Patents

Literature

44results about How to "High transmission rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

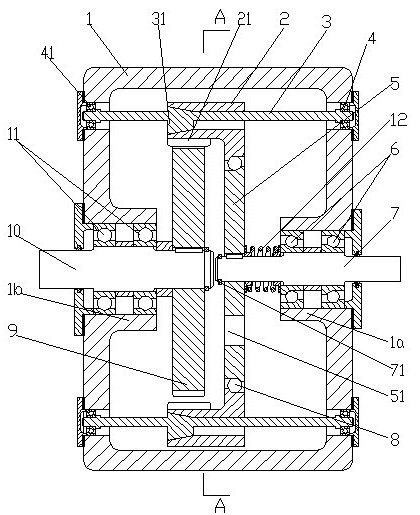

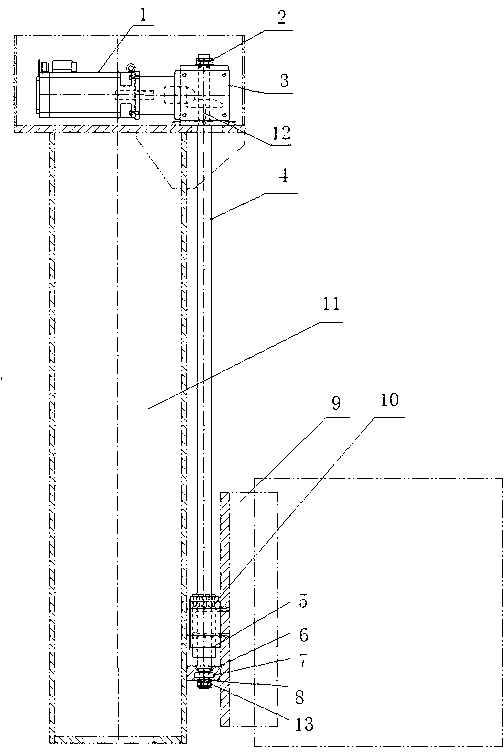

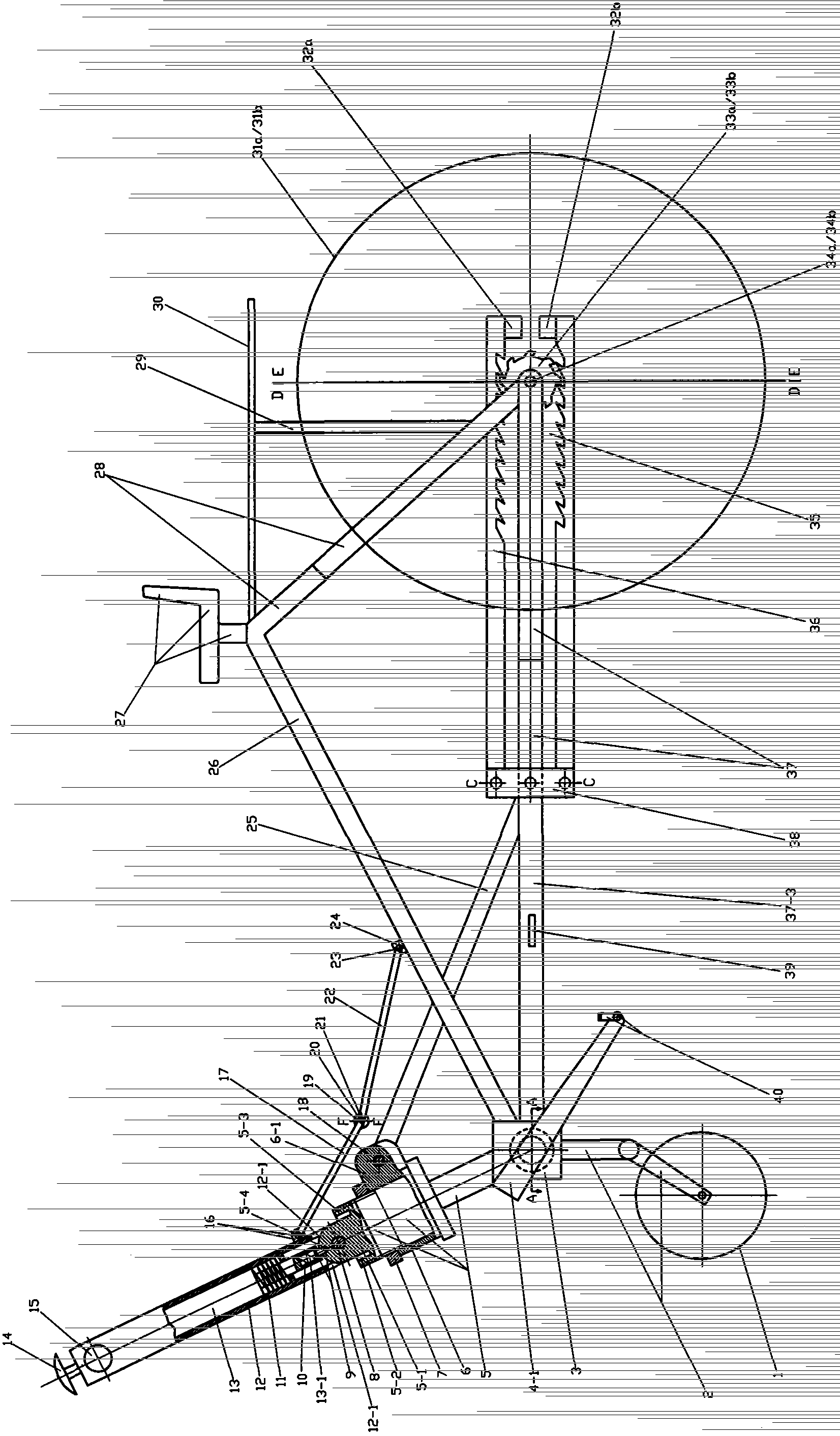

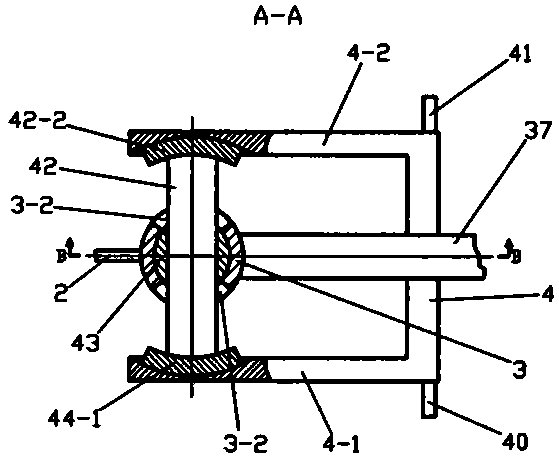

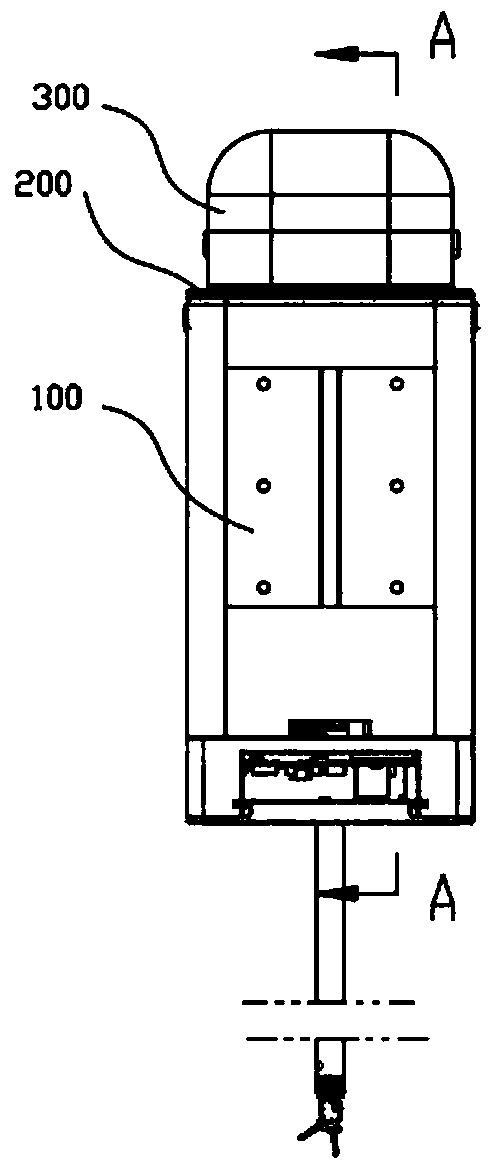

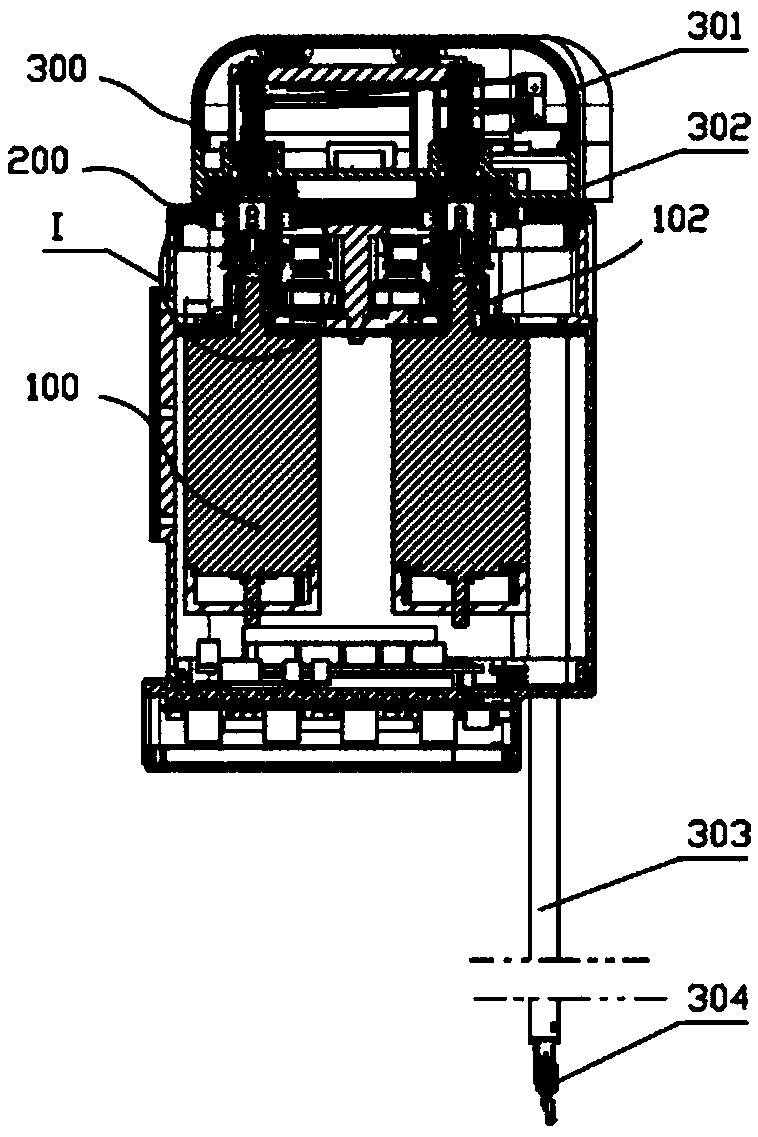

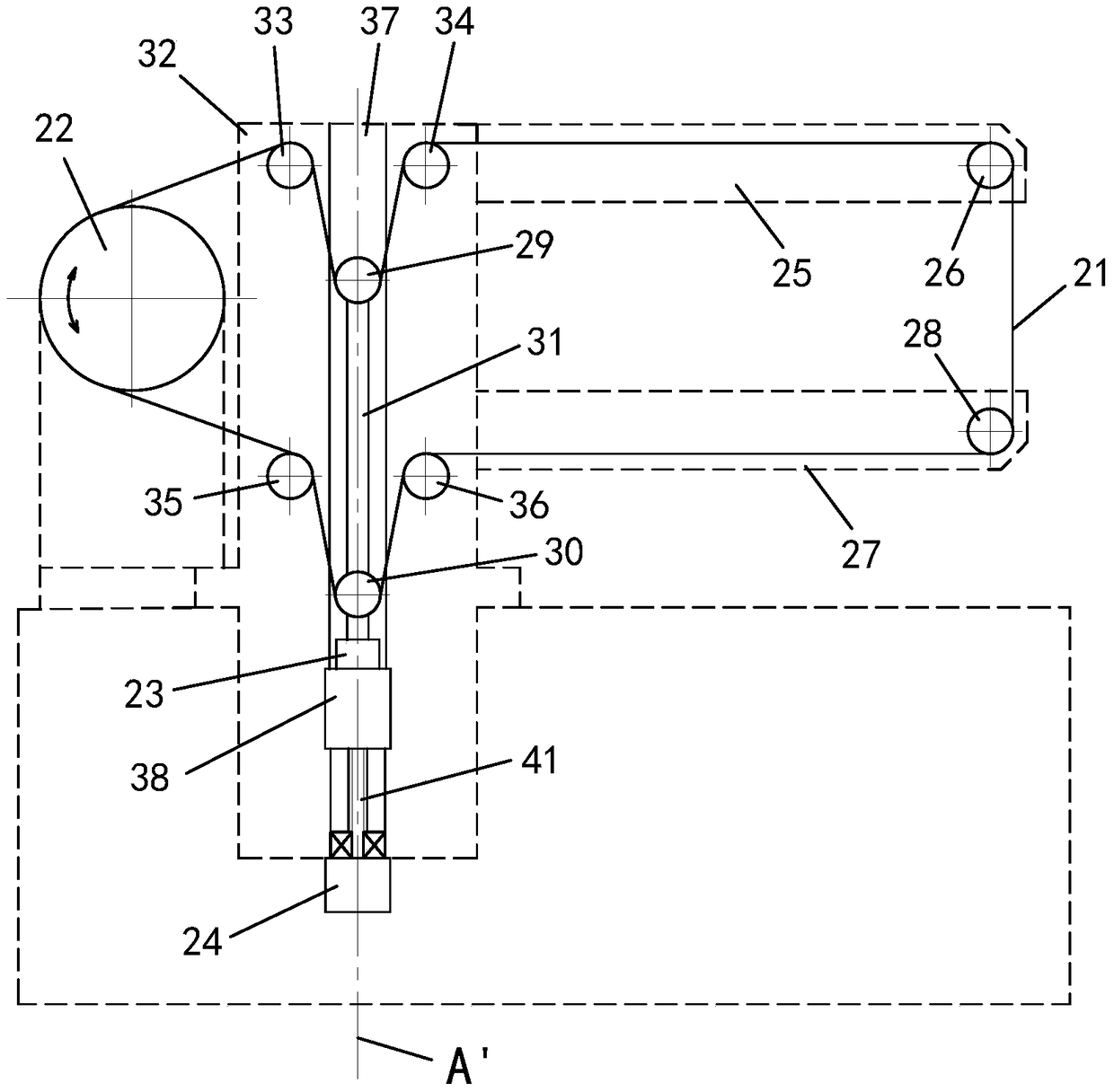

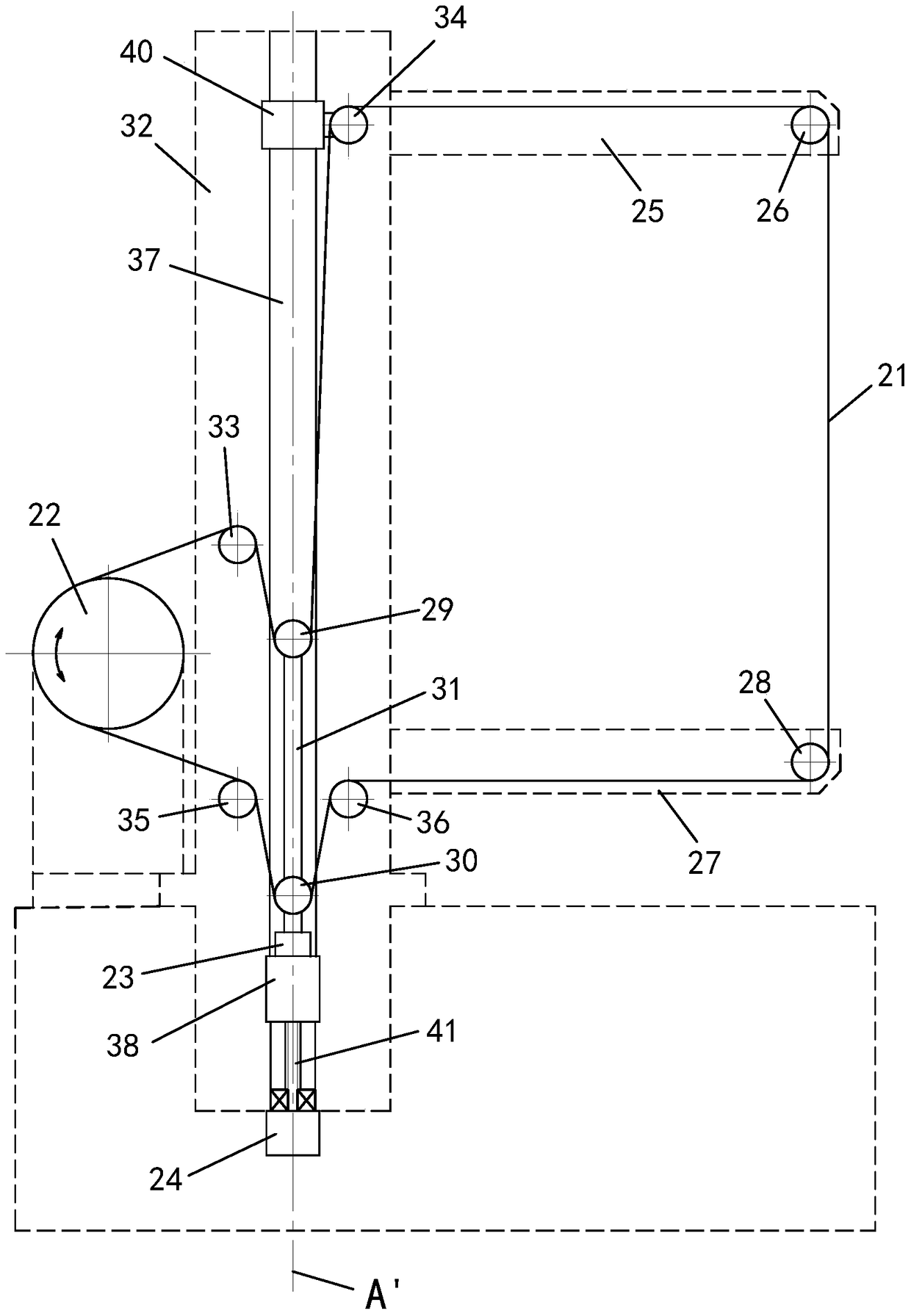

Wire-cut electric discharge machine wire transport mechanism capable of realizing accurate closed-loop control on tension of electrode wire

ActiveCN104070248ASolve the technical difficulties of precise tension controlHigh transmission rigidityElectrical-based machining electrodesElectric dischargeClosed loop

