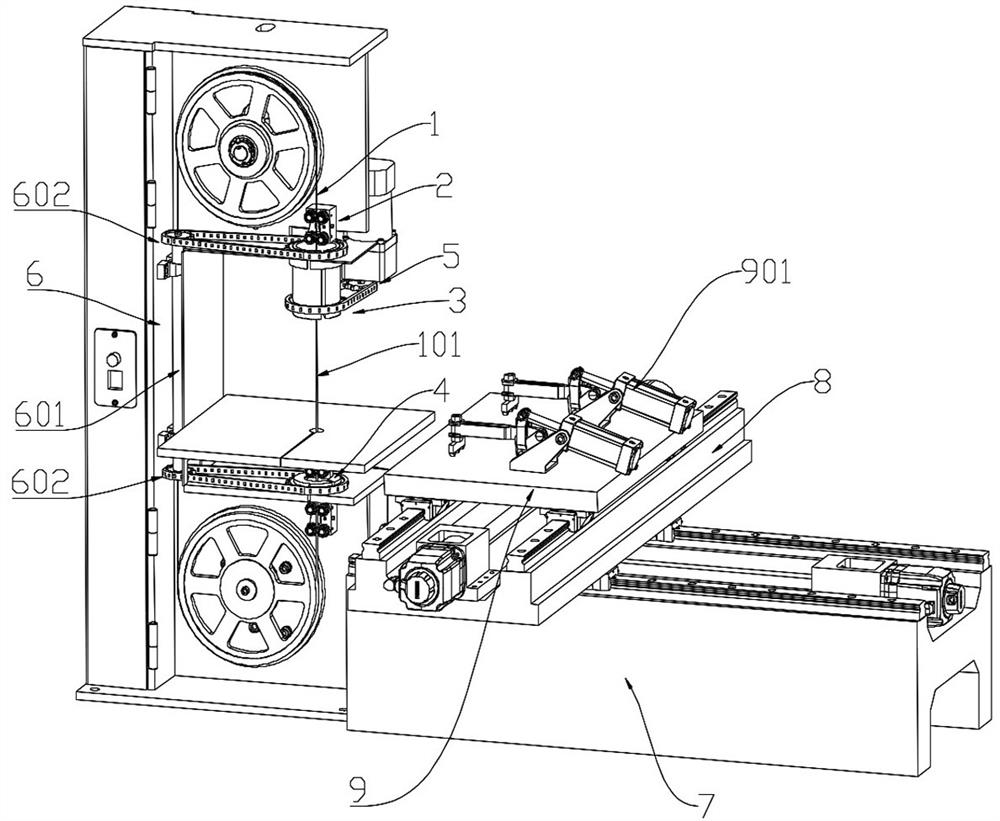

Arc-shaped saw for cutting arc-shaped wood

A cutting action and arc-shaped technology, which is applied in the direction of wood processing equipment, band saws, sawing equipment, etc., can solve the problems of large processing knife edge, wood waste, and physical exertion, so as to avoid friction, improve service life, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

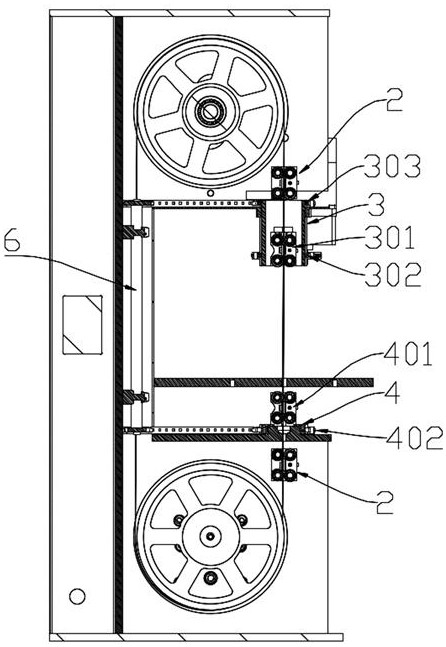

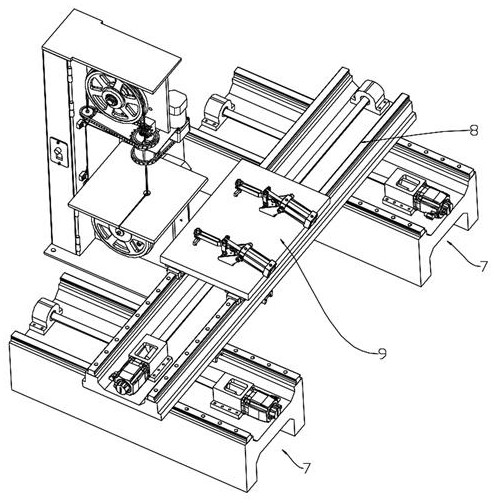

[0020] Embodiment 2: Combination image 3 As shown, the difference from Embodiment 1 is that there are two bases 7 arranged in parallel, the middle support plate 8 overlaps and slides on the two bases 7, and the cutting section 101 of the arc saw is arranged on the two bases 7. Between the bases 7. During use, the plate to be processed is pressed on the upper side of the servo slip pallet 9 by the pneumatic clamping jaw 901 . When used, the processable range of the plate is increased,

Embodiment 3

[0021] Example Three: Combining Figure 4 As shown, the difference from the second embodiment is that there are two servo sliding pallets 9 on the middle pallet 8 . When in use, it can clamp larger plates to be processed, making the clamping of the processed plates more stable, and can process plates with different widths and different curves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com