Method and clamping device for numerical control machining of component closed corner

A clamping device and part technology, applied in the field of CNC machining parts closed angle, method and clamping device, can solve the problems of insufficient five-axis swing angle machining stroke, insufficient Y-direction stroke, etc., to expand the machinable range and reduce Y The effect of the stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

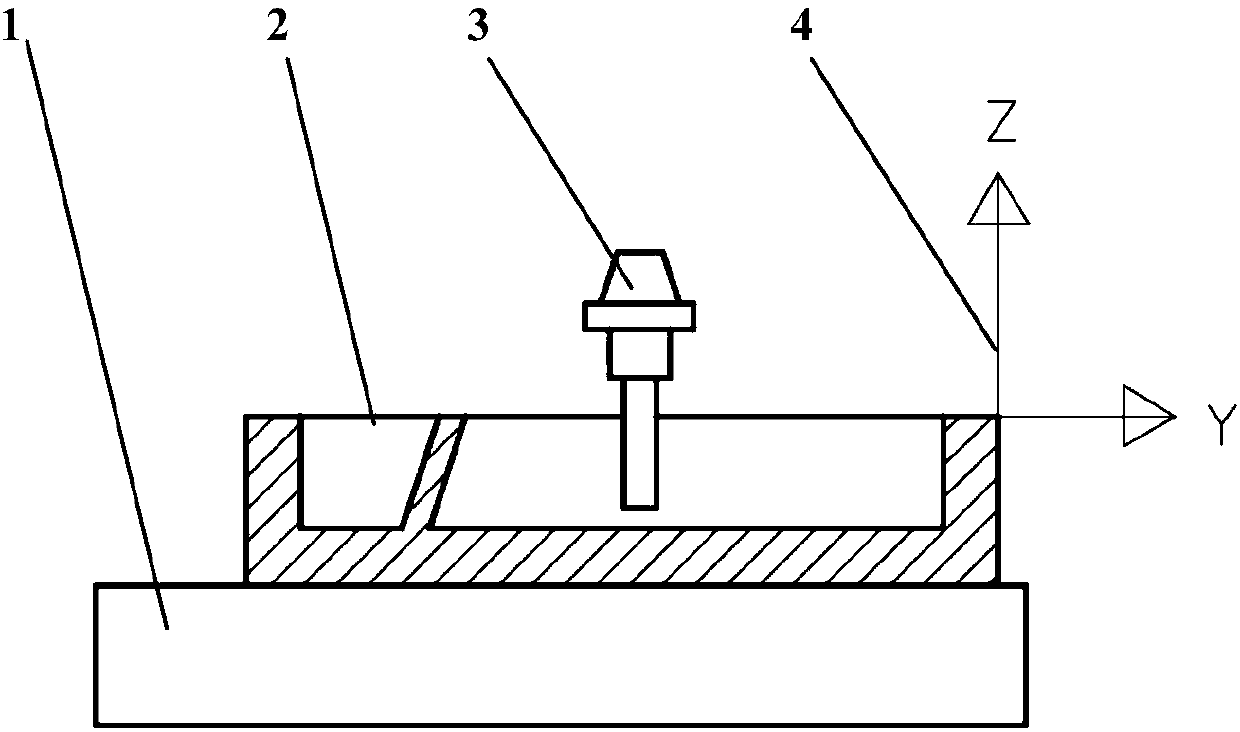

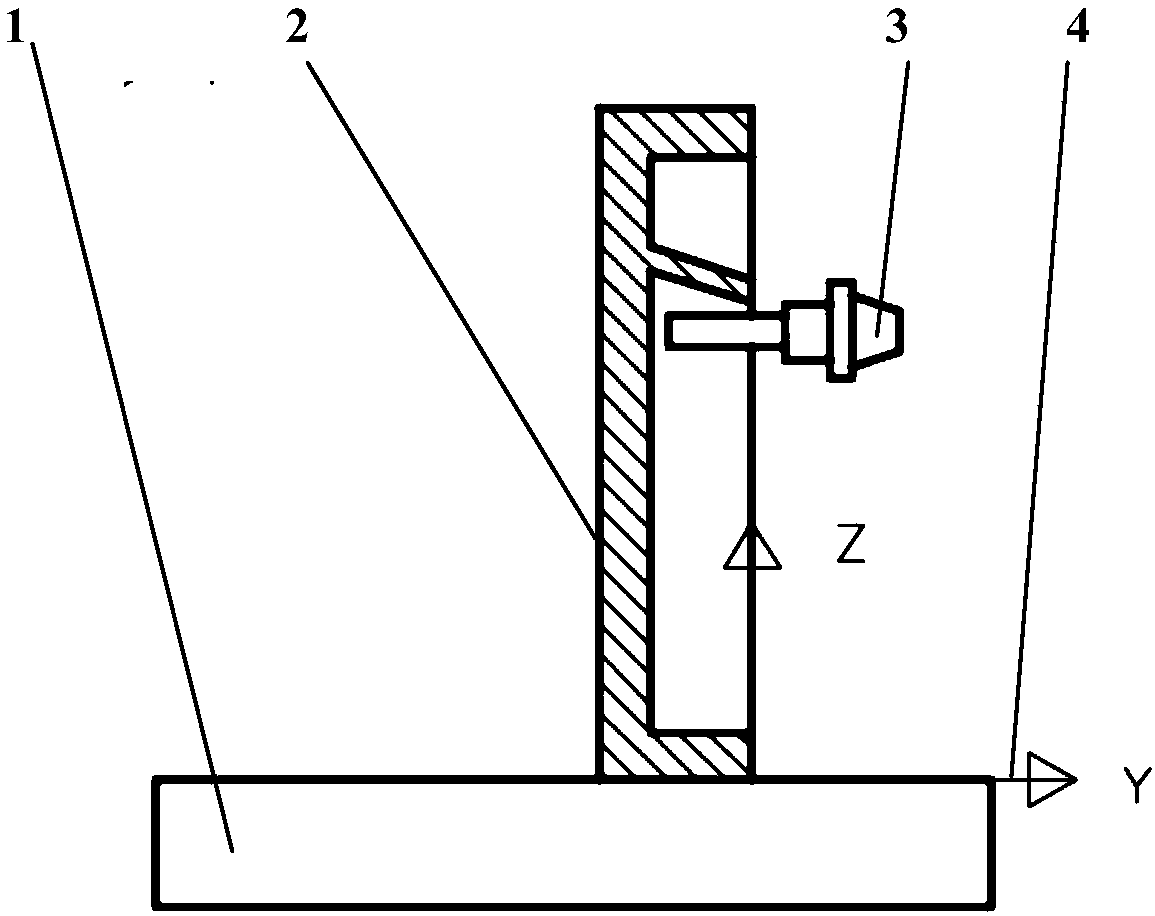

