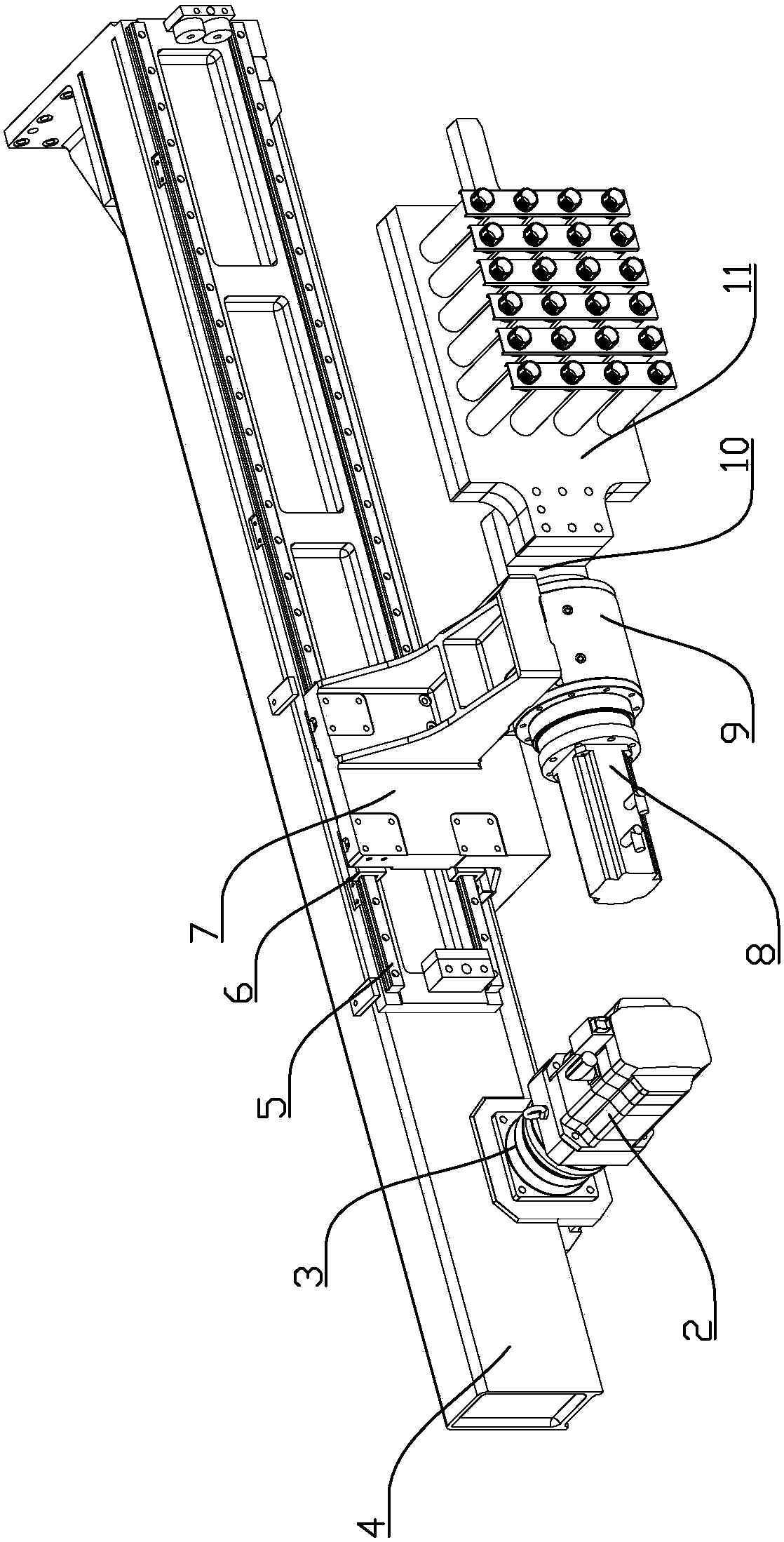

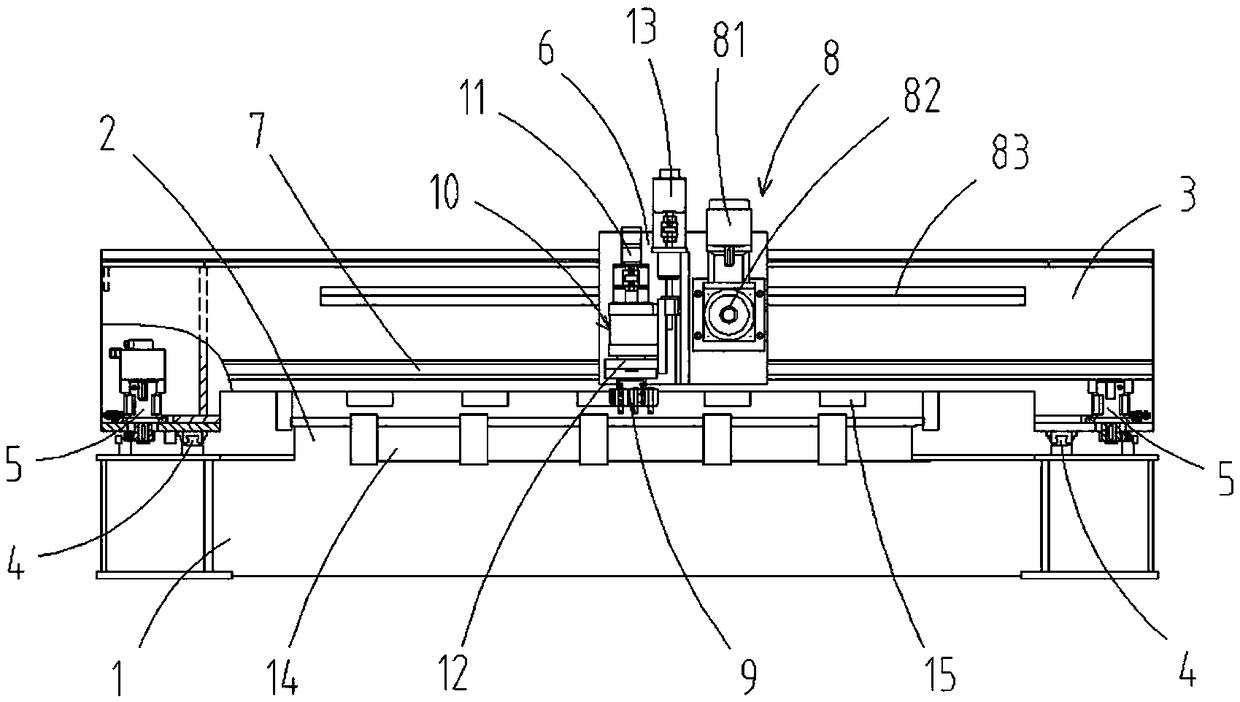

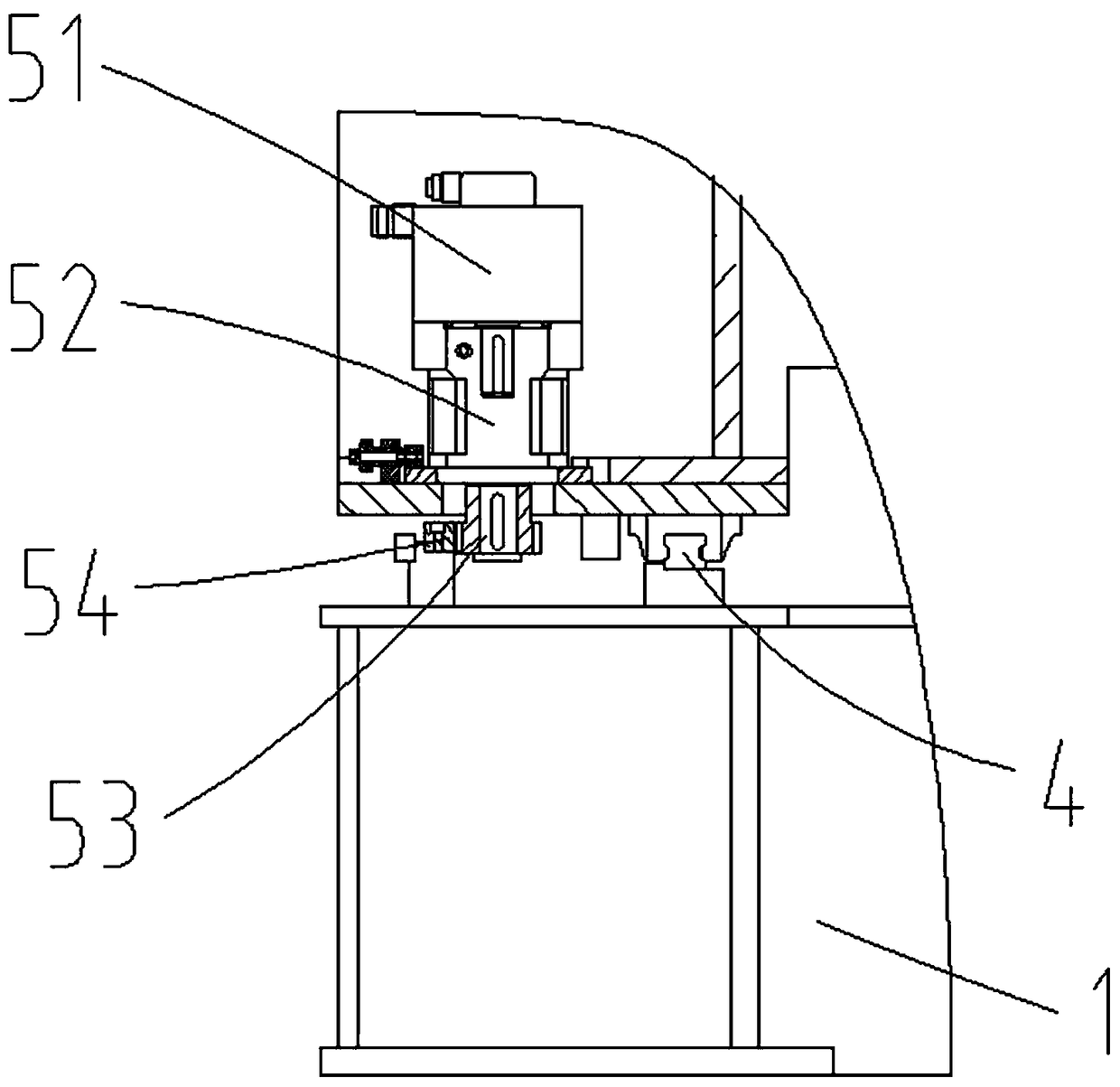

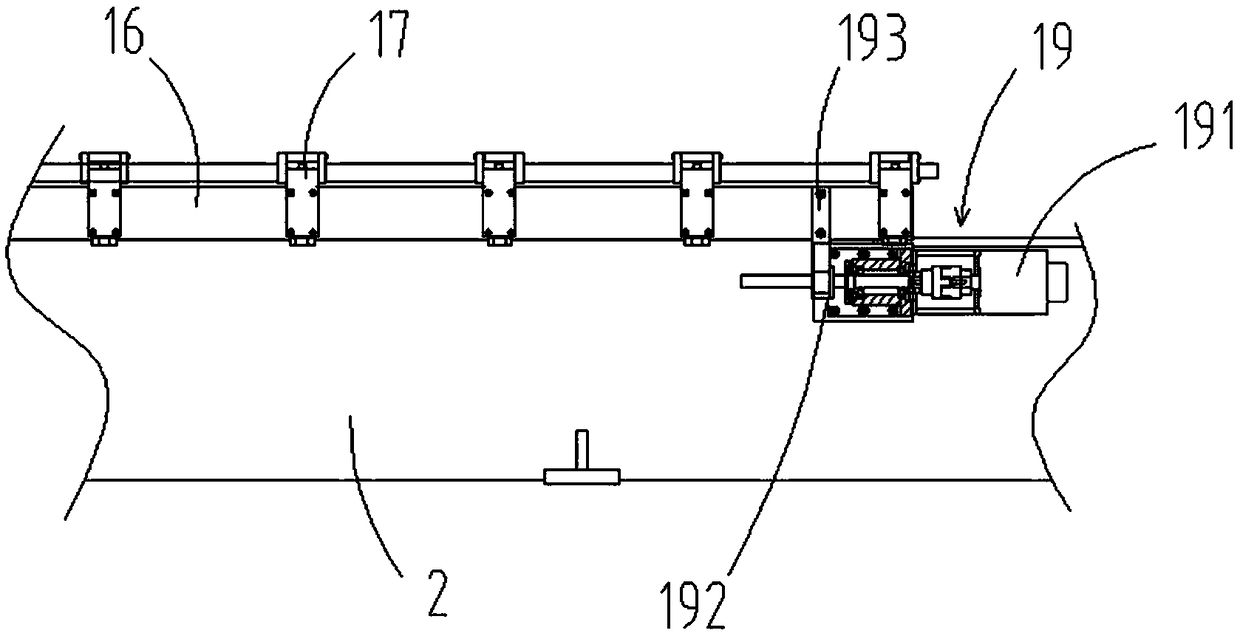

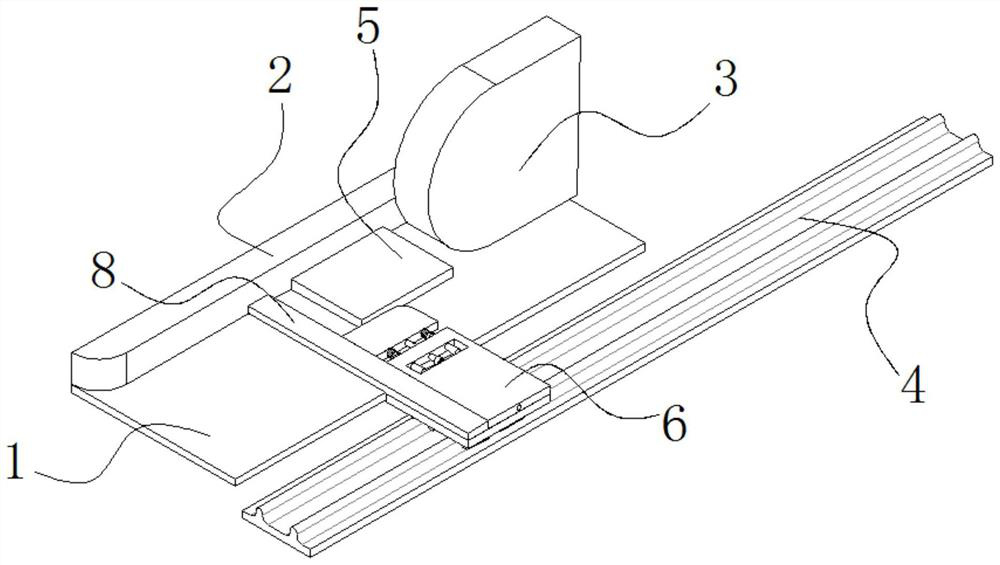

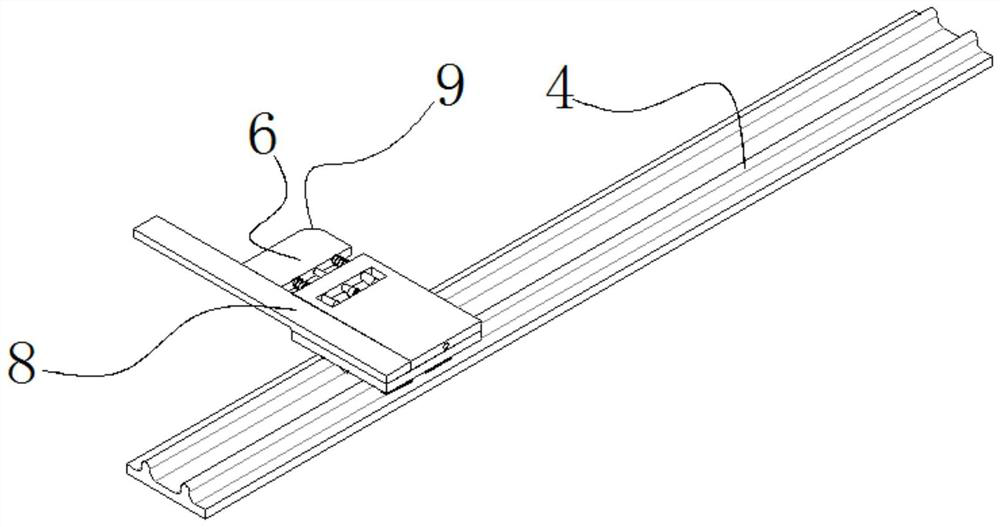

Linear robotic arm and robot collaborative billet removal system

The invention discloses a linear robot arm and a robot cooperative blanking system, including a robot unloading system, a frame and a linear robotic arm blanking system. The linear robotic arm blanking system includes a beam, a servo motor, two guide rails, and two sliders , slider seat, transmission mechanism, overturning motor and blank take-off plate, the robot blank unloading system includes the robot and the blank unloading plate installed on the terminal shaft of the robot, the blank unloading position and the blank take-off position are set on the guide rail, the servo motor drives the slide The block reciprocates between the blank unloading position and the blank picking position. When the slider is at the blank unloading position, after the blank unloading plate and the blank taking plate are arranged in parallel to form a blank unloading space between the two, the turning motor drives the blank picking work. The end is turned from horizontal to vertical downward, and the unloading plate is turned over with the blank plate. The drop height of the preform is small, and the instantaneous impact force on the preform is small, which avoids the drop deformation of the preform and effectively guarantees the quality of the preform, especially suitable for the working conditions of heavy weight and long length of the preform.