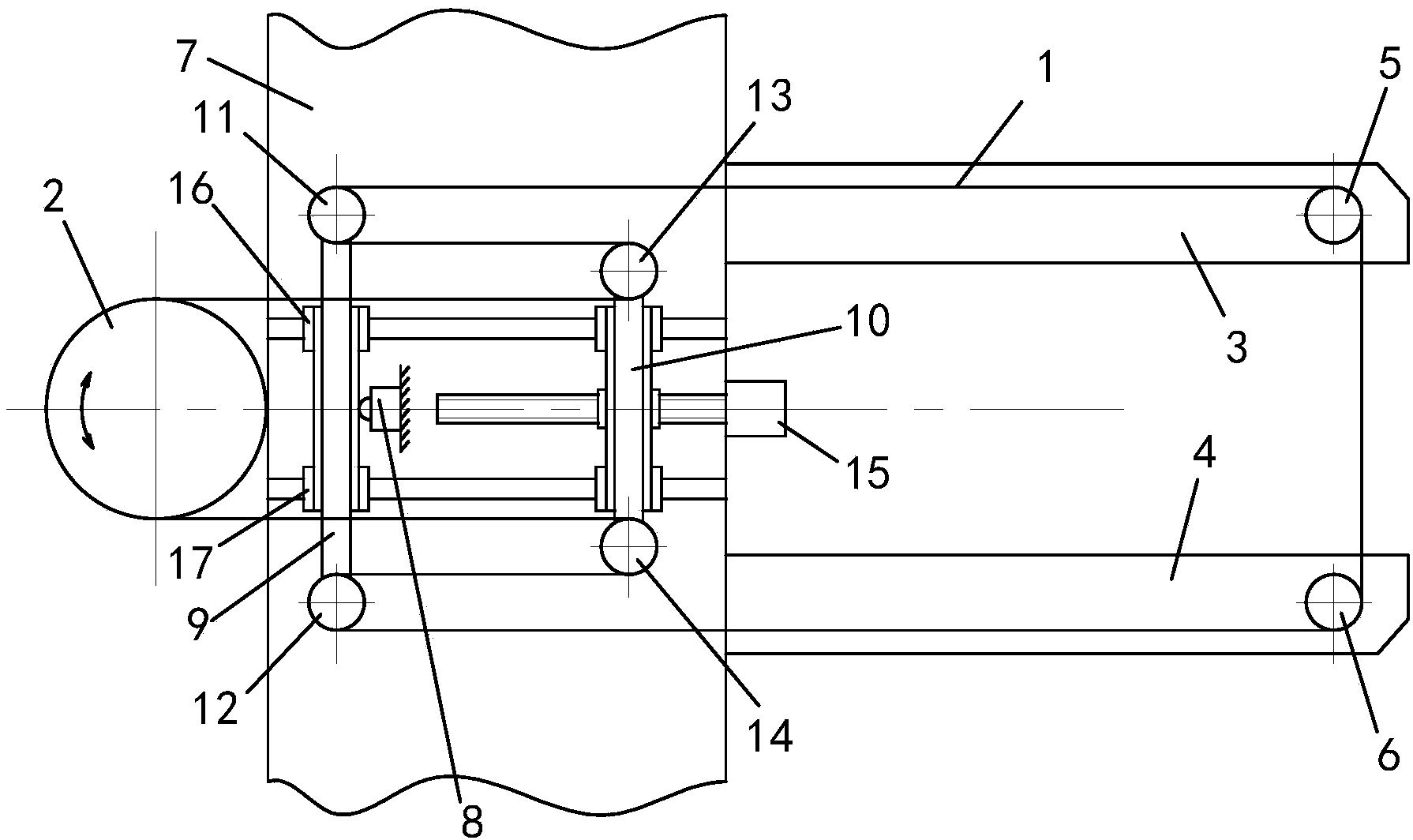

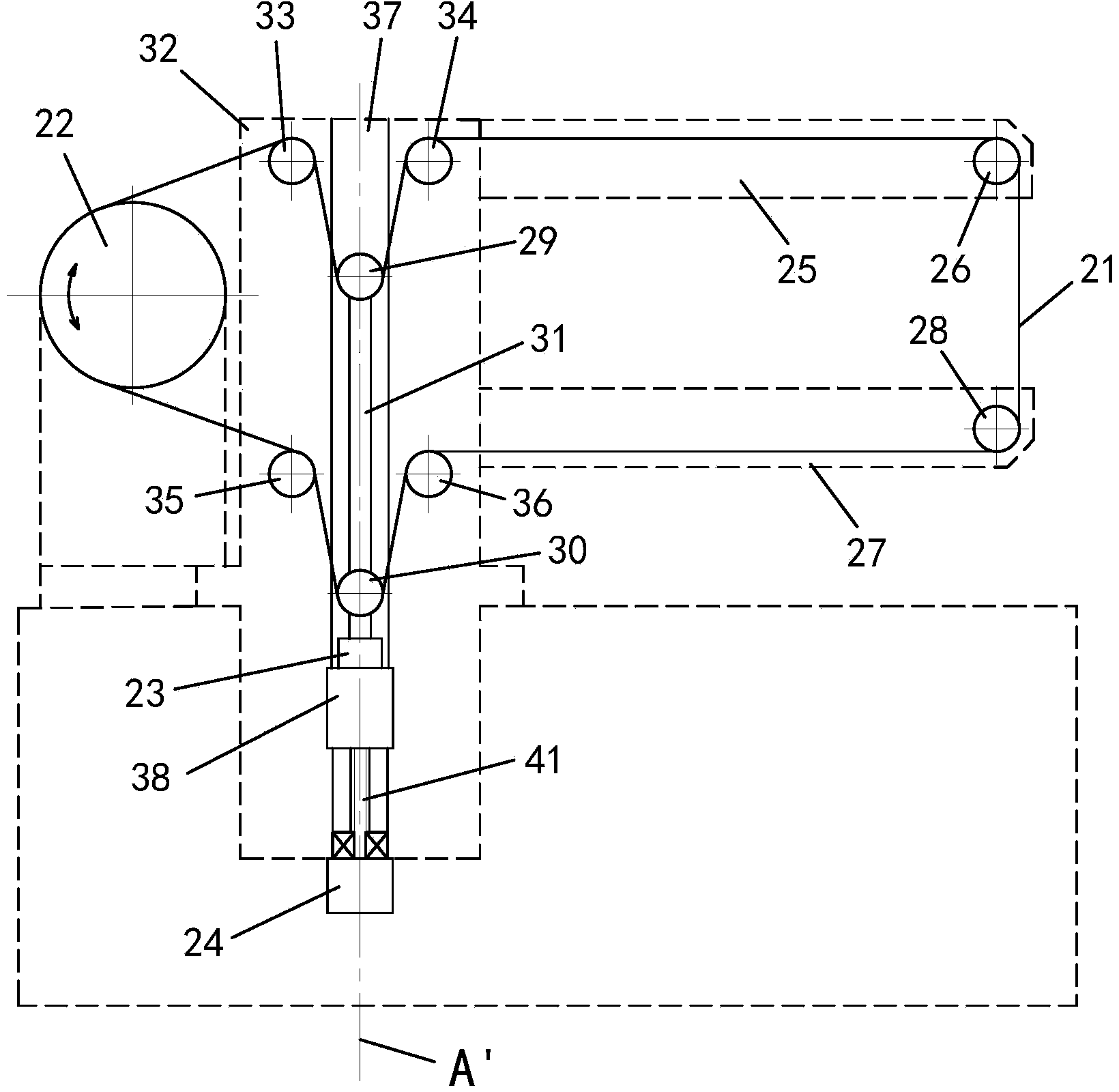

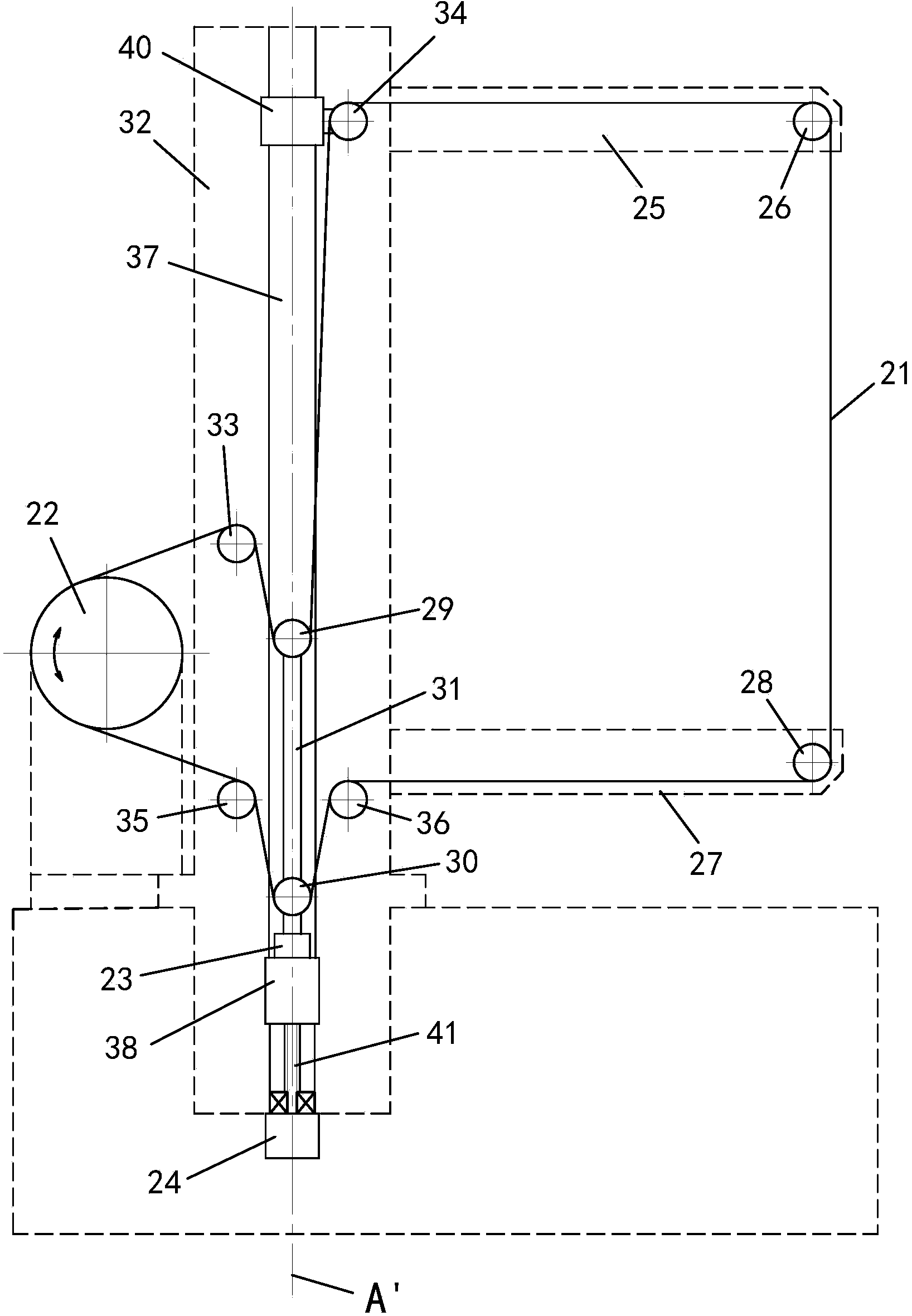

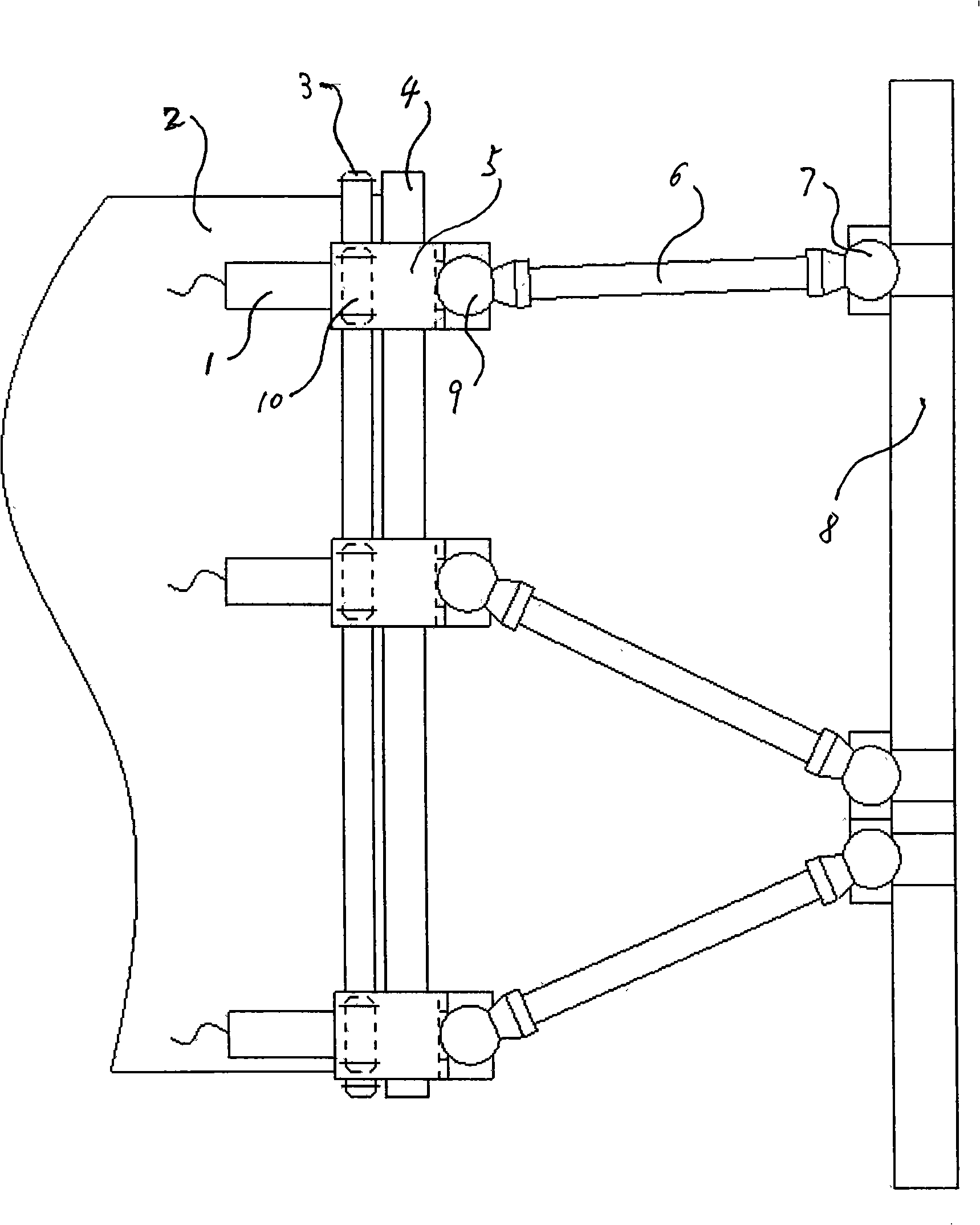

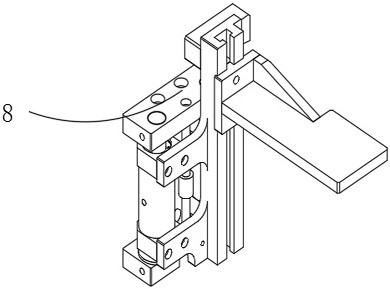

The invention discloses a wire-cut electric discharge machine wire transport mechanism capable of realizing accurate closed-loop control on the tension of an electrode wire. The wire-cut electric discharge machine wire transport mechanism is characterized in that an upper tensioning wheel, a lower tensioning wheel and a connection plate form a tensioning element; the tensioning element is slidably connected with the vertical column of an opposite-line cutting machine along a vertical direction; the tensioning element is in transmission connection with a drive device through a force transducer, one end of the force transducer is fixedly connected with the tensioning element, and the other end of the force transducer is in transmission connection to the drive device; the directions of the acting forces of the upper tensioning wheel, the lower tensioning wheel, the force transducer and the drive device are located on the same axis; an annular closed electrode wire starts from a wire storage barrel, sequentially passes through an upper left reversing wheel, the upper tensioning wheel, an upper right reversing wheel, an upper guide wheel, a lower guide wheel, a lower right reversing wheel, the lower tensioning wheel and a lower left reversing wheel, and returns to the wire storage barrel; the signal acquired by the force transducer is used for controlling the drive device after being processed by a control circuit. The wire-cut electric discharge machine wire transport mechanism disclosed by the invention realizes accurate control on the tension of the electrode wire of a reciprocating wire-transport type wire-cut electric discharge machine.

Owner:江苏冬庆数控机床有限公司

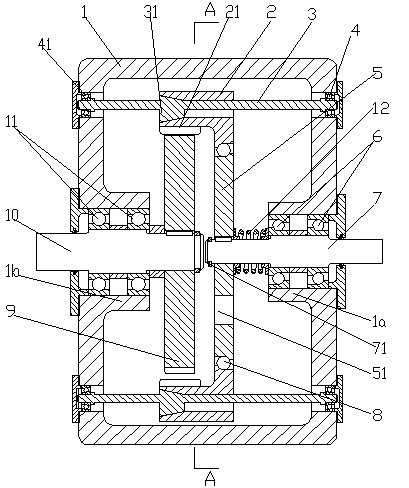

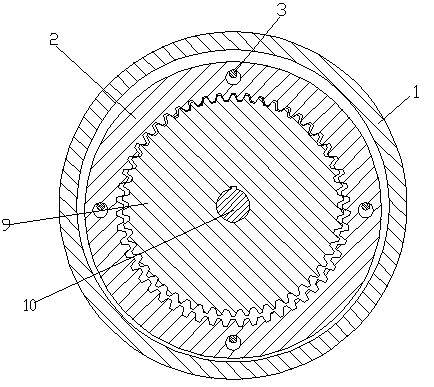

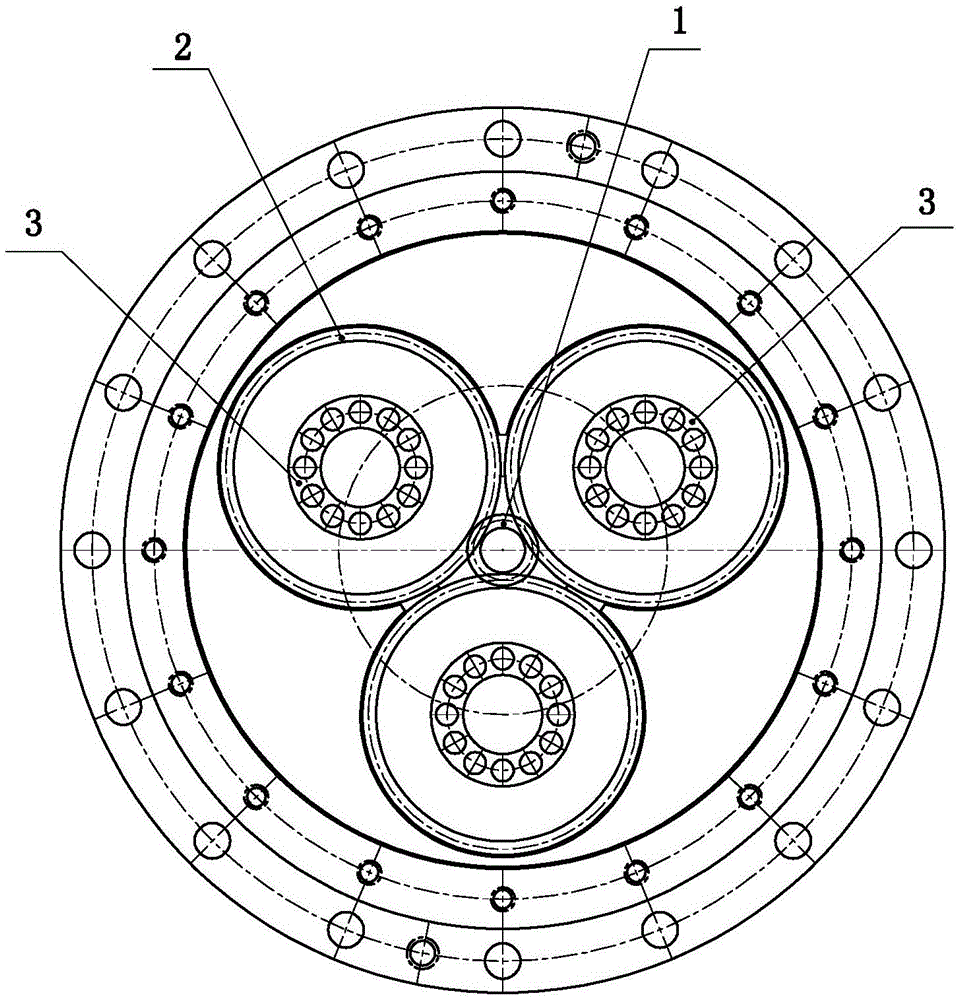

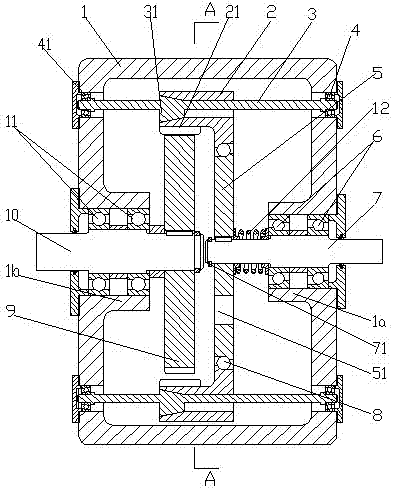

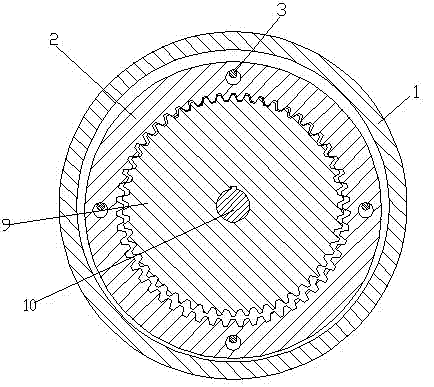

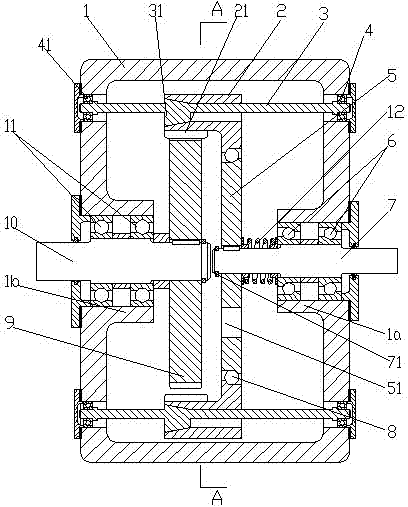

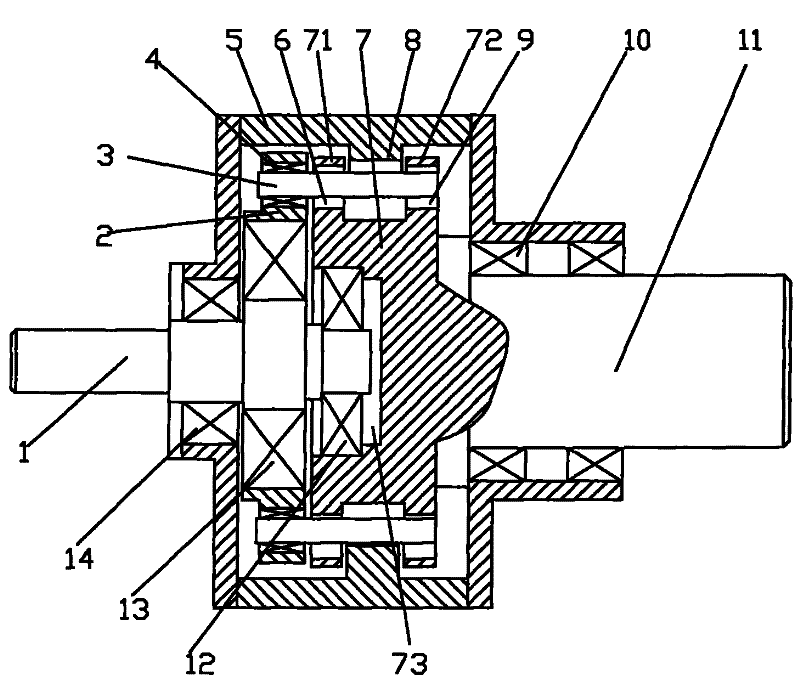

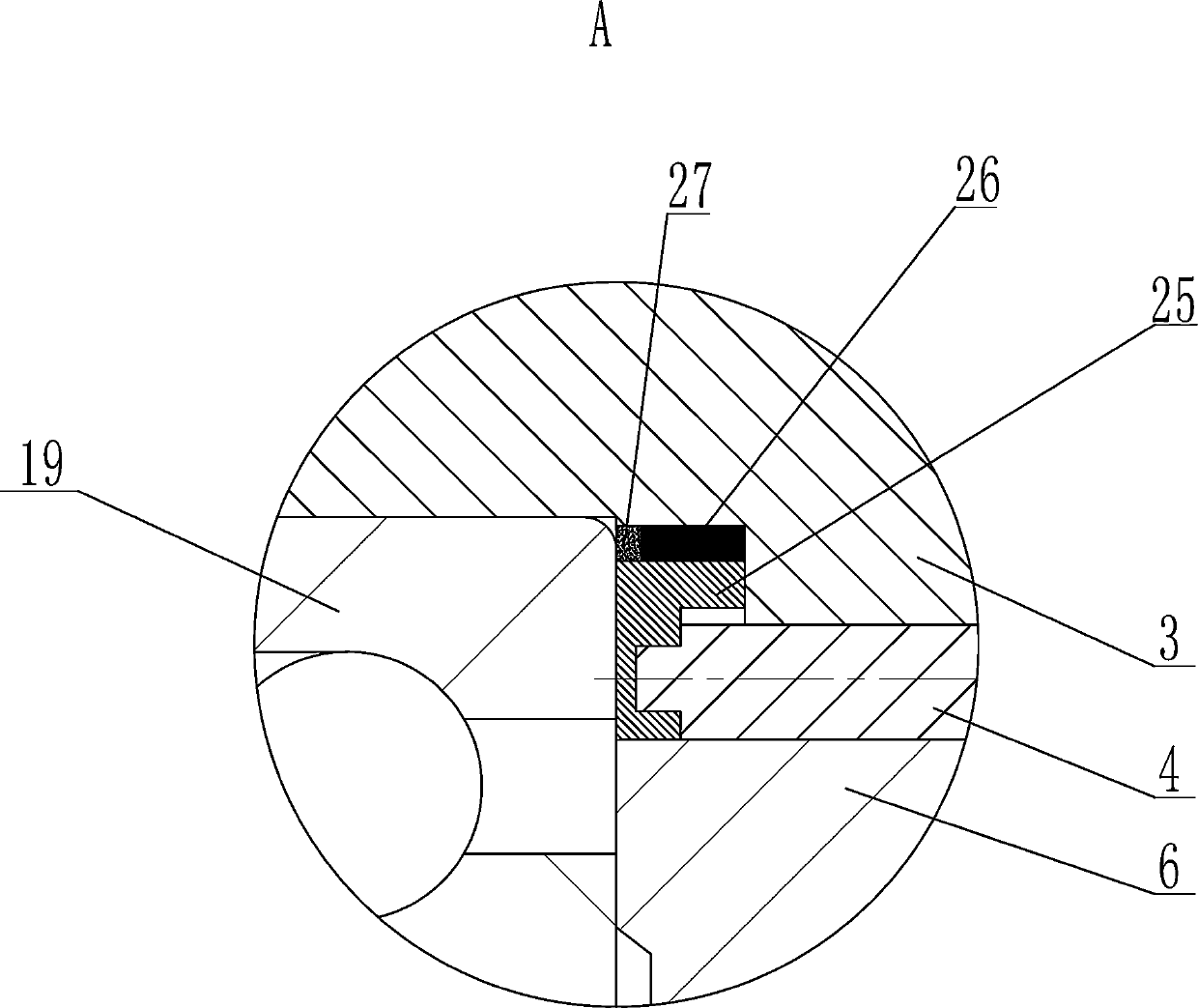

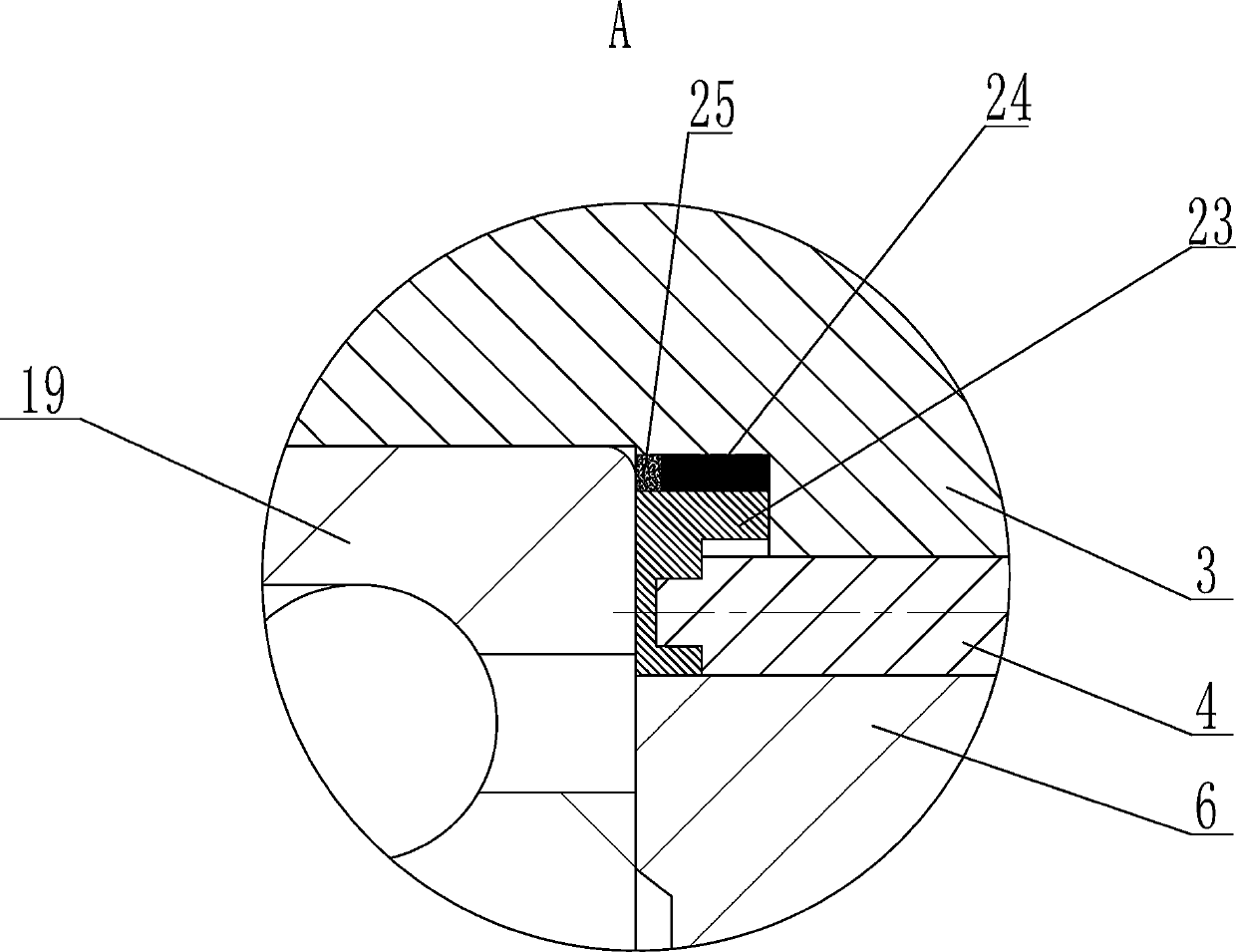

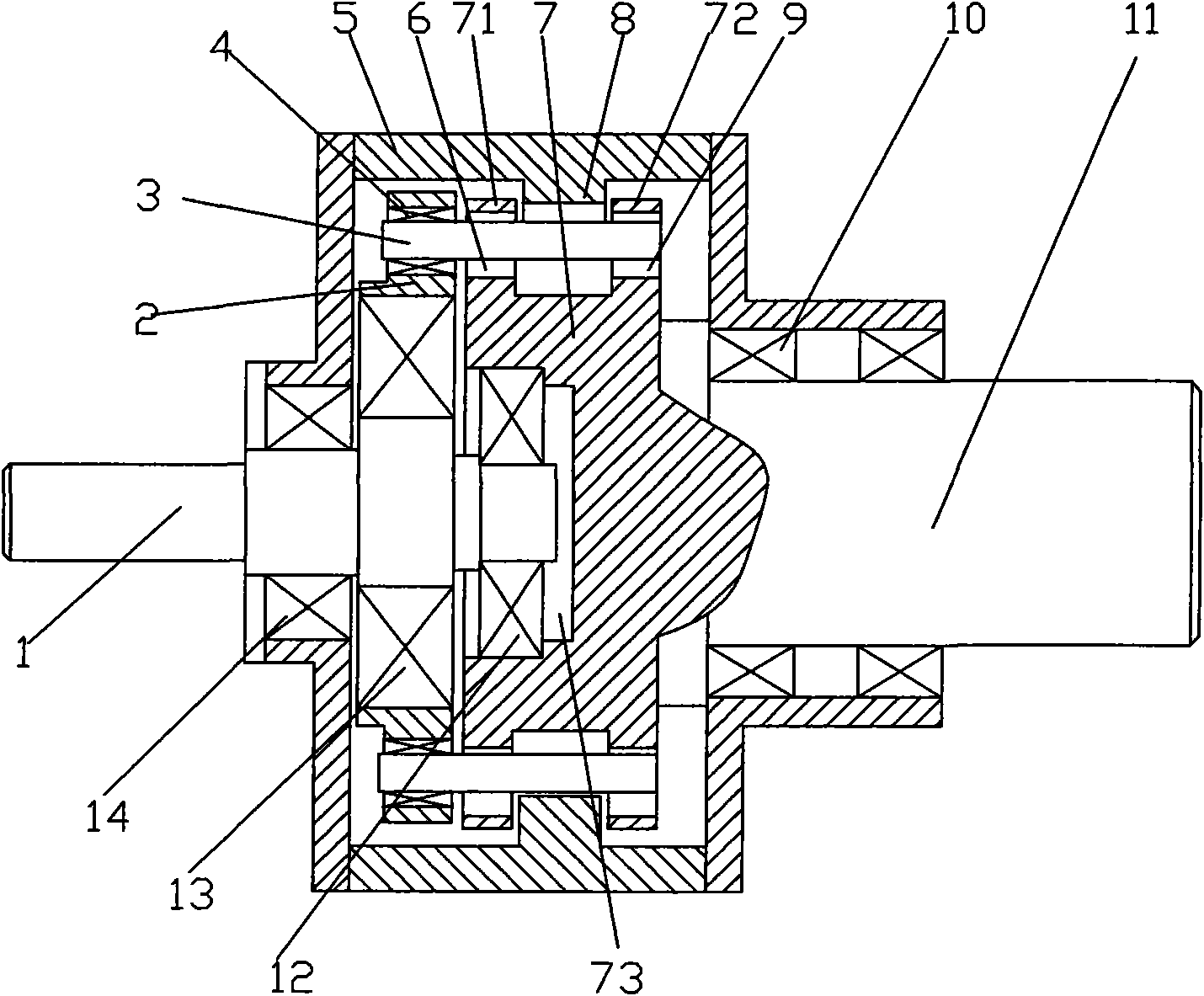

Constrained speed reducer with small teeth difference

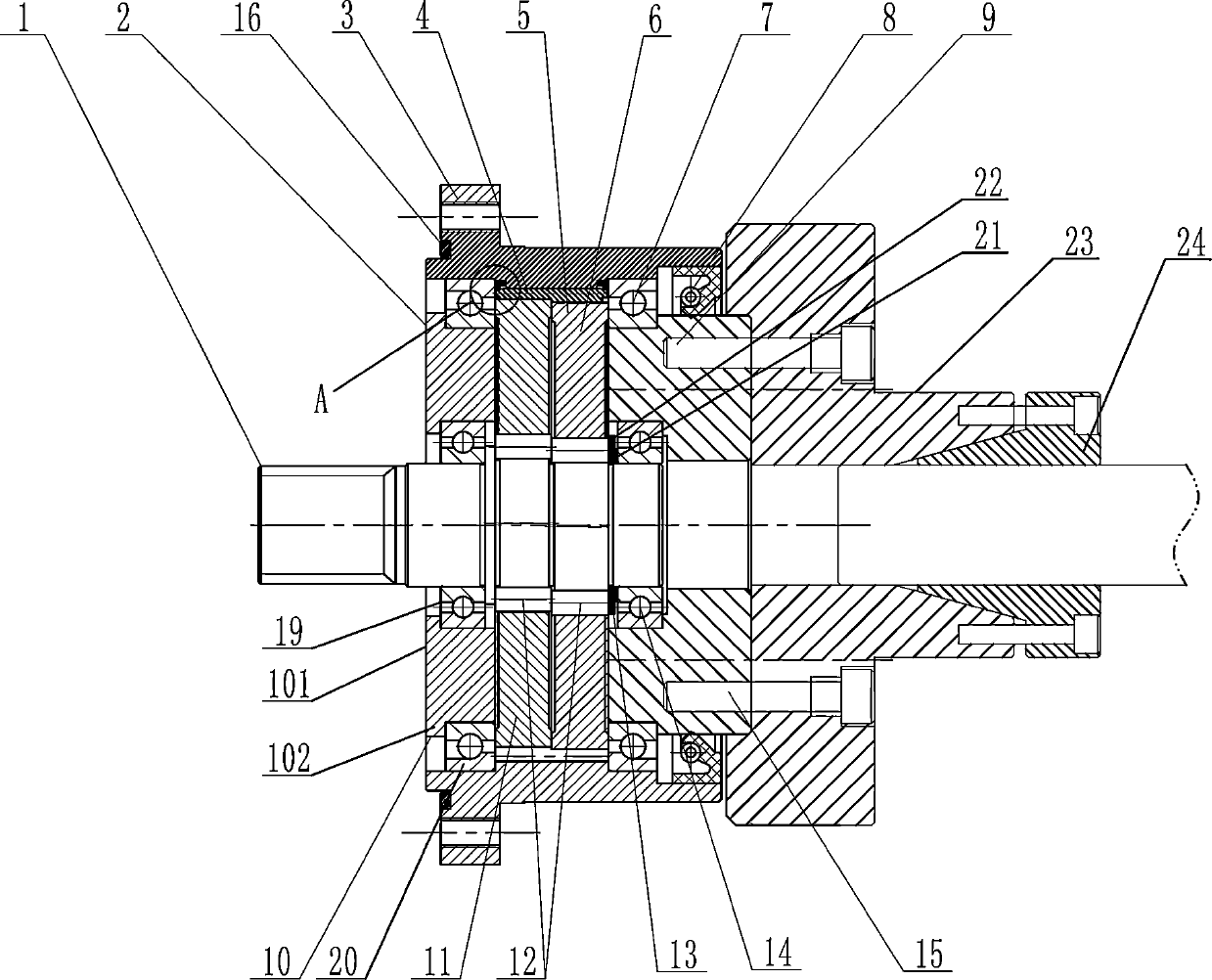

InactiveCN101915286AEliminate relative rotational motionLarge reduction ratioToothed gearingsReduction driveReduction ratio

The invention discloses a constrained speed reducer with small teeth difference, which comprises a shell, a power input shaft and a power output shaft, wherein the power input shaft is provided with a transmission inner tooth disc of inner engaging teeth through an eccentric sleeve, the power output shaft is fixedly matched and provided with an outer gear in the circumferential direction, and the outer gear is engaged with the inner engaging teeth of the transmission inner tooth disc in a small teeth difference mode; and eccentric shaft sections of constraint shafts in running fit with the shell pass through the transmission inner tooth disc and are in running fit with the transmission inner tooth disc, at least two constraint shafts are uniformly distributed along the circumferential direction, and the eccentric distance of the eccentric shaft sections is equal to that of the eccentric sleeve. The constrained speed reducer eliminates the relative spinning motion of a power input mechanism, outputs power by revolution, and has high reduction ratio, high transmission rigidity and high load transfer capability; when motion disturbance or other additional motion appears, the speed reducer can rotate normally, improve the transmission efficiency and successfully output the motion; meanwhile, the speed reducer has a simple and compact structure and small volume mass, and provides an effective path for selection of the speed reducer in mechanical engineering.

