Meat slice processing equipment

A processing equipment and sheet-forming technology, which is applied in meat processing equipment, meat processing, slaughtering and other directions, can solve the problems of shortened life of crank-slider transmission mechanism, adverse effects of yaw force, unbalanced force on meat materials, etc. The effect of overcoming adverse effects, increasing the machinable range, and compact mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

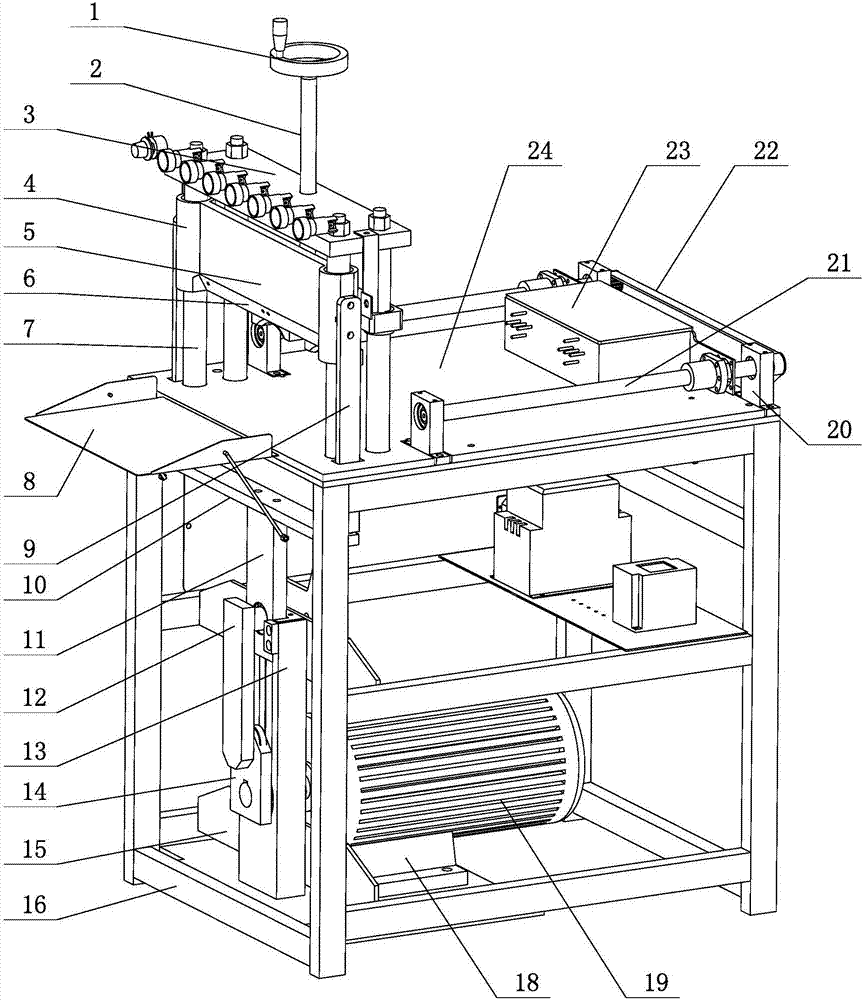

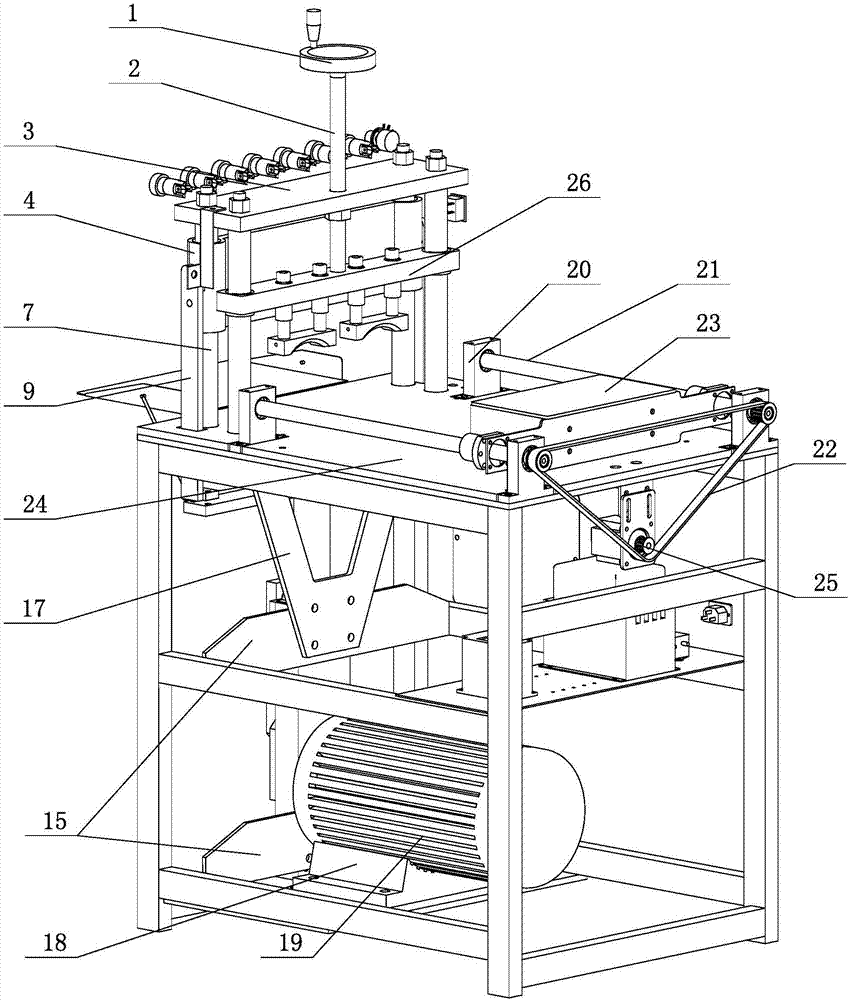

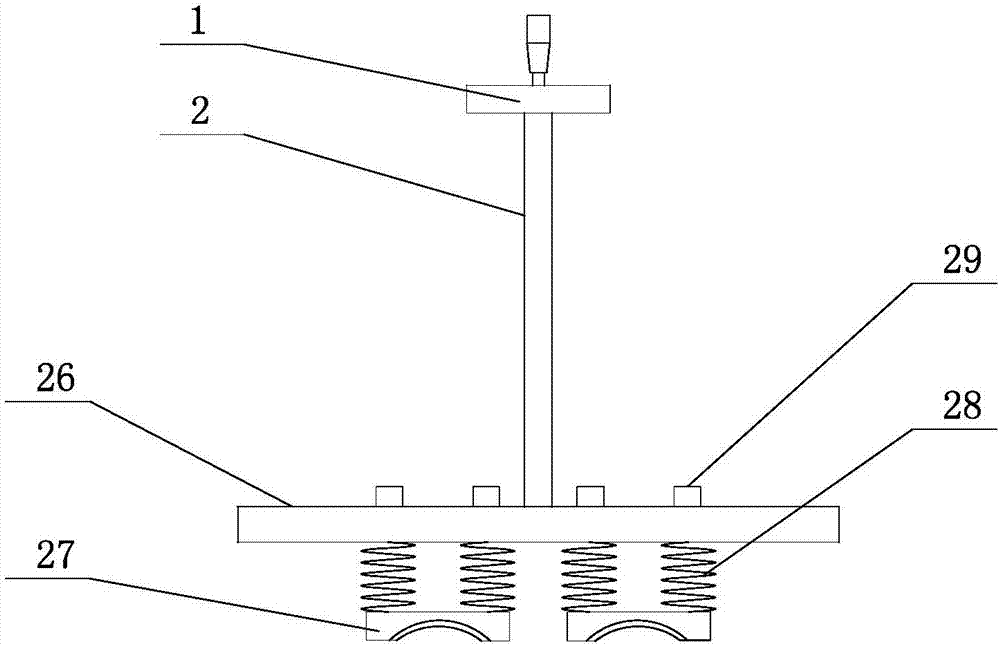

[0024] The present invention will be further described below in conjunction with accompanying drawing:

[0025] Such as Figure 1 ~ Figure 3As shown, the meat slice processing equipment according to the present invention includes a frame 16, a panel 24 is arranged on the top of the frame 16, and a driving mechanism is arranged on the bottom of the frame 16, and the driving mechanism is connected to a cutting mechanism. The cutting mechanism includes a transmission assembly, and the transmission assembly The top is connected with the guide assembly, and the guide assembly is connected with the cutting assembly. The cutting assembly is located above one end of the panel 24. The other end of the panel 24 is provided with a propulsion mechanism. The cutting assembly is provided with a discharge plate 8 on the outside and a clamping mechanism on the inside. The crank 14 connected by the mechanism, the rocker 12 is hinged on the top of the crank 14, the top of the rocker 12 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com