Facing head feeding mechanism and facing head

A technology of feed mechanism and flat rotating disk, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., and can solve the problems of poor transmission rigidity in the feed direction, stroke limitation, limited cutting accuracy and speed of flat rotating disk, etc. , to achieve the effect of improving transmission rigidity, compact transmission structure and increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

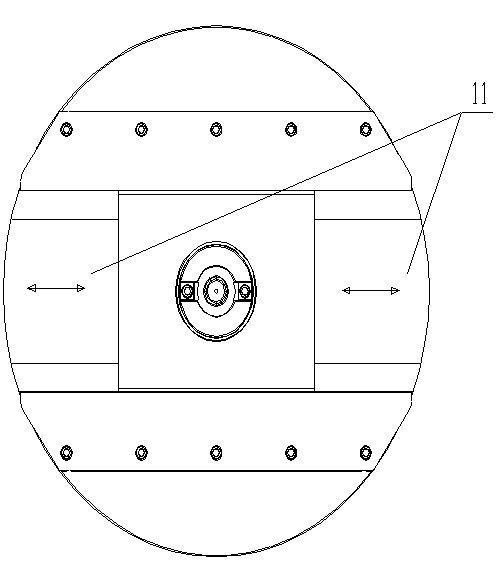

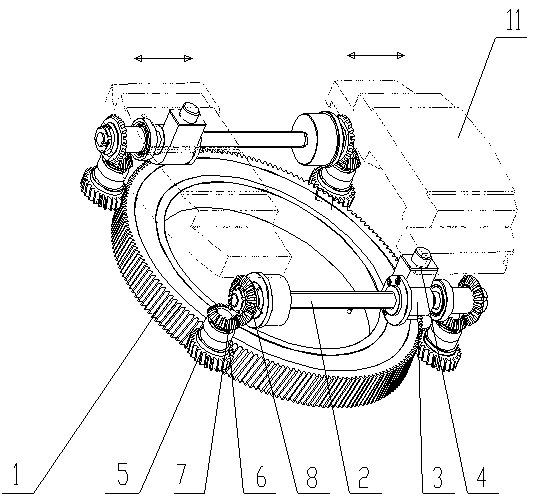

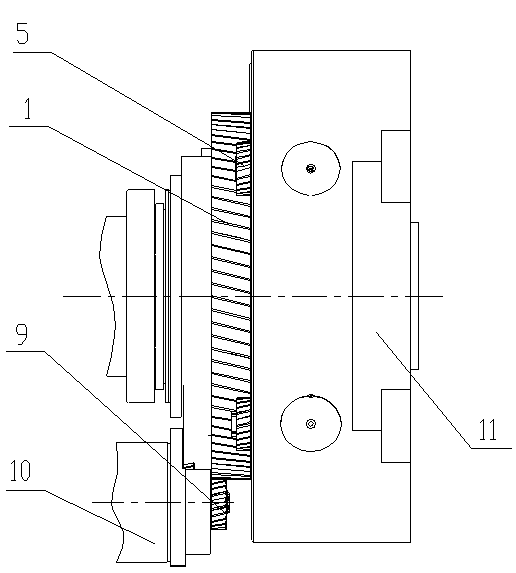

[0023] Such as figure 1 , figure 2 and image 3 Shown is an embodiment of a feed mechanism of the present invention, comprising a large gear 1, a transmission mechanism, a lead screw 2, a lead screw nut 3 and a transmission block 4, two lead screws 2, two lead screws 2 They are parallel to each other and symmetrical about the axis of the large gear 1. There are four sets of transmission mechanisms. The two ends of each lead screw 2 are respectively connected to the large gear 1 through a set of transmission mechanisms. The pair of bars, transmission block 4 is connected and fixed with leading screw nut 3.

[0024] The working principle of the above technical solution is: the power is transmitted to the lead screw 2 through the transmission mechanism through the rotation of the large gear 1, and the rotation of the lead screw pair drives the movement of the lead screw nut 3 and the transmission block 4 installed on the lead screw 2 , in order to realize the movement process...

Embodiment 2

[0031] Such as figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention differs from Embodiment 1 in that the transmission of the second bevel gear 8 can be replaced by a worm gear pair, the transmission block 4 can be made into one part with the lead screw nut 3 or the slide plate 11, and the rest are the same. The same parts are not repeated here.

[0032] In the embodiment of the present invention, by manufacturing the transmission block 4 and the lead screw nut 3 or the slide plate 11 into one component, the installation is quicker and the production efficiency is improved. The structure of the double slides 11 has a compact transmission structure, which can also achieve a larger feed stroke for a flat rotating disk with a smaller diameter; one sliding plate is driven by two small gears, which improves the transmission rigidity of the flat rotating disk.

[0033] Embodiments of the present invention also include a flat-rotating disk, which inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com