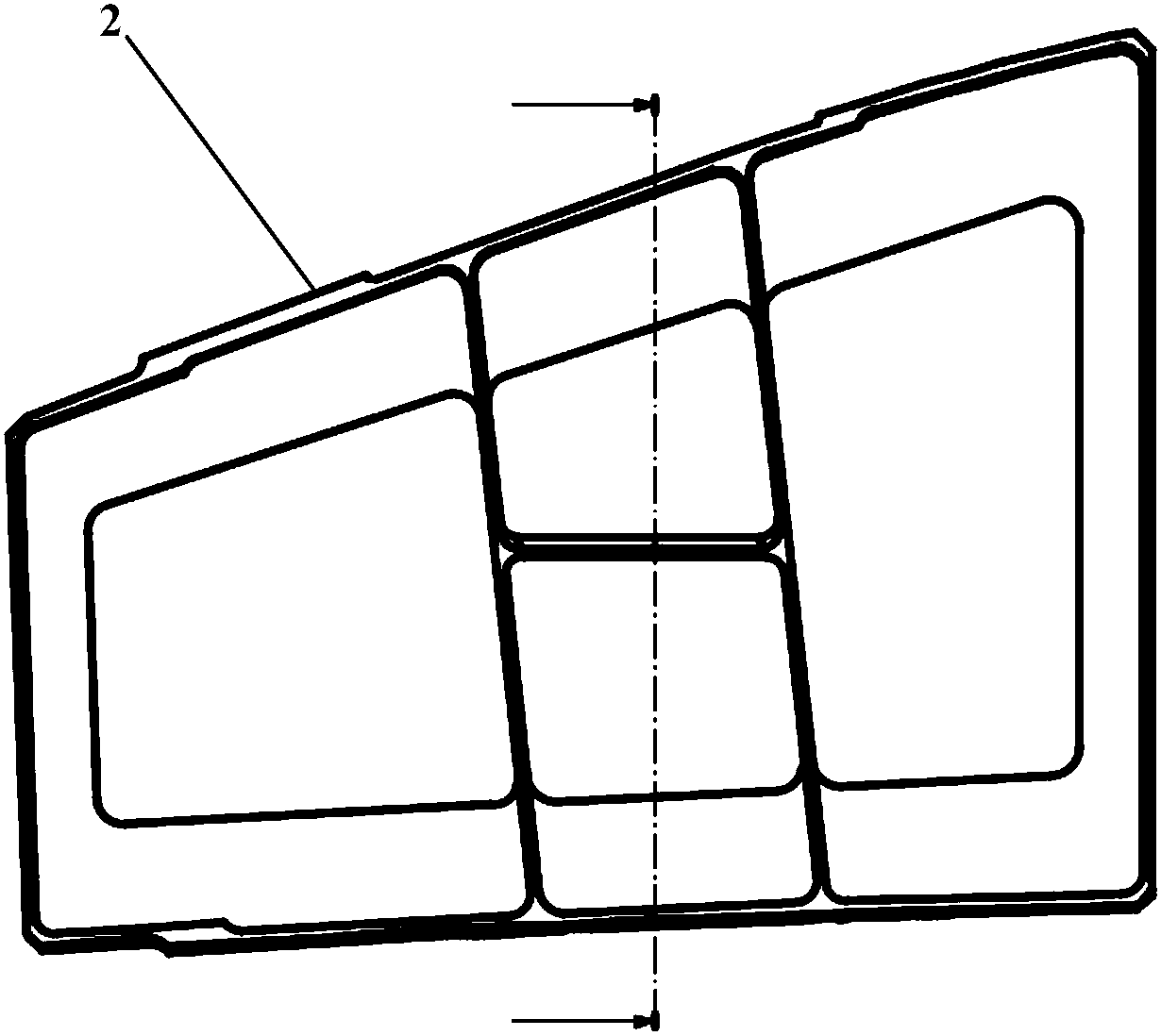

[0024] This embodiment takes a part 2 with a double-sided cavity structure as an example to describe in detail. For a schematic diagram of the part structure, see image 3 , the section structure see Figure 4 . The part is a double-sided multi-groove structure, with edge plates and vertical ribs with varying angles, and the maximum closed angle angle β.

[0025] First, the clamping device 5 for closed-angle CNC machining is designed according to the part structure. Figure 5 It is the axonometric drawing of the closed-angle CNC machining clamping device, Image 6 It is a side view of the closed-angle CNC machining clamping device. The cross section of the clamping device 5 is a right-angled trapezoid, narrow at the top and wide at the bottom. The bottom plane 13 is rectangular and fits the machine tool platform; the top plane 7 is also rectangular and used for Z-direction tool setting during processing; the top plane 7 is parallel to the bottom plane 13 . A step 12 protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com