Owner:广州一道注塑机械股份有限公司

An all-round plane planing equipment with intelligent pressing system

ActiveCN106077784BReduce contact surfaceAutomatic height adjustmentPlaning/slotting machinesPositioning apparatusEngineeringSlide plate

The invention discloses all-dimensional planar planing equipment with an intelligent pressing system. The all-dimensional planar planing equipment comprises a machine frame, a work table arranged on the upper surface of the machine frame and a moving beam suspended above the work table, wherein the two ends of the moving beam are connected to the machine frame through transverse guide rails and transverse drive devices are arranged at the two ends of the machine frame; a longitudinal sliding plate device is arranged on one side of the moving beam and is connected to the moving beam through a longitudinal guide rail; and a longitudinal driving device is arranged on one side of the longitudinal sliding plate device, a cutter box is arranged at the lower end of the longitudinal sliding plate device, and a set of cutters are arranged inside the cutter box. According to the design, bidirectional planing and slotting in the longitudinal direction and the transverse direction can be realized, inclined planing and slotting can be realized through simultaneous moving of the moving beam and the longitudinal sliding plate device, and inclined planing and slotting at different angles can be realized by controlling the moving speed of the moving beam and the moving speed of the longitudinal sliding plate device.

Owner:施泰德精密机械(太仓)有限公司

A circuit board processing device

ActiveCN112605417BRealize multilaterationAchieving multi-sizingFeeding apparatusPositioning apparatusDrive wheelElectric machinery

The invention discloses a circuit board processing device, which comprises a box body, an electric telescopic rod is fixed on the top of the box body, a telescopic plate is fixed on the telescopic end of the bottom of the electric telescopic rod, a bearing is fixed on the top end of the telescopic plate, and a bearing is rotatably connected inside the bearing. Drill, the driven wheel is fixed on the top of the drill, the motor is fixed on the left side of the top of the telescopic plate, the driving wheel is fixed on the top output end of the motor, and the driving wheel is connected to the driving belt. The driving belt is connected to the circuit board processing device. The circuit board to be processed in the hole is placed on the processing table, and the limit plates are respectively pulled outward to make the adjustment block slide in the adjustment groove, so that the corner end of the circuit board to be processed can be snapped into the limit plate. The tension effect of the spring is used to support the limit block, which improves the fastening effect of the limit plate when the corner end of the circuit board to be processed is clamped, and at the same time expands the size range applicable to processing.