Owner:CHONGQING UNIV

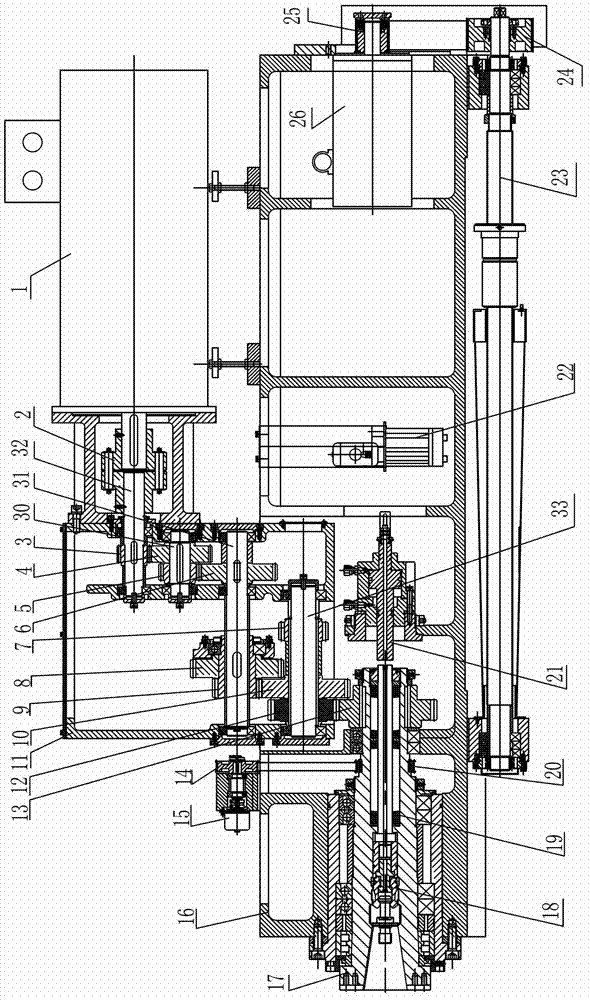

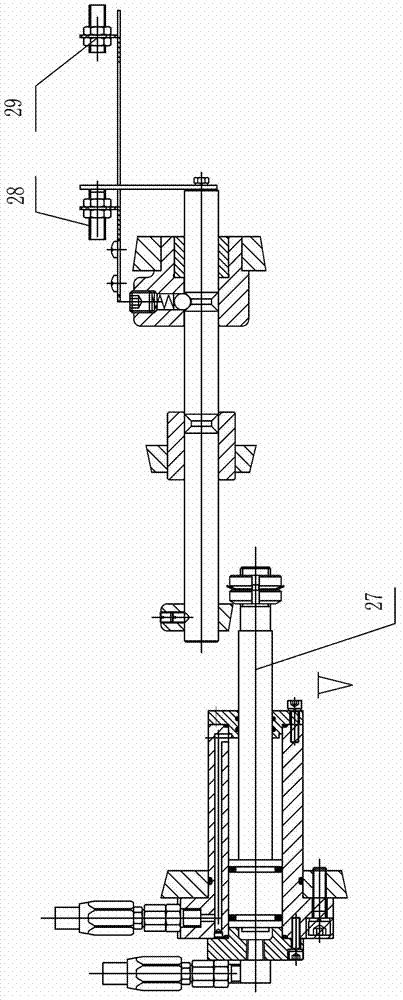

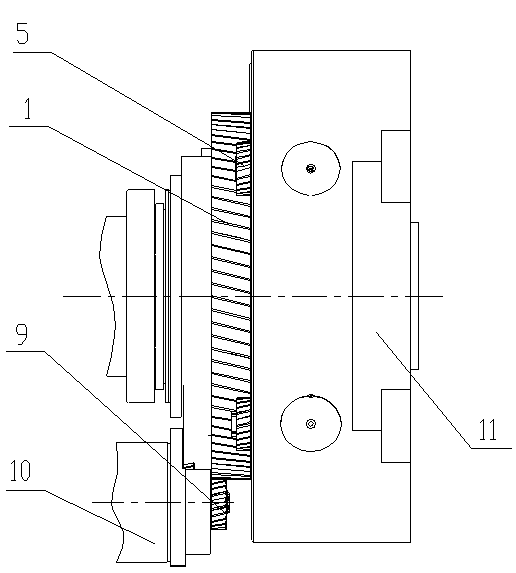

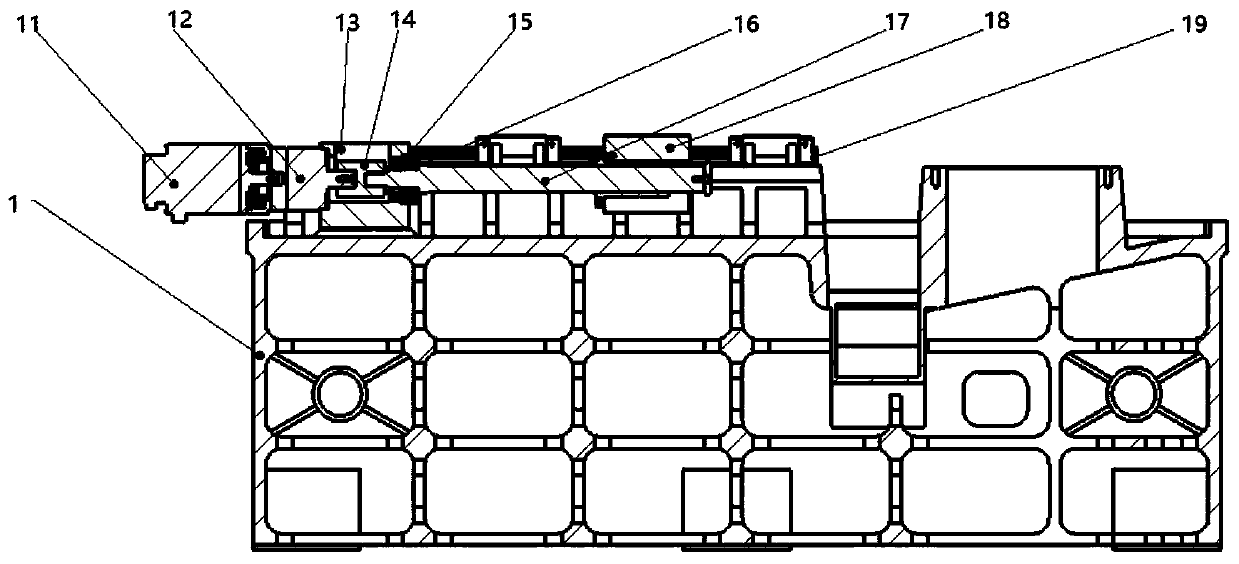

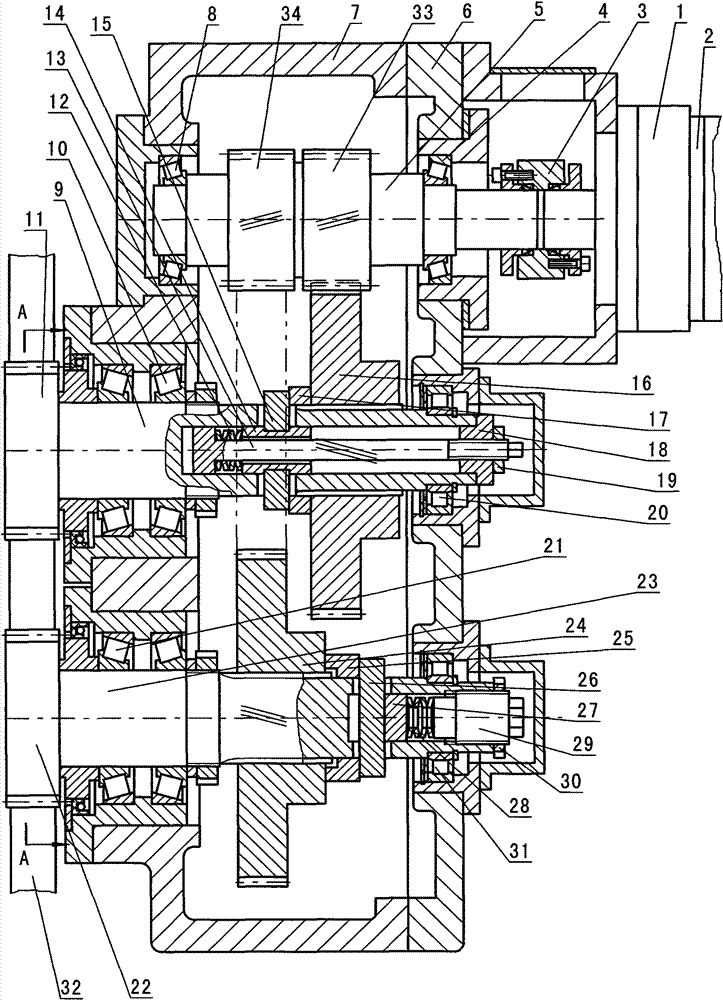

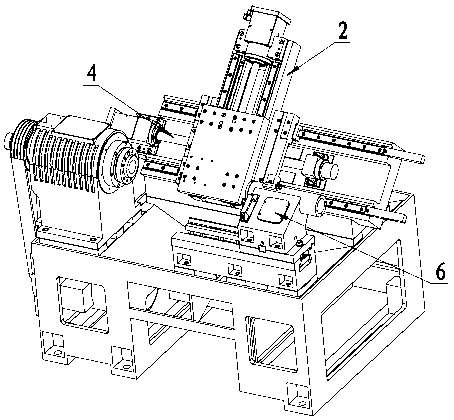

High-speed feeding transmission mechanism for ram type milling head for numerical control machine tool

InactiveCN103317377AGood transmission rigidityIncrease feed rateFeeding apparatusMachine toolPower apparatus

The invention provides a high-speed feeding transmission mechanism for a ram type milling head for a numerical control machine tool. The high-speed feeding transmission mechanism is applied to high-speed feeding of vertical rams of large high-speed five-axis numerical control machine tools, the transmission rigidity is good, high feeding speed, operating accuracy and reliability can be achieved, and the service life can be prolonged. According to the technical scheme, a power device is arranged on a ram of the numerical control machine tool and connected with a lead screw and nut pair, two ends of a lead screw in the lead screw and nut pair are fixed axially, and a nut in the lead screw and nut pair is connected with a slide carriage of the numerical control machine tool circumferentially.

Owner:JIER MACHINE TOOL GROUP

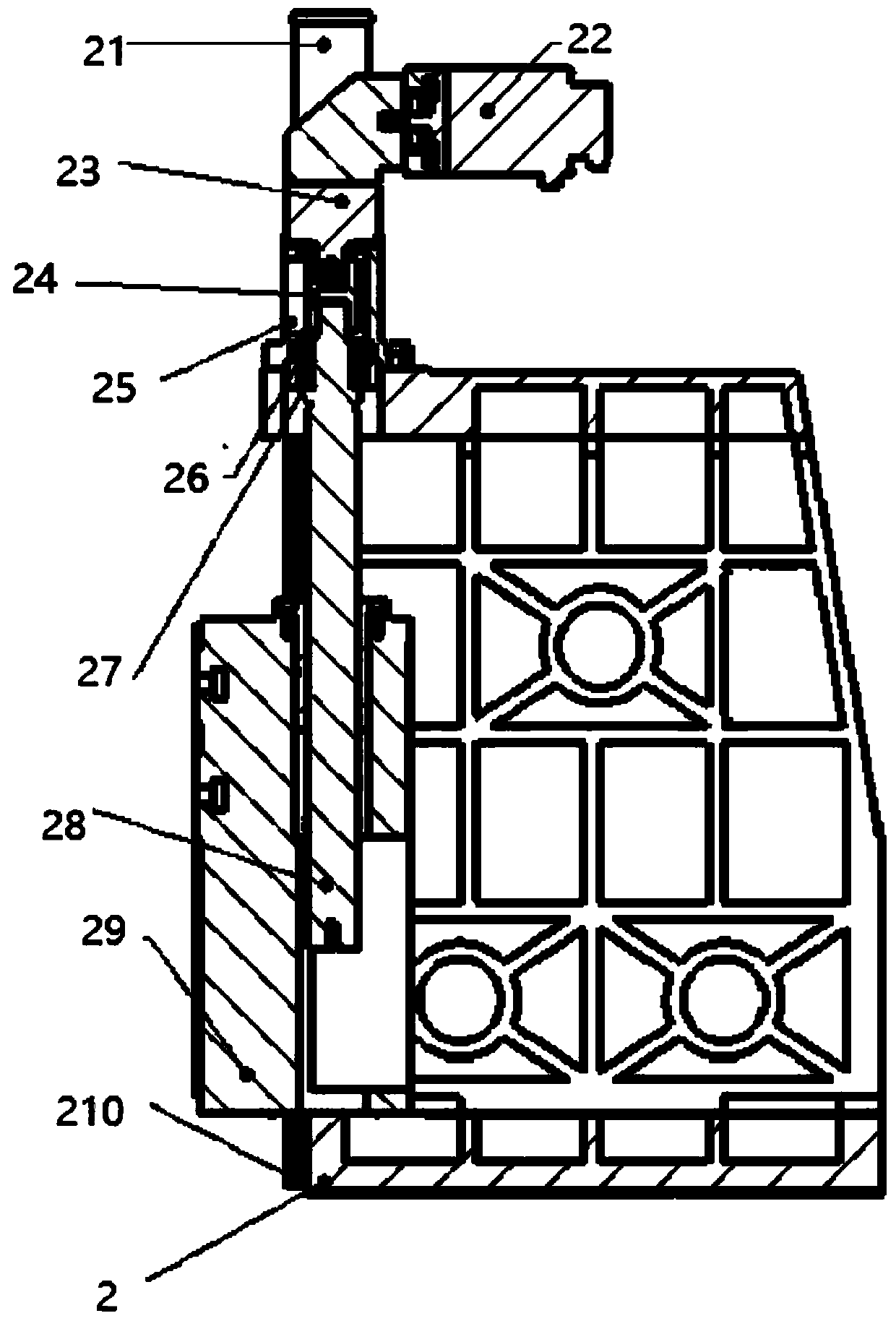

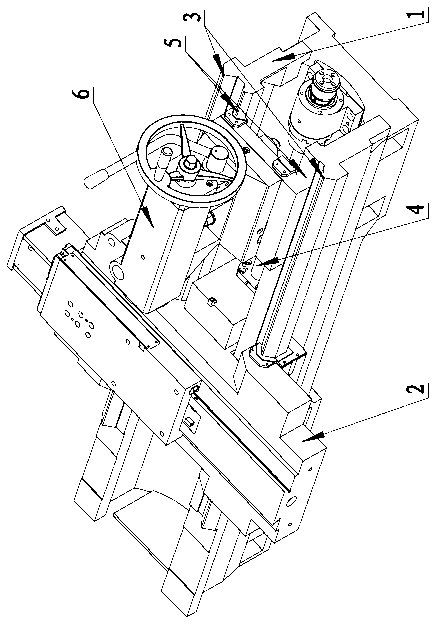

Ram type main transmission mechanism for milling machine

InactiveCN102922355ASimple structureSmall sizeFeeding apparatusDriving apparatusGear driveDrive shaft

The invention provides a ram type main transmission mechanism for a milling machine. The ram type main transmission mechanism comprises a spindle driving servo motor, a transmission gear box and a machine tool spindle, wherein the machine tool spindle is arranged in the front of a ram; the transmission gear box is arranged at a position, which corresponds to the machine tool spindle, of the ram; the lower part of the transmission gear box is positioned in the ram; the spindle driving servo motor is arranged on the ram; an input shaft of the transmission gear box is connected with the spindle driving servo motor through a coupling; an output shaft of the transmission gear box is connected with the machine tool spindle through an output gear and a machine tool spindle gear; and the input shaft and the output shaft of the transmission gear box can be connected with each other through multilevel gear transmission pairs which are arranged on different transmission shafts and can realize high-gear and low-gear rotational speed output. The transmission gear box and the ram are separated from each other, transmission of the transmission gear box is realized by gears, transmission rigidity is high, the size of the ram is small, the ram is simple in structure, the transmission gear box is convenient to mount and maintain, and the ram type main transmission mechanism is modularly designed and manufactured easily.

Owner:GUILIN MACHINE TOOL

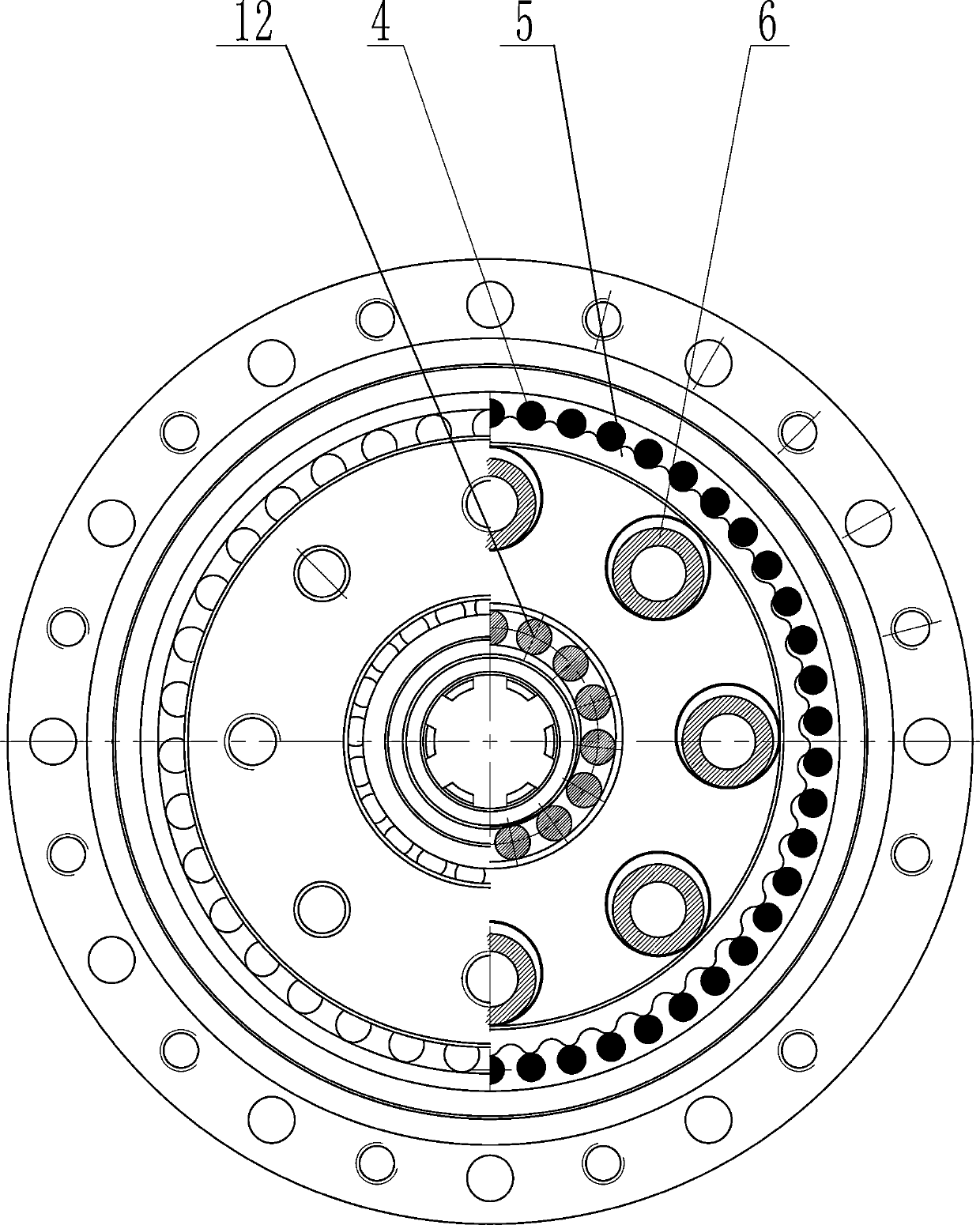

Precise combination bearing with adjustable pre-tightening force

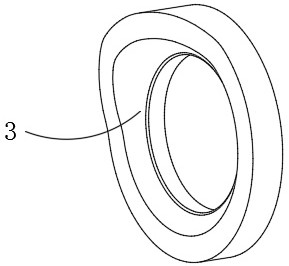

PendingCN110566577ASmooth runningHigh precisionBall and roller bearingsBearing componentsEngineeringMechanical engineering

The invention relates to a precise combination bearing with adjustable pre-tightening force. The precise combination bearing with adjustable pre-tightening force comprises a small inner ring, a largeinner ring, an outer ring, an axial retainer, axial rollers and a radial roller, wherein the small inner ring is arranged on the small inner ring; the axial rollers are tapered rollers, and the linearspeeds of the two ends of each axial roller are consistent; tapered grooves matched with the axial rollers in size and shape are formed in the axial retainer; the axial rollers are mounted in the tapered grooves; the surfaces, correspondingly contacted with the axial rollers, of the small inner ring and the large inner ring are inclined surfaces matched with the tapered surfaces of the axial rollers; the outer end of each axial roller is provided with a pre-tightening device capable of adjusting pre-tightening force, and the pre-tightening devices are arranged outside the axial retainer; theradial roller is a spherical roller; each pre-tightening device comprises a piston, a spring and a small threaded plug; and the springs are connected with the axial rollers through small ball bodies.The precise combination bearing with the adjustable pre-tightening force has the advantages of high transmission rigidity, stable transmission, convenient mounting, high precision of machine operationand the like, and is not influenced by the speed difference of long-time operation.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

