Movement implementing mechanism for LAMOST type astronomical focus panel

A technology for astronomical telescopes and motion mechanisms, applied in telescopes, installations, optics, etc., can solve problems that affect control accuracy and increase the complexity of control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

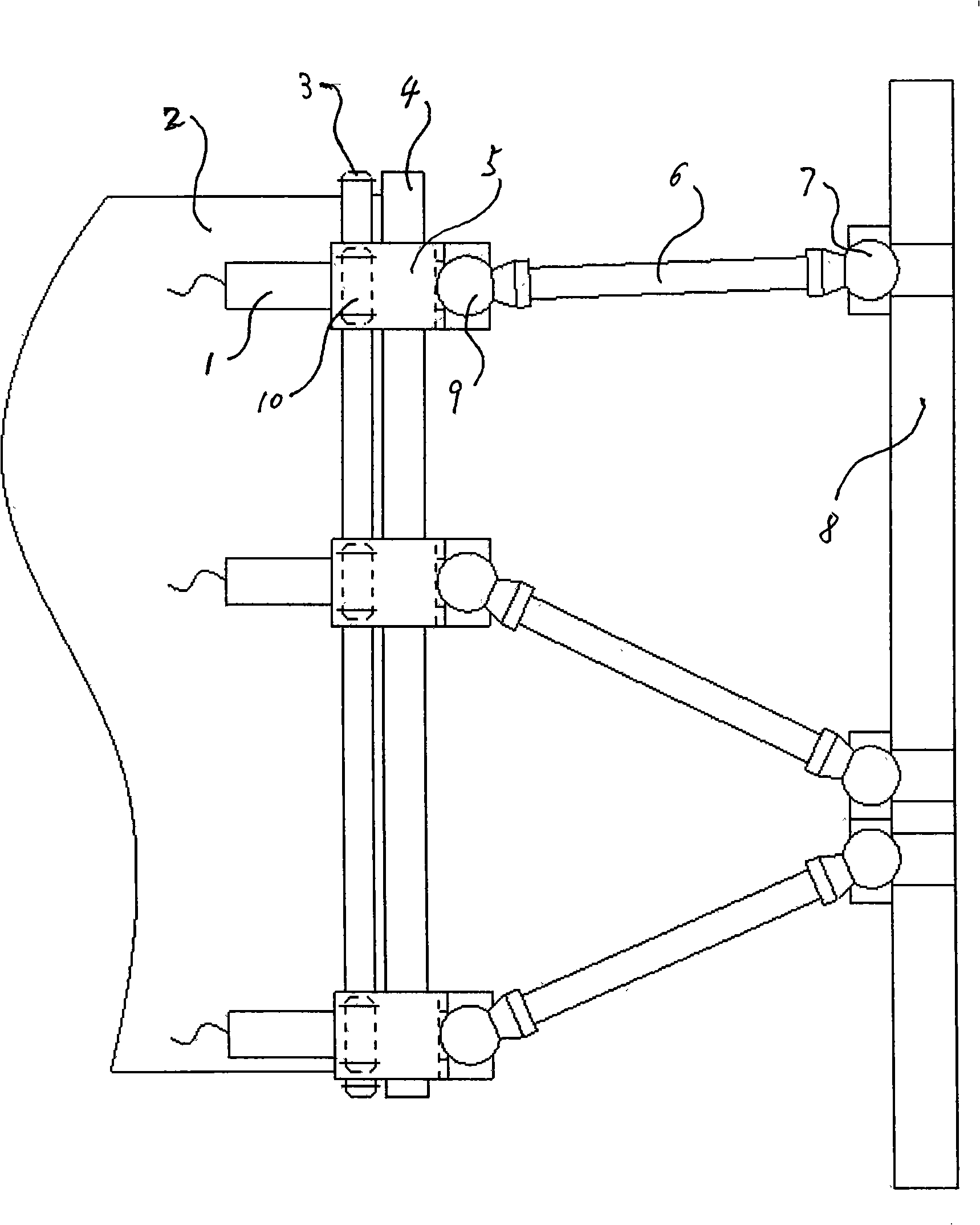

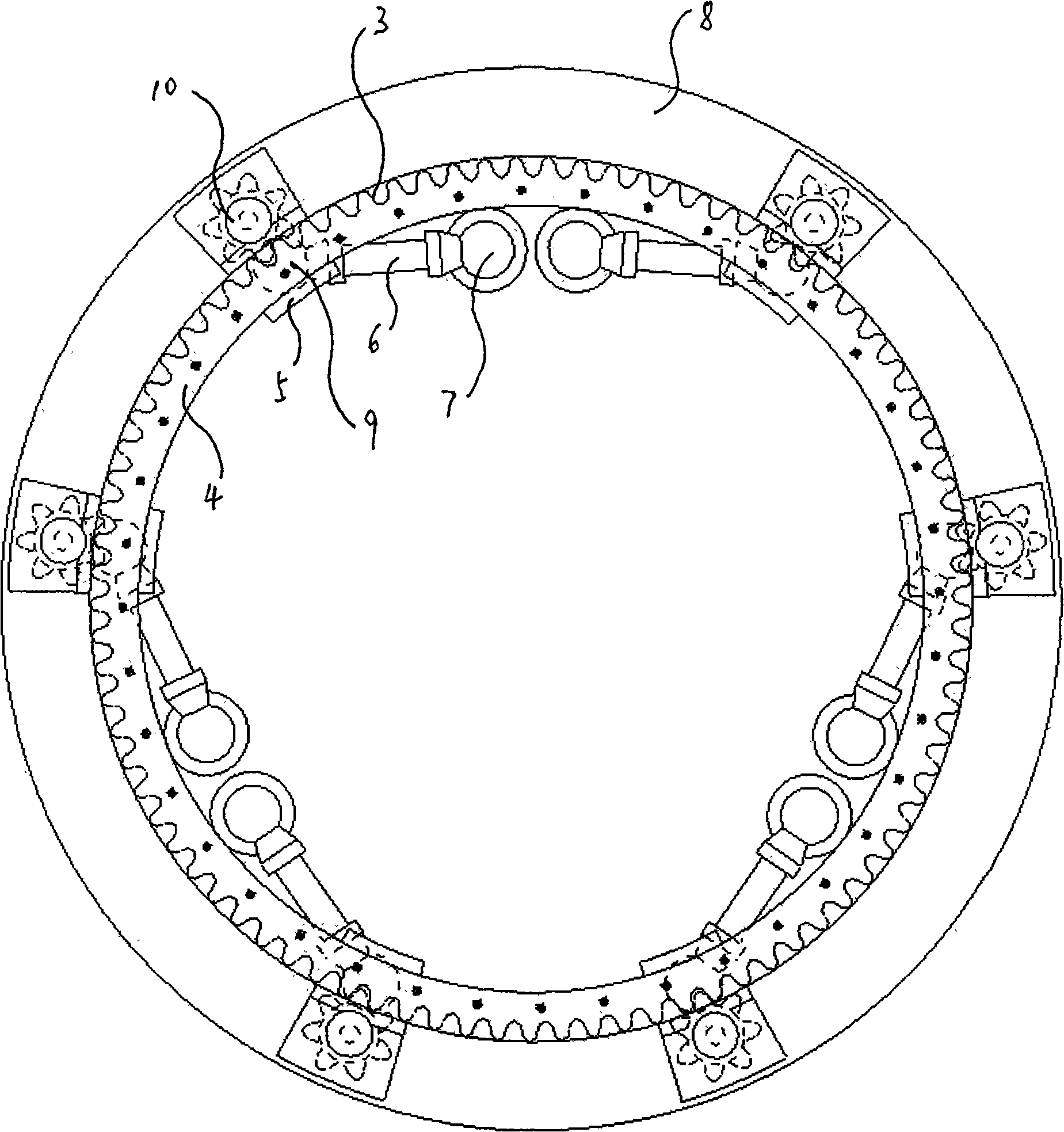

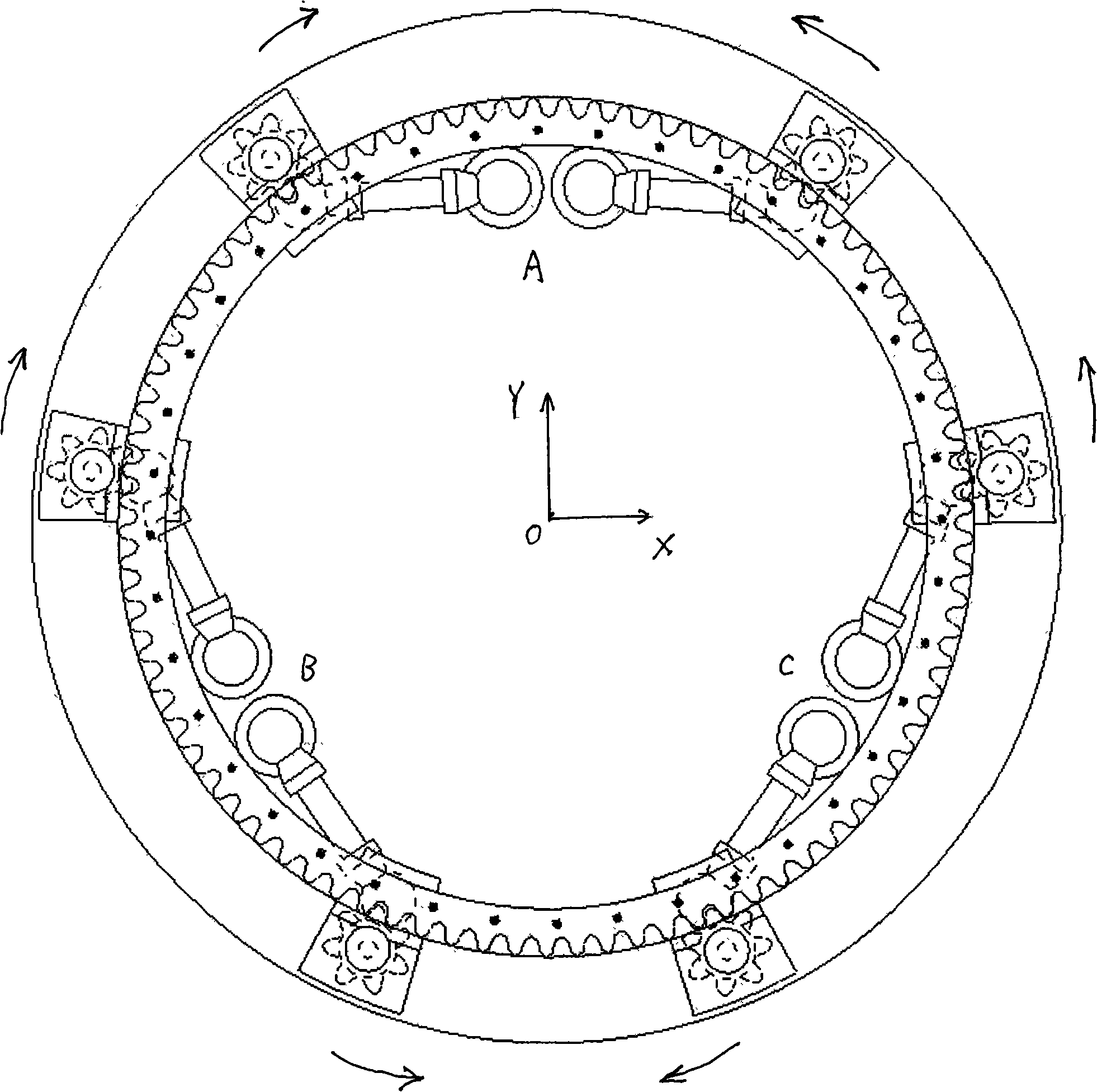

[0031] Embodiment 1, with reference to Figure 1 ~ Figure 4 : The large gear 3 and the circular guide rail 4 are fixedly connected by screws and installed on the base 2. 6 matching slide blocks 5 are distributed on the circular guide rail 4 (see figure 2 ). Left single-rod joint bearing 9 (6 in total, see figure 2 ) are respectively connected to the corresponding sliders. Right single-rod joint bearing 7 (6 pieces in total, see figure 2 ) are connected to the focus panel 8 respectively. The left single rod joint bearing 9 is connected with the right single rod joint bearing 7 through the support rod 6 . The pinion 10 (total 6 that matches with bull gear 3, see figure 2 ) is connected to the slider 5 through the connecting plate. Drive motor 1 (total 6, see figure 2 ). When the drive motor 1 drives the pinion 10 to rotate, since the pinion 10 is connected to the slider 5, the pinion 10 drives the slider 5 to rotate around the big gear 3 together (the big gear 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com