Scroll

A technology for rewinding shafts and main shafts, which is applied in the field of serially mounted pneumatic rewinding reels, which can solve the problems that materials are prone to breakage, rewinding expansion force cannot be zero, and parts are easy to be lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

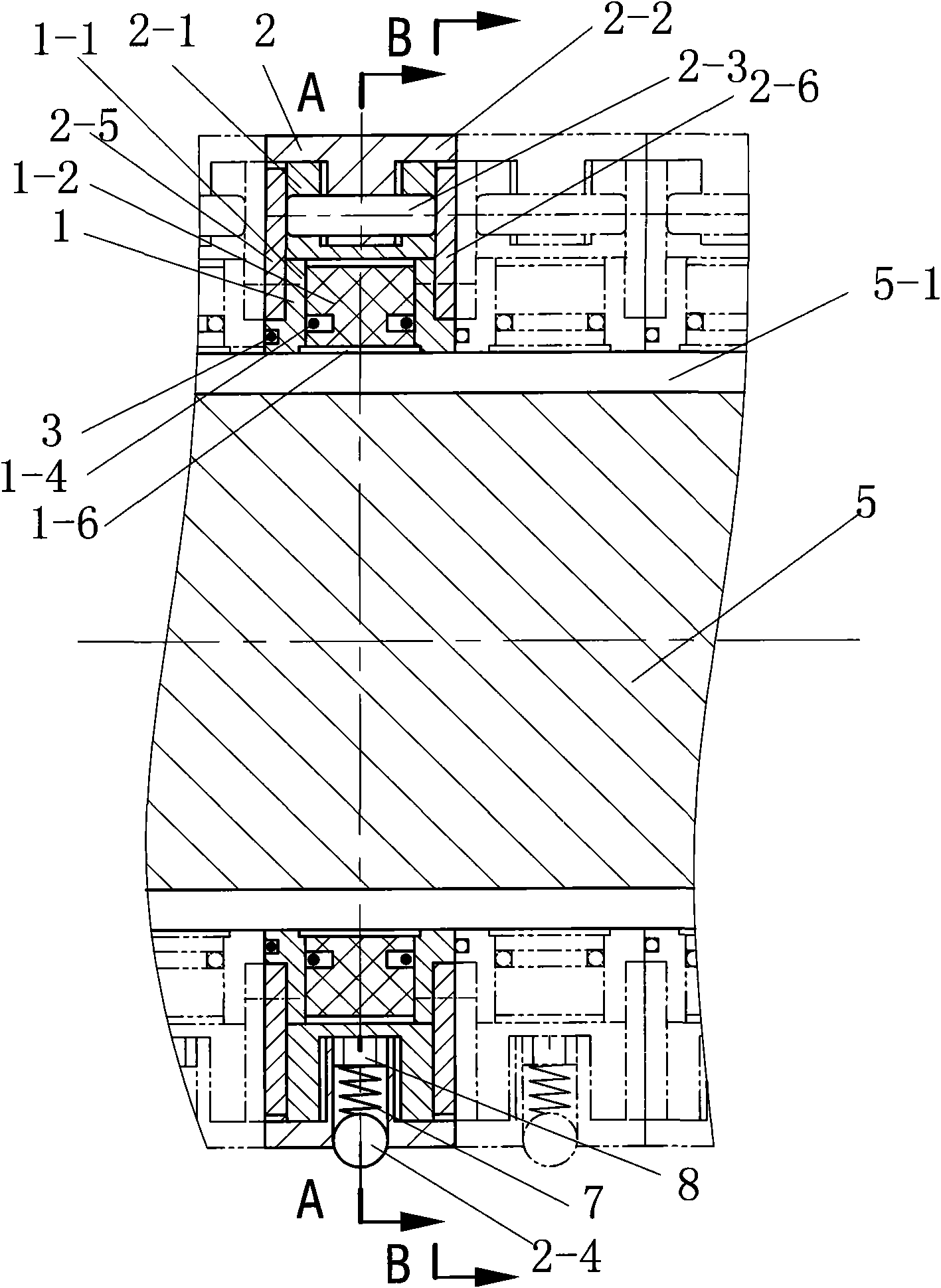

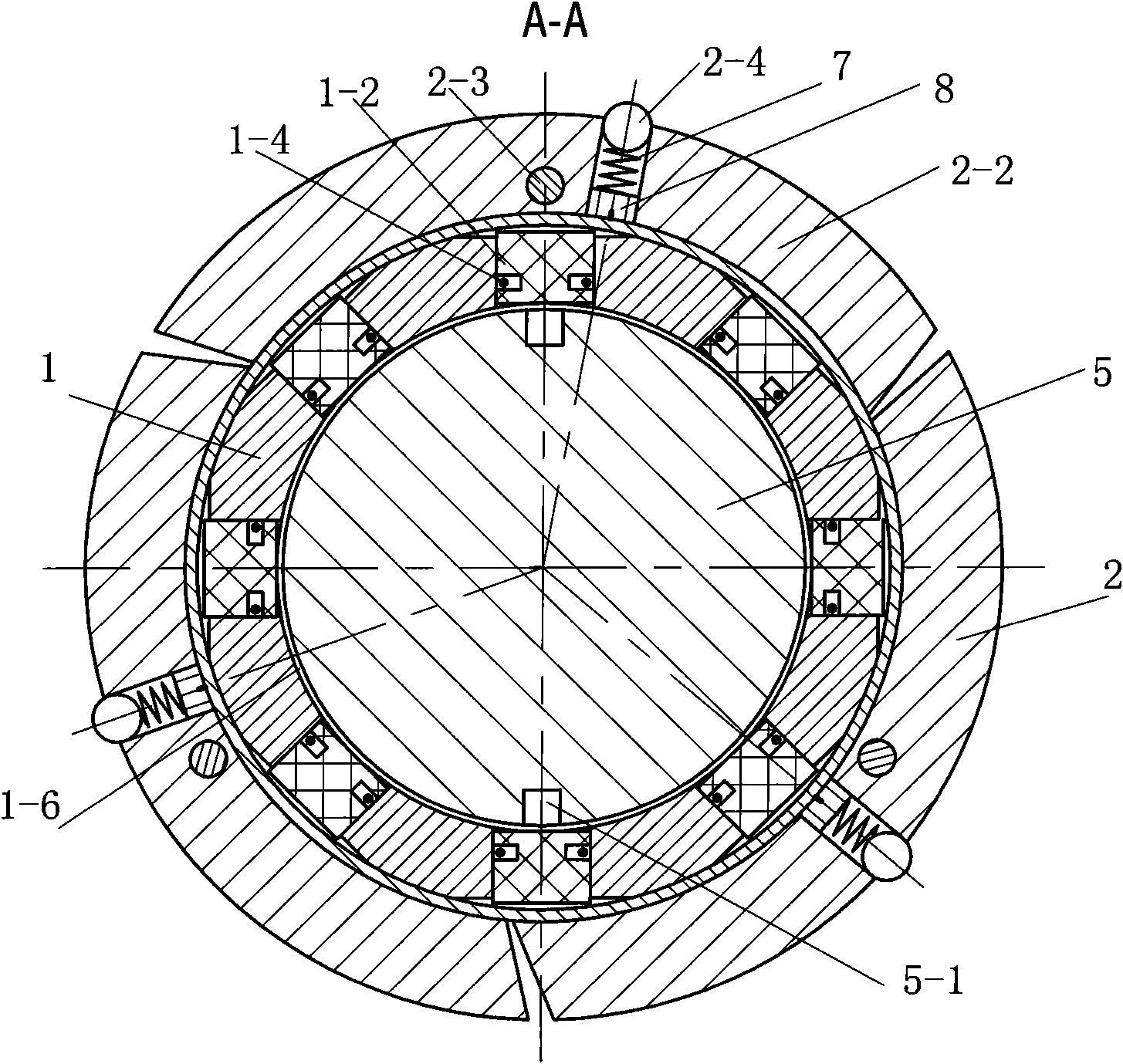

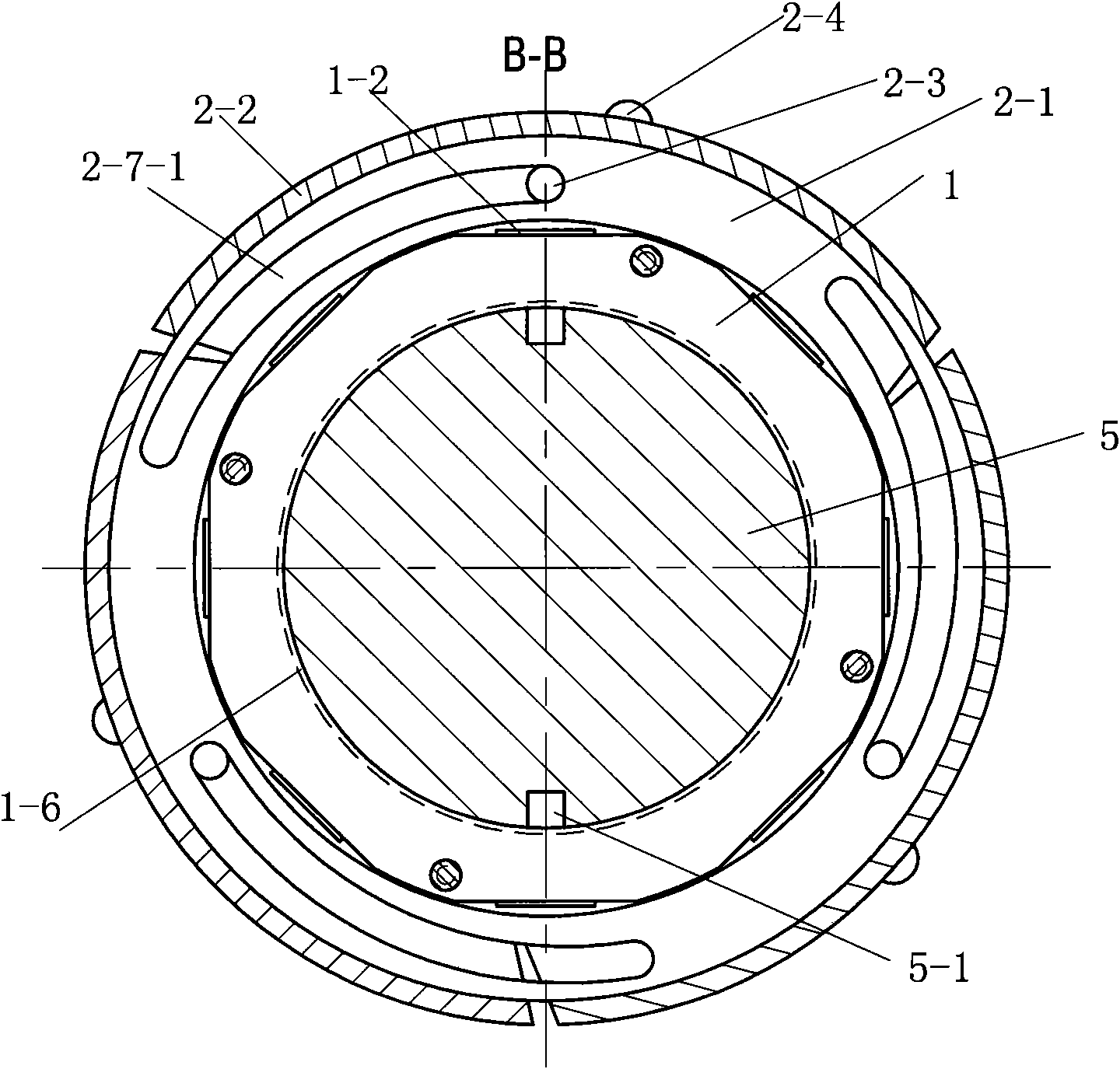

[0030] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

[0031] see Figure 1-16 As shown, a winding shaft is composed of a plurality of friction pairs mounted in series on a main shaft 5 with an air inlet passage 5-1. The friction pairs include a fixed ring 1, and the fixed ring 1 includes a ring body 1-1, a piston 1-2 and piston sealing ring 1-4, the ring body 1-1 is set on the main shaft 5, both sides of the ring body 1-1 have annular steps 1-1-1, and the ring body 1-1 is evenly distributed in the circumferential direction There are at least six radial piston holes 1-5, and each radial piston hole 1-5 is equipped with a piston 1-2 with a piston sealing ring 1-4, and one end of the radial piston hole 1-5 is connected to the air inlet The channel 5-1 is connected, and the other end is the inlet and outlet hole of the piston 1-2; the friction pair also includes an expansion ring 2 used in conjun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com