Owner:湖南维胜科技电路板有限公司

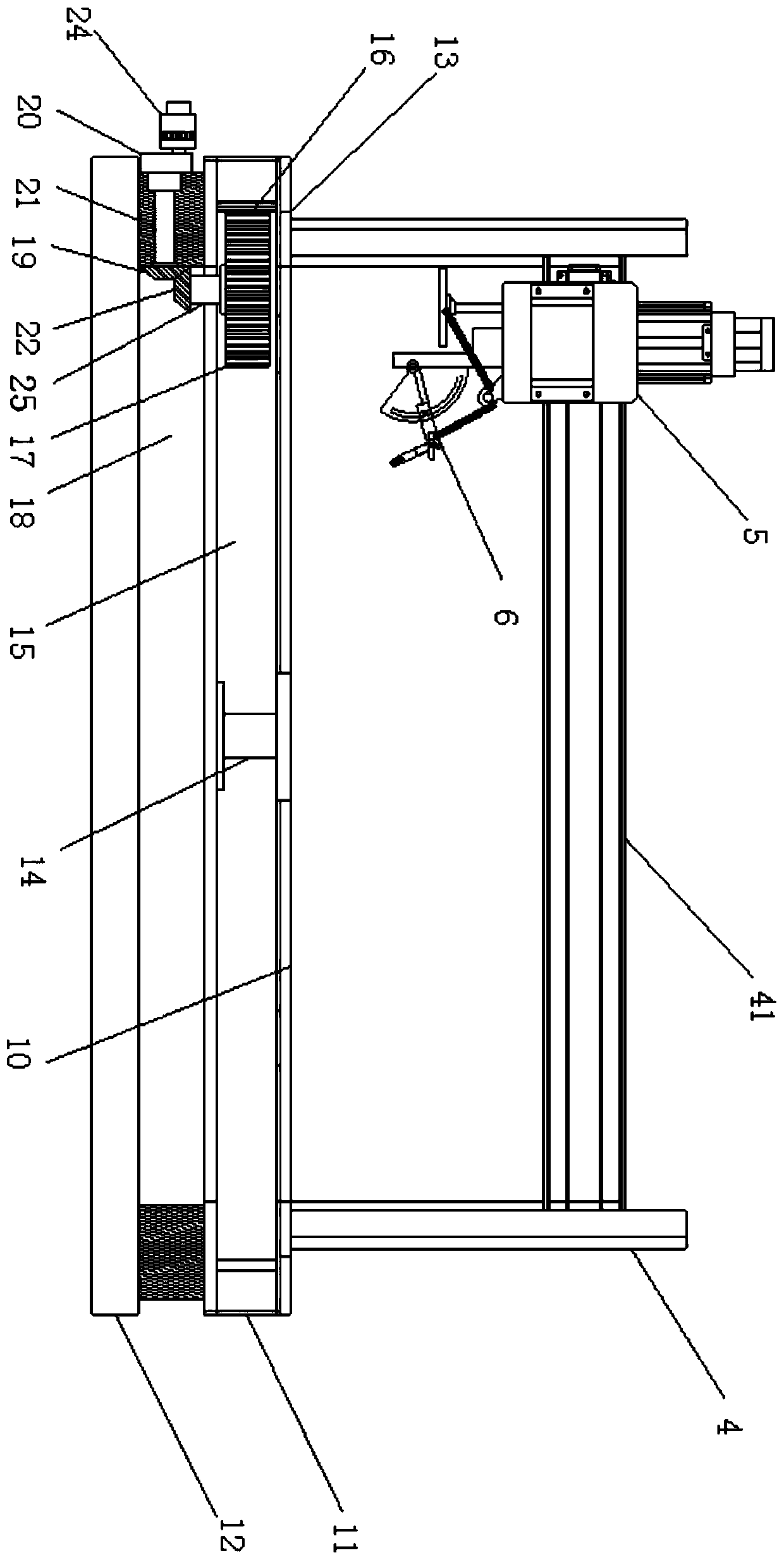

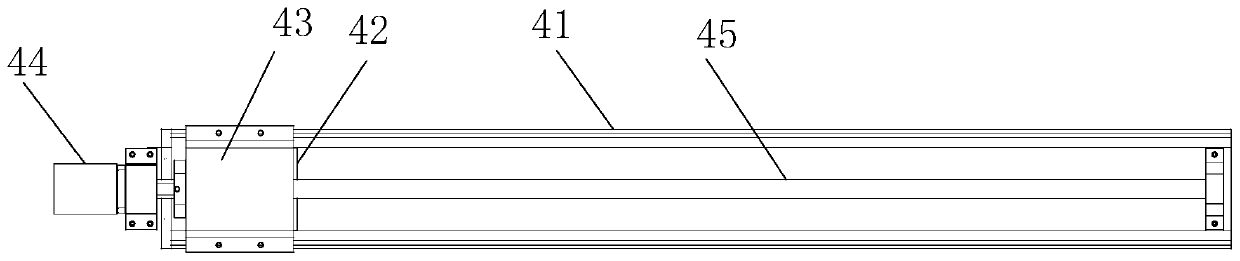

A rotary automatic welding robot and its welding method

ActiveCN110549048BExpand the range of processingHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

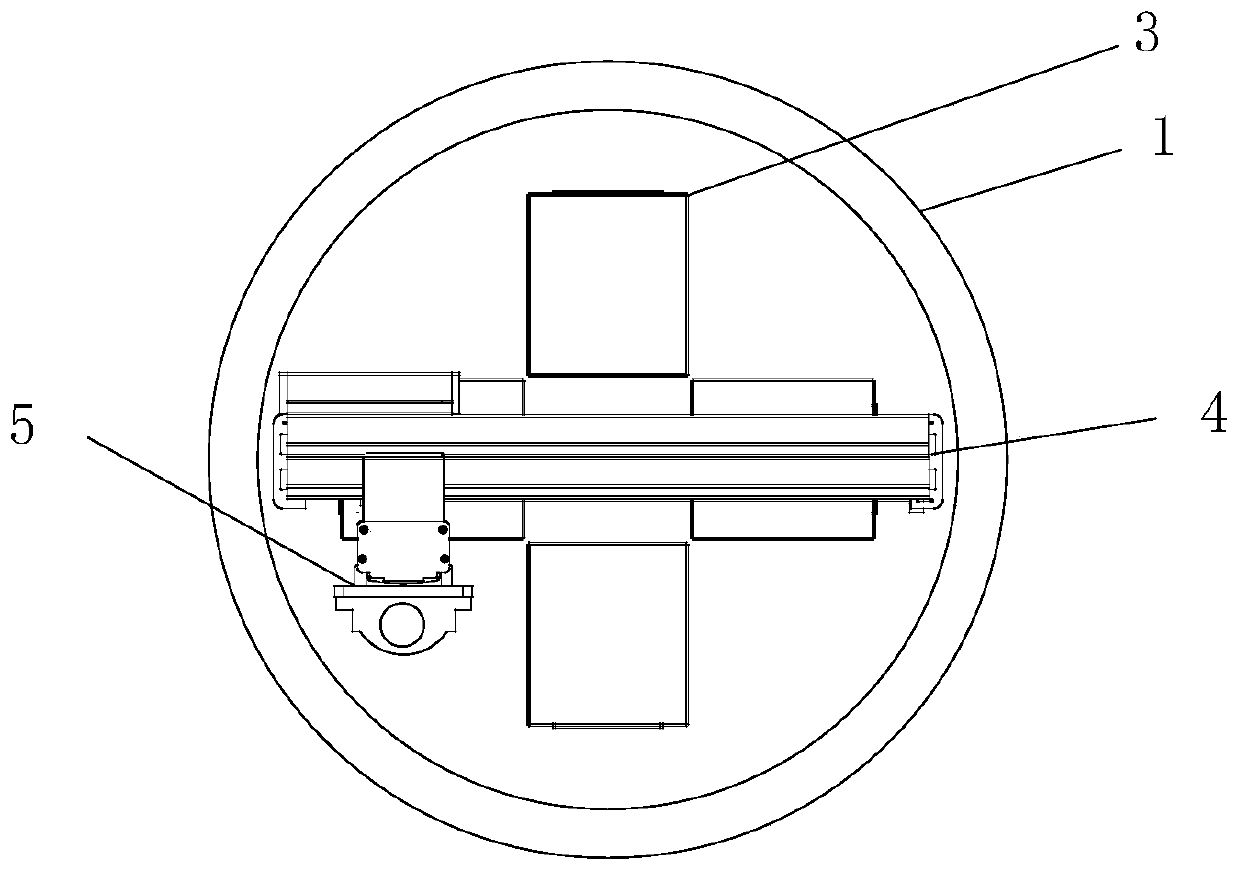

A rotary automatic welding robot, comprising a rotary base (2). An operation machine frame (4) is installed on the rotary base and provided with a Y-axis guide rail (41). An adjusting machine frame (5) is movably installed on the Y-axis guide rail and provided with a Z-axis guide rail (51). A welding frame (6) is movably installed on the Z-axis guide rail. A bearing platform (10) is fixedly installed on an upper surface of the rotary base. The rotary base comprises an upper carrying table (11) and a lower carrying table (12). The upper carrying table is installed on the lower carrying table by means of a supporting rotary shaft (14). A transmission cavity (15) is formed in an inner cavity of the upper carrying table. An annular rack (16) is provided on the inner wall of the transmission cavity. A transmission gear (17) is built in the transmission cavity. The transmission gear is meshed with the annular rack. A stereoscopic machining and adjusting mode is achieved by the whole rotary automatic welding robot, the machining range and machining precision are increased, and the machining quality is ensured. Also provided is a welding method of the rotary automatic welding robot.

