Power transmission mechanism capable of independently automatically eliminating backlash

A power transmission mechanism and anti-backlash technology, which is applied to transmission devices, mechanical equipment, components with teeth, etc., can solve problems affecting the rigidity and stability of the workbench, the stability of the transmission system, and the influence of transmission rigidity, etc., to achieve The structure is compact, the transmission stability is ensured, and the transmission chain is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

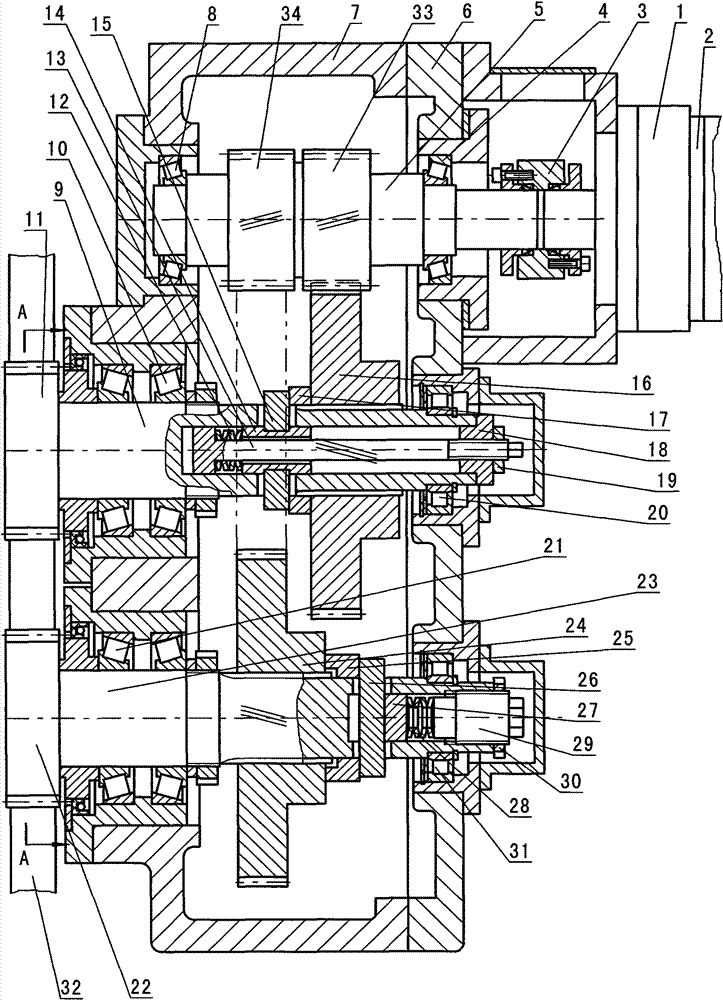

[0030]The present invention mainly includes a motor 2, a reduction box 1, an intermediate shaft 5, and two output shafts 9,23. The intermediate shaft 5 is a gear shaft, on which there are two helical gears 33, 34; the intermediate shaft 5 is supported on the transmission box body 7 and the transmission case cover 6 by the bearings 8, 4 at both ends; the intermediate shaft 5 passes through the coupling 3 is directly connected with the reduction box 1 and the servo motor 2. The motor 2 and the reduction box 1 can be combined or separated, and the reduction box 1 can not be used in some special cases.

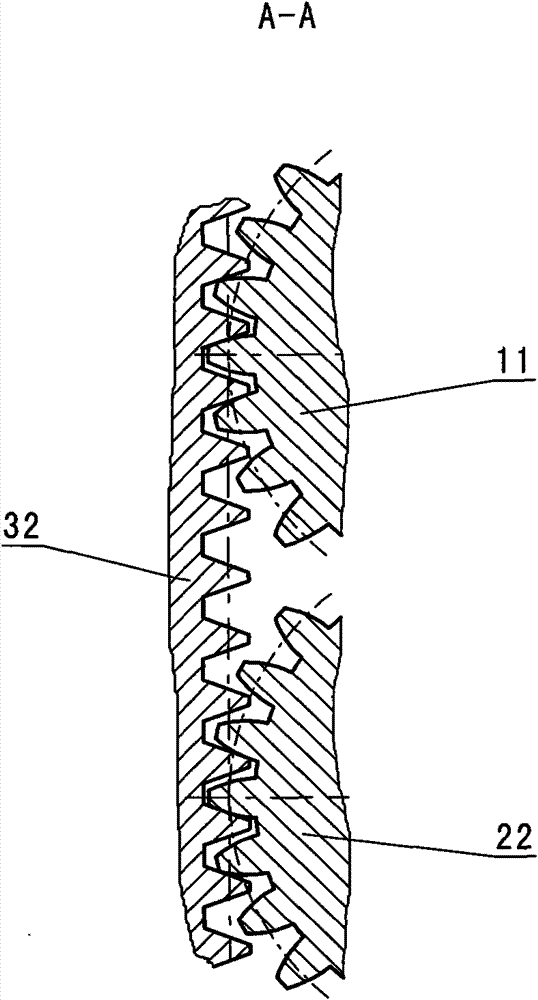

[0031] A helical gear 16, 24 and an output gear 11, 22 are respectively coupled to the two output shafts 9, 23 through splines, wherein the output shaft 9 is the first output shaft, and the output shaft 23 is the second output shaft. The two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com