3D curved glass forming mold and forming method thereof

A curved glass and forming mold technology, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve problems such as poor contour, distortion of forming area, and poor flatness, and achieve low equipment requirements and reduce The effect of simple production cost and linkage design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a further position and connection relationship between the embodiments, configurations, each of the various components, such as the respective components of the present invention, such as the interaction between the embodiments, configurations, and each portion of the present invention. Detailed description:

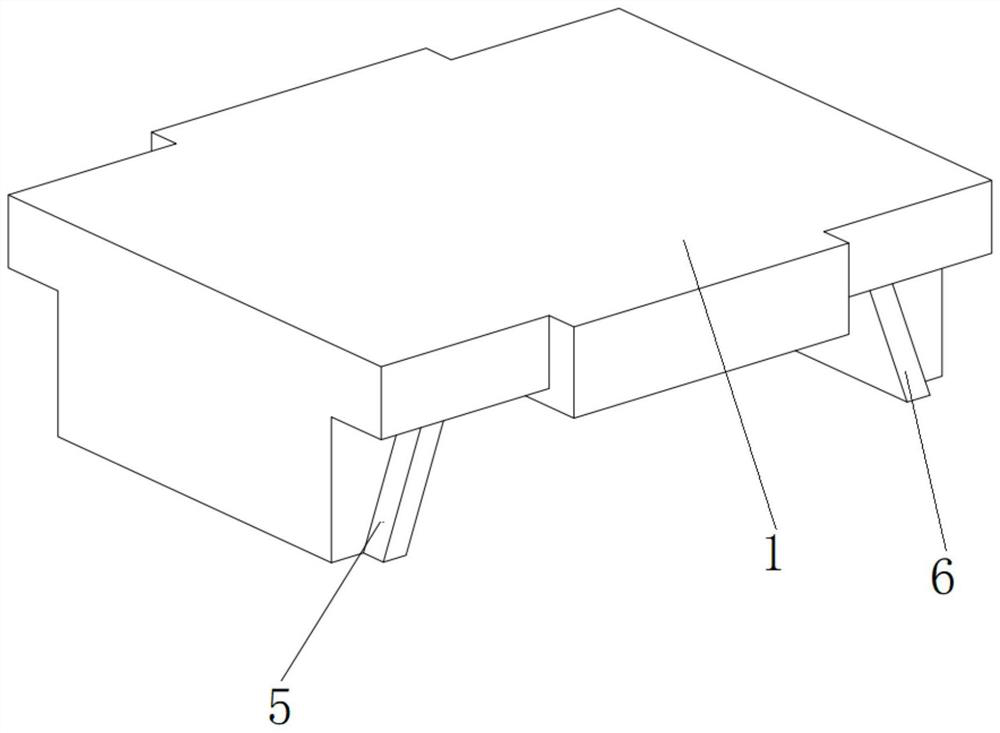

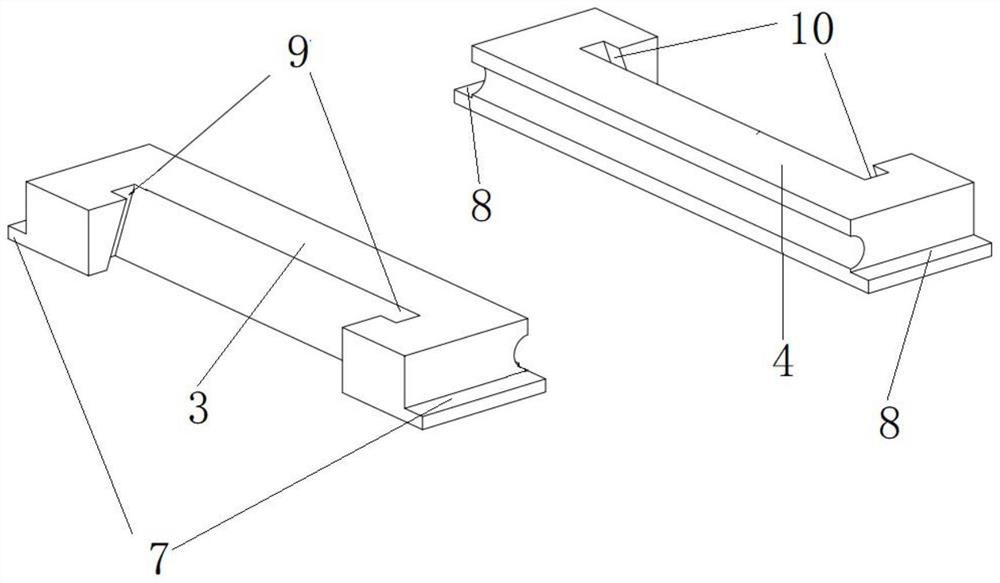

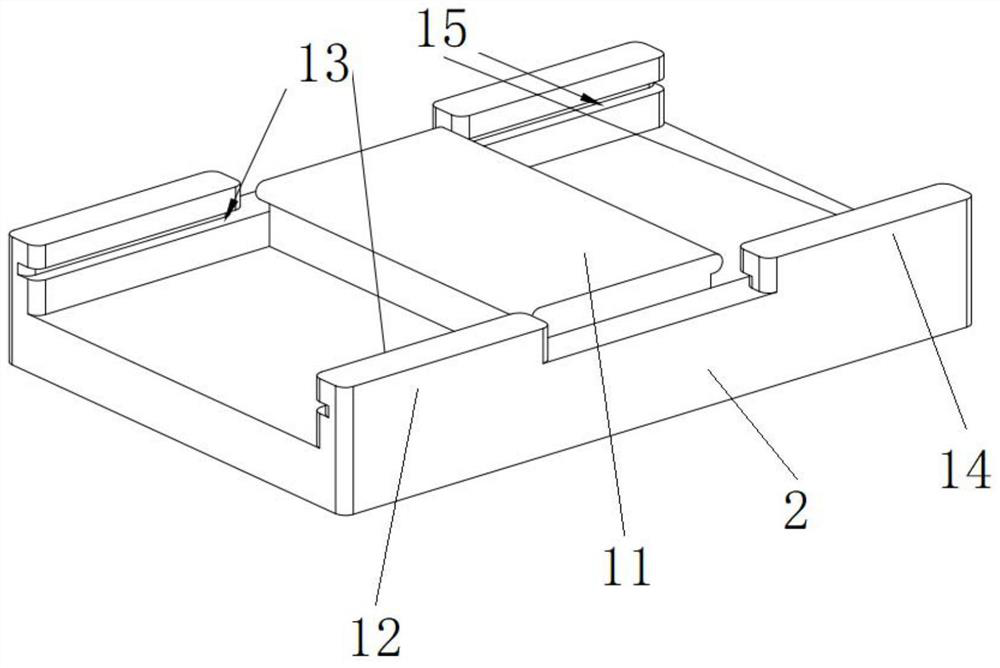

[0029] Append figure 1 Addition Figure 4As shown, the present invention is a 3D curved glass molding die comprising an upper mold 1, a lower mold 2, a movable slider I3, a movable slider II4, a top mold 1 side, and a torched bobbin I5, on the other side of the upper mold 1 Set the shocked beam type II6, the movable slider I3 respectively set the flat boss I7, and the movable slider II4 separately sets the flat boss II8, and two oblique slides I9 are also provided on the movable slider I9, and the movable slider II4. Also provided two oblique slots II10, the middle of the lower mold 2 is provided in the lower mold type portion 11, and the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com