Owner:江西宜春市华达实业有限公司

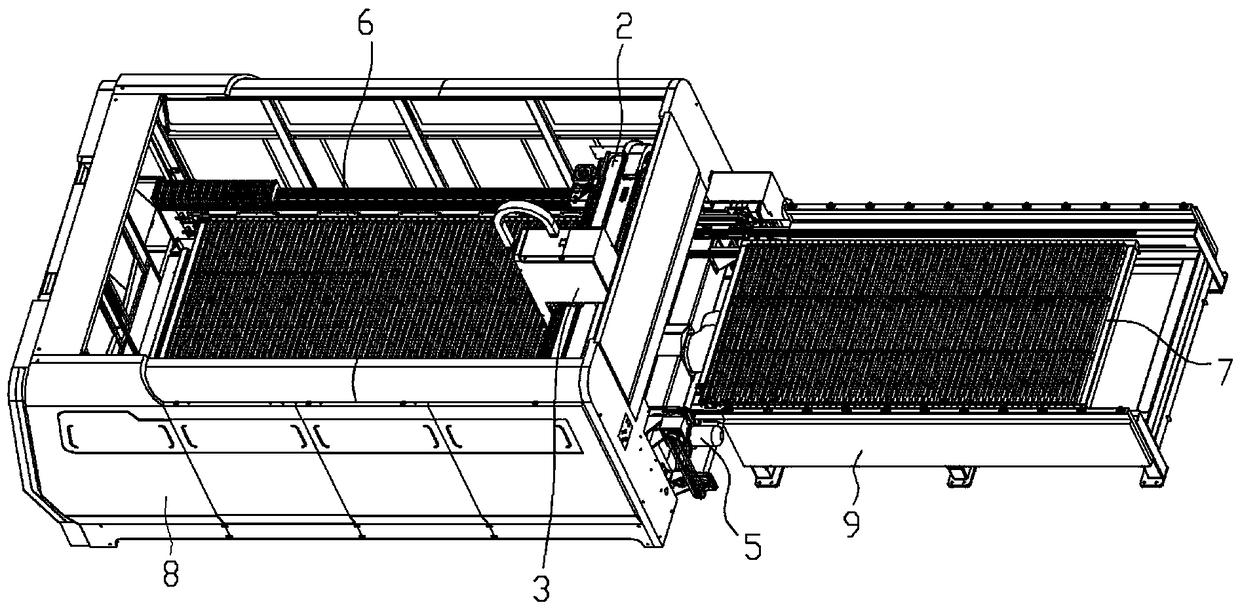

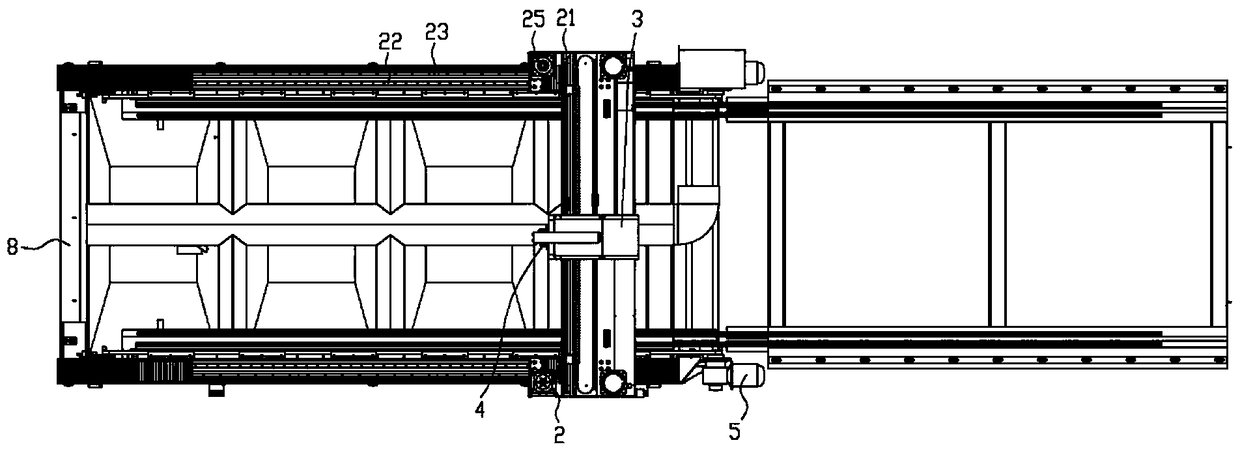

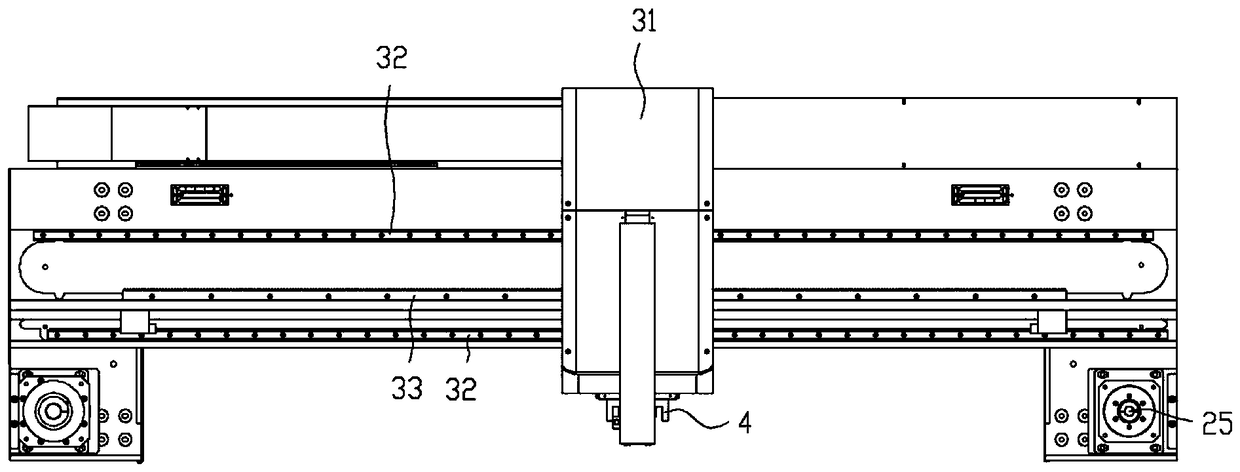

Novel laser cutting machine

PendingCN108971750AExpand the scope of processingVersatilityLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a novel laser cutting machine. The cutting machine comprises a laser cutting head, a left and right moving mechanism, a front and back moving mechanism, an up and down moving mechanism, a dual-power dual-dragging mechanism, an upper worktable, a lower worktable, a work machine body and a feeding machine body; the dual-power dual-dragging mechanism is arranged on the work machine body, the feeding machine body is connected with the work machine body, the left and right moving mechanism is arranged on the feeding machine body, the front and back moving mechanism is arranged on the left and right moving mechanism, the up and down moving mechanism is arranged on the front and back moving mechanism, the laser cutting head is arranged on the up and down moving mechanism,and the dual-power dual-dragging mechanism drags the upper worktable and the lower worktable to move between the work machine body and the feeding machine body. Under the work of the up and down moving mechanism, the front and back moving mechanism and the left and right moving mechanism, the laser cutting head can move up and down, front and back and left and right, the machine can adapt to machining of various different products, the machining range is large, and university is high.

Owner:DONGGUAN GLORYSTAR LASER TECH

Short material edge sealing and feeding device for edge sealing process in furniture industry

PendingCN113120584AEasy to holdImprove operational safetyConveyorsWood working apparatusHand partsEngineering

The invention discloses a short material edge sealing and feeding device for the edge sealing process in the furniture industry. The short material edge sealing and feeding device comprises a feeding table and a semicircular guide rail base, and a feeding backer is welded to the upper surface of the feeding table. According to the short material edge sealing and feeding device, a fixing plate is pushed to push a workpiece to the position below a pressing beam of an edge sealing machine, an operator only needs to place the workpiece at the proper position of the feeding table with one hand and pushes the fixing plate with the other hand, the fixing plate is located on the outer side of the pressing beam of the edge sealing machine, the risk that the hands are pressed is completely avoided, the edge sealing machine machines the workpiece, the operation safety of the equipment is greatly improved, operation is easy, the production efficiency is high, the clamping performance is stable, and the product quality is high; and the elastic range is adjusted by a screw, the depth of the screw in a threaded hole is controlled, so that a feeding mechanism can clamp workpieces in different ranges, the machinable range of the equipment is expanded, and the device is modularly designed and can be mounted on all single-side edge sealing machines.

Owner:泰州市龙洋木业有限公司

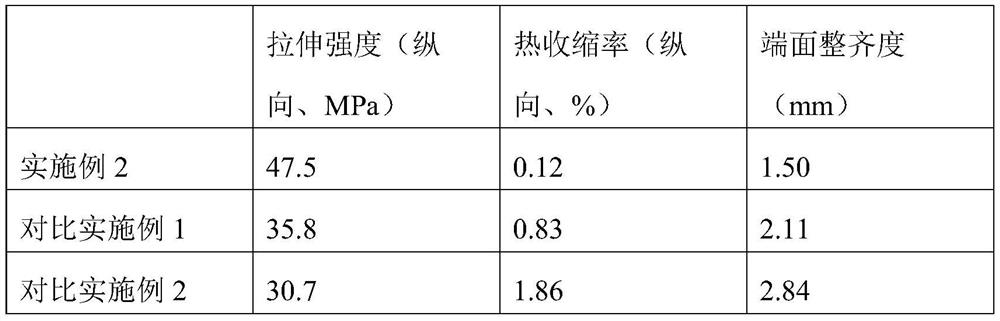

Preparation method of recyclable packaging box containing polypropylene synthetic paper

PendingCN113897019AStable mechanical qualityImprove machinabilityFlat articlesPolymer scienceWeather resistance

The invention discloses a preparation method of a recyclable packaging box containing polypropylene synthetic paper, and belongs to the technical field of packaging printing. The preparation method comprises the following steps: (1) preparing a modified polypropylene copolymer, (2) preparing a modified filler, (3) preparing a premix, and (4) preparing a finished product. The method is simple, and the prepared packaging box has the advantages of being high in weather resistance, stable in mechanical quality, high in machinability, easy to recycle and the like.

