Preparation method of recyclable packaging box containing polypropylene synthetic paper

A polypropylene synthetic paper and packing box technology, applied in the field of packaging and printing, can solve problems such as unsatisfactory satisfaction, unreachable quality, and short performance, so as to improve surface smoothness, stable mechanical quality, weather resistance and anti-corrosion The effect of water ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

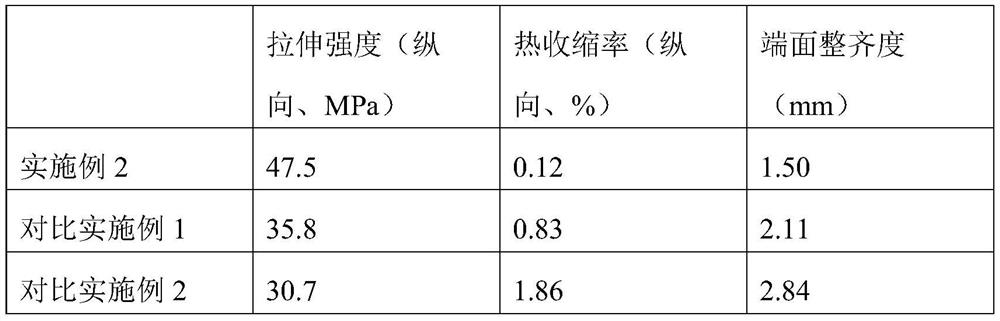

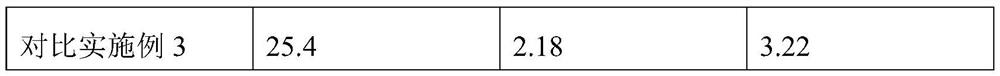

Examples

Embodiment 1

[0029] A preparation method for a recyclable packaging box containing polypropylene synthetic paper, comprising the steps of:

[0030] (1) Preparation of modified polypropylene copolymer:

[0031] Blending the polypropylene grafted with methyl methacrylate and the propylene-based elastomer, stirring evenly to obtain a modified polypropylene copolymer for subsequent use;

[0032] (2) Modified filler preparation:

[0033] a. Put the kaolin into the calciner, and take it out after calcining for 1 hour;

[0034] b. Put kaolin into the composite modification solution, and filter it out after ultrasonic treatment for 40 minutes;

[0035] c. Microwave the kaolin and take it out after 5 minutes to obtain the modified filler;

[0036] (3) Premix preparation:

[0037] a. Take by corresponding parts by weight: 60 parts of modified polypropylene copolymers made by step (1), 10 parts of modified fillers made by steps (2), 25 parts of calcium carbonate, 3 parts of ethyl cellulose, 0.2 ...

Embodiment 2

[0051] A preparation method for a recyclable packaging box containing polypropylene synthetic paper, comprising the steps of:

[0052] (1) Preparation of modified polypropylene copolymer:

[0053] Blending the polypropylene grafted with methyl methacrylate and the propylene-based elastomer, stirring evenly to obtain a modified polypropylene copolymer for subsequent use;

[0054] (2) Modified filler preparation:

[0055] a. Put the kaolin into the calciner, and take it out after calcination for 1.5 hours;

[0056] b. Put kaolin into the composite modification solution, and filter it out after ultrasonic treatment for 45 minutes;

[0057] c. Microwave the kaolin and take it out after 7 minutes to obtain the modified filler;

[0058] (3) Premix preparation:

[0059] a. Take by corresponding parts by weight: 63 parts of modified polypropylene copolymers made by step (1), modified fillers made by 13 parts of steps (2), 28 parts of calcium carbonate, 5 parts of ethyl cellulose, ...

Embodiment 3

[0073] A preparation method for a recyclable packaging box containing polypropylene synthetic paper, comprising the steps of:

[0074] (1) Preparation of modified polypropylene copolymer:

[0075] Blending the polypropylene grafted with methyl methacrylate and the propylene-based elastomer, stirring evenly to obtain a modified polypropylene copolymer for subsequent use;

[0076] (2) Modified filler preparation:

[0077] a. Put the kaolin into the calciner, and take it out after calcination for 2 hours;

[0078] b. Put kaolin into the composite modification solution, and filter it out after ultrasonic treatment for 50 minutes;

[0079] c. Microwave the kaolin and take it out after 8 minutes to obtain the modified filler;

[0080] (3) Premix preparation:

[0081] a. Take by corresponding parts by weight: 65 parts of modified polypropylene copolymers made by step (1), modified fillers made by 15 parts of steps (2), 30 parts of calcium carbonate, 6 parts of ethyl cellulose, 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com