Plastic graphene oxide composites and electrodes and methods for their preparation

A technology of graphene and composites, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as poor plasticity, and achieve the effects of expanding application range, suitable viscosity, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] At the same time, the present invention also provides a method for preparing a plastic graphene oxide composite, the preparation method comprising the following steps: S1, preparing an aqueous solution of graphene oxide; S2, mixing the aqueous solution of graphene oxide with aniline , stirred to form a precipitate.

[0042] The present invention utilizes the surface and edge of graphene oxide due to the introduction of a large number of polar groups, so that it can be uniformly dispersed in water or other organic solvents. The characteristics of gravity, hydrogen bonding and π-π interaction make aniline combine with graphene oxide dispersed in water to form a precipitate, and then obtain the desired plastic graphene oxide composite. The method has simple process steps, is easy to operate, and is suitable for large-scale production.

[0043] According to the above-mentioned preparation method of the present invention, preferably, in step S1, an aqueous solution of graph...

Embodiment 1

[0066] It is used to illustrate the plastic graphene oxide composite and its preparation method of the present invention.

[0067] (1) Preparation of graphene oxide composites with plasticity:

[0068] Distilled water was added to the graphene oxide aqueous solution prepared above to dilute to prepare a graphene oxide aqueous solution with a graphene oxide concentration of 8 mg / mL;

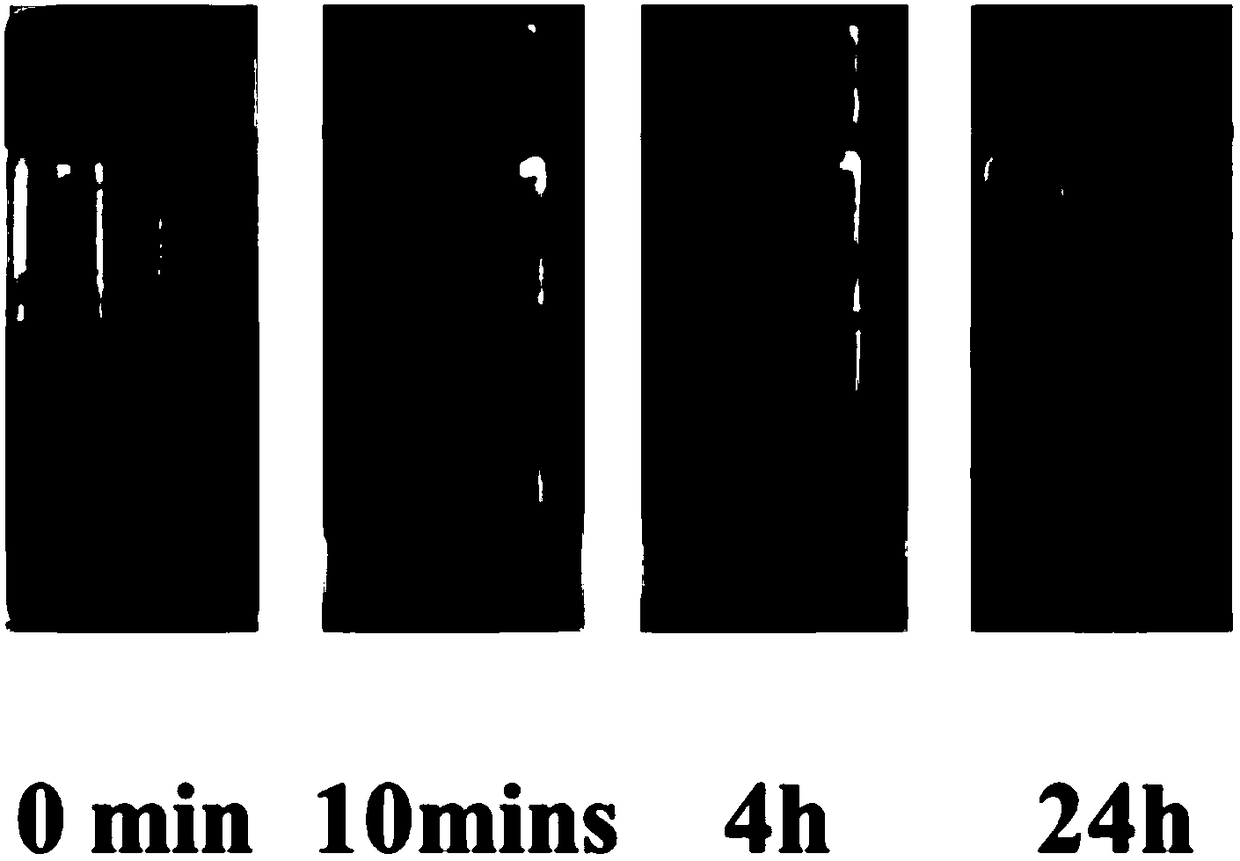

[0069] Add 10 mL of the graphene oxide aqueous solution prepared above and 1 mL of aniline to a 20 mL isotope bottle, stir at room temperature (25°C) with a stirrer (800 rpm) for 24 hours, separate the excess water phase in the isotope bottle, and take out The precipitate is the required 3D printing material. figure 1 is the change diagram of the product of the mixture in the isotope bottle with time, such as figure 1 As shown, the color of the graphene oxide aqueous solution gradually becomes lighter, accompanied by the gradual generation of precipitates, wherein the produced precipitates are t...

Embodiment 2

[0073] It is used to illustrate the plastic graphene oxide composite and its preparation method of the present invention.

[0074] (1) Preparation of a plastic graphene oxide composite: Referring to Example 1, the difference is that 10 mL of the graphene oxide aqueous solution prepared above and 2 mL of aniline were added to a 20 mL isotope bottle.

[0075] (2) Composition and characterization of graphene oxide composites with plasticity:

[0076] After analysis, it can be seen that the graphene oxide composite contains graphene oxide, aniline and water, and based on 100% by weight of the graphene oxide composite, it contains 3.1% by weight of graphene oxide, 77.5% by weight of aniline and 19.4% by weight. The water of weight %; And the viscosity of this graphene oxide compound is 10000Pa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com