Owner:郑州启晨装潢包装科技有限责任公司

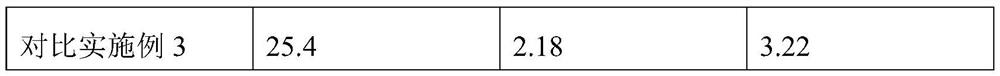

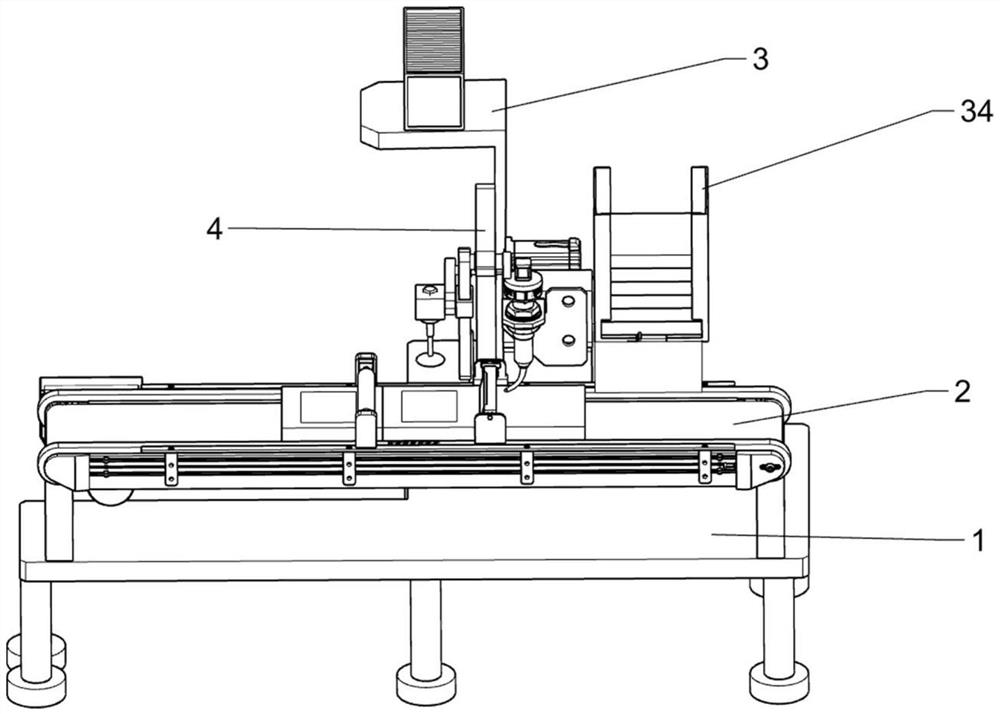

Self-glue-dripping type packaging box labeling device

ActiveCN112141471AAccurate and stable feedingImprove efficiencyLabelling machinesProcess engineeringElectrical and Electronics engineering

