Precise combination bearing with adjustable pre-tightening force

A combined bearing and preload technology, applied in the field of bearings, can solve problems such as unstable axial rollers, difficult assembly of YRT bearings, uncontrollable clearance of radial rollers, etc., to achieve large axial thrust and transmission rigidity Large, solve the effect of inconvenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

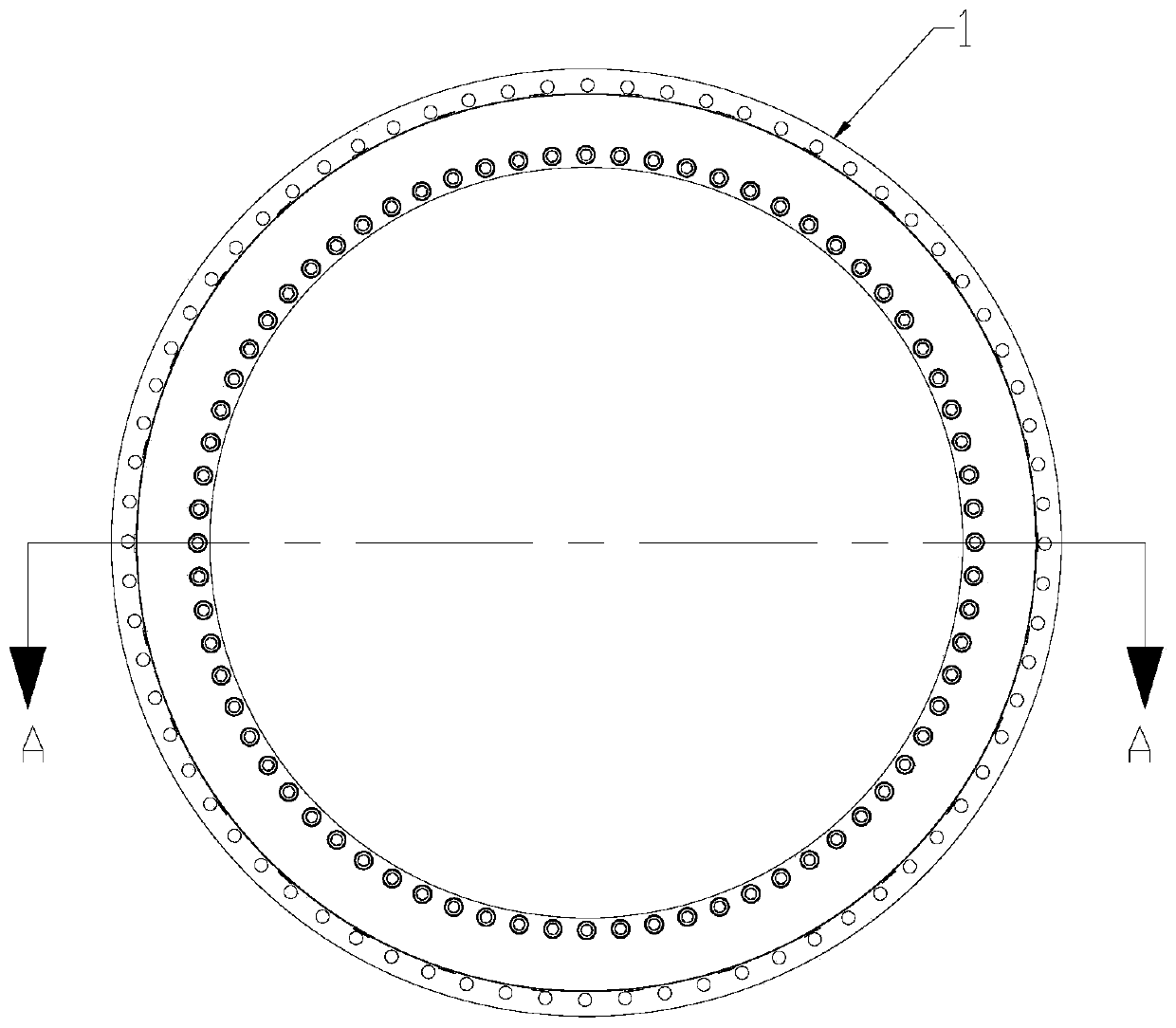

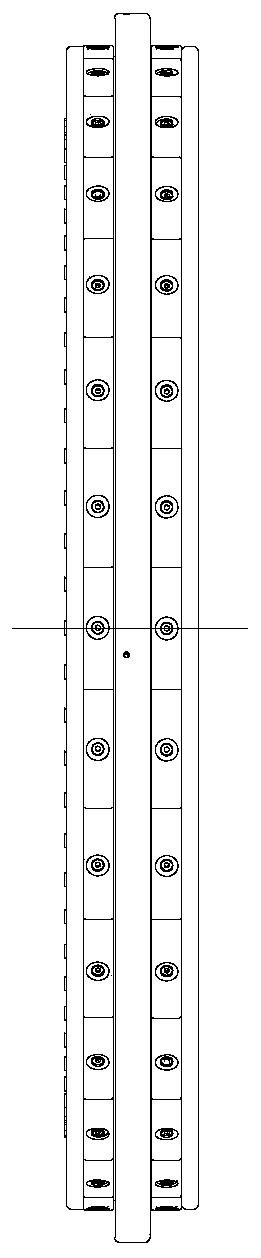

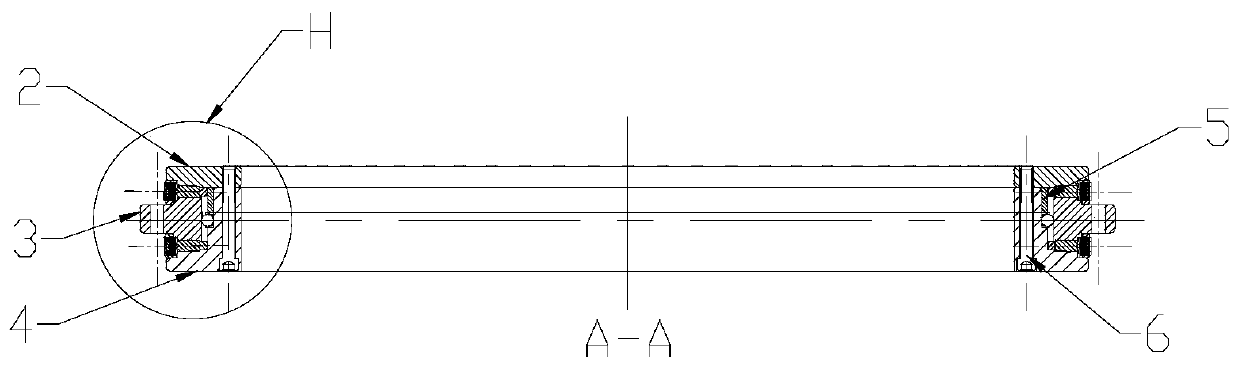

[0040] Such as Figure 1-20 As shown, this embodiment provides a precision composite bearing with adjustable preload, including a small inner ring 2 of the bearing, a large inner ring 4 of the bearing, an outer ring 3 of the bearing, an axial cage 7, an axial roller 13 and diameter To the roller 14, the axial roller 13 is a tapered roller, and the linear velocity at both ends of the axial roller is the same, and the axial cage 7 is provided with a The tapered groove 71, the axial roller 13 is installed in the tapered groove 71, the surfaces of the small inner ring 2 of the bearing and the large inner ring 4 of the bearing and the axial roller 13 are all in contact with the axial roller The inclined surface matched with the tapered surface, the main body of the axial cage has great rigidity. In terms of bearing axial force, the axial roller is made into a tapered roller with a certain taper, so that the linear speed of the bearing running in the axial rolling direction The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com