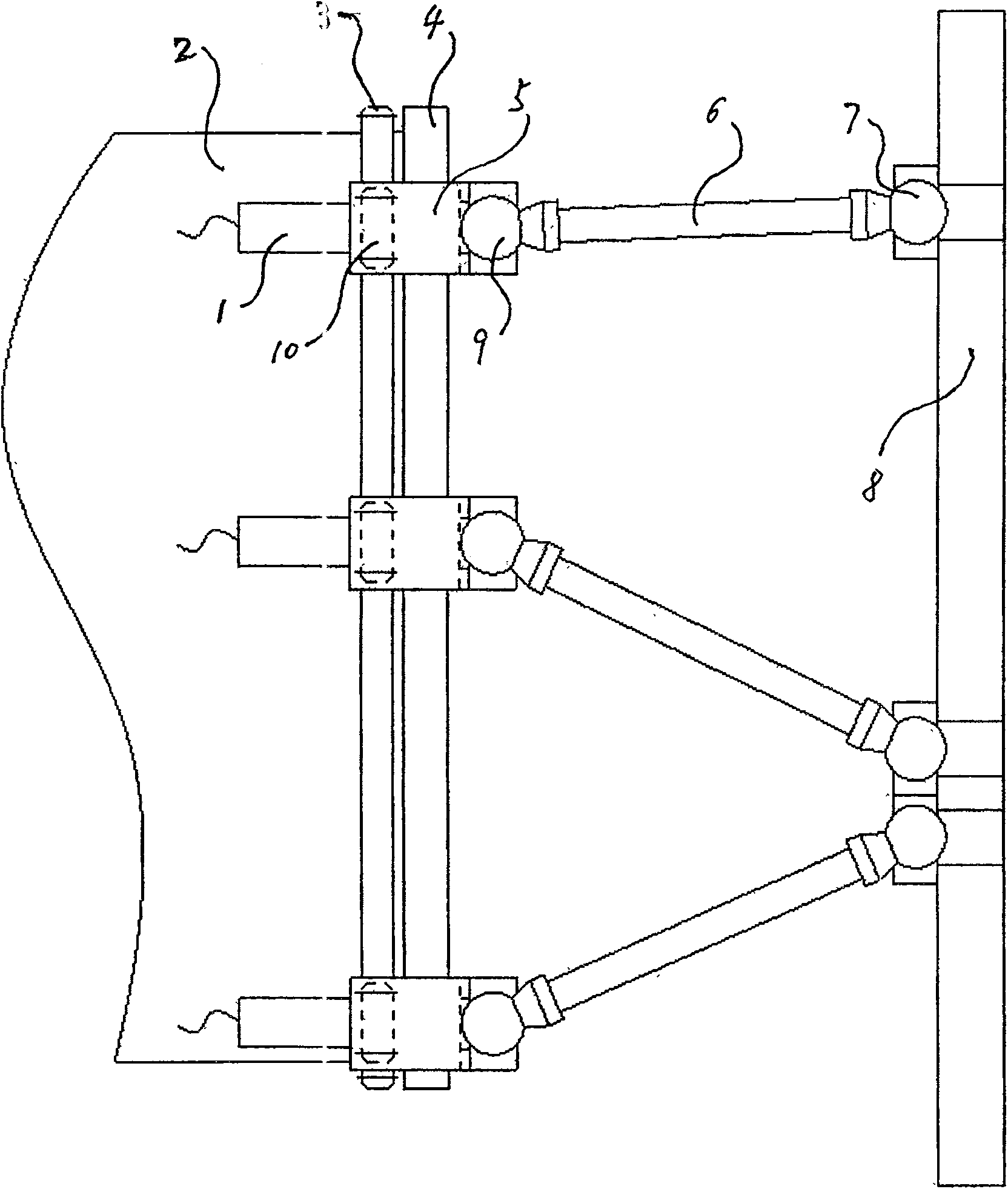

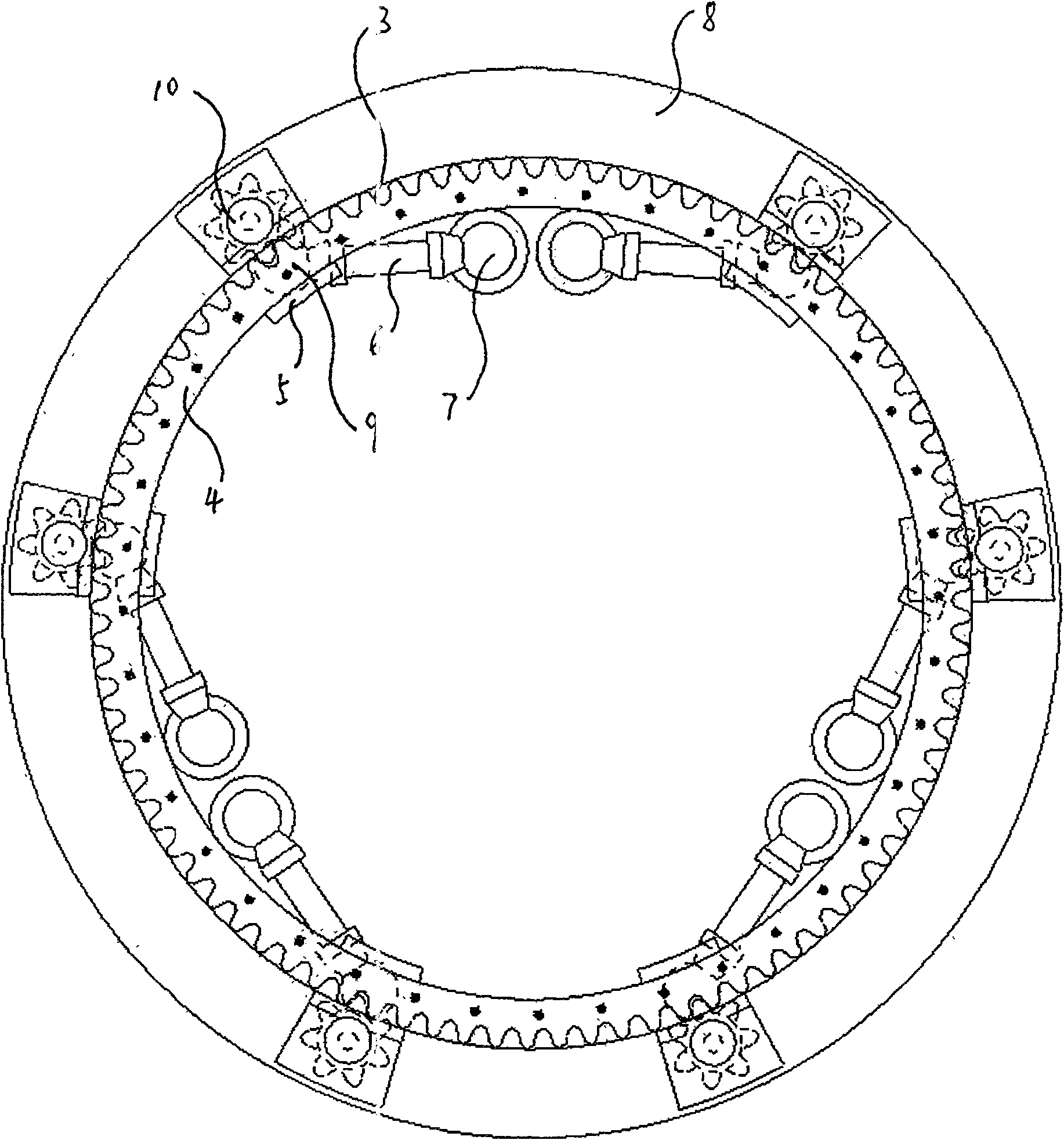

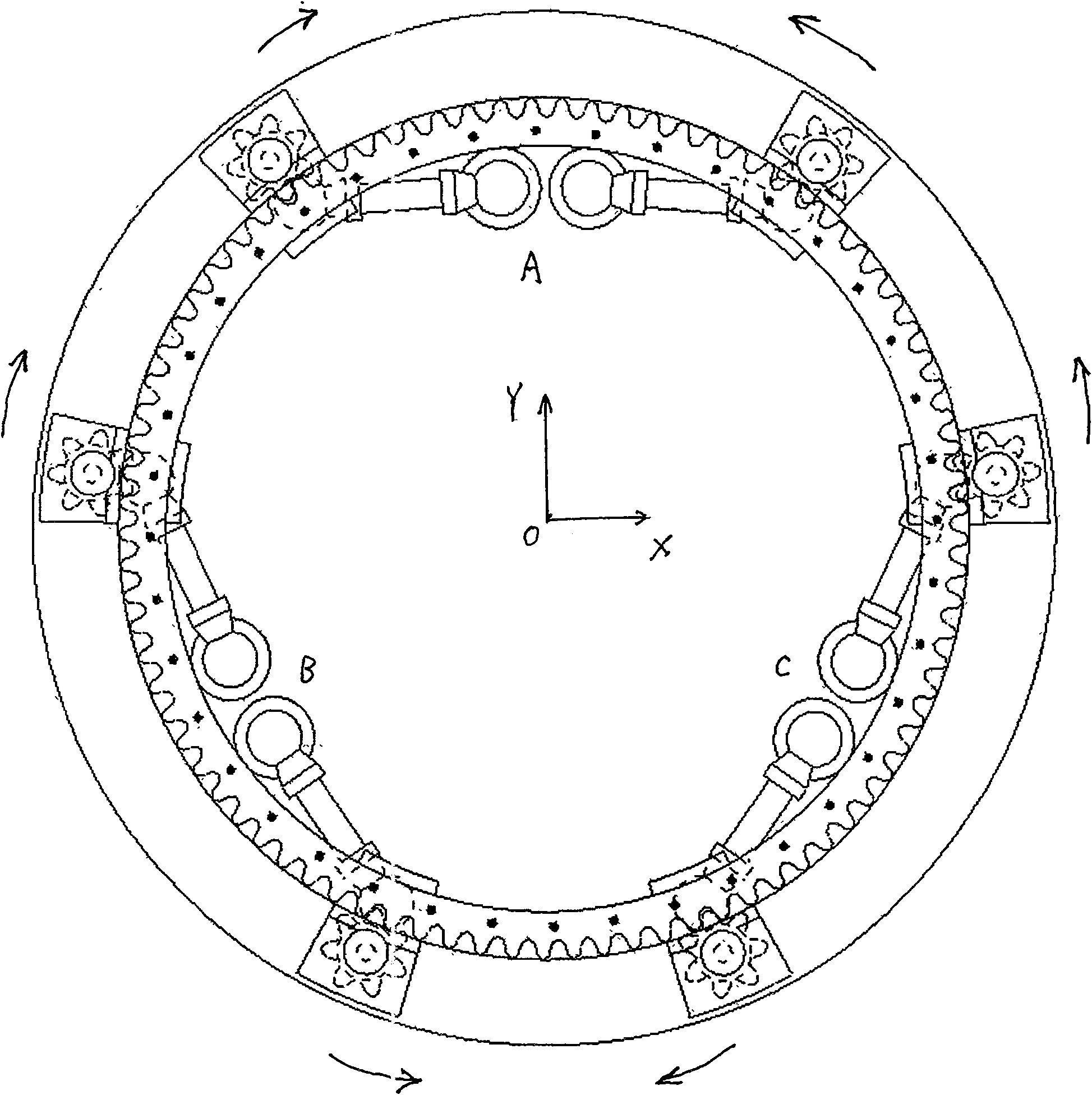

Movement implementing mechanism for LAMOST type astronomical focus panel

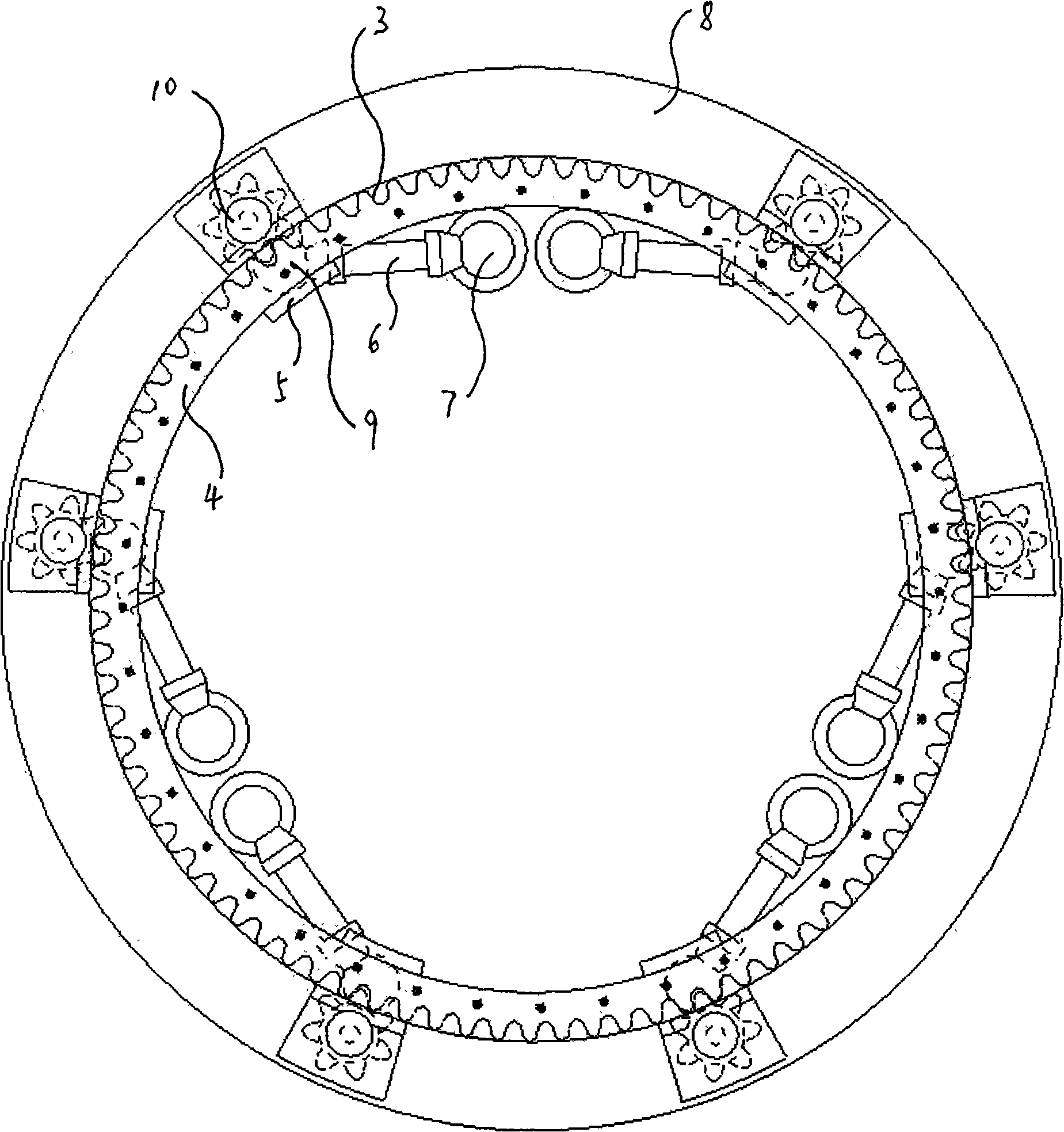

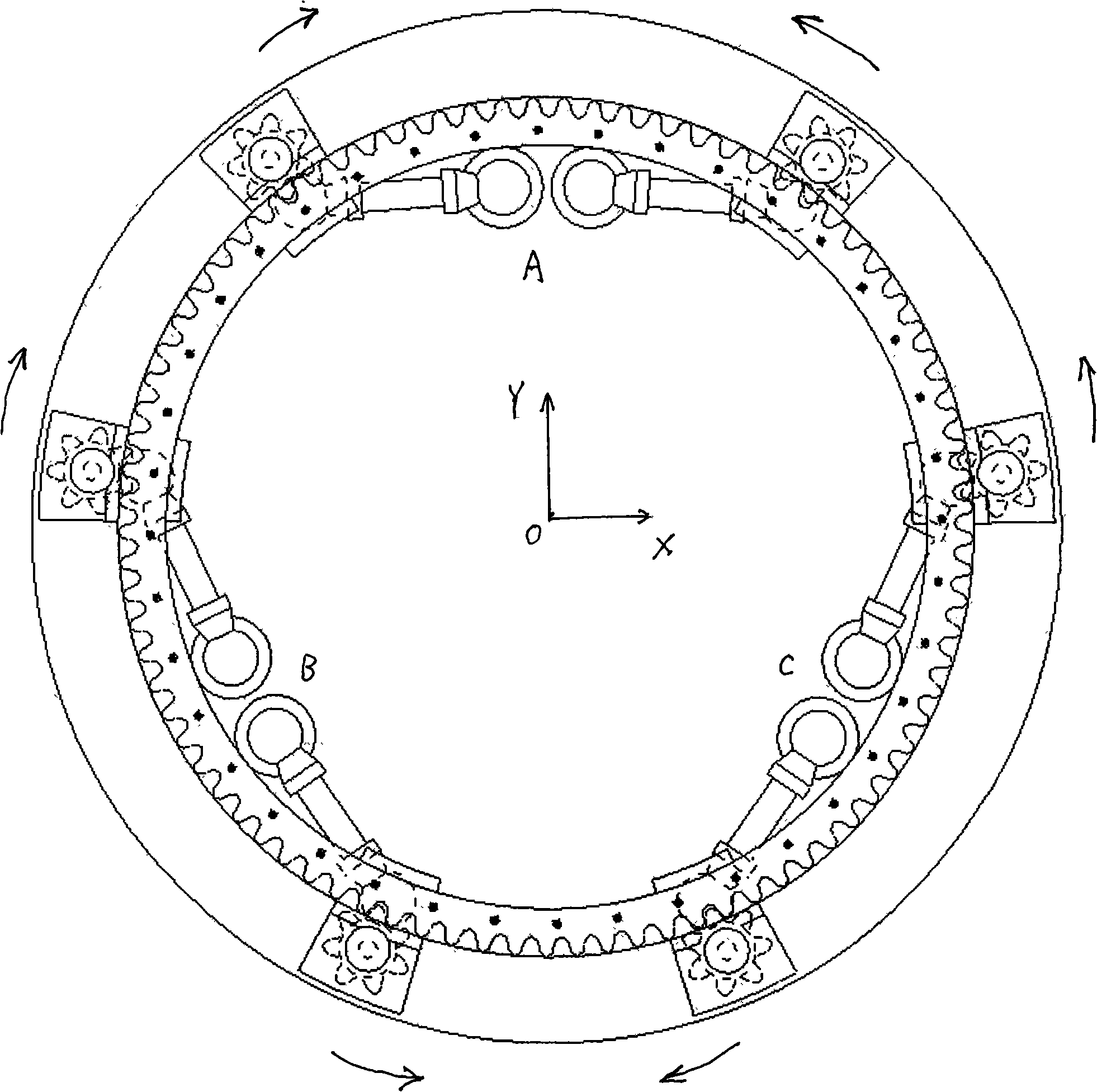

InactiveCN101359090ACompact structureSimple mechanical structureTelescopesBundled fibre light guideControl systemGear wheel

An LAMOST astronomical telescope focal panel movement realizing mechanism is characterized in that a rotary movement mechanism, a tilted movement mechanism and a focusing movement mechanism are set as a co-movement mechanism, wherein, a large gear and a circular guide rail are fixedly connected on a base; six matched slide blocks are distributed on the circular guide rail; the slide blocks are connected with pinions through connecting plates; each pinion is meshed with the large gear; a drive motor is arranged on a shaft; the slide blocks are respectively connected with supporting rods through left single rod joint bearings; each supporting rod is connected on a focal panel through a right single rod joint bearing; every two supporting rods are arranged as one group in a V-shaped form, and one end of each of the two supporting rods leans against the connecting points of the focal panel through the right single rod joint bearings; three groups of connecting points are distributed in the same circle on the focal panel by 120 degrees; and the other end of each of the two supporting rods has a certain distance through the locations of the two slide blocks connected with the left single rod joint bearing on the circular guide rail. The invention not only simplifies the mechanical structure and the control system, but also improves the stability of the system.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

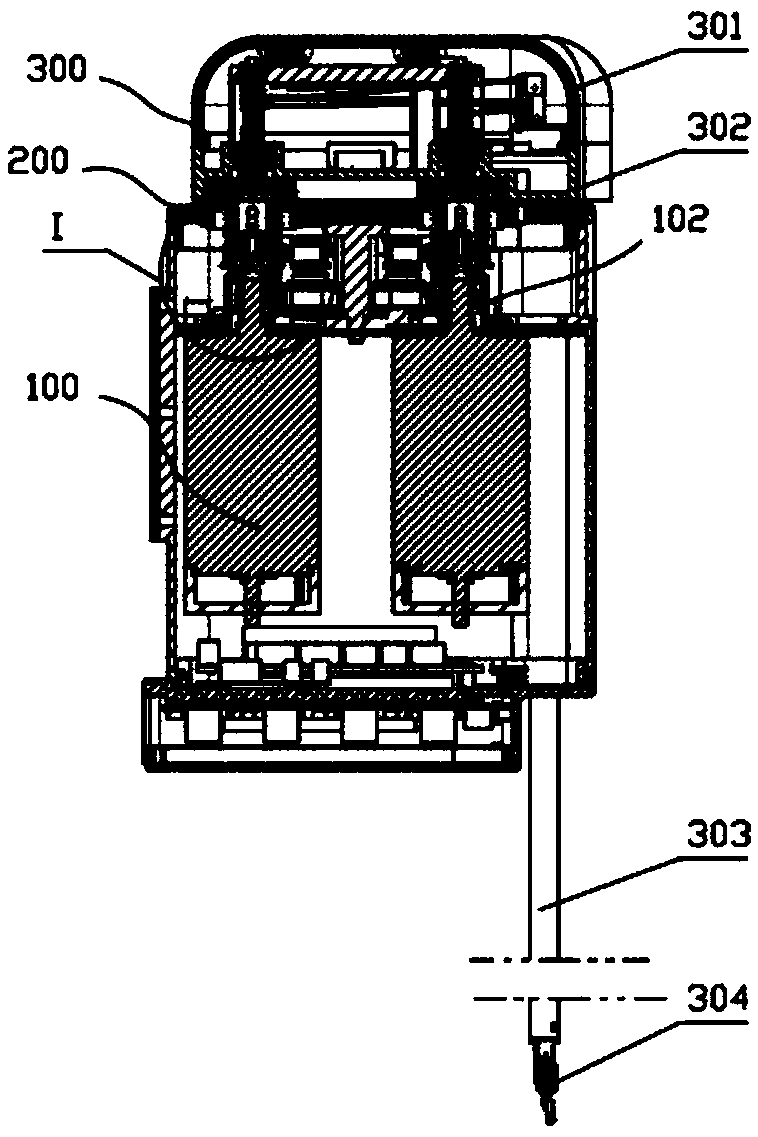

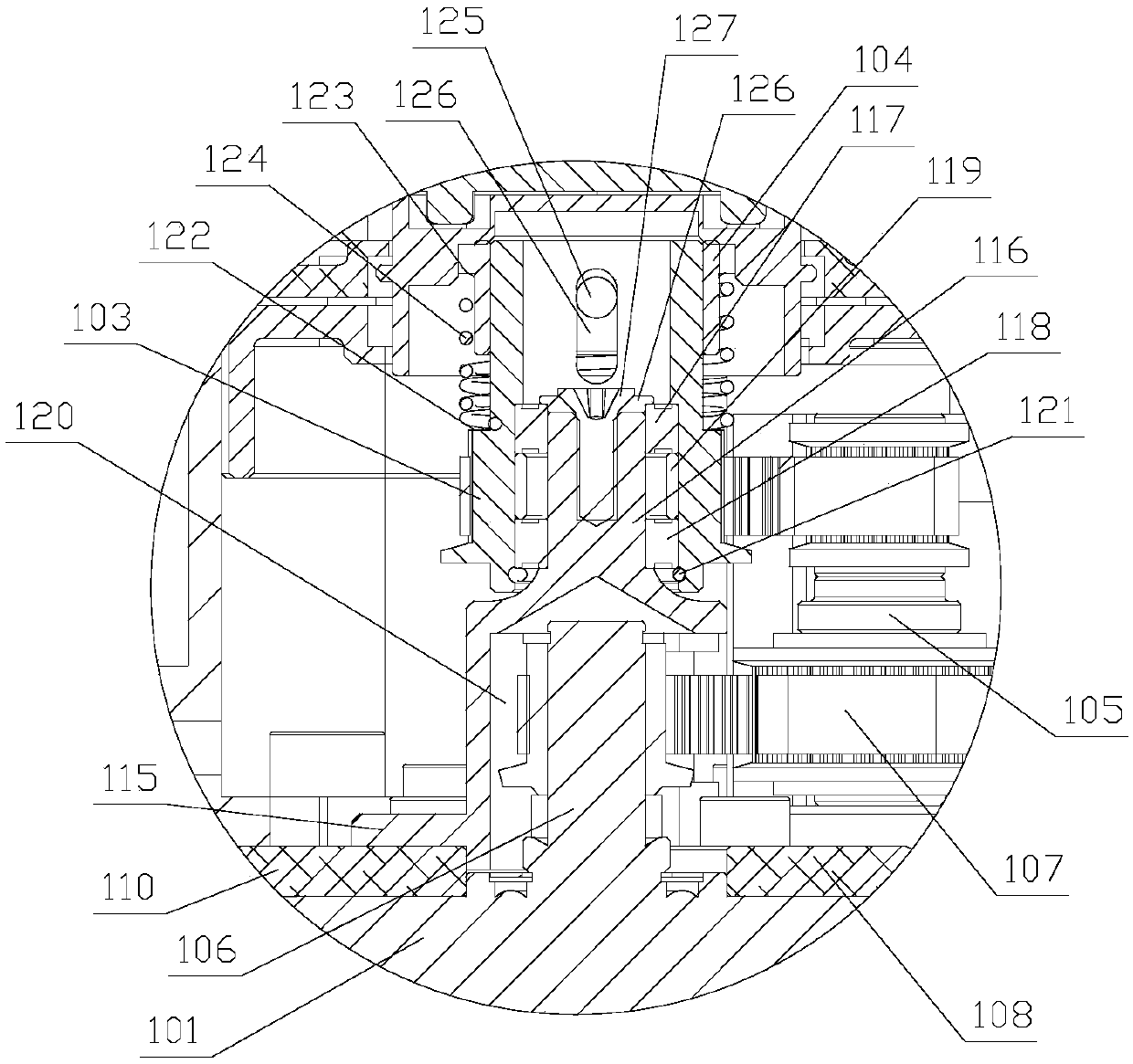

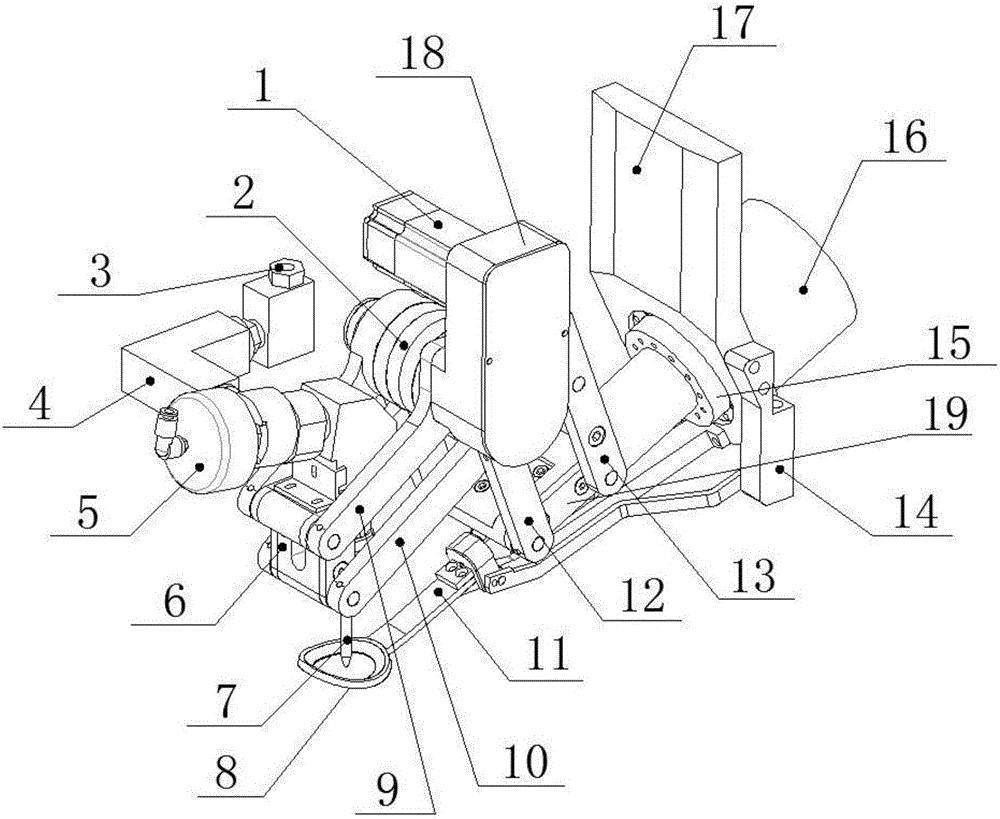

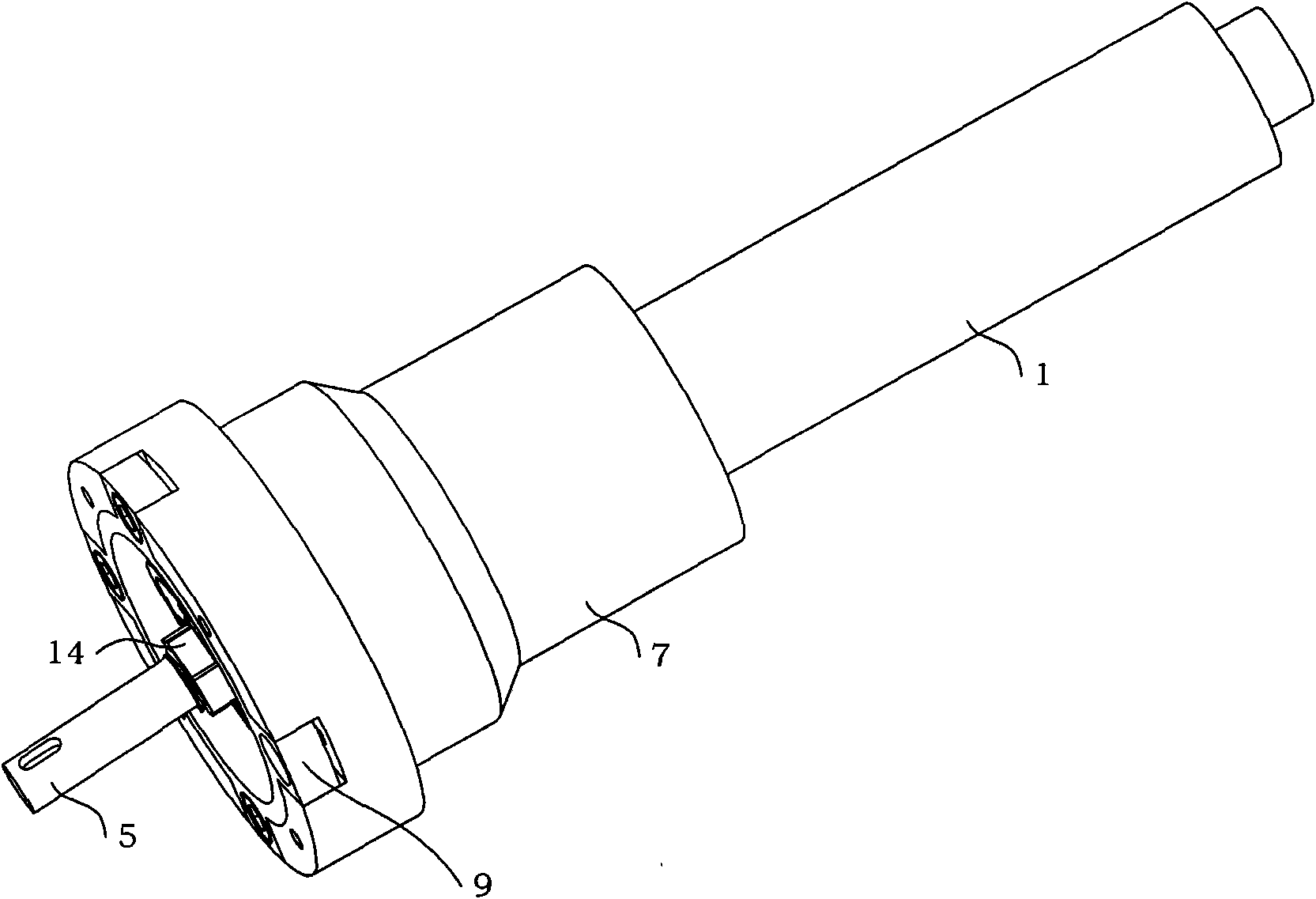

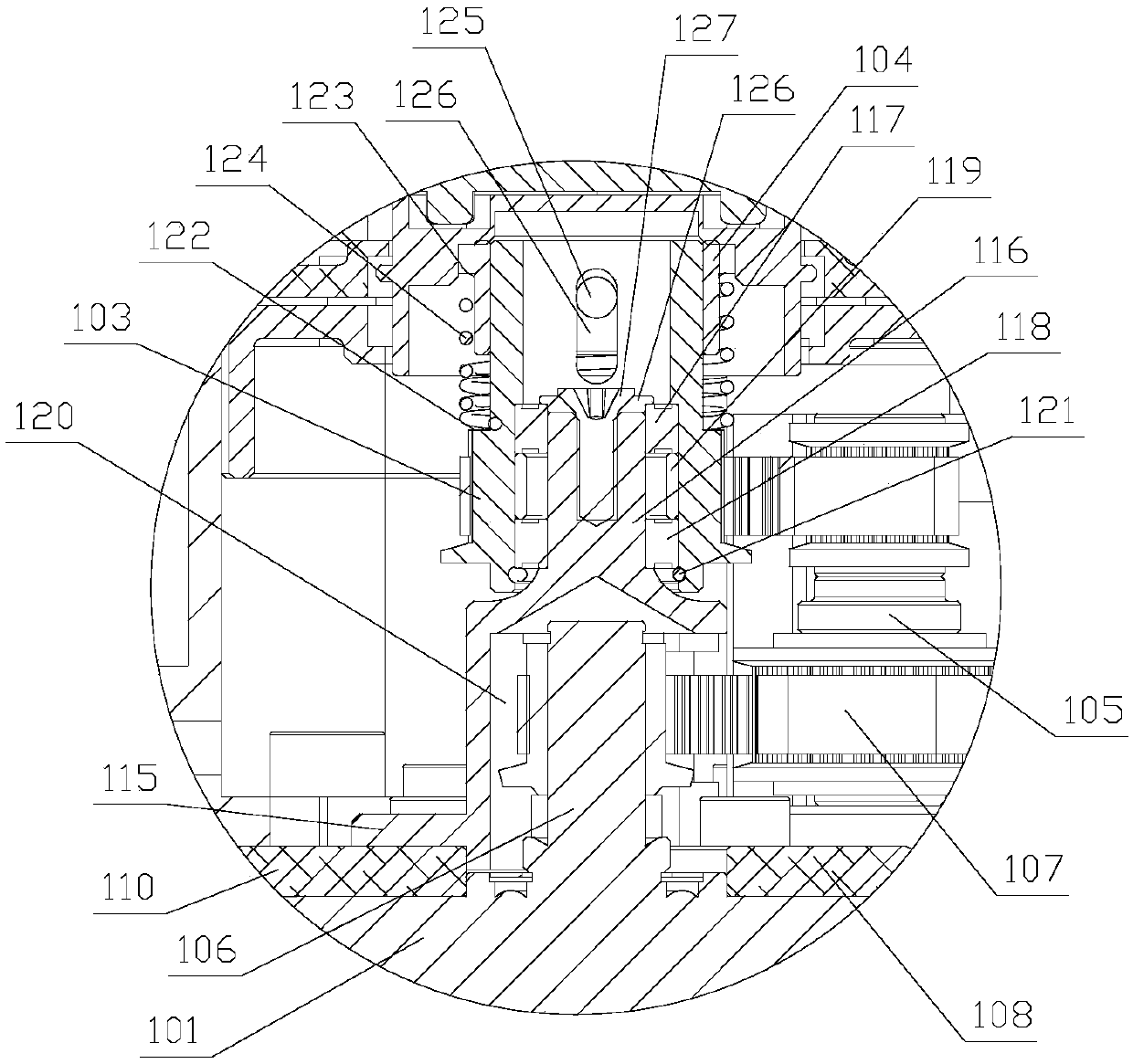

Surgical auxiliary robot instrument system

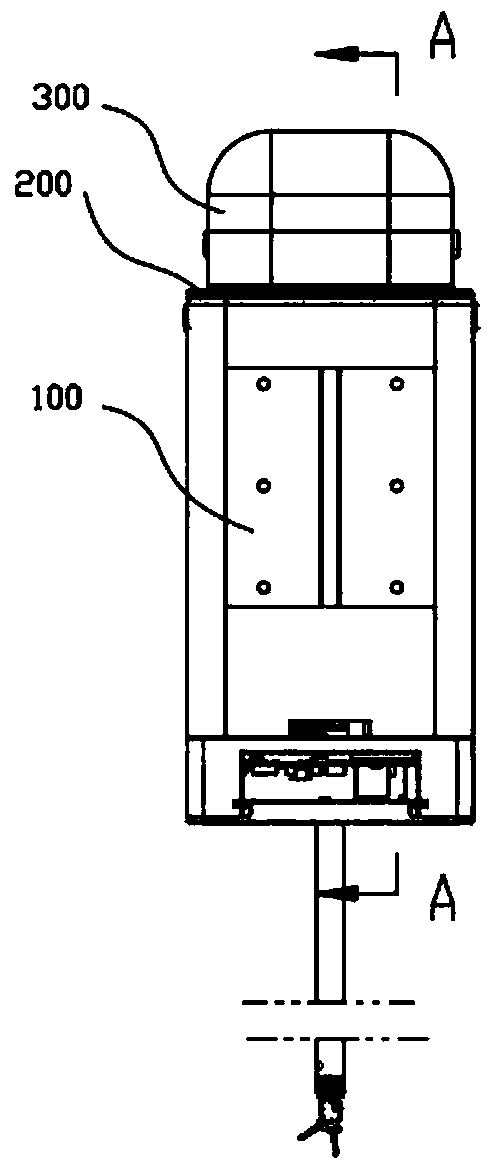

PendingCN111166488APrecise Surgical ControlAccurately grasp the severity of surgical movementsSurgical manipulatorsSurgical robotsSurgical ManipulationPhysical medicine and rehabilitation

The present invention discloses a surgical auxiliary robot instrument system. The surgical auxiliary robot instrument system comprises a power part, a sterile separator and an instrument, and the power part comprises at least one power group; each power group comprises a motor; each motor is connected with a speed reducer; an output shaft of each speed reducer is sleeved with a telescopic output flange; each output flange can be in inserted connection with a transition flange of the sterile separator; each transition flange can be in inserted connection with an input flange of the instrument;and the number and the positions of the output flanges, the transition flanges and the input flanges are corresponding. The surgical auxiliary robot instrument system provides mechanical conditions for realizing force feedback, realizes direct-sensing operation, greatly improves safety performance of surgical operations, also improves overall safety performance of the device, and is good in stability, high in motion precision, high in mechanism reliability, simple and convenient in operation, simple in manufacture and convenient in maintenance.