Owner:杭州中杭印刷有限公司

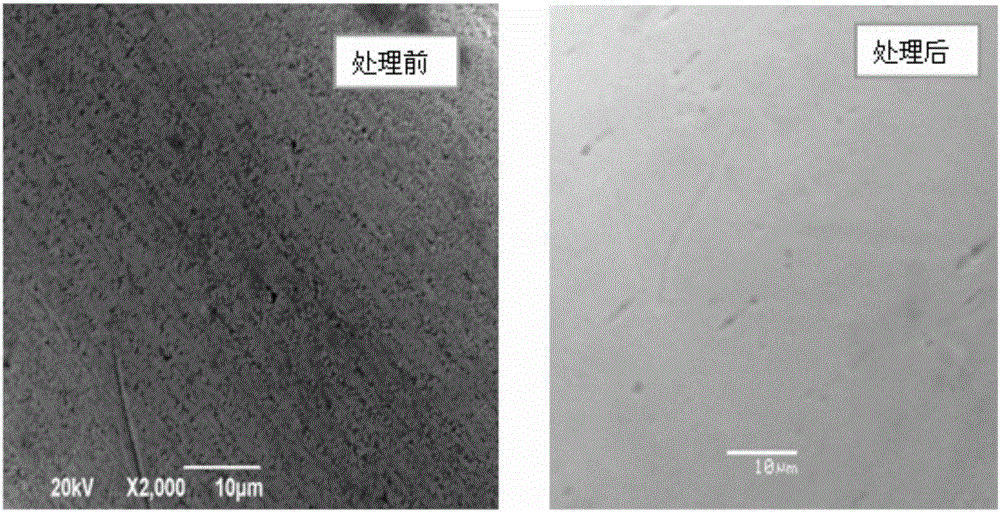

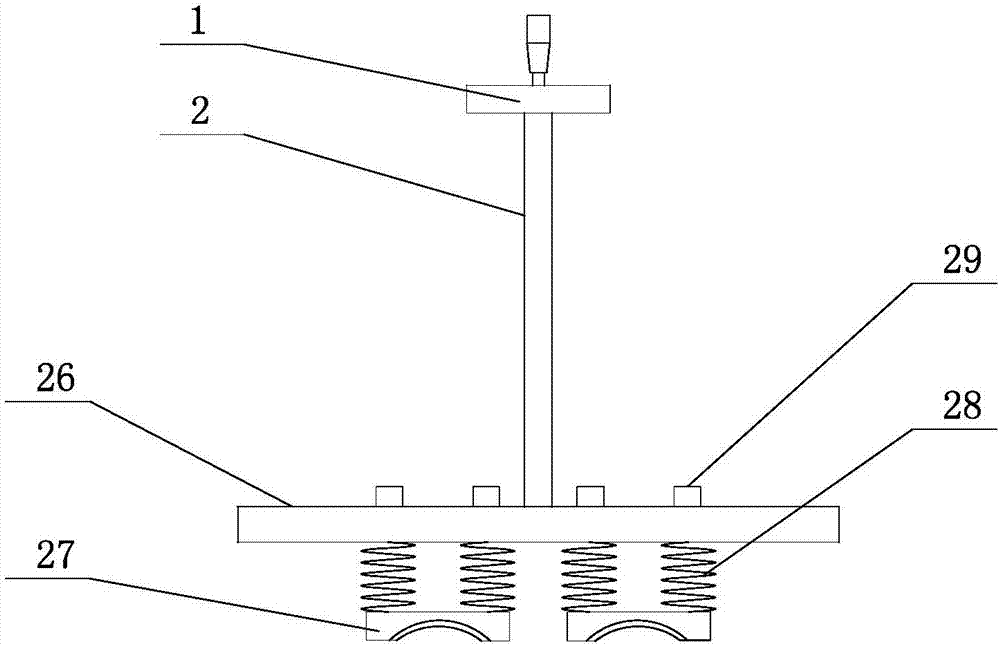

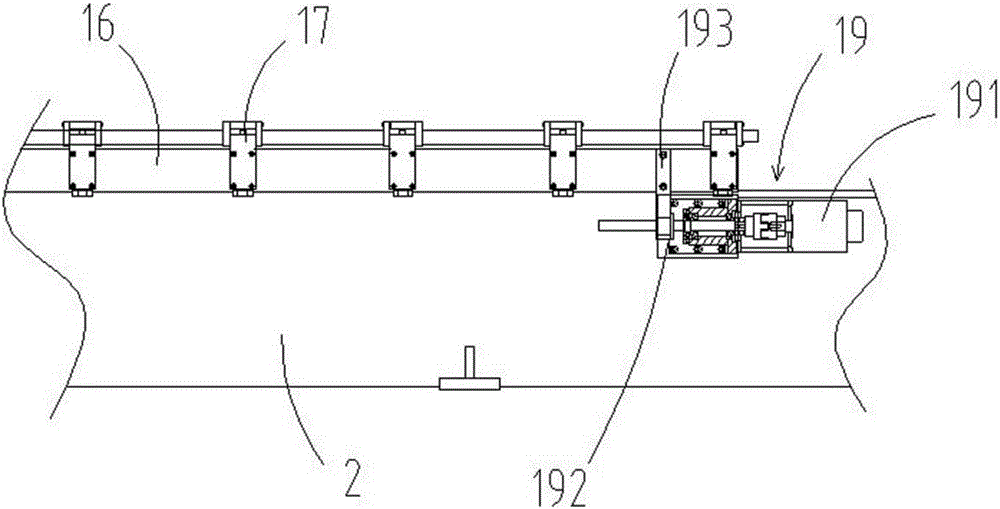

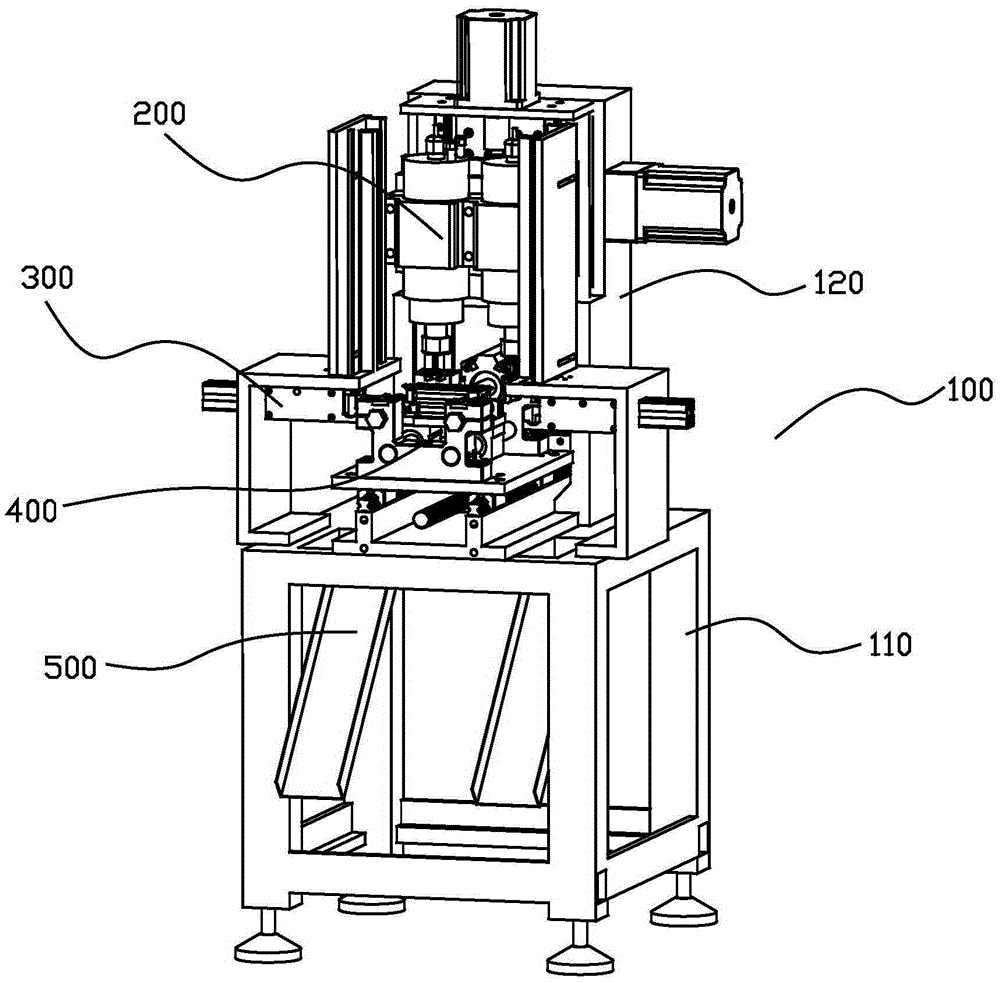

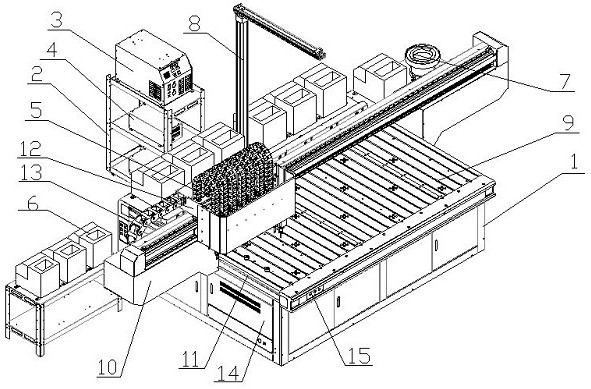

A fully automatic CNC two-station lock case drilling pinball hole machine

ActiveCN103480886BExpand the range of processingSimplify the manual operation processFeeding apparatusMetal working apparatusNumerical controlControl system

The invention discloses a fully-automatic numerical control two-station marble hole drilling machine for a lock case. A main body lathe bed comprises a base and a portal frame. A drilling mechanism comprises two drilling machines which are arranged in parallel. The two drilling machines are arranged on the portal frame through guide rails and guide pillars, which are matched with each other in a sliding way, and move along an X axis and a Z axis. A positioning clamping mechanism is arranged on the base below the two drilling machines, and a working tabletop is arranged below the positioning clamping mechanism, and moves along a Y axis through the guide rails and the guide pillars, which are matched with each other in the sliding way. A feeding mechanism is arranged above one end of the Y axis. A blanking mechanism is arranged below the positioning clamping mechanism corresponding to the feeding mechanism. A control system is connected with the drilling mechanism, the feeding mechanism, the positioning clamping mechanism and the blanking mechanism respectively. According to the machine, manual operation procedures are simplified, the efficiency is improved, the accuracy is greatly improved, the reject rate is lowered, and a plurality of machines can be operated by an operator.

Owner:JIUJIANG JINYING TECH

Quick turn top tightening mechanism

ActiveCN106624958BTight and reliableExpand the range of processingMetal working apparatusFree rotationEngineering

The invention relates to a rapid overturning and tightly-abutting mechanism. An installation groove is formed in the top of the installation seat. An overturning block is hinged to the installation seat through small hinge shafts installed on side plates on the two edges of the installation groove. The small hinge shafts are installed on the side plates on the two edges of the installation groove. The overturning block can freely rotate with the small hinge shafts as the rotation center. When the overturning block is overturned to a limiting position, the overturning block abuts against the bottom of the installation groove. The overturning block is provided with a pin hole. A tightly-abutting shaft is assembled in the pin hole and can axially and freely move in the pin hole. A screwing-down handle is connected to threads at the left end of the pin hole in a threaded manner. The right end of the screwing-down handle is connected with the tightly-abutting shaft. The right end of the tightly-abutting shaft is used for tightly abutting against a workpiece and locating the workpiece. An overturning frame is hinged to the installation seat through hinge shafts. The hinge shafts are installed on the installation seat. The overturning frame can freely rotate with the hinge shafts as the rotation center. When overturning to the limiting position upwards, the overturning frame presses the overturning frame without exerting force. The rapid overturning and tightly-abutting mechanism is convenient to operate and capable of reliably and tightly abutting against the workpiece, rapidly leaving a workpiece machining area, expanding the machining range and shortening the operation time.

