Rapid overturning and tightly-abutting mechanism

A top-tight, fast technology, applied in the field of mechanical processing, to achieve the effect of expanding the machining range, large axial thrust, and reliable reverse interlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

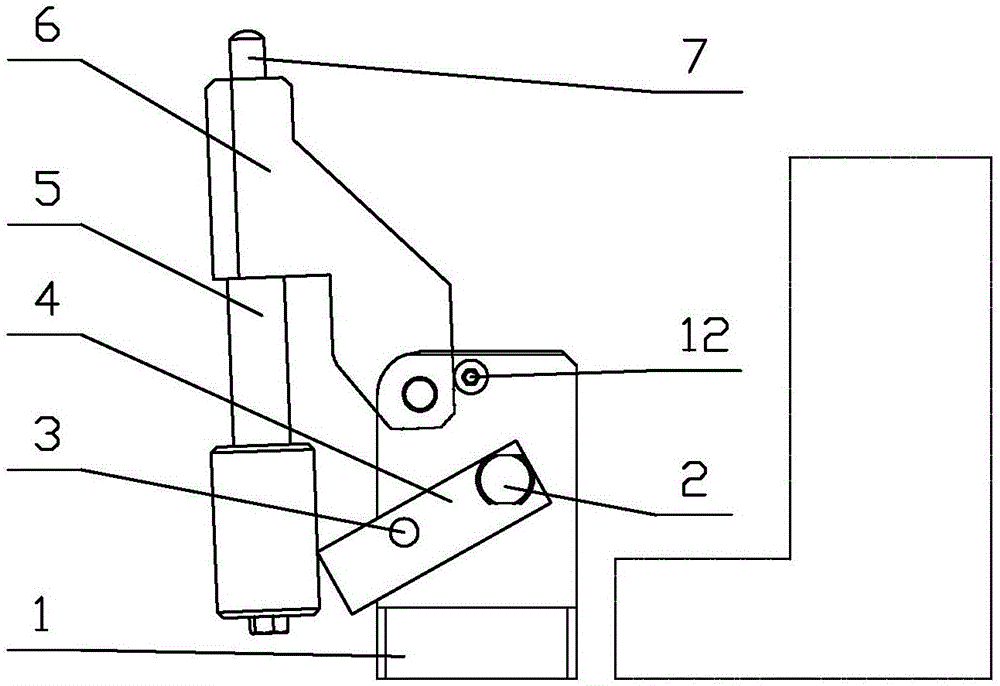

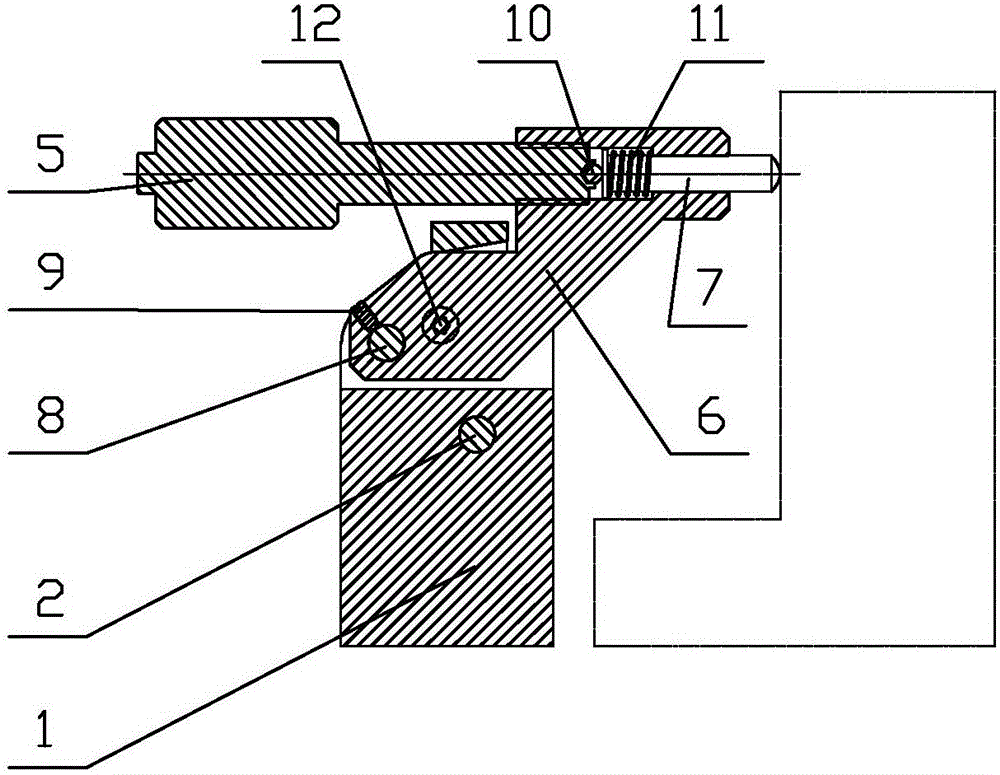

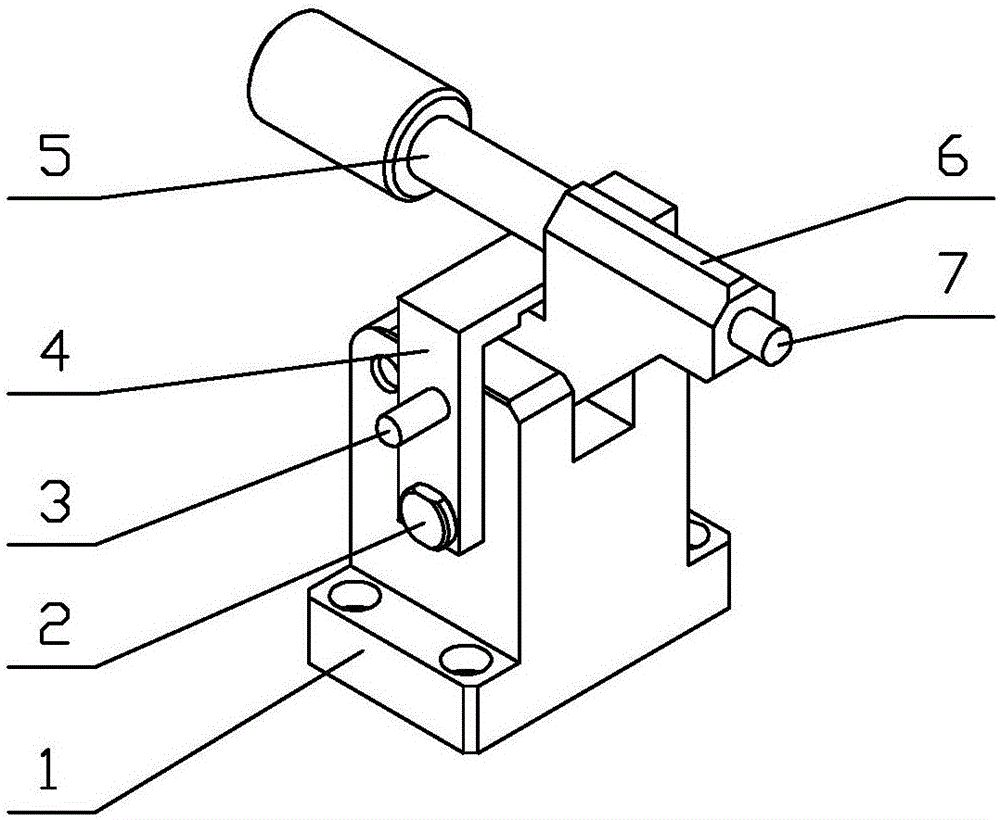

[0017] As shown in the figure, the fast turning and tightening mechanism in the embodiment is mainly composed of a mounting seat 1, a pin shaft 2, a handle 3, a turning frame 4, a tightening handle 5, a turning block 6, a tightening shaft 7, a small pin shaft 8, a tightening Parts such as set screw 9, steel ball 10, spring 11, ball head elastic clip 12 are formed.

[0018] Such as Figure 1~Figure 3 As shown, the mounting seat 1 is fixed on the fixture during installation and application, and the top of the mounting seat 1 is provided with a mounting groove, and the flip block 6 is hinged to the mounting seat 1 through the small pin shafts 8 installed on the side plates on both sides of the mounting groove. Above, the small pin shaft 8 is installed on the side plates on both sides of the installation groove, the turning block 6 can rotate freely with the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com