Owner:CHONGQING JINSHAN MEDICAL ROBOTICS CO LTD

Output rapid chaining mechanism and speed reducer

InactiveCN109681585AAvoid eccentricityCurb tiltToothed gearingsGearing detailsReduction driveCoupling

The invention discloses an output rapid chaining mechanism and speed reducer. A shell, an output base and an input shaft are included. The input shaft is provided with an eccentric wheel, and the eccentric wheel is connected with cycloidal gears through crank bearings. A plurality of gear pins are arranged on the inner wall of the shell along the circumference. The gear pins are intermittently engaged with the cycloidal gears. A positioning flange is arranged at the outer end of the output base. A positioning cylinder is arranged at one end of the positioning flange and arranged in an inner hole of the output base for inner hole positioning. A shaft fastening component is arranged at the other end of the positioning flange, the shaft fastening component and the positioning flange are of anintegrated structure, a crack is arranged between the positioning flange and the shaft fastening component, and shaft connection can be rapidly conducted. The problems that the traditional coupler installing time is long, and during installation, debugging is needed are solved.

Owner:湖北斯微特传动有限公司

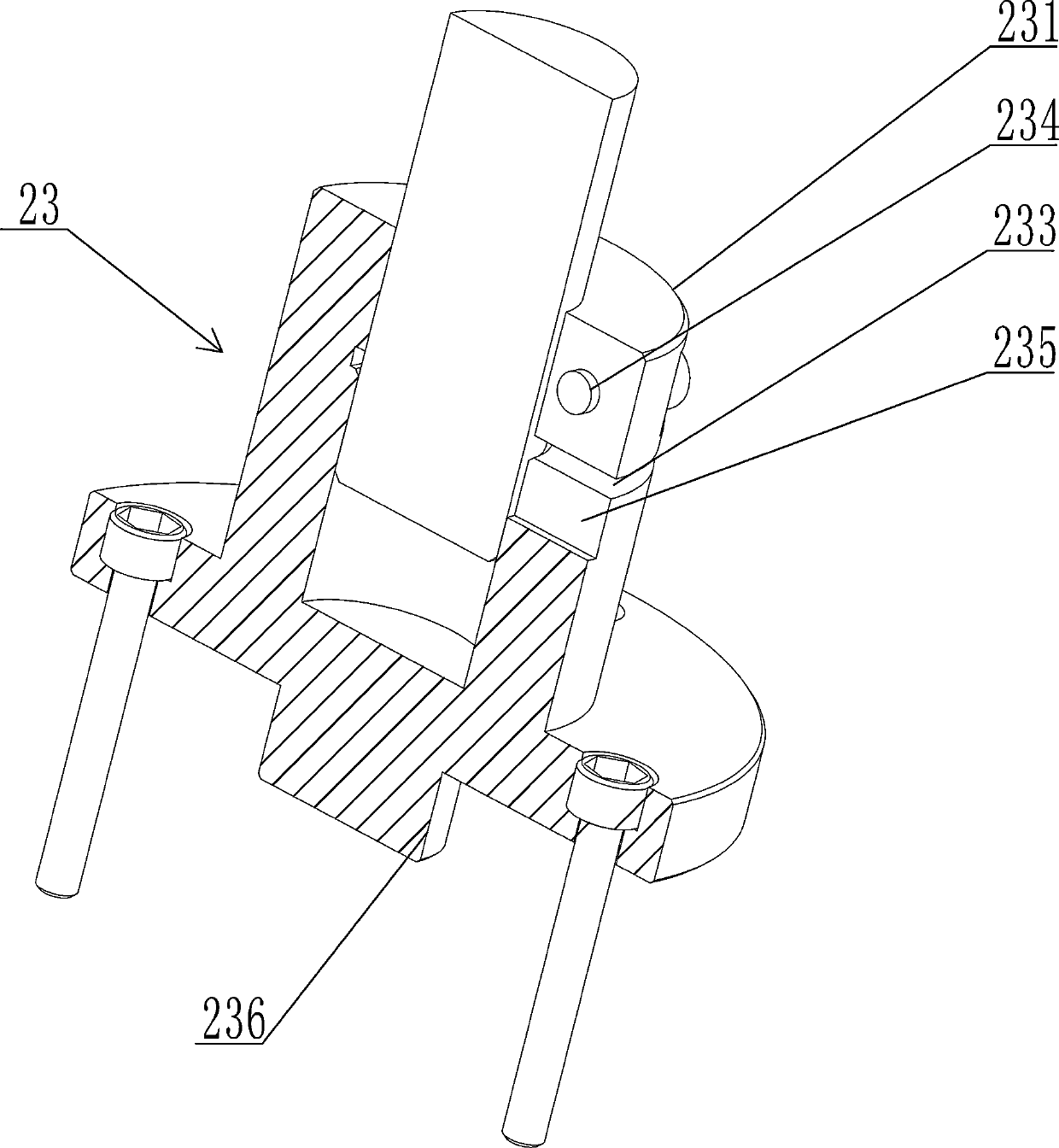

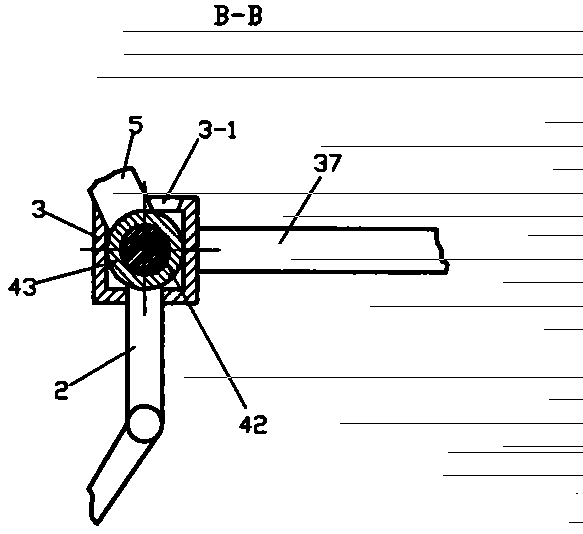

45-degree swing tool bit

InactiveCN106735596AImprove machining accuracySimple structureFeeding apparatusLarge fixed membersEngineeringReducer

The invention discloses a 45-degree swing tool bit. The 45-degree swing tool bit comprises a B-axle motor, and a B-axle harmonic speed reducer matched and connected with an output shaft of the B-axle motor; a tool bit mounting base is arranged on the outer wall of the B-axle harmonic speed reducer; a height measuring sensor is arranged on the right side of the tool bit mounting base; a connecting rod support plate is arranged on an output shaft of the B-axle harmonic speed reducer, and is synchronously hinged with a third connecting rod and a fourth connecting rod; an A-axle motor and an A-axle harmonic speed reducer are arranged at the tops of the third connecting rod and the fourth connecting rod; the third connecting rod and the fourth connecting rod are synchronously hinged with a first connecting rod and a second connecting rod; gun head mounting bases are arranged on one sides of the first connecting rod and the second connecting rod; cutting nozzles are arranged at the bottoms of the gun head mounting bases; and gun heads are arranged at the tops of the gun head mounting bases. The 45-degree swing tool bit is simple in overall structure, low in working noise, high in machining precision and excellent in transmission rigidity, can get rid of vertical cutting of a traditional water cutter, can cut in a manner of front-back or left-right inclination, and greatly improves the machining efficiency.

Owner:佛山市顺德区天擎电脑机械有限公司

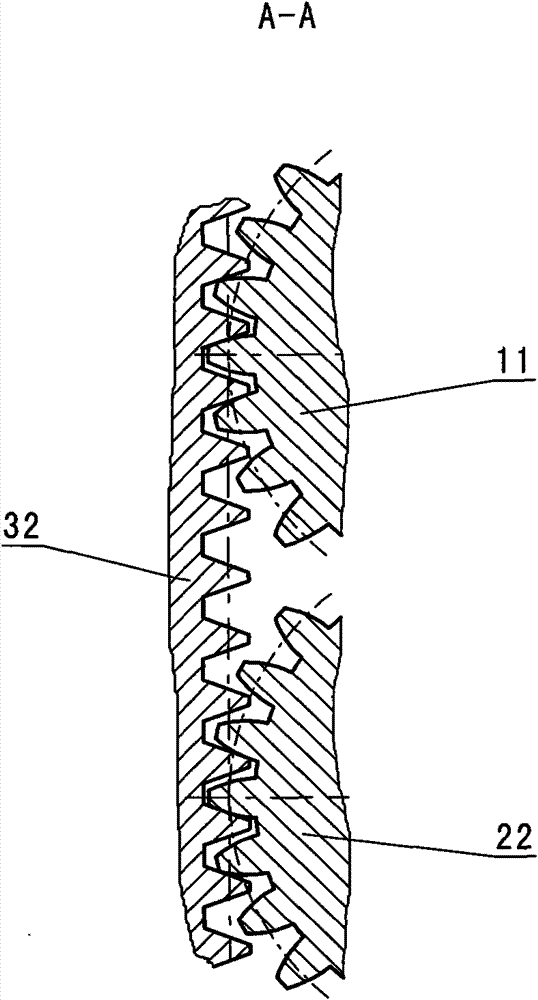

Hand-and-foot double driving type no-chain bicycle

InactiveCN103419883AIncrease heightImprove climbing abilityVehicle transmissionRider propulsionVehicle frameMagnet

Provided is a hand-and-foot double driving type no-chain bicycle. A cant beam, a rear slant fork and a horizontal rear fork are connected to form a triangular bicycle frame. The front end of the bicycle frame is fixed to a circular tube shell. The upper portion of a front bicycle fork, pedal frames and the lower portion of a connecting circular rod are connected with round balls through hinged shafts in the circular tube shell. The upper portion of the connecting circular rod is hinged to the lower portion of a push-pull tube provided with handles on the top portion. The push-pull tube and the connection circular tube not only can be combined to form a rigid push-pull rod, but also can relatively swing and rotate forwards and backwards, and the push-pull rod enables the front bicycle fork to twist a front wheel to veer. The pedal frame and the push-pull rod can be assembled to be a push-pull lever. A back wheel and a ratchet wheel are coaxially arranged in the horizontal rear fork. A sliding block is arranged on a sliding rod on the front portion of the horizontal rear fork. The front end and the rear end of a connecting rod are respectively hinged to the lower portion of the push-pull lever and the sliding block. The front end of an upper toothed plate and the front end of a lower toothed plate are hinged to the sliding block, and the toothed portion of the upper toothed plate and the toothed portion of the lower toothed plate clamp the ratchet wheel vertically. The upper toothed plate and the lower toothed plate are mutually attracted through magnets at intervals. The bicycle seat with a backrest is arranged on the top end of the triangular bicycle frame. Pedals and the hand push-pull lever drive the ratchet wheel to rotate and enable the bicycle to move forward through the connecting rod, the sliding block and the toothed plates.

Owner:刘新广

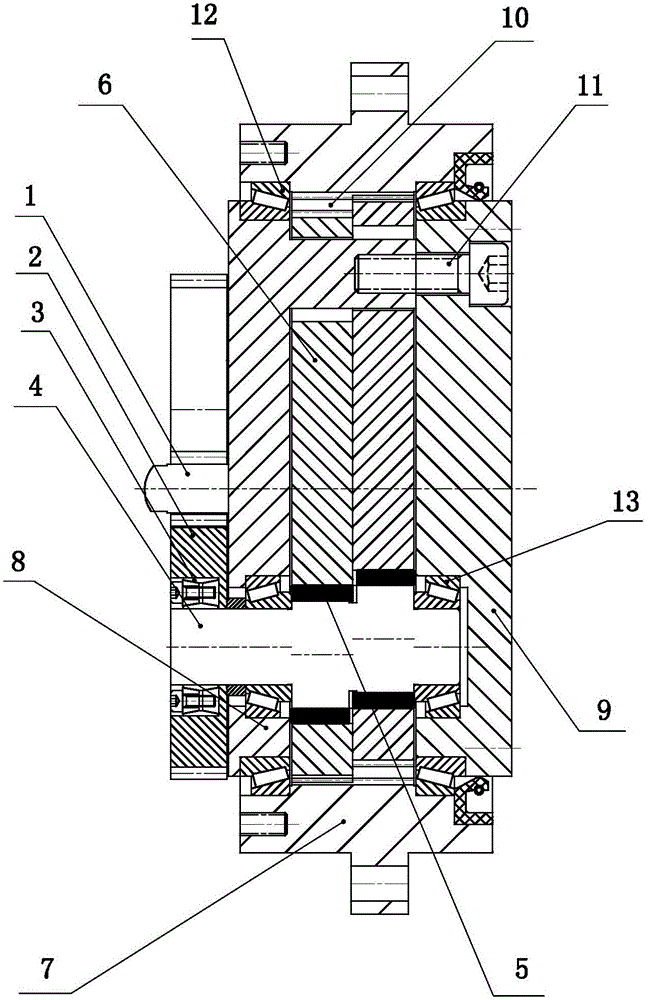

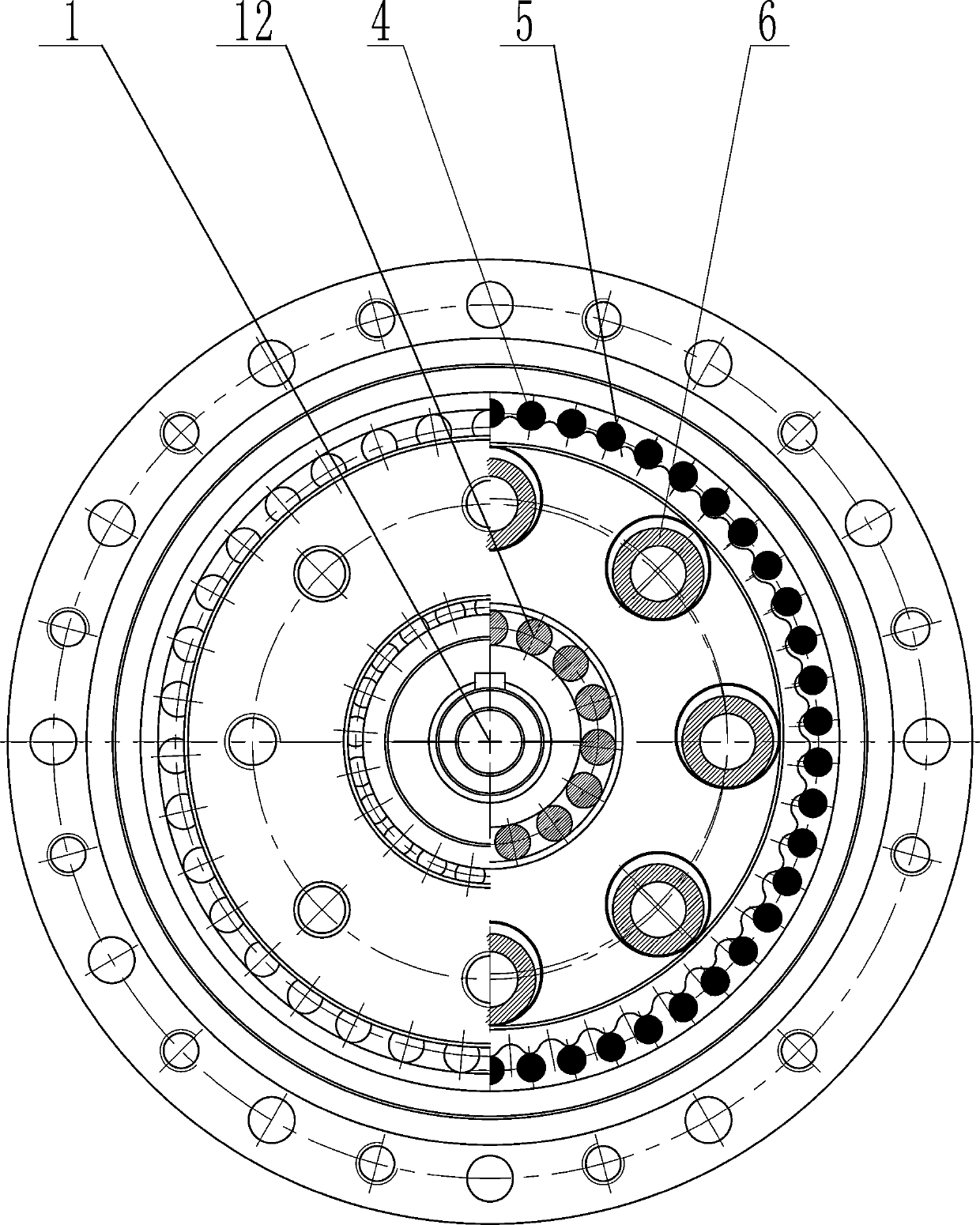

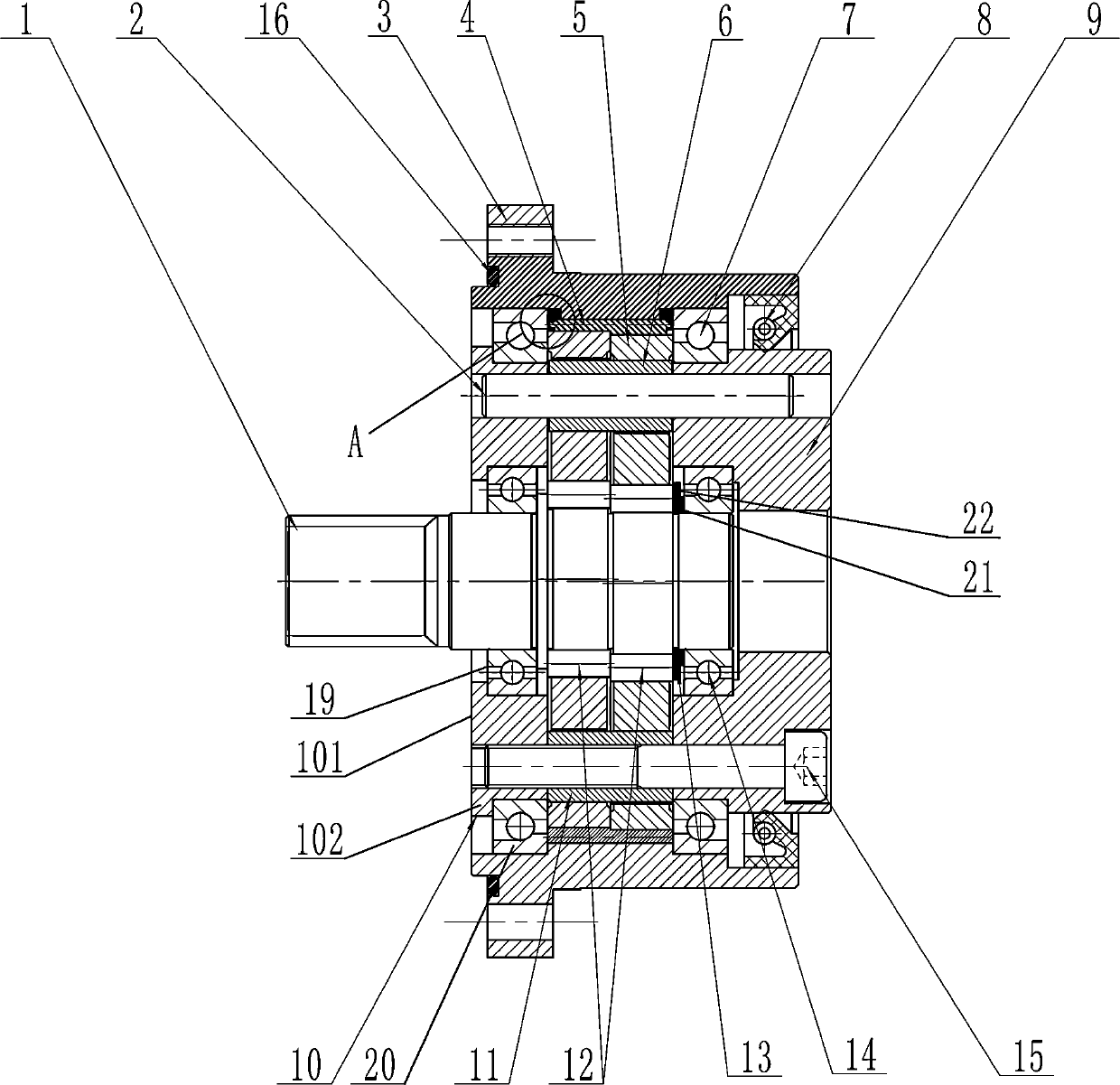

Precise reduction transmission mechanism

ActiveCN105134888ASmall amount of deformationIncreasing the thicknessToothed gearingsGearing detailsEngineeringFlange

The invention relates to a precise reduction transmission mechanism which has the advantages of favorable properties and high precision. The precise reduction transmission mechanism is characterized by comprising a sun wheel, a planetary wheel, a tensioning sleeve, cycloidal shafts, a cycloidal gear, a shell, a front cycloidal shaft flange and a back cycloidal shaft flange, wherein the front cycloidal shaft flange and back cycloidal shaft flange are fixedly connected and respectively rotatablely installed in the shell; the three cycloidal shafts are rotatablely installed between the front cycloidal shaft flange and back cycloidal shaft flange, and uniformly distributed on one circumference; the cycloidal shaft which protrudes out of the front cycloidal shaft flange is fixedly provided with the planetary wheel; the front cycloidal shaft flange is rotatablely provided with the sun wheel; the sun wheel and planetary wheel form a mesh fit; the cycloidal shaft arranged inside the shell is provided with the cycloidal gear; and a cycloidal bearing is arranged between the cycloidal gear and cycloidal shaft and forms a mesh fit with an inner gear ring positioned on the shell. The reduction mechanism has the advantages of favorable properties and high precision, and is beneficial to popularization and application in industry.