Owner:WUXI BEST PRECISION MACHINERY

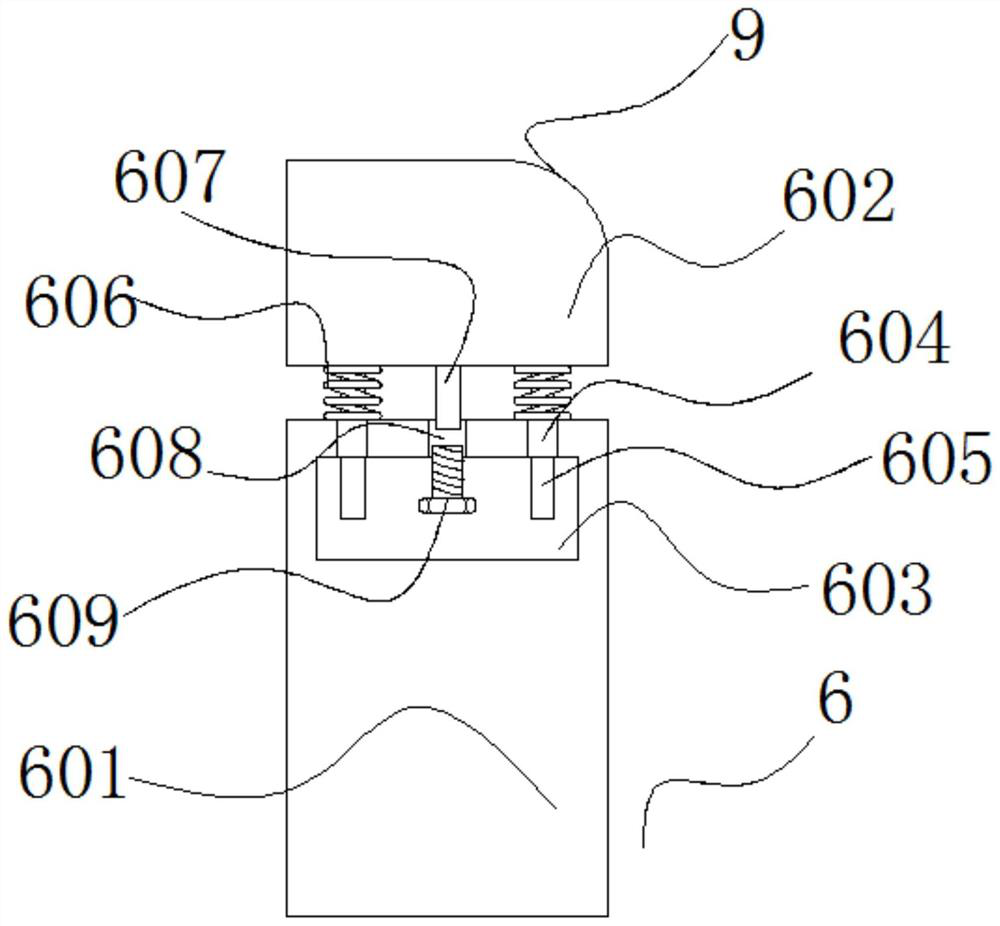

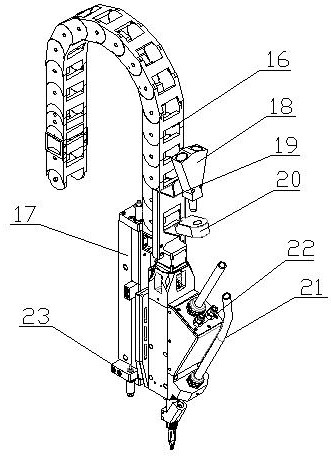

A stud welding equipment with self-adaptive stud height

ActiveCN112872560BStructural Design ScienceEasy to install and operateElectrode supporting devicesWelding accessoriesStructural engineeringStud welding

The invention relates to the technical field of stud welding equipment, in particular to a stud welding equipment with self-adaptive stud height. Threaded welding stud vibrating plate, internal threaded welding stud vibrating plate, welding stud conveying pipe suspender, bakelite platform, support truss, truss installation slide rail, said bakelite platform is installed on the upper part of the frame and fixed with the frame The invention specifically measures the length of the welding stud before welding the stud, and can freely adjust the length of the thimble according to the length specification of the welding stud during welding, thereby satisfying the welding operation of studs of different lengths with the same specification, reducing The installation quantity of the welding gun is reduced, the processing time is saved, and the reliability and stability of the nail feeding equipment are realized on the basis of increasing the processing range.

Owner:洛阳市锐创电气设备有限公司

Plastic graphene oxide composites and electrodes and methods for their preparation

The invention discloses a graphene oxide compound with plasticity, an electrode and a preparation method of the graphene oxide compound and the electrode. Main ingredients of the graphene oxide compound are graphene oxide, aniline and water. By characteristics that an electrostatic force exists between the graphene oxide and the aniline, and hydrogen bonds and Pi-Pi interact, the graphene oxide and the aniline are combined to each other together to prepare the graphene oxide compound with plasticity, the graphene oxide compound with plasticity has the advantages that the viscosity is suitable and the graphene oxide compound can be formed at normal temperature without being heated, and the graphene oxide compound can be used for manufacturing products in various shapes under the simple external condition. Moreover, the product containing the graphene oxide can be treated to obtain a corresponding reduced graphene oxide product (electrode material), then processing ranges of graphene oxide products and corresponding reduced graphene oxide products are expanded, and an application scope of corresponding products is extended.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

A method of processing circuit board with laser direct forming technology

ActiveCN103917052BHigh precisionLow costConductive material chemical/electrolytical removalLaser etchingOptoelectronics

The invention relates to a method for processing a circuit board by laser direct forming technology. Firstly, the conductive layer covered on the substrate material is thinned, and then the conductive layer is selectively and directly removed by laser after being processed by hole making and electroplating thickening process. Thus, a conductive pattern structure meeting design requirements is obtained. The steps are as follows: first, make a monitoring disk, that is, use a laser to photoetch and remove the conductive layer from the monitoring pattern area; then, use a micro-etching liquid to thin the material of the conductive layer until the micro-etching is thinned until it is at the monitoring disk pattern. When the substrate is exposed; finally, after drilling and metallizing the thinned substrate material and the conductive layer material, the conductive layer covered by the substrate material is removed by laser direct forming, leaving the required conductive layer. The invention solves the processing problem in the current technology that the conductive layer is too thick after hole formation and is not suitable for direct removal of the conductive layer by laser or mechanical methods, and at the same time broadens the application range of the laser photoetching method for processing PCBs.

Owner:德中(天津)技术发展股份有限公司

A combined diameter-reducing mechanism of a seam welding machine

Owner:JIANGSU UNIV OF SCI & TECH

3D curved glass forming mold and forming method thereof

PendingCN114133132ALinkage design structure is simpleControl accuracy does not affectGlass reforming apparatusDisplay deviceEngineering

The invention provides a 3D curved glass forming mold applied to the technical field of electronic display devices, and further relates to a 3D curved glass forming method, an upper mold (1) of the 3D curved glass forming mold is provided with an inclined boss I (5) and an inclined boss II (6), a movable sliding block I (3) is provided with a flat boss I (7), a movable sliding block II (4) is provided with a flat boss II (8), and the inclined boss I (5) and the inclined boss II (6) are arranged on the upper mold (1). The movable sliding block I (3) is provided with two inclined sliding grooves I (9), the movable sliding block II (4) is provided with an inclined sliding groove II (10), the lower mold (2) is provided with a glass molding part (11), the lower mold (2) is provided with a smooth sliding groove I (13), and the lower mold (2) is provided with a smooth sliding groove II (15). The hot bending forming of special-shaped, complex-structure or concave 3D curved glass products is conveniently and quickly realized, the problems of distortion, poor flatness and poor profile tolerance of a forming area in the forming process are solved, and the production efficiency is improved.

Owner:WUHU TOKEN SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com