A fully automatic CNC two-station lock case drilling pinball hole machine

A two-station, fully automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problem of unreasonable design of reference position positioning, high labor intensity of workers, and low yield Advanced problems, to achieve the effect of expanding the range of processing, simplifying the manual operation process, and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

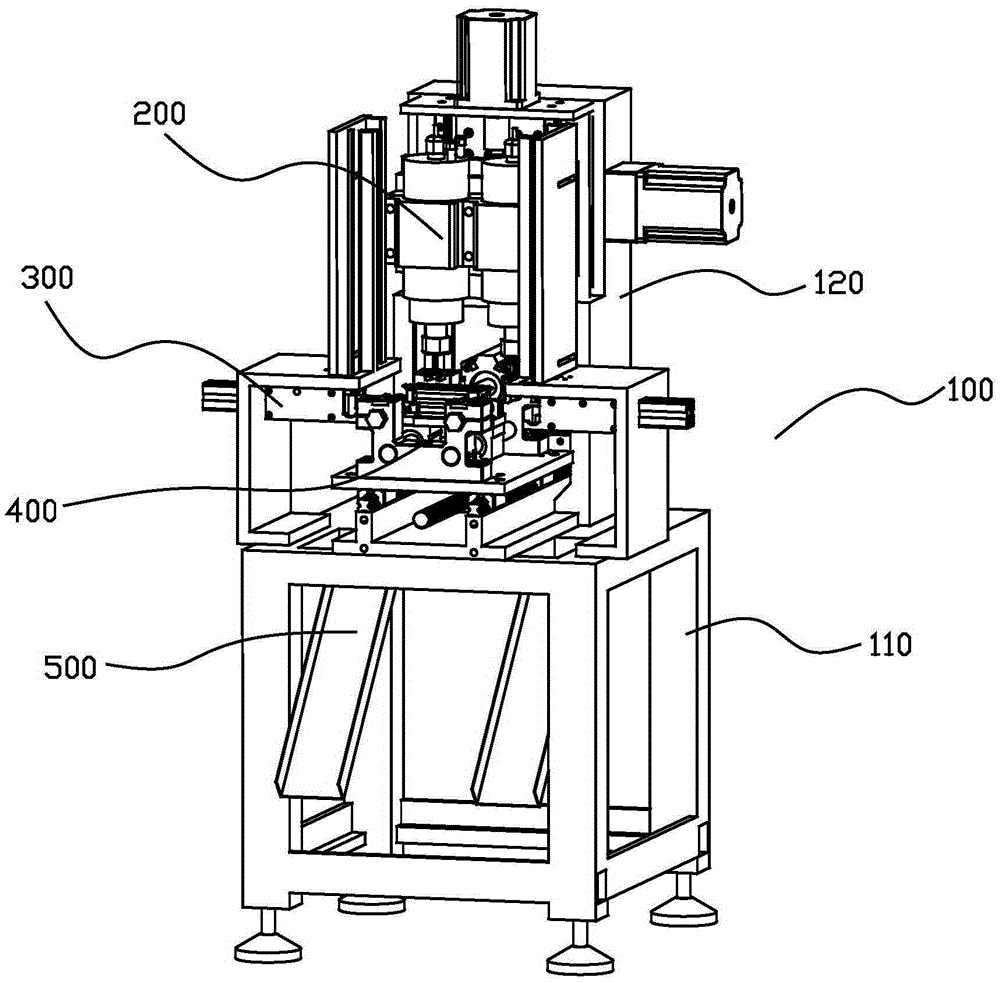

[0013] see figure 1 , a fully automatic CNC two-station lock case drilling machine for pinball holes, comprising a main body 100 and a drilling mechanism 200 arranged on the main body 100, a feeding mechanism 300, a positioning and clamping mechanism 400, and a feeding mechanism 500 and the control system, the main body bed 100 includes a base 110 and a gantry frame 120, and the drilling mechanism 200 includes two drilling machines arranged side by side. Moving along the X-axis and Z-axis, the positioning clamping mechanism 400 is set on the lower base 110 of the two drilling machines, and the positioning clamping mechanism 400 is provided with a guide rail and a guide column that slides and cooperates with each other to move along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com