Owner:山东万维传动科技有限公司

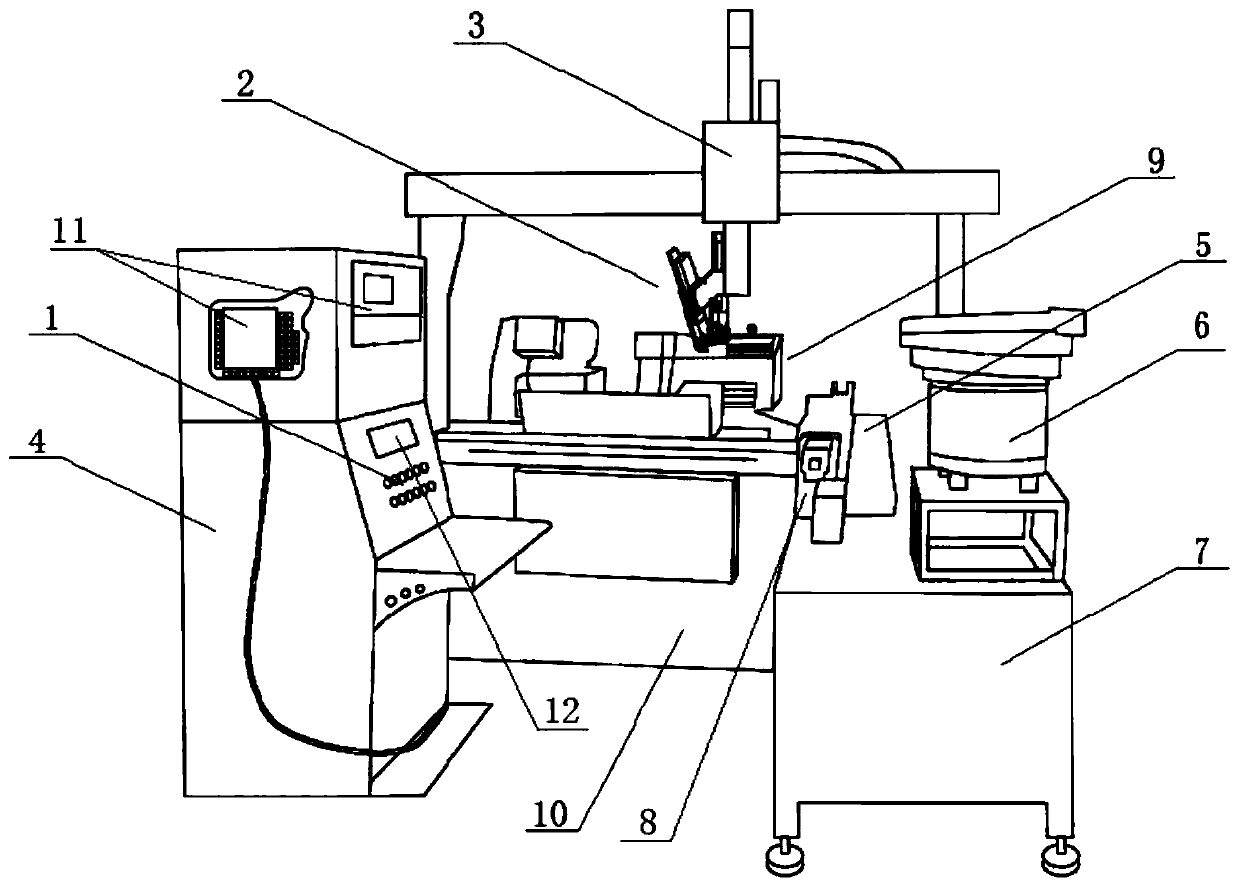

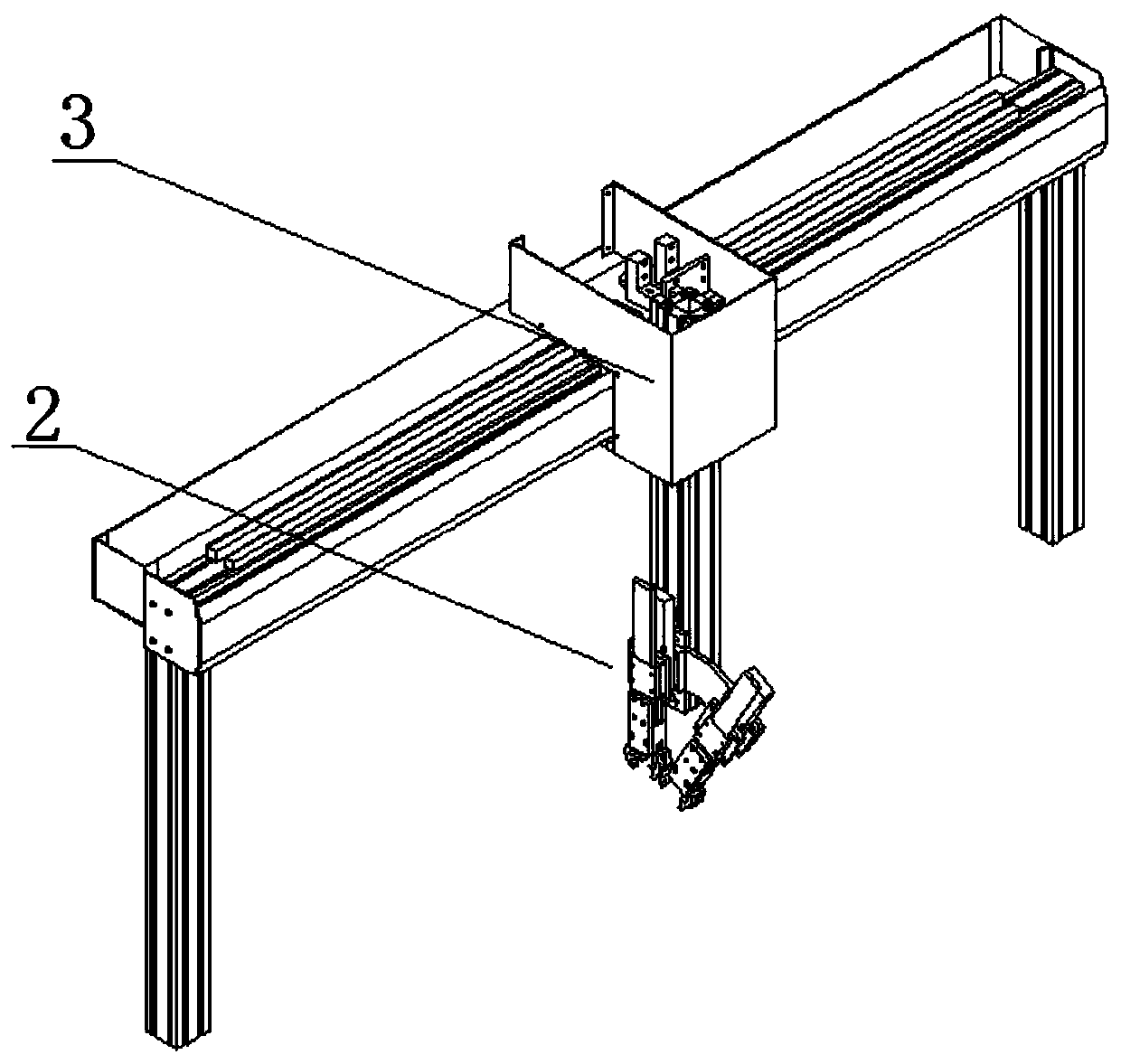

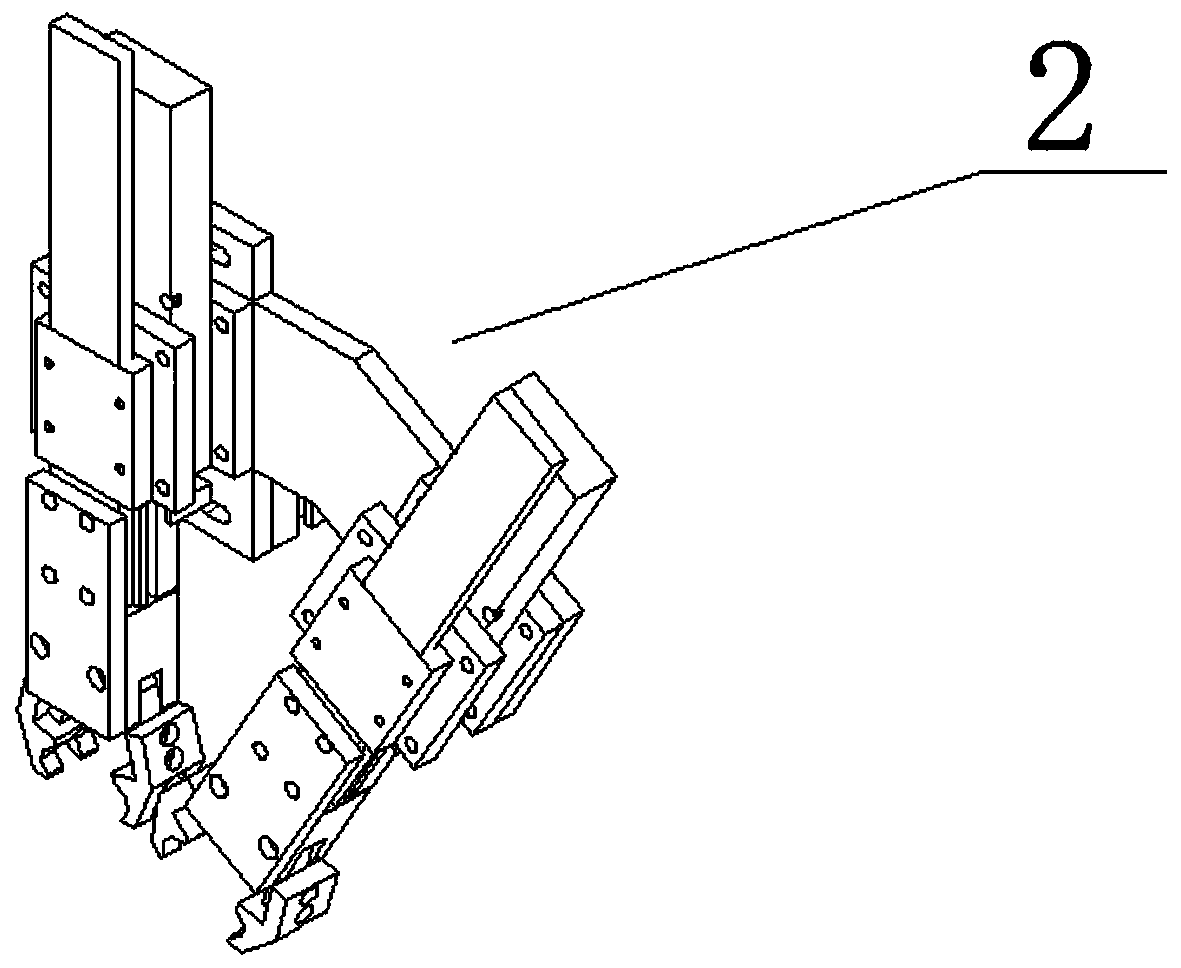

Machining tool truss manipulator

InactiveCN111215912ASave human resourcesNot easy to rustLarge fixed membersMetal working apparatusManipulatorNumerical control system

The invention discloses a machining tool truss manipulator. The machining tool truss manipulator comprises a rack, wherein a machine tool machining mechanism is arranged at the top of the rack; a workpiece and tool clamp loading and unloading mechanism is arranged at the top of the rack and is positioned right above the machine tool machining mechanism; the workpiece and tool clamp loading and unloading mechanism comprises a clamping jaw mechanism and a truss manipulator; the truss manipulator comprises an aluminum alloy section horizontal beam and an aluminum alloy section vertical arm; the clamping jaw mechanism is arranged on the vertical arm; a base is arranged on one side of the rack; a movable workbench and a loading, unloading, conveying and receiving mechanism are arranged at the top of the base; an electric control box is arranged on one side of the rack; and a switch button knob, two numerical control system controllers and a motion controller are arranged on the surface of the electric control box. According to the machining tool truss manipulator, steel beams and columns are replaced with aluminum alloy sections, secondary machining of mounting holes is not needed, thelength is random, large equipment for machining the mounting holes is omitted, tedious machining procedures and tool clamps are omitted, and manpower resources required by secondary machining are saved.

Owner:宁波广博瑞数控设备有限公司

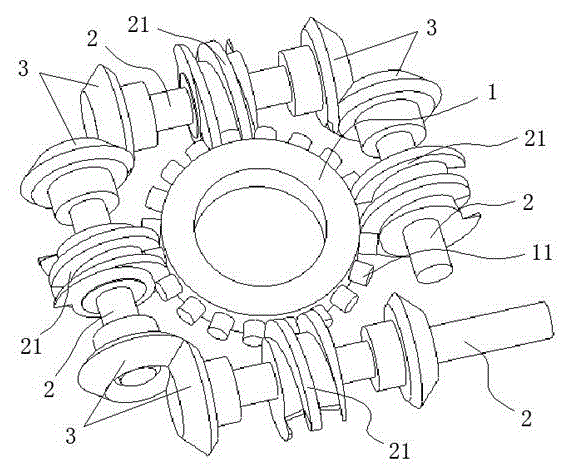

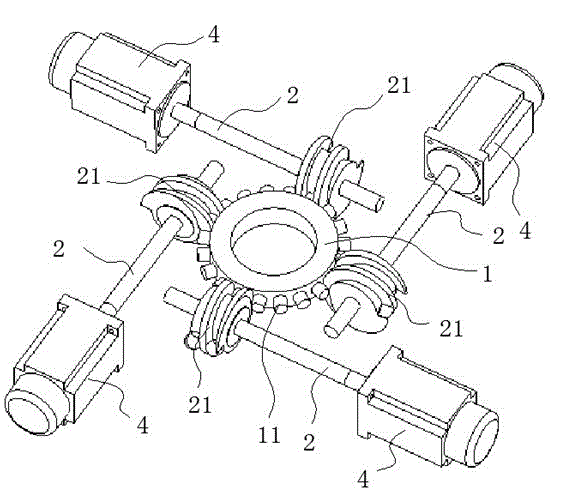

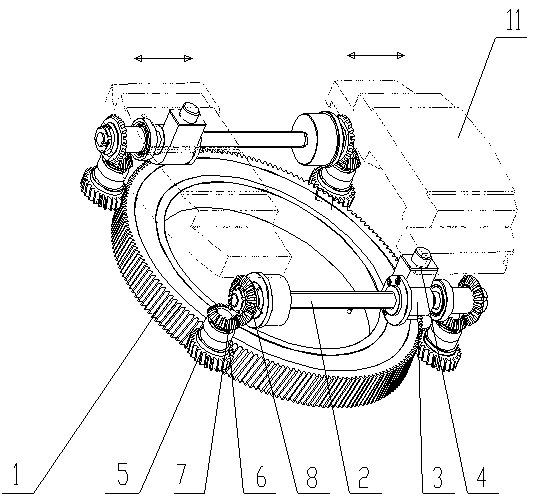

Cam roller type numerical control indexing head

InactiveCN105033754AMaintain motion processing accuracyHigh transmission rigidityPrecision positioning equipmentNeedle roller bearingNumerical control

The invention provides a cam roller type numerical control indexing head. The cam roller type numerical control indexing head mainly comprises an indexing plate and globoidal cams positioned on transmission shafts. Multiple needle bearings are circumferentially and evenly distributed on the periphery of the indexing plate. The needle bearings can be sequentially engaged with the globoidal cams. The number of the transmission shafts with the globoidal cams is at least two. The transmission shafts are arranged around the indexing plate. The transmission shafts are sequentially connected end to end for transmission or synchronously driven by respective drive motors. The globoidal cams on the transmission shafts are in zero-clearance engaging transmission with the needle bearings on the corresponding side of the indexing plate. According to the design, the transmission rigidity of the indexing head can be improved in a multiplied manner; the cam roller type numerical control indexing head has the characteristics of being simple in structure and high in machining accuracy; and the machining range of the cam roller type numerical control indexing head can be greatly widened.

Owner:TAIZHOU AOTU TRANSMISSION PARTS CO LTD

Axial load resistant no-return-difference torque output ball-hinged driving mechanism

InactiveCN101640446AEliminate hysteresisGood transmission rigidityMechanical energy handlingMotor shaftHinge joint

The invention discloses an axial load resistant no-return-difference torque output ball-hinged driving mechanism, comprising a driving unit, a transmission unit and an aligning unit; a servo direct current motor is arranged on a motor mounting seat and is connected with a motor shaft coupling block so as to form the driving unit; an output shaft, a criss-cross sliding block and the motor shaft coupling block are coupled by a longitudinal slot and a horizontal slot so as to form the transmission unit; a pressure side ring is used for fastening a ball-hinged joint outer ring in a mounting hole of the motor mounting seat and a ball-hinged joint inner ring and the ball-hinged joint outer ring are mutually matched to realize the aligning function; a bearing outer baffle ring is used for pressing two angular contact ball bearings in a bearing mounting hole of a ball-hinged joint; and the output shaft and the angular contact ball bearing are locked by fastening nuts, thus forming the aligningunit together. The axial load resistant no-return-difference torque output ball-hinged driving mechanism adopts the ball-hinged joint to realize axial load characteristic, simultaneously uses the floating criss-cross sliding block to transfer torque, overcomes return difference of the servo direct current motor when switching by forward and reverse rotation, and compensates the radial and axial errors caused by deflection of the output shaft.

Owner:BEIHANG UNIV

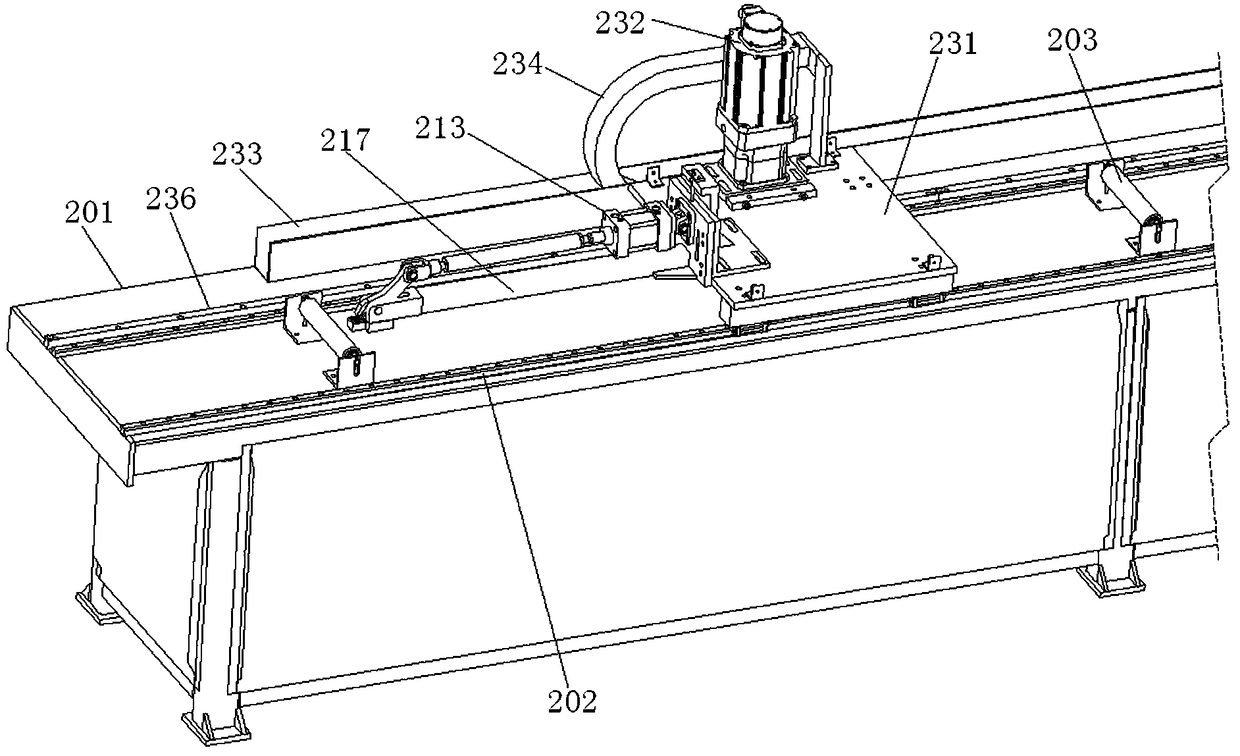

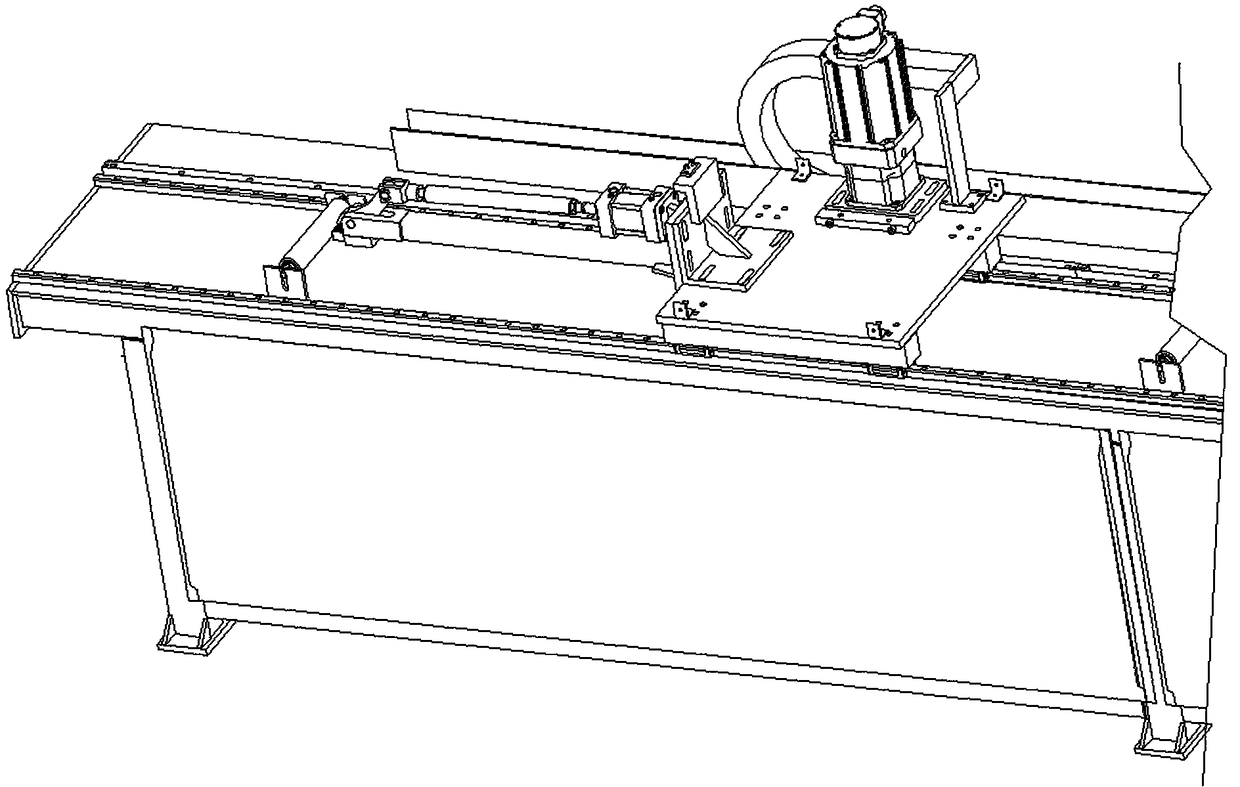

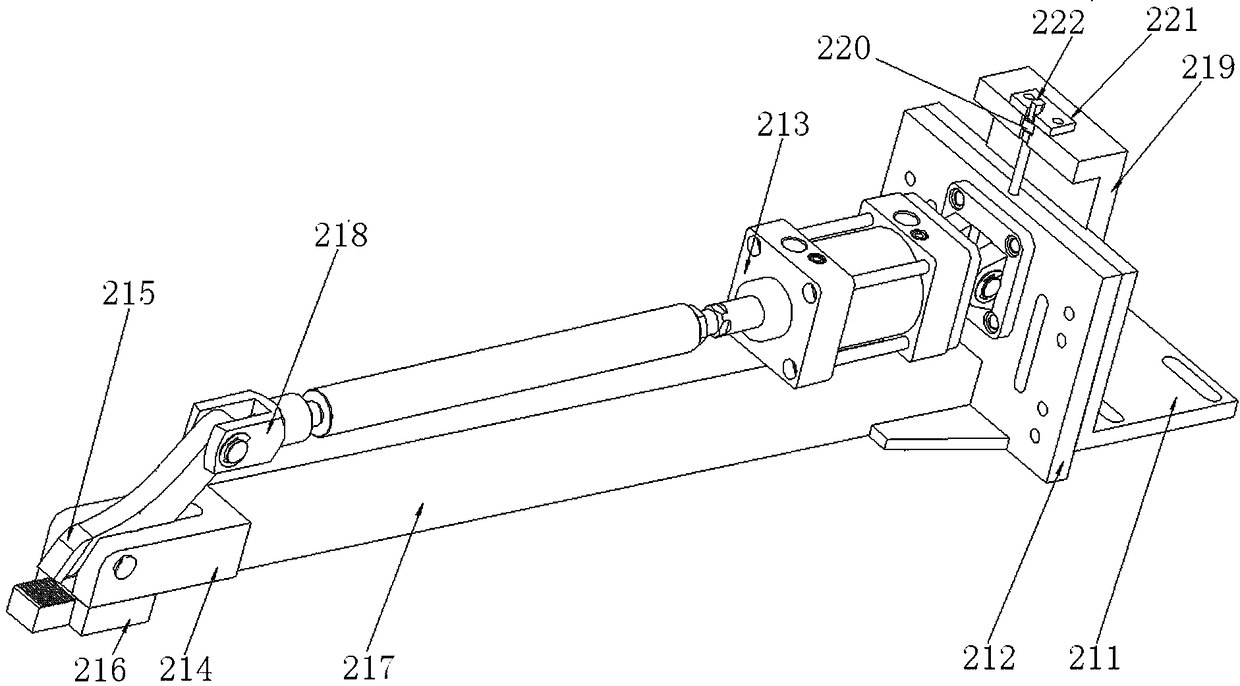

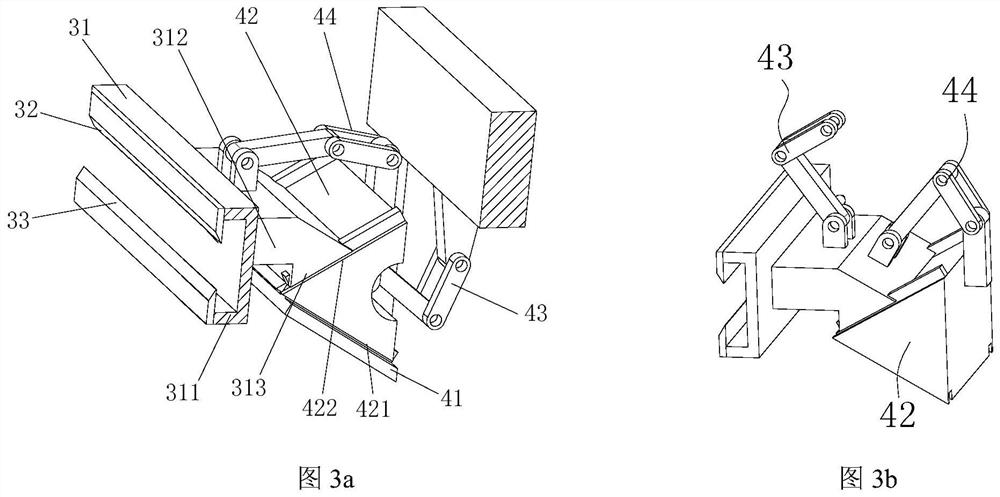

Workpiece feeding device applicable to long section

PendingCN109304494APrecise positioningAvoid knockingFeeding apparatusBoring/drilling componentsEngineeringSupport plane

A workpiece feeding device applicable to a long section comprises a supporting frame, a workpiece clamp mechanism, a servo transmission mechanism, dragging wheel devices and two linear guide rails, wherein the two linear guide rails are mutually symmetrically mounted on the bottom surface of the supporting frame; one end of the workpiece clamping mechanism is used for clamping a workpiece while the other end of the workpiece clamp mechanism is mounted on the servo transmission mechanism; the servo transmission mechanism is glidingly connected to the linear guide rails; a plurality of draggingwheel devices are arranged at intervals on the supporting frame in the linear guide rails at two sides; and the workpiece clamping mechanism is driven to slide on the linear guide rail through the servo transmission mechanism, so that a workpiece clamped by the workpiece clamping mechanism can roll on the dragging wheel devices.

Owner:江苏众利达自动化设备有限公司

Aseptic separator and surgically assisted robot instrument system

PendingCN111166486APrecise Surgical ControlAccurately master the operationSurgical furnitureSurgical manipulatorsPhysicsSurgical Manipulation

The invention discloses an aseptic separator. The aseptic separator includes upper partition plates connected to an instrument box and lower partition plates connected to power units; each upper partition plates and one corresponding lower partition plate are provided with a hollow cavity for accommodating a transition flange; each transition flange is arranged in one corresponding hollow cavity;the inner diameter of each hollow cavity is greater than the outer diameter of one corresponding transition flange; the part, located at the upper end of one corresponding hollow cavity, of each upperpartition plate is provided with a first limit boss; the part, located at the lower end of one corresponding hollow cavity, of each lower partition plate is provided with a second limit boss; the outer surface of each transition flange is provided with a third limit boss corresponding to one first limit boss and one second limit boss; a gap where a sterile cover is arranged is arranged between the upper partition plates and the lower partition plates; and each upper partition plate is fixedly connected with one corresponding lower partition plate by screws. The aseptic separator provides mechanical conditions for realization of force feedback, realizes intuitive operation, greatly increases the safety performance of surgical operation, and has improved overall safety performance.

Owner:CHONGQING JINSHAN MEDICAL ROBOTICS CO LTD

A wire feeding mechanism for wire electric discharge cutting machine with precise closed-loop control of electrode wire tension

ActiveCN104070248BSolve the technical difficulties of precise tension controlHigh transmission rigidityElectrical-based machining electrodesElectric dischargeWire tension

The invention discloses a wire-cut electric discharge machine wire transport mechanism capable of realizing accurate closed-loop control on the tension of an electrode wire. The wire-cut electric discharge machine wire transport mechanism is characterized in that an upper tensioning wheel, a lower tensioning wheel and a connection plate form a tensioning element; the tensioning element is slidably connected with the vertical column of an opposite-line cutting machine along a vertical direction; the tensioning element is in transmission connection with a drive device through a force transducer, one end of the force transducer is fixedly connected with the tensioning element, and the other end of the force transducer is in transmission connection to the drive device; the directions of the acting forces of the upper tensioning wheel, the lower tensioning wheel, the force transducer and the drive device are located on the same axis; an annular closed electrode wire starts from a wire storage barrel, sequentially passes through an upper left reversing wheel, the upper tensioning wheel, an upper right reversing wheel, an upper guide wheel, a lower guide wheel, a lower right reversing wheel, the lower tensioning wheel and a lower left reversing wheel, and returns to the wire storage barrel; the signal acquired by the force transducer is used for controlling the drive device after being processed by a control circuit. The wire-cut electric discharge machine wire transport mechanism disclosed by the invention realizes accurate control on the tension of the electrode wire of a reciprocating wire-transport type wire-cut electric discharge machine.

Owner:江苏冬庆数控机床有限公司

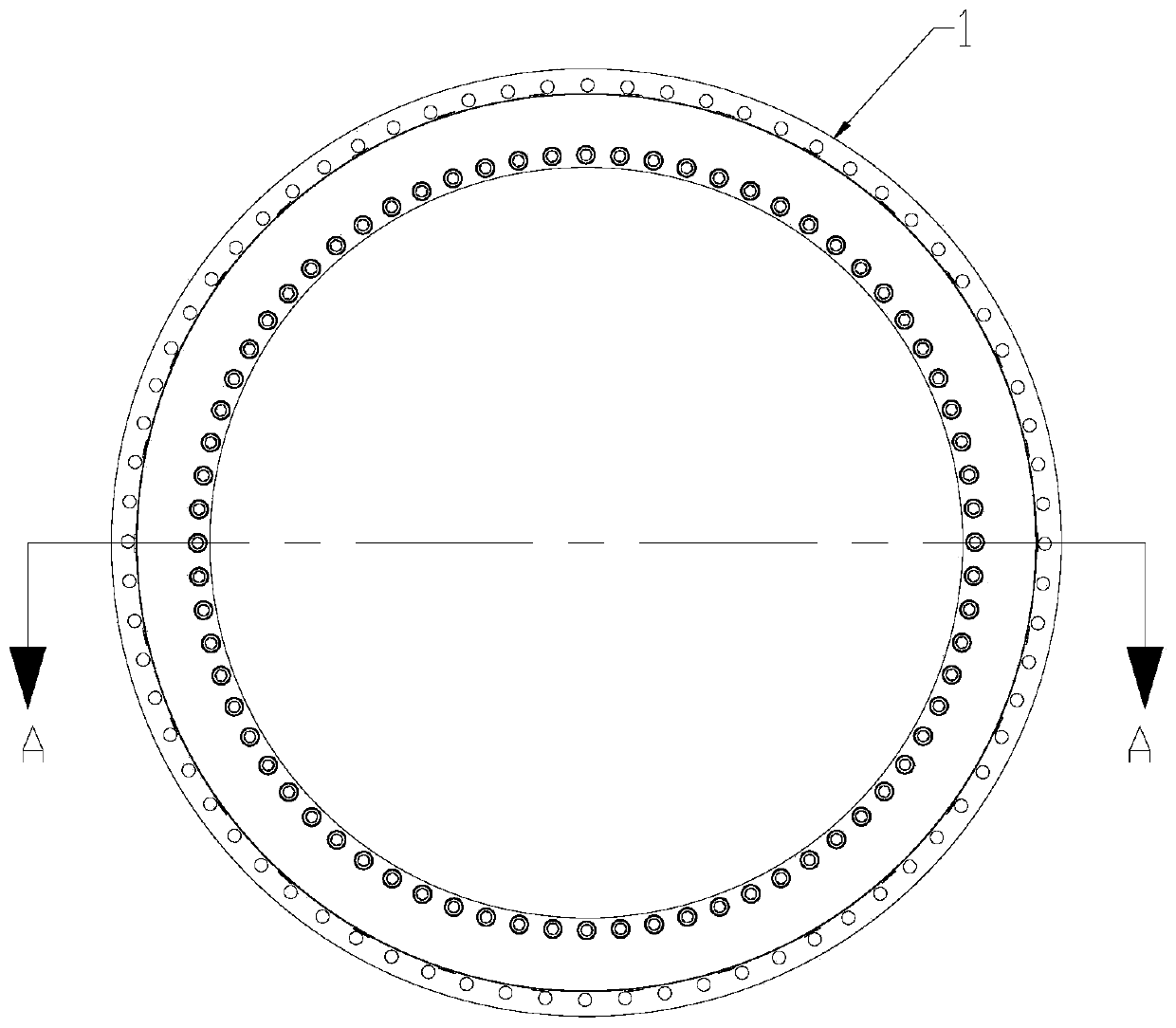

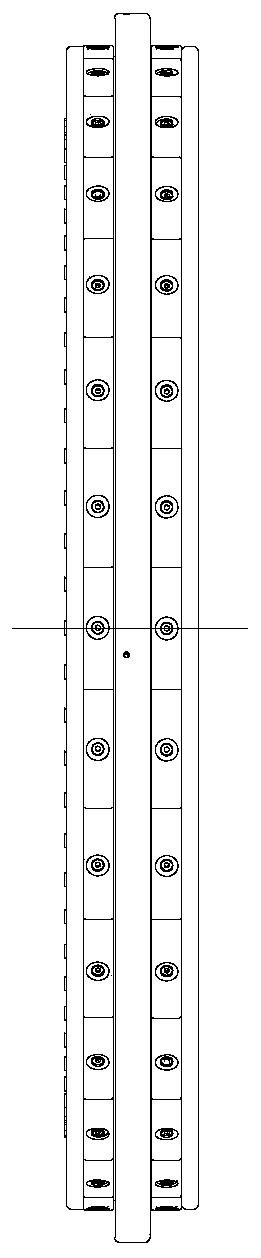

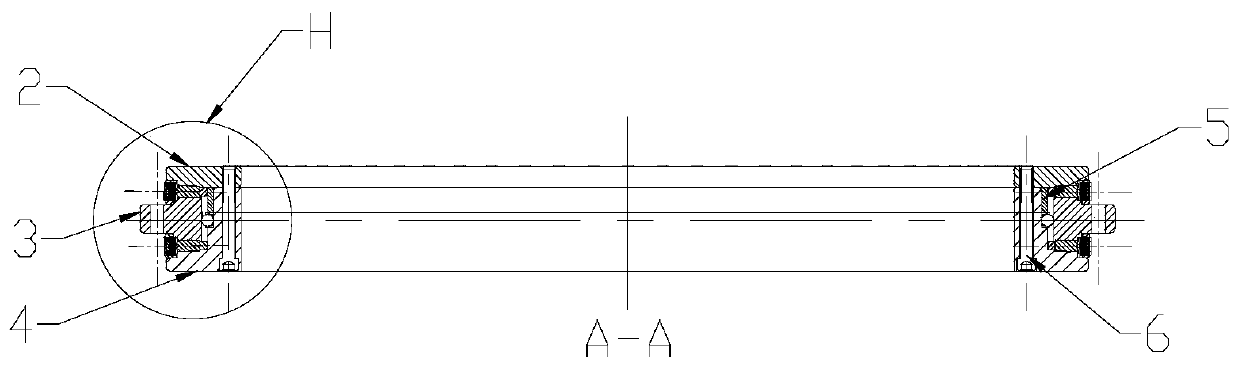

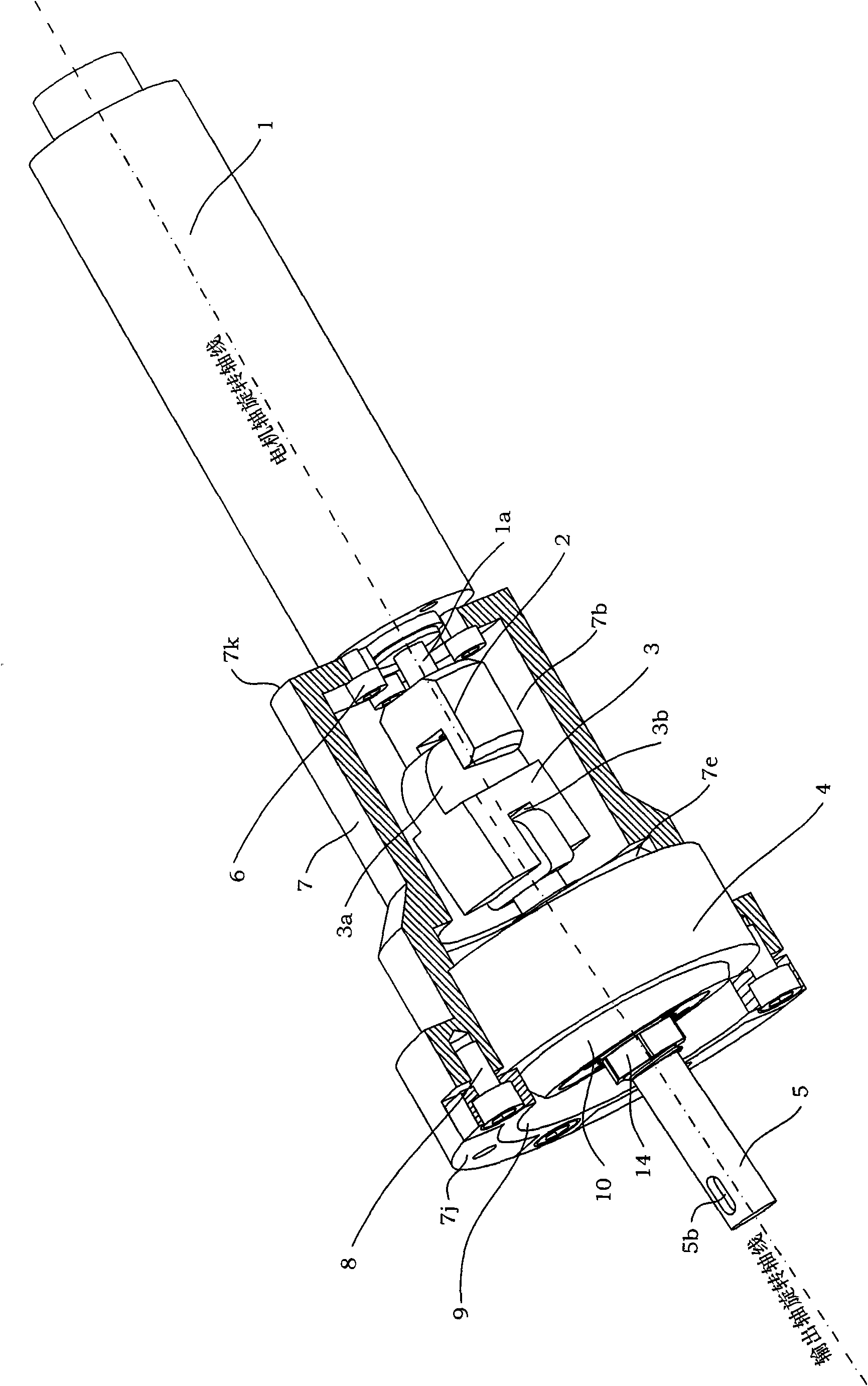

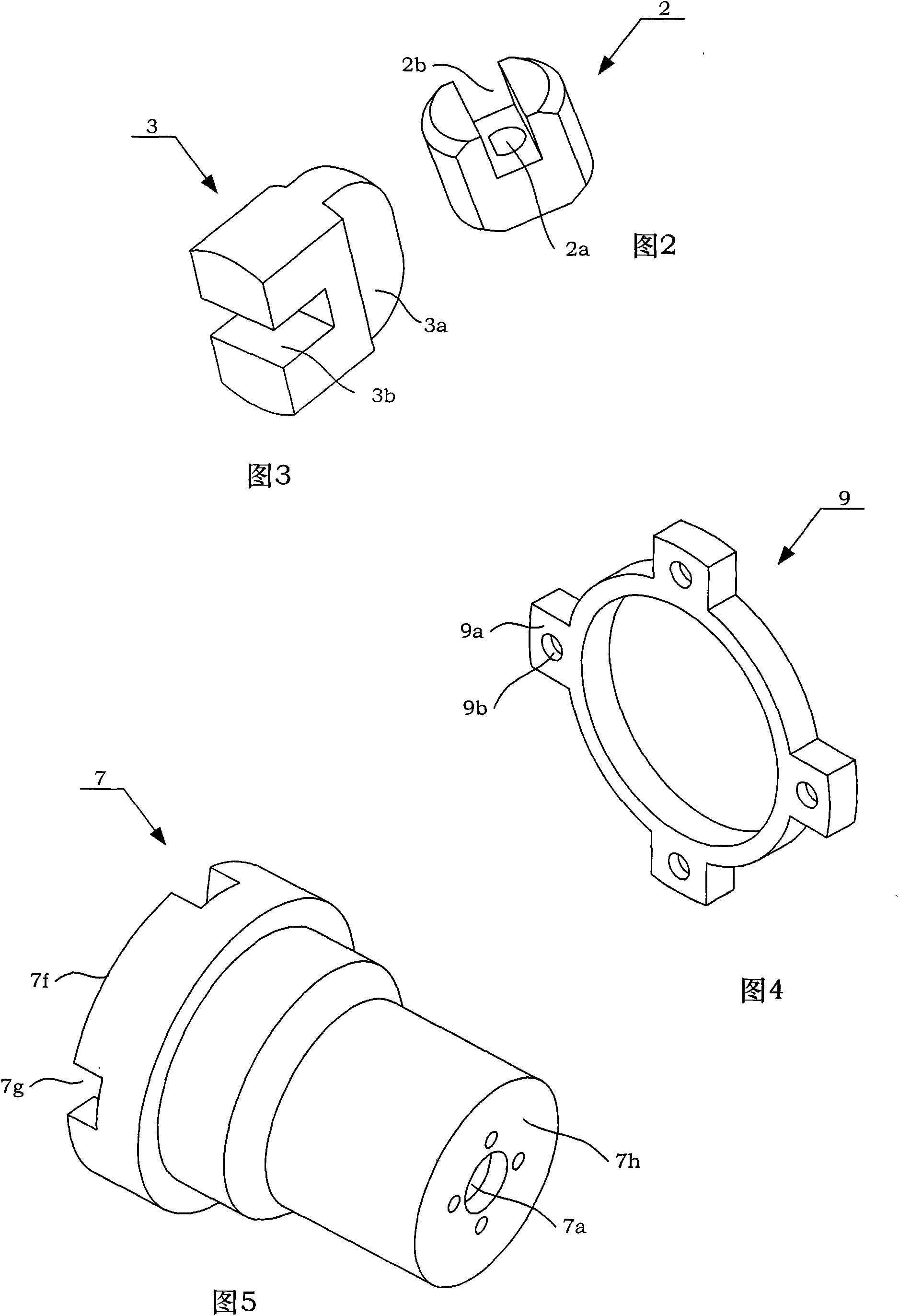

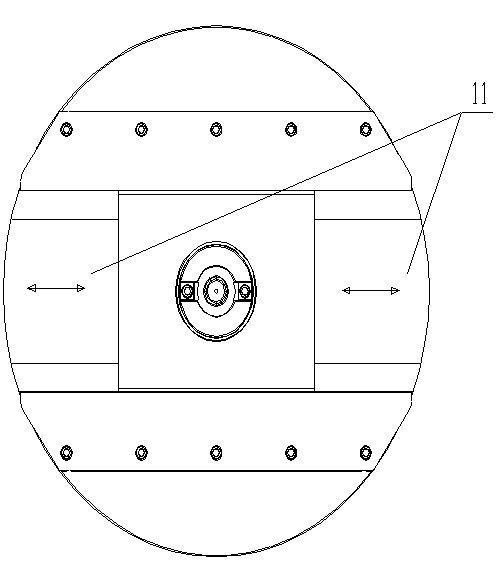

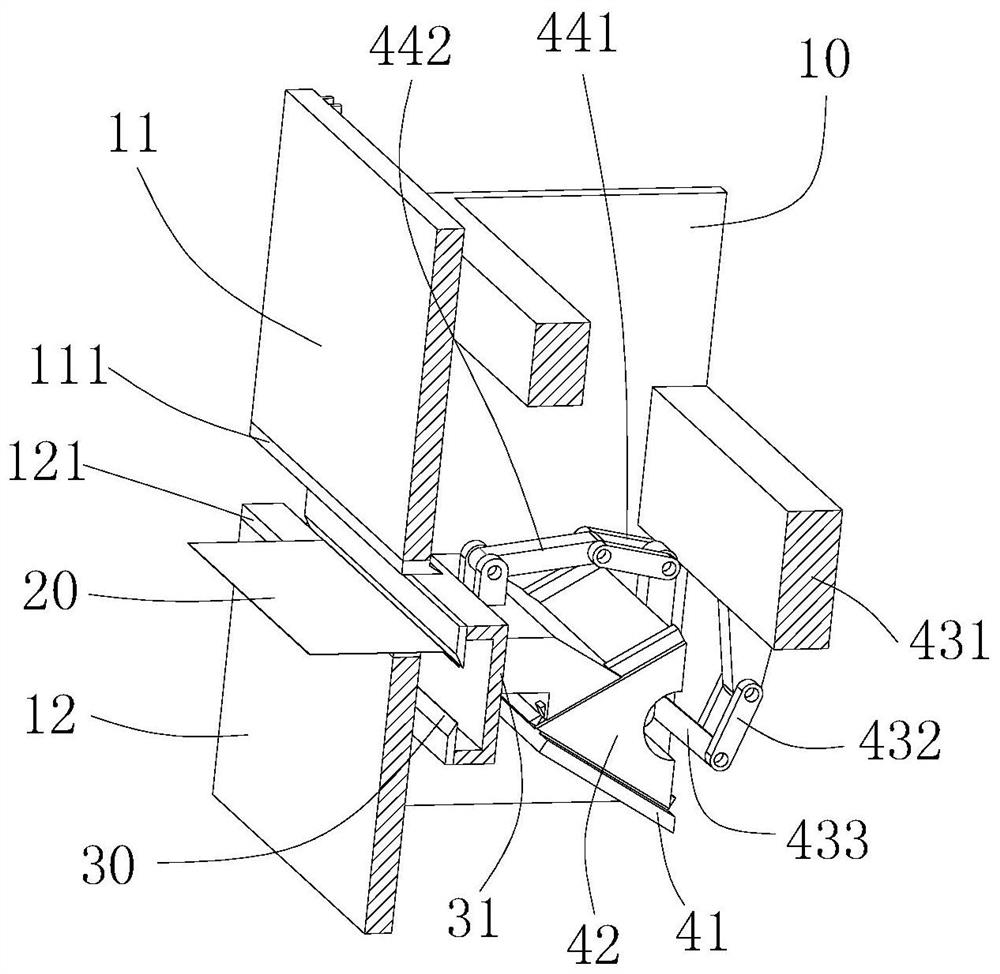

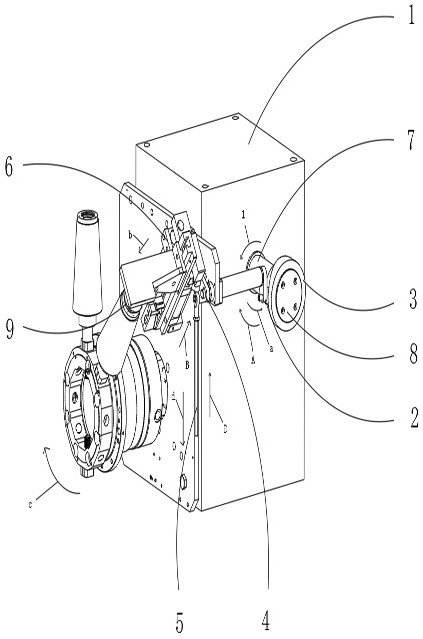

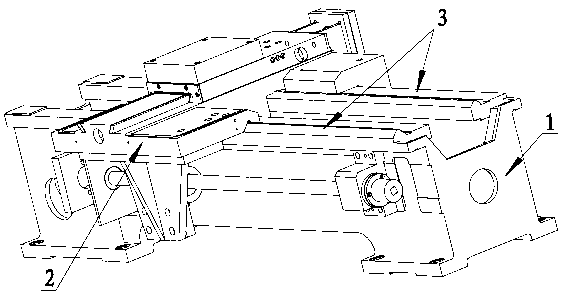

Facing head feeding mechanism and facing head

InactiveCN102848207AImprove processing efficiencyMeet dynamic balance requirementsFeeding apparatusLarge fixed membersDynamic balanceGear wheel

The invention discloses a facing head feeding mechanism and a facing head, which relate to the field of feeding mechanisms for machine tools. The facing head feeding mechanism is characterized by comprising a large gear, four groups of transmission mechanisms, two lead screws, lead screw nuts and transmission blocks, wherein the two lead screws are parallel to each other and are symmetrical with each other relative to the axis of the large gear; the two ends of each lead screw are respectively connected with the large gear through one group of transmission mechanisms; the lead screw nuts are sleeved on the lead screws to form a lead screw pair; and the transmission blocks and the lead screw nuts are fixedly connected with one another. The facing head feeding mechanism has the beneficial effects that the facing head is provided with dual sliding plates, so that the machining efficiency is doubled; according to symmetrical transmission structures, the dynamic balance requirement on the facing head can be met, and a counter weight of the facing head is eliminated; each sliding plate is driven by two pinions, and thus the transmission rigidity of the facing head is improved; and the dual sliding plate structure can realize high feeding travel of the small-diameter facing head.

Owner:SANY GRP

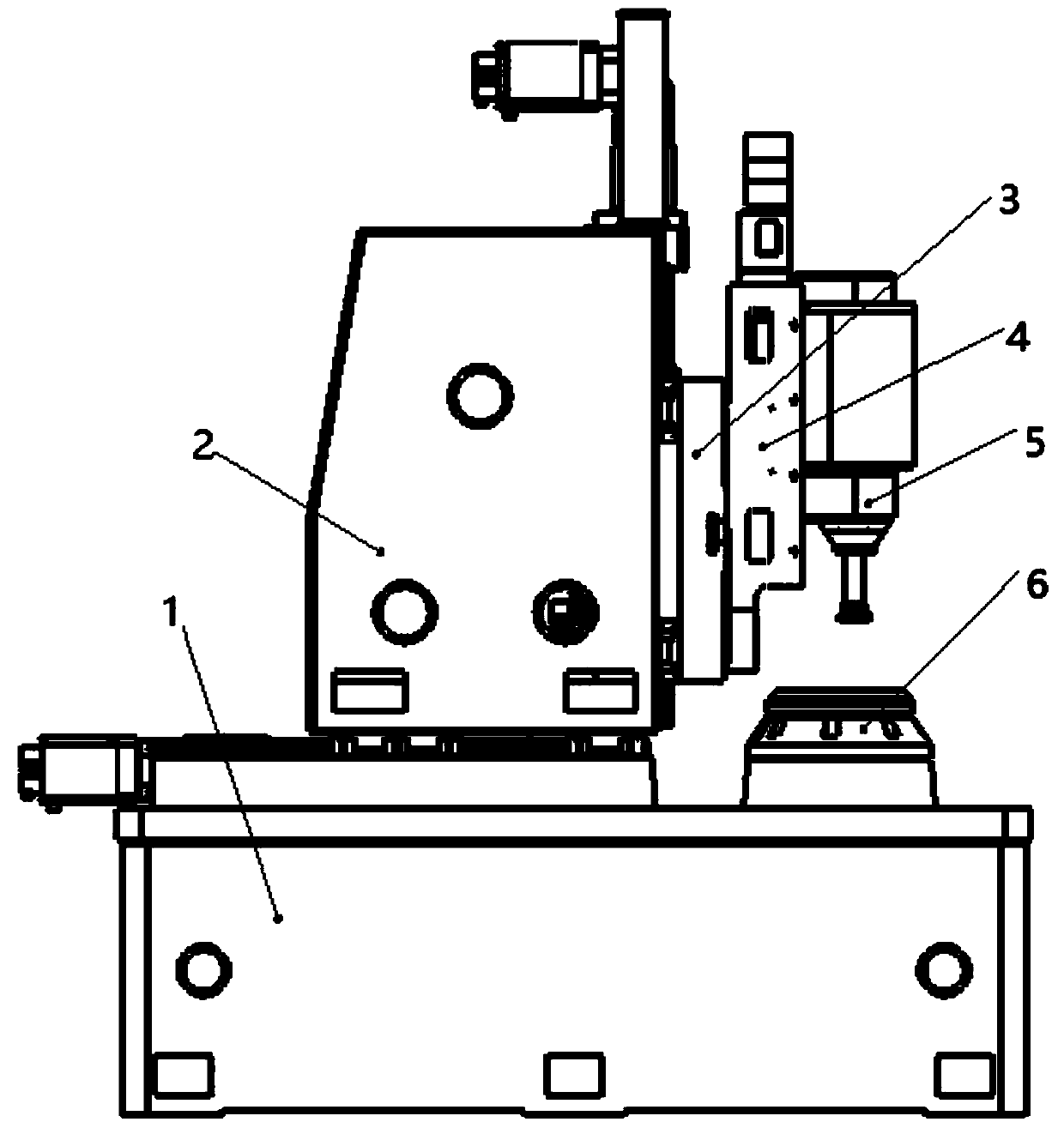

Gear turning machine

PendingCN111266665ALow efficiencyReduce precisionGear-cutting machinesMaintainance and safety accessoriesRotational axisHobbing

The invention discloses a gear turning machine. The gear turning machine is characterized in that a six-axis four-linkage machining mode is adopted, an X axis formed by a machine tool bed and other parts is responsible for radial cutter depth feeding, a Z axis formed by a machine tool stand column and other parts is responsible for axial cutting feeding, a C axis is responsible for workpiece rotation, a B axis is responsible for cutter rotation, hydraulic pressure is provided for workpiece clamping and cooling through a hydraulic station connected through an oil pipe, an A axis formed by an Aaxis dragging plate, a stand column dragging plate and other parts is responsible for adjustment of the angle of a cutter, and a Y axis formed by the A axis dragging plate and other parts is responsible for adjustment of the center of the cutter. According to the gear turning machine, gear machining is achieved through simultaneous action of gear shaping and gear hobbing, and the problems of low efficiency and low precision of traditional gear machining are solved; high-efficiency and high-precision machining is achieved; the efficiency of machining a common gear is 4 times or more that of a traditional machining process, and the precision grade can reach grade 6; and cutter angle adjustment adopts direct connection, and the positioning precision is high; and the C axis adopts a direct drive motor, then the power transmission links are few, the transmission rigidity is high, the efficiency is high, and the positioning precision is better.

Owner:重庆市迈雷特数控技术有限公司

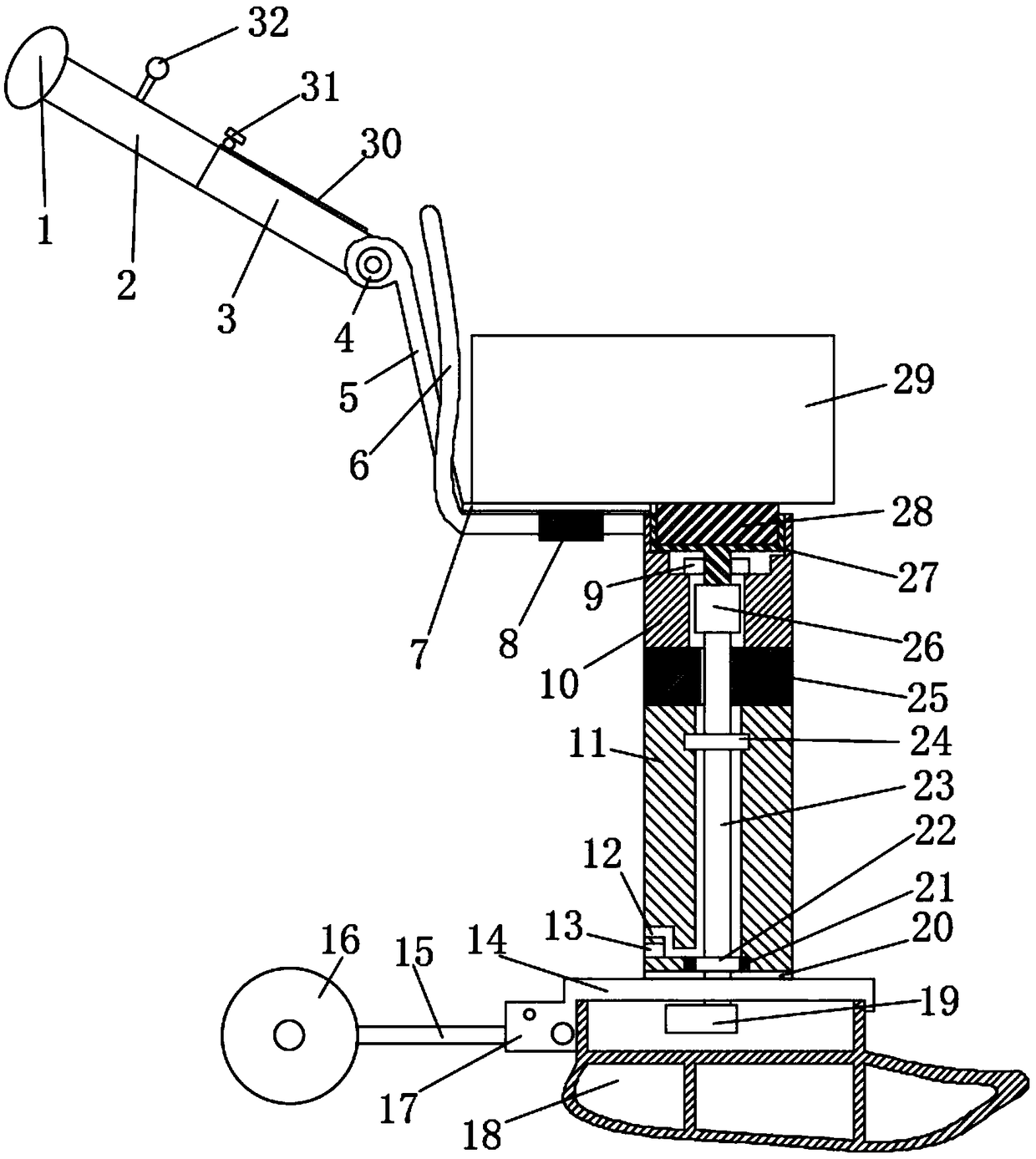

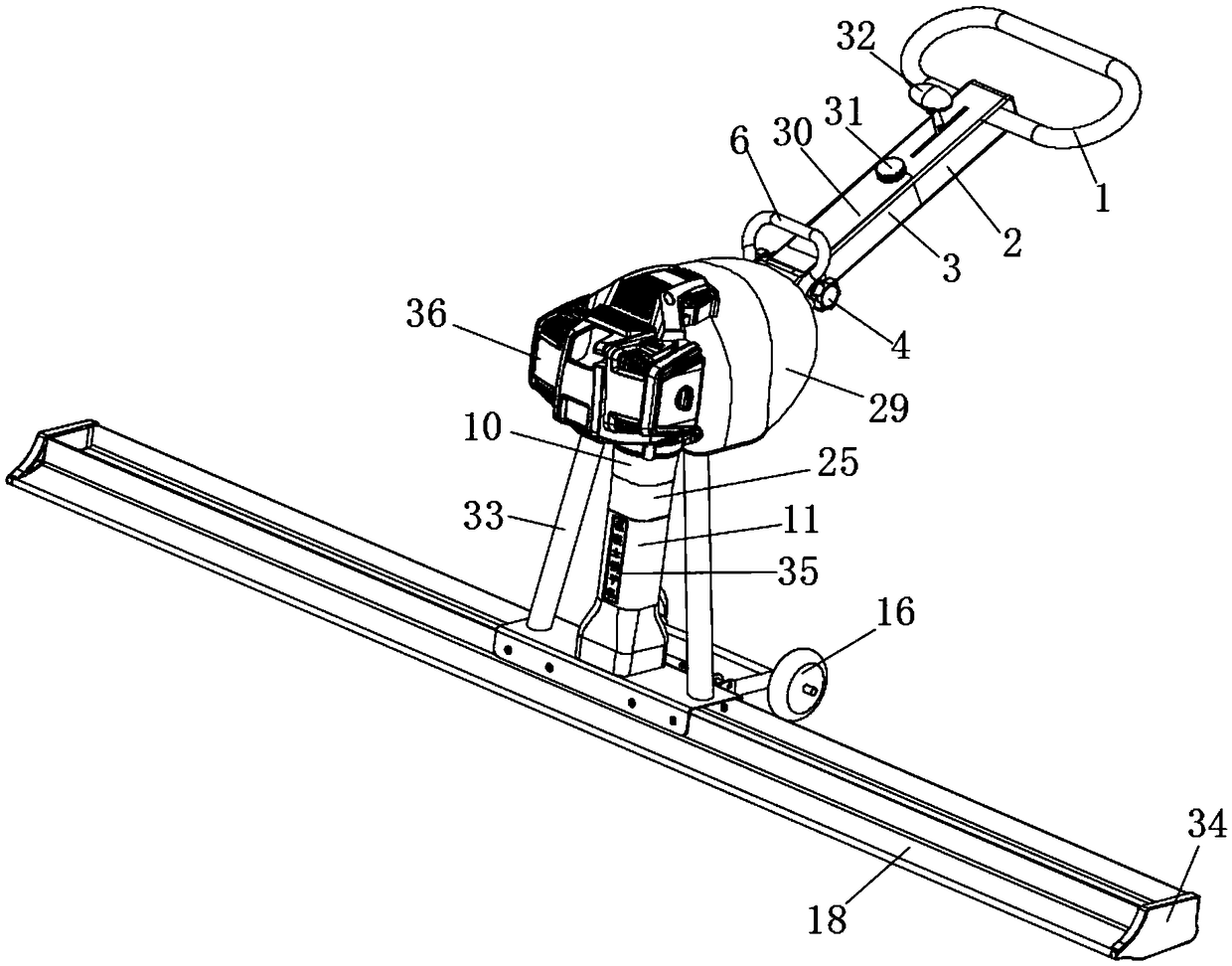

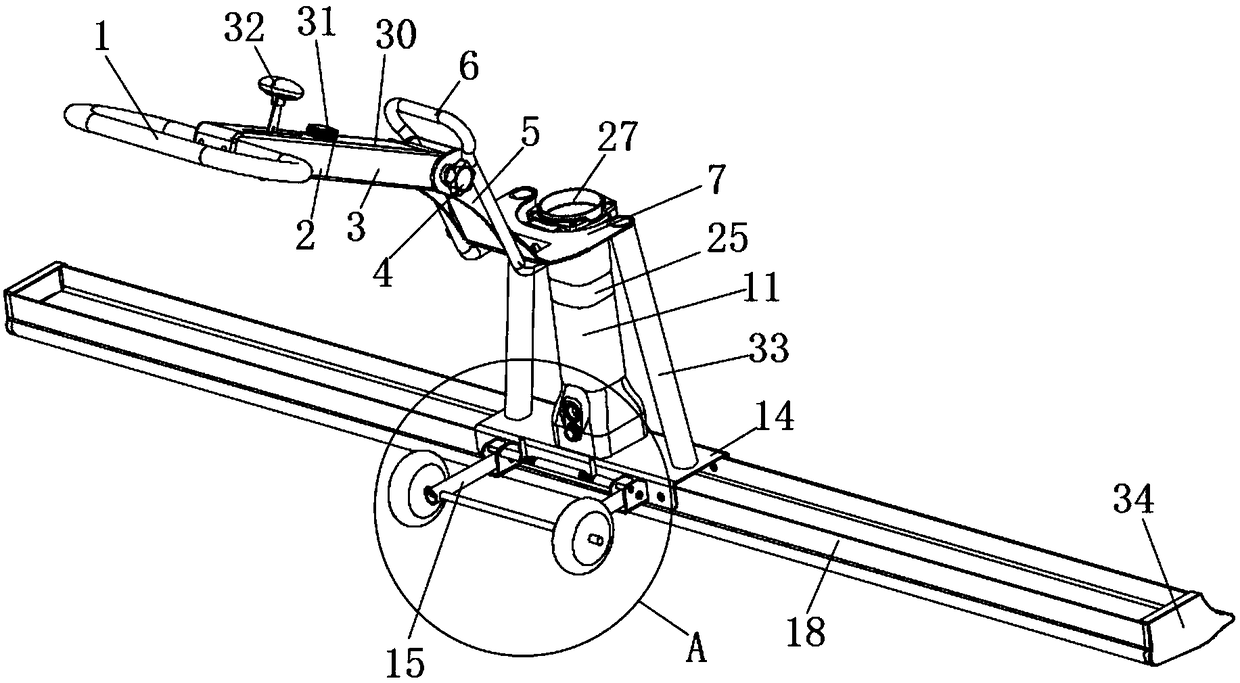

Efficient handheld concrete vibrating and leveling machine

PendingCN108286339AEasy to moveReduce fuel consumptionFoundation engineeringBridge erection/assemblyEngineeringLubrication

The invention discloses an efficient handheld concrete vibrating and leveling machine. The machine comprises a movable bracket, a back supporting frame and an engine, the lower end of the movable bracket is rotationally connected with the upper end of the back supporting frame; according to the efficient handheld concrete vibrating and leveling machine, the engine and an eccentric wheel are connected through a long shaft, the transmission rigidity is high, the coaxiality is higher when the machine works, the machine can bear larger exciting force, shaking is small in the process of vibrating and leveling, the lubrication design is adopted, so that the service life of the long shaft is longer, the machine is further provided with foldable grips, the floor space is smaller when the vibratingand leveling machine is not in use, a tool box is arranged to provide convenience for placing various tools, concrete grout uneasily adheres to the surface of a vibrating and leveling ruler in the process of use, cleaning is easier, the arrangement of a damping block and damping column further reduces the vibration of the vibrating and leveling machine in the process of working, so that the exciting force concentrates on the vibrating and leveling ruler, and the working efficiency is higher.

Owner:南通劳浩莱机械科技有限公司

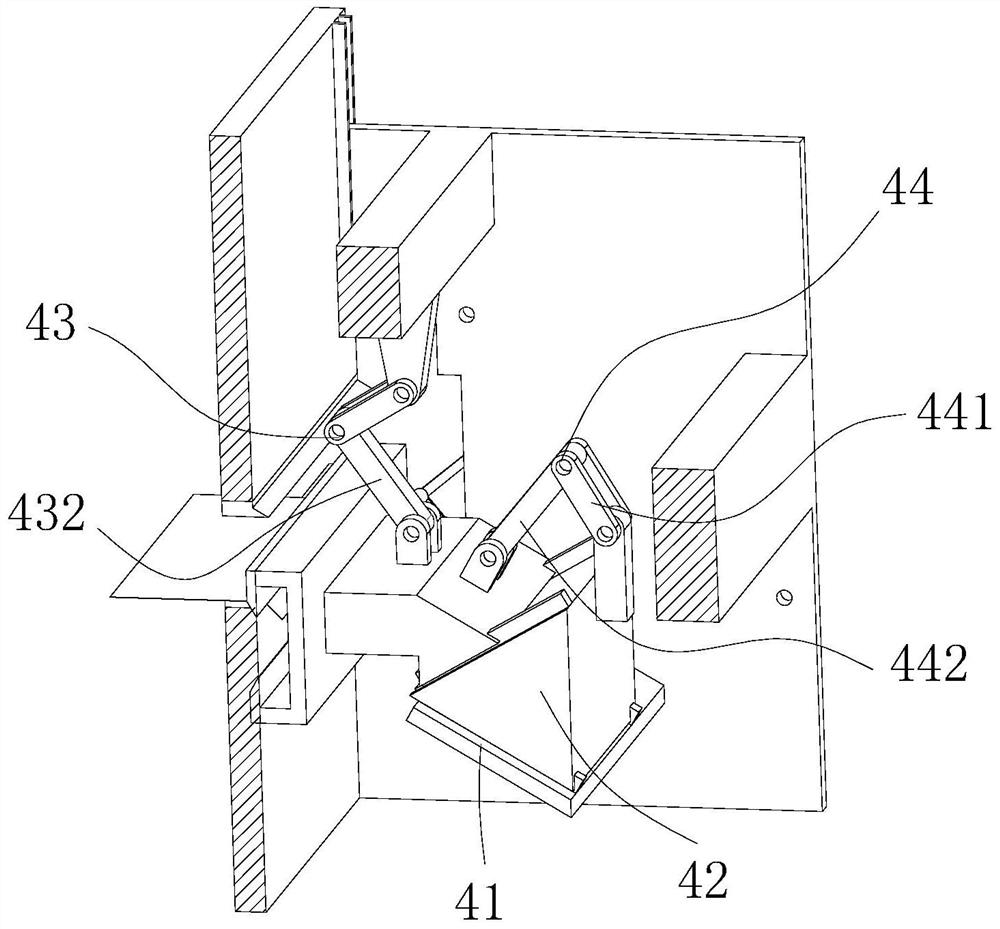

A high-speed, high-precision CNC edge folding machine and a method for solving the displacement of the edge folding beam

ActiveCN111804782BEasy to controlAvoid indentationShaping toolsUsing optical meansNumerical controlCrank

The invention discloses a high-speed, high-precision numerical control folding machine and a method for solving the displacement of a folding beam, including a machine frame, a blanking beam, a folding die, a folding beam, an inclined slide rail, a driving seat, and a first crank connecting rod Mechanism and the second crank-link mechanism; the driving seat has intersecting slope one and slope two; slope one is slidably connected to the slope slide rail, and the slope slide rail is fixed on the frame; slope two slides with the folding beam of the edge folding machine Cooperate; one end of the first crank-link mechanism is fixed on the machine frame, and the other end is hinged with the driving seat or the flange beam; one end of the second crank-link mechanism is hinged with the drive seat, and the other end is hinged with the flange beam; The side beam realizes the displacement in the vertical direction and the horizontal direction under the common coupling action of the two crank-link mechanisms. The invention can realize translational movement in the horizontal direction and the vertical direction without additional swing, the control precision of the tool tip track is high, the appearance of the plate surface is smooth and clean during the bending process, and there is no indentation; the rigidity of the bending die is high, and the moving secondary load Small.

Owner:南京云上自动化科技有限公司

Constrained speed reducer with small teeth difference

InactiveCN101915286BEliminate relative rotational motionLarge reduction ratioToothed gearingsReduction driveReduction ratio

The invention discloses a constrained speed reducer with small teeth difference, which comprises a shell, a power input shaft and a power output shaft, wherein the power input shaft is provided with a transmission inner tooth disc of inner engaging teeth through an eccentric sleeve, the power output shaft is fixedly matched and provided with an outer gear in the circumferential direction, and theouter gear is engaged with the inner engaging teeth of the transmission inner tooth disc in a small teeth difference mode; and eccentric shaft sections of constraint shafts in running fit with the shell pass through the transmission inner tooth disc and are in running fit with the transmission inner tooth disc, at least two constraint shafts are uniformly distributed along the circumferential direction, and the eccentric distance of the eccentric shaft sections is equal to that of the eccentric sleeve. The constrained speed reducer eliminates the relative spinning motion of a power input mechanism, outputs power by revolution, and has high reduction ratio, high transmission rigidity and high load transfer capability; when motion disturbance or other additional motion appears, the speed reducer can rotate normally, improve the transmission efficiency and successfully output the motion; meanwhile, the speed reducer has a simple and compact structure and small volume mass, and provides an effective path for selection of the speed reducer in mechanical engineering.

Owner:CHONGQING UNIV

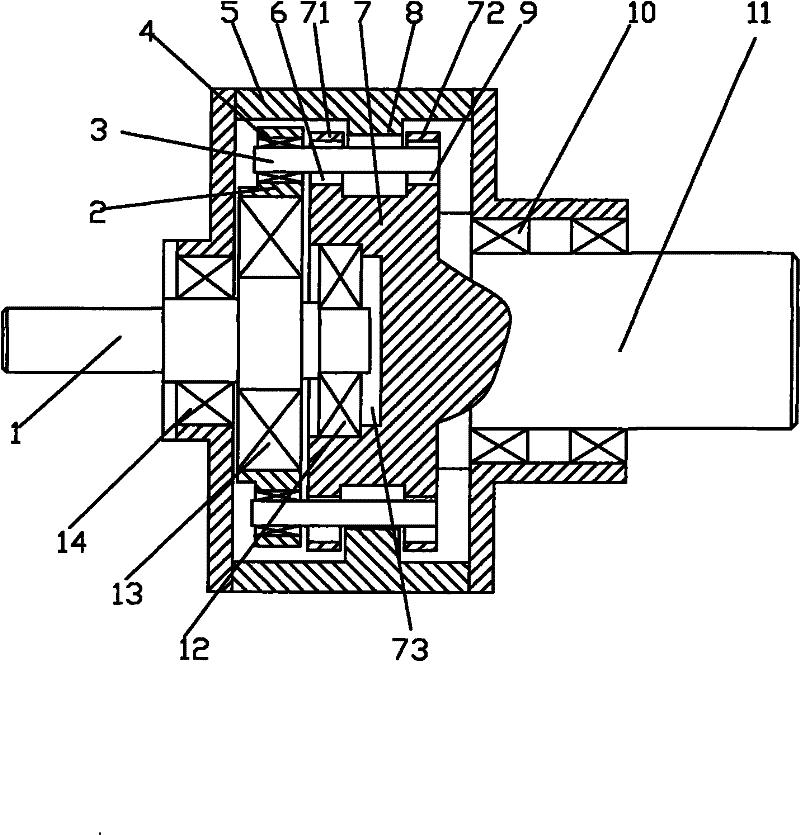

Fixed-axis cycloid transmission device

InactiveCN101634350BIncrease layout spaceImprove carrying capacityToothed gearingsReduction driveGear wheel

Owner:CHONGQING UNIV

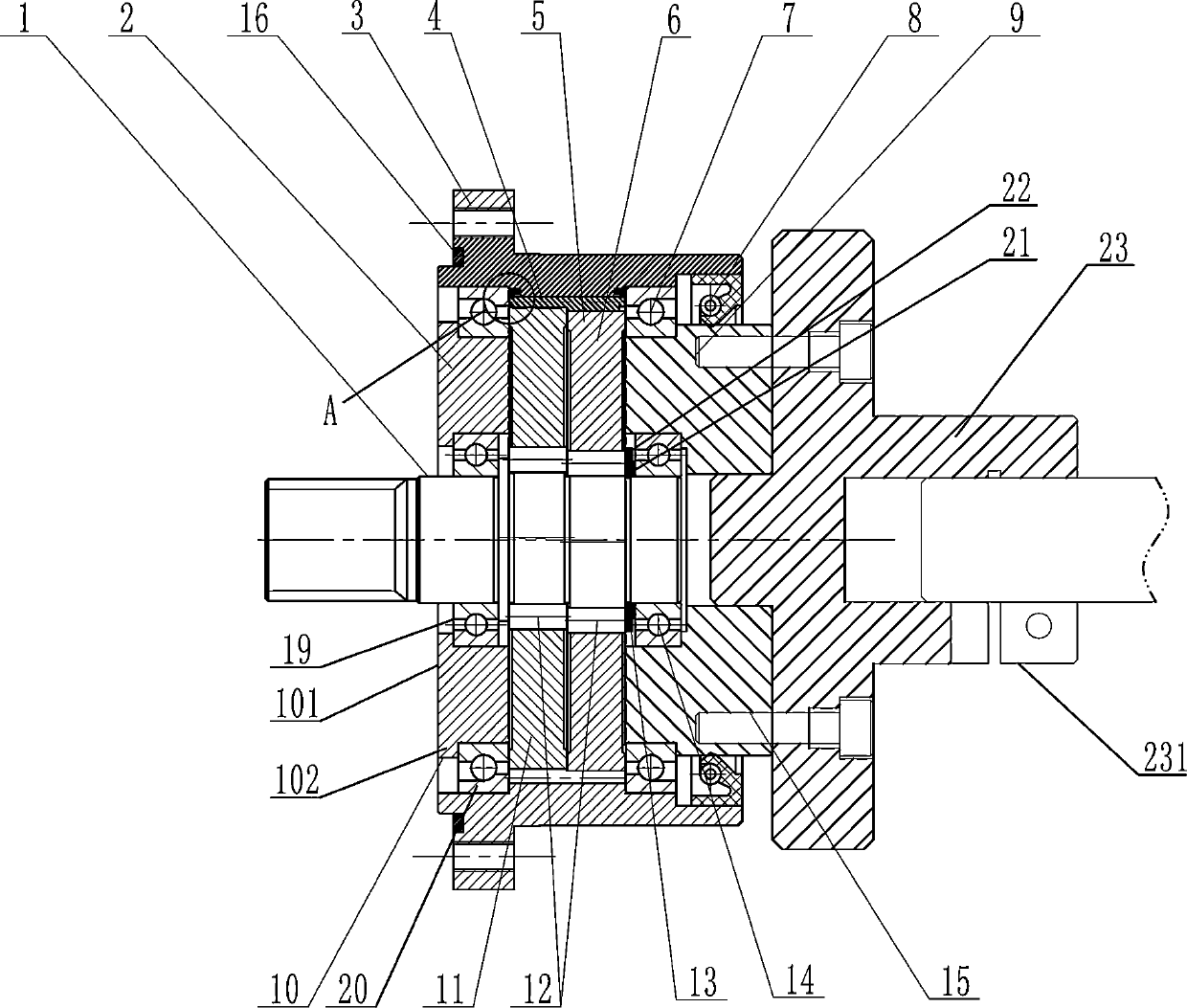

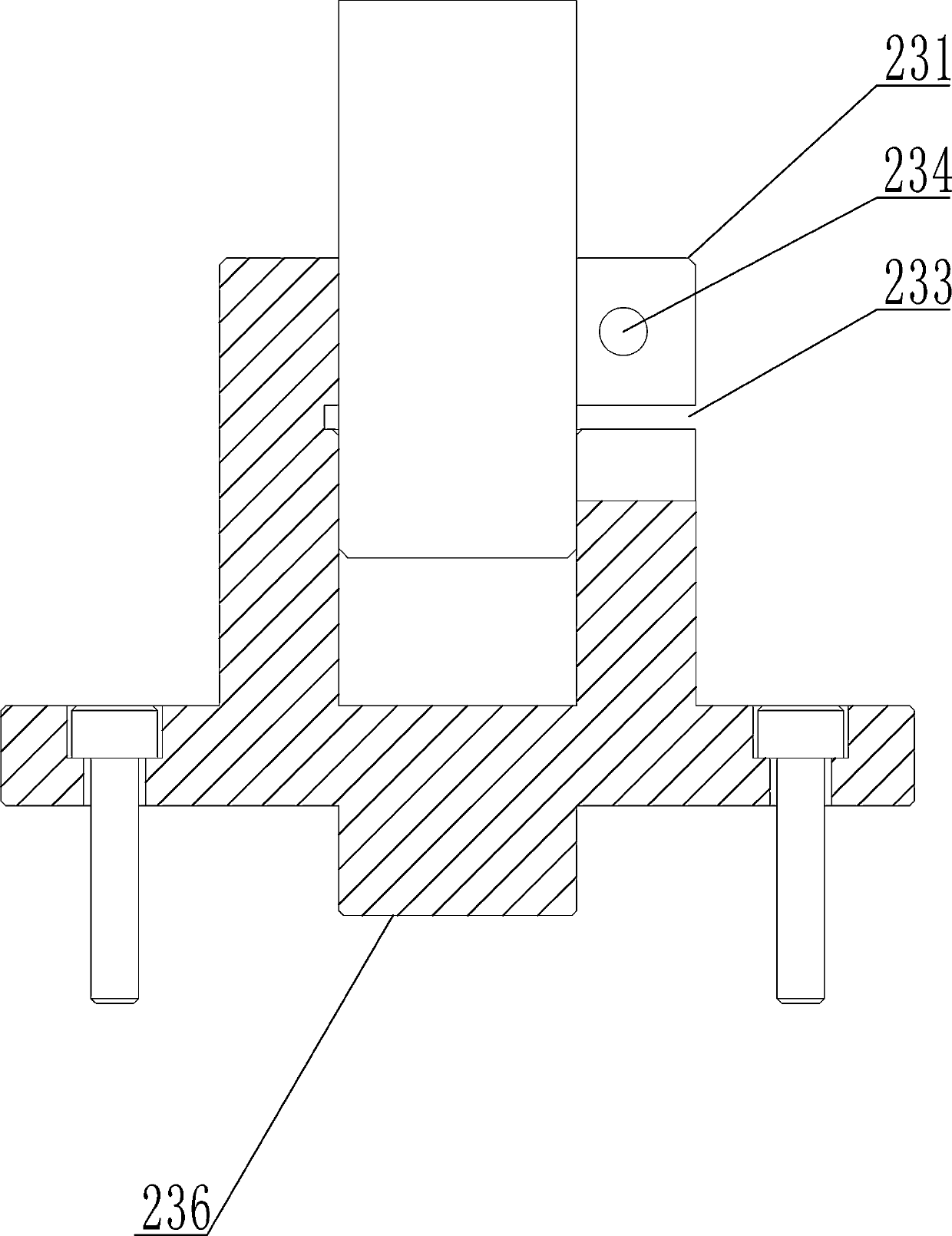

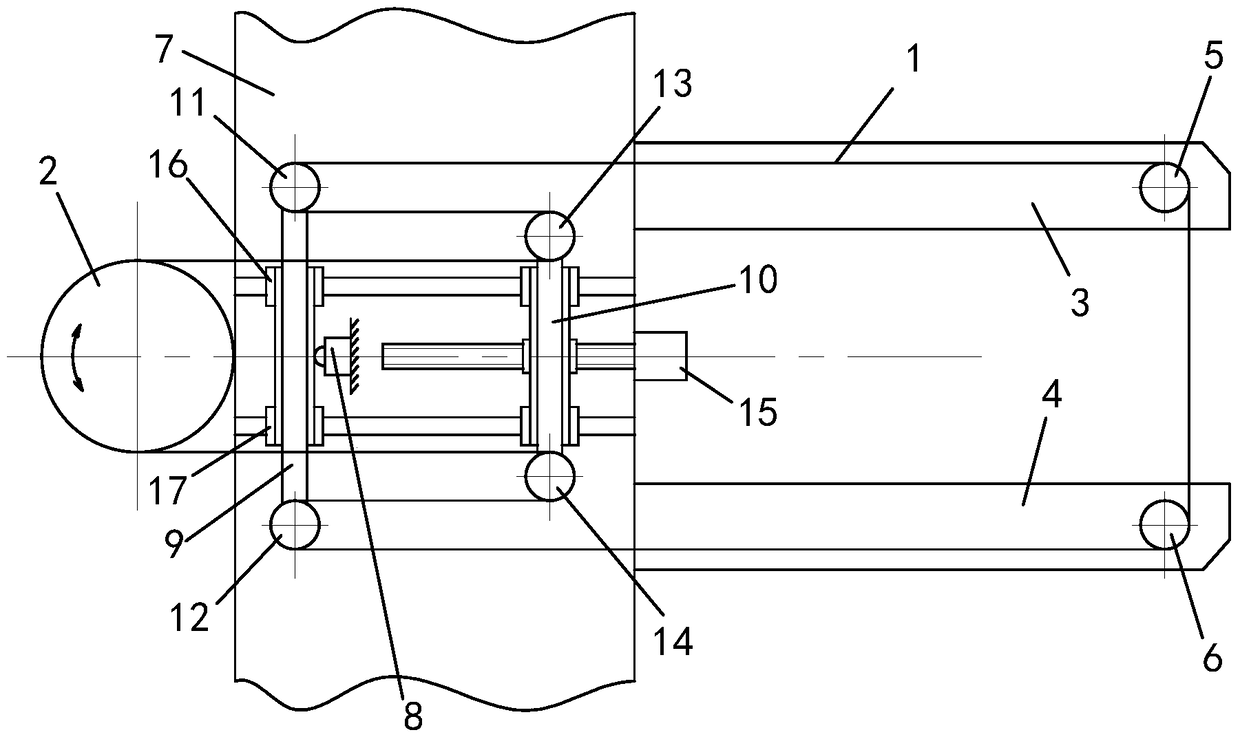

Power transmission mechanism capable of independently automatically eliminating backlash

ActiveCN101949438BEnsure smooth transmissionGuaranteed positioning accuracyGearingPortable liftingMotor driveControl theory

The invention relates to a power transmission mechanism capable of independently automatically eliminating a backlash, which comprises a motor (2), an intermediate shaft (5), and two output shafts (9,23), wherein the motor (2) drives the intermediate shaft (5); two bevel wheels (33,34) on the intermediate shaft (5) drive the two output shafts (9,23) through sliding bevel wheels (16,24) on the two output shafts; and two output gears (11,22) arranged on the two output shafts (9,23) are meshed with a rack (32) for power transmission. The power transmission mechanism is characterized in that the two output shafts (9,23) are respectively provided with a group of spring backlash eliminated structure. The power transmission mechanism has the advantages that: the backlash or interference trend between two output shaft gears and the rack is separately compensated by pushing the sliding bevel gears through a disc spring on respective output shaft, additional rotation of the intermediate shaft cannot happen in the compensation process, additional ruleless interference cannot happen in the process that the servo motor drives the output shafts to work, and the transmission stability and the positioning accuracy of a working table are ensured.

Owner:JIANGSU HENGLI MACHINE TOOL

Divider driving synchronous reciprocating motion device

The invention relates to the technical field of plastic cup and formed paper cup printing machines, and discloses a divider-driven synchronous reciprocating motion device, a power source end face driving cam of the reciprocating motion device and a divider share a force input shaft, power is transmitted to a driven rocker through a driving rocker, and then motion is transmitted to a reciprocating motion assembly. Belt transmission used by an old-fashioned cup jacking device is abandoned, a rocker transmission structure is used, the transmission structure is simplified, the limitation of the transmission direction of belt transmission power is eliminated, and two or more reciprocating motion devices are driven to move synchronously by a reciprocating motion device power source end face driving cam at the same time. A power source end face driving cam of the reciprocating motion device drives the cup pressing device to move downwards to start to be combined with a cup in the return stroke stage, when the reciprocating motion device is arranged at the three o'clock position of a divider output shaft, an unpowered rotating wheel is arranged, cup pressing is kept in the stop stage, and distortion of printed patterns is effectively avoided.

Owner:SUZHOU CAI MACHINE

Output mechanism and speed reducer

InactiveCN109826938AImprove connection accuracyImprove efficiencyProgramme-controlled manipulatorToothed gearingsCouplingReduction drive

The invention discloses an output mechanism and a speed reducer. A shell, an output, a base and an input shaft are involved, wherein the input shaft is provided with an eccentric wheel, the eccentricwheel is connected with a cycloid wheel through a crank bearing correspondingly, a plurality of pin tooth pins are arranged on the inner wall of the shell along the circumference, the pin tooth gear pins are intermittently meshed with the cycloid gear, a positioning flange is arranged at the outer end of the output base, the positioning flange is in a T shape, one end of the positioning flange sleeves the output base, and the other end of the positioning flange is provided with a tensioning flange base; and a contraction joint is arranged on the tensioning flange base, the upper end of the tensioning flange base is cylindrical, the lower end of the cylindrical shape is a conical surface which contracts downwards, and the positioning flange is connected to the shrunk conical surface of thetensioning flange base in a sleeved mode. The positioning flange is provided with a conical surface matched with the outer side surface of the tensioning flange base, a clamping sleeve adopted is a coupling, the assembling and disassembling are simple, rapid and convenient.

Owner:湖北斯微特传动有限公司

Micro large-speed-ratio speed reducer and needle gear positioning flange mounting method thereof

InactiveCN109667892AHigh positioning accuracyImprove contact effectToothed gearingsGearing detailsPins needlesReduction drive

The invention discloses a micro large-speed-ratio speed reducer. The micro large-speed-ratio speed reducer comprises a housing, an output base and an input shaft, wherein eccentric wheels are fixedlyarranged on the input shaft; the two eccentric wheels are separately connected to cycloidal gears through crank bearings; a plurality of pin gear pins are arranged at the periphery of the inner wall of the housing; the pin needle gears are in intermittent engagement with two cycloidal gears; the outer diameter of the housing of the speed reducer is not greater than 45 mm; and the thickness of thespeed reducer is not smaller than 26.4 mm. The speed reducer is smaller in size, and operation of a mounting mechanical hand is more flexible, so that use, in the field with insufficient output torqueof a harmonic speed reducer, can be completely replaced.

Owner:湖北斯微特传动有限公司

Movement implementing mechanism for LAMOST type astronomical focus panel

InactiveCN101359090BCompact structureSimplified mechanical junctionTelescopesBundled fibre light guideControl systemGear wheel

An LAMOST astronomical telescope focal panel movement realizing mechanism is characterized in that a rotary movement mechanism, a tilted movement mechanism and a focusing movement mechanism are set as a co-movement mechanism, wherein, a large gear and a circular guide rail are fixedly connected on a base; six matched slide blocks are distributed on the circular guide rail; the slide blocks are connected with pinions through connecting plates; each pinion is meshed with the large gear; a drive motor is arranged on a shaft; the slide blocks are respectively connected with supporting rods through left single rod joint bearings; each supporting rod is connected on a focal panel through a right single rod joint bearing; every two supporting rods are arranged as one group in a V-shaped form, and one end of each of the two supporting rods leans against the connecting points of the focal panel through the right single rod joint bearings; three groups of connecting points are distributed in the same circle on the focal panel by 120 degrees; and the other end of each of the two supporting rods has a certain distance through the locations of the two slide blocks connected with the left single rod joint bearing on the circular guide rail. The invention not only simplifies the mechanical structure and the control system, but also improves the stability of the system.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Device with middle lead screw and tailstock for numerical control lathe

ActiveCN102581306BImprove textureImprove the finishTailstocks/centresFeeding apparatusNumerical controlTailstock

The invention relates to a part for a numerical control lathe, in particular to a device with a middle lead screw and a tailstock for a numerical control lathe. The device comprises two guide rails, a large carriage and the lead screw, wherein the two guide rails are integrated with the lathe body, the large carriage is mounted on the guide rails and connected with the lead screw for controlling the large carriage to move on the guide rails, and the lead screw is arranged between the two guide rails. Tailstock guide rails are arranged on the lathe body beside the two guide rails, the tailstock moving along with the tailstock guide rails is arranged on the tailstock guide rails, and the tailstock is positioned right above the lead screw. Owing to the structure, the device has the advantages of compact structure, low manufacturing cost, high stability in application to the numerical control lathe, high workpiece machining precision and improvement of production efficiency.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

Fixed-axis cycloid transmission device

The invention discloses a fixed-axis cycloid transmission device comprising a shell, a power input shaft and a power output shaft. The power input shaft and the power output shaft are coaxially arranged and are respectively in rotation match with the shell; a driving disk is arranged in eccentric transmission match with the excircle of the power input shaft; a power output disk is arranged in transmission match with the power output shaft; transmission pins are uniformly arranged in rotation match along the circumference direction of the driving disk to form a pin gear which is engaged with an involute inner gear fixedly arranged on the shell; and the transmission pins are in eccentric rotation match with the power output disk. In the fixed-axis cycloid transmission device, the bearing capability of a cycloid reducing mechanism is enhanced, and a cantilever pin output mechanism of a traditional pin gear reducer is not used any nore, and power is directly output by the power output disk driven by the revolution motion of the transmission pins so as to enhance the transmission rigidity, improve the transmission efficiency and the transmission stability and further improve the bearing capacity. The invention has simple structure, small size, light weight, low cost, simplified mounting and dismounting processes and improved